Understanding the intricacies of your vehicle’s gear mechanism is essential for optimal performance and longevity. This guide aims to provide detailed insights into troubleshooting and maintenance processes, ensuring you can confidently tackle any challenges that arise.

Whether you’re experiencing unusual noises or shifting issues, delving into the inner workings of the system will empower you to make informed decisions. Knowledge of key components and their functions can be the ultimate advantage when it comes to diagnosing problems effectively.

By exploring techniques and best practices, you’ll gain the confidence needed to address any faults and enhance your vehicle’s efficiency. Let’s embark on this journey to uncover the essential steps and tools necessary for a successful overhaul.

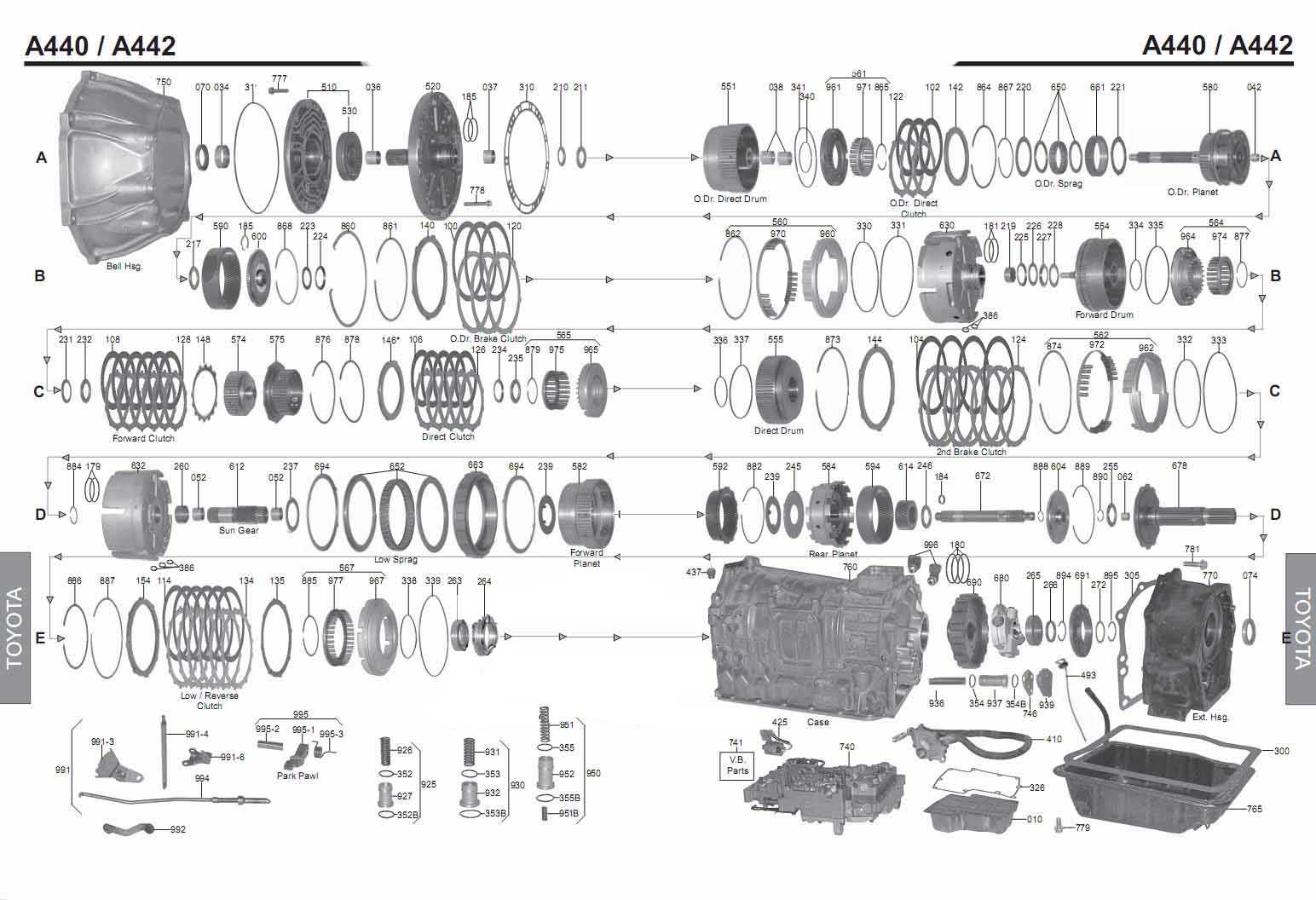

A442F Transmission Overview

This section provides a comprehensive look into a specific automatic gear system commonly used in various vehicles. It plays a crucial role in optimizing engine performance and enhancing the driving experience. Understanding its components and functionality can aid in maintaining vehicle efficiency and reliability.

Key Features

- Fluid coupling for smooth power delivery

- Electronic control for precise gear shifts

- Multiple gear ratios for improved acceleration and fuel economy

Common Applications

- Light trucks

- Sport utility vehicles (SUVs)

- Some passenger cars

By recognizing these characteristics, vehicle owners can make informed decisions regarding upkeep and potential upgrades to enhance their driving performance.

Common Issues with A442F Units

The unit in question is known for several recurring problems that can affect its performance and reliability. Understanding these issues can help users and technicians address them effectively, ensuring smoother operation and longevity.

| Issue | Description | Potential Causes |

|---|---|---|

| Shifting Delays | Experiencing a lag when changing gears. | Low fluid levels, contaminated fluid, or worn components. |

| Slipping | Unexpected loss of power during acceleration. | Worn clutches, inadequate fluid pressure, or damaged seals. |

| Overheating | Excessive heat leading to operational failures. | Insufficient cooling, blocked lines, or fluid degradation. |

| Fluid Leaks | Visible fluid escaping from the unit. | Worn gaskets, seals, or loose fittings. |

| Unusual Noises | Strange sounds during operation, such as grinding or whining. | Worn bearings, loose components, or insufficient lubrication. |

Addressing these common challenges promptly can help maintain the efficiency and effectiveness of the unit, preventing more serious issues in the future.

Tools Required for Repairs

When embarking on a project that involves complex mechanical components, having the right instruments at your disposal is essential. The effectiveness of any undertaking relies heavily on the availability of specific tools designed to facilitate the disassembly, assessment, and reassembly processes. Understanding which implements to gather beforehand can save time and enhance the overall efficiency of the task.

Essential Hand Tools

Among the basic implements, a set of wrenches and sockets is crucial. These allow for precise adjustments and are vital for loosening or tightening fasteners. Additionally, a torque wrench is necessary to ensure that connections are secured to the manufacturer’s specifications. Other useful hand tools include pliers, screwdrivers, and hammers, which can assist in various stages of the operation.

Specialized Equipment

In addition to standard tools, certain specialized devices are indispensable for thorough assessments. A diagnostic scanner can provide insights into the system’s performance and help identify issues. Furthermore, a lifting device, such as a floor jack or hoist, is critical for safely accessing components. Having these specialized items readily available ensures that the work proceeds smoothly and effectively.

Step-by-Step Disassembly Process

This section outlines a detailed procedure for systematically taking apart the component in question. Each phase is crucial for ensuring that all parts are carefully handled and documented, making reassembly more manageable. Following these steps will help in identifying any issues and facilitate a smoother workflow.

Required Tools and Safety Precautions

Before beginning, ensure you have all necessary tools at hand. Taking proper safety measures is essential to prevent injuries and damage to components. Below is a table listing the tools you will need and recommended safety practices.

| Tool | Purpose |

|---|---|

| Socket Set | To remove bolts and screws |

| Screwdriver Set | To take off panels and covers |

| Pliers | For gripping and twisting |

| Torque Wrench | To ensure proper tightening |

| Safety Glasses | To protect your eyes |

Disassembly Steps

Begin the disassembly by following these steps:

- Disconnect the power source and remove any external connections.

- Remove outer casing using appropriate tools, ensuring not to strip screws.

- Carefully take out internal components, documenting their arrangement and condition.

- Inspect each part for wear and tear, making notes for reassembly.

- Store all components in labeled containers to prevent loss and confusion.

By adhering to these guidelines, the disassembly process will be efficient and organized, paving the way for successful maintenance or upgrades.

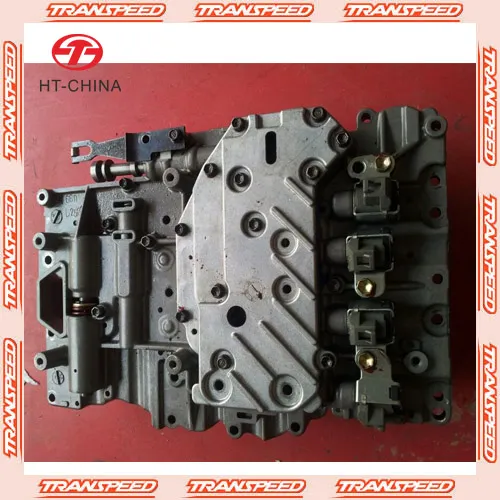

Inspecting Internal Components

Thorough examination of the internal elements is crucial for ensuring optimal performance and longevity of the unit. By meticulously assessing each part, one can identify signs of wear, damage, or malfunction that could impact overall functionality.

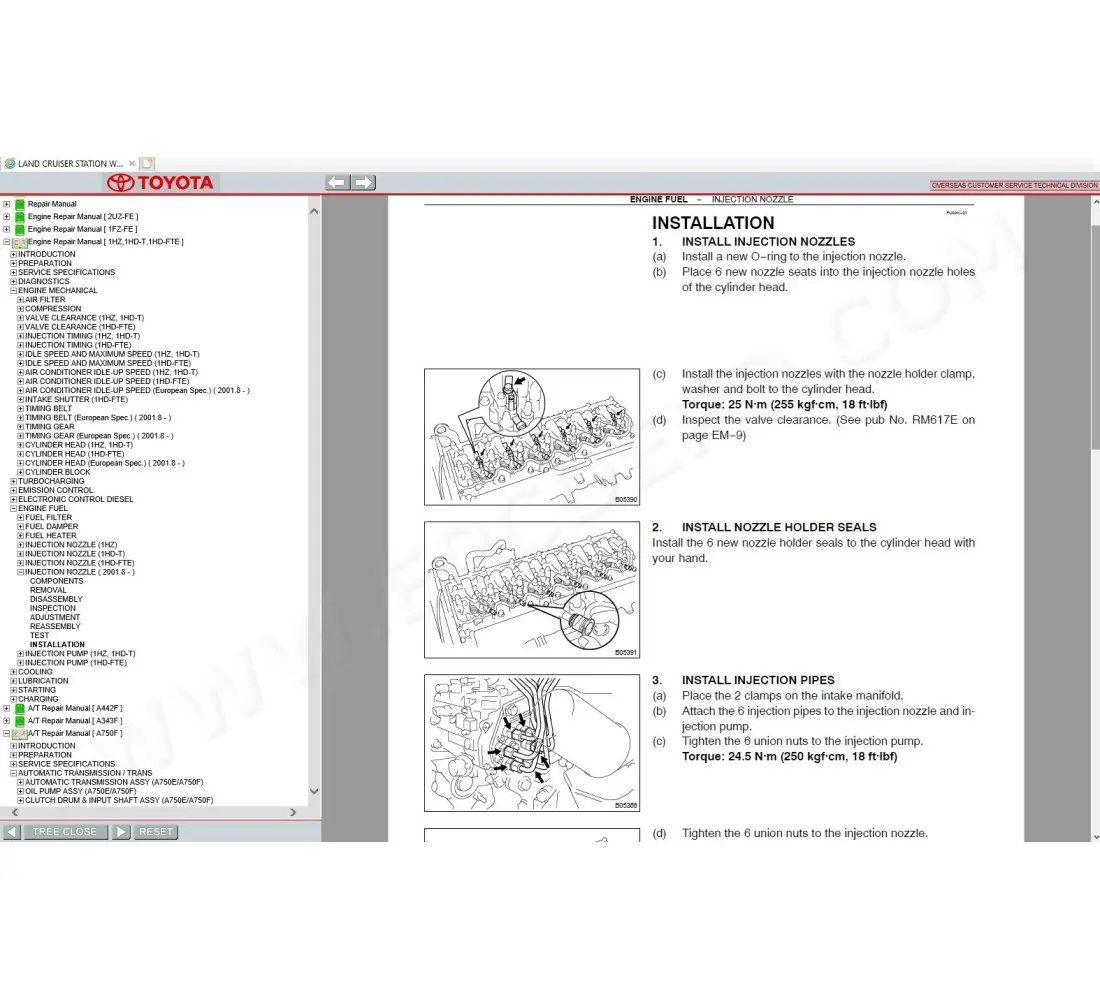

Begin by disassembling the assembly carefully, paying attention to the order of components to facilitate reassembly. Inspect gears, clutches, and seals for any irregularities. Look for scoring, pitting, or excessive play that might indicate a need for replacement. Additionally, evaluate the condition of any fluid pathways to ensure they are clear and free from debris.

Check for alignment issues among the various components, as misalignment can lead to premature failure. Use precision tools to measure tolerances where applicable. Keeping detailed notes during this process will help track any abnormalities and inform necessary adjustments or replacements.

Finally, ensure all surfaces are clean and free from contaminants before reassembly. This attention to detail will contribute to the reliability and efficiency of the entire system.

Rebuilding the A442F Transmission

Reconstructing a complex gear system requires a careful approach and attention to detail. This process not only involves disassembling the unit but also inspecting and replacing worn components to ensure optimal performance. Understanding the intricacies of each part is essential for achieving a reliable and efficient assembly.

Disassembly and Inspection

The initial step in the rebuilding process is to carefully disassemble the unit. Each component should be labeled and stored systematically to prevent confusion during reassembly. Inspecting the gears, seals, and other parts for wear and damage is crucial. This assessment helps identify which elements need replacement and which can be reused, ensuring a successful rebuild.

Reassembly and Testing

Once the necessary components have been replaced, the next phase is reassembly. Proper alignment and torque specifications must be adhered to for effective functionality. After reassembly, conducting thorough testing is vital to verify the integrity and performance of the system. This stage ensures that all adjustments have been correctly implemented, leading to a smooth operation.

Fluid Types and Maintenance Tips

Understanding the various types of fluids and their maintenance is crucial for ensuring the optimal performance of your vehicle’s system. Regular attention to these fluids can prevent wear and tear, enhance efficiency, and prolong the lifespan of critical components.

Types of Fluids: Different systems require specific types of fluids, each formulated to meet unique demands. For hydraulic operations, a high-viscosity fluid may be necessary, while for cooling purposes, a mixture of water and antifreeze is ideal. Additionally, synthetic fluids are available, offering improved performance under extreme conditions.

Maintenance Tips: Regular checks are essential for maintaining fluid levels. It’s advisable to inspect fluid levels every few months or during routine servicing. When changing fluids, always use the type recommended by the manufacturer to avoid compatibility issues. Furthermore, consider flushing the system periodically to remove contaminants and ensure smooth operation.

In summary, keeping a close eye on the types and conditions of these fluids is integral to maintaining the functionality and efficiency of your vehicle.

Troubleshooting Electrical Problems

Electrical issues can often disrupt the functioning of your vehicle’s components, leading to performance inconsistencies. Identifying and resolving these problems requires a systematic approach to diagnose the source of the malfunction effectively. This section outlines key steps and considerations to help you navigate through common electrical challenges.

| Problem | Possible Causes | Solutions |

|---|---|---|

| Battery Not Charging | Faulty alternator, worn battery terminals, damaged cables | Test alternator output, clean battery terminals, replace cables if necessary |

| Flickering Lights | Loose connections, weak battery, faulty relay | Tighten connections, check battery voltage, replace relay |

| Starter Not Engaging | Bad ignition switch, malfunctioning starter motor, weak battery | Inspect ignition switch, test starter motor, charge or replace battery |

| Erratic Gauges | Grounding issues, bad sensors, wiring faults | Check grounding points, replace faulty sensors, repair wiring |

By methodically assessing these aspects, you can pinpoint electrical faults and implement appropriate fixes. Always ensure safety precautions are followed while working with electrical systems to avoid potential hazards.

Testing After Repairs

Ensuring the functionality of a vehicle’s components after maintenance is crucial for optimal performance. This phase involves a series of assessments to verify that all alterations have been executed correctly and that the system operates smoothly. A systematic approach can help identify any lingering issues, ensuring safety and efficiency on the road.

Key Testing Procedures

The following procedures should be employed to assess the effectiveness of the adjustments made:

| Test Type | Description | Purpose |

|---|---|---|

| Fluid Level Check | Examine and top up necessary fluids as required. | To ensure proper lubrication and cooling. |

| Leak Inspection | Look for any signs of fluid leakage around connections. | To prevent potential damage and maintain performance. |

| Functionality Test | Engage and disengage mechanisms under various conditions. | To confirm operational reliability. |

| Noise Assessment | Listen for any unusual sounds during operation. | To identify possible issues that need attention. |

Final Evaluation

After conducting these assessments, it’s essential to perform a road test. This helps in observing the vehicle’s behavior under real-world conditions. Documenting findings during this phase will aid in making informed decisions for any further adjustments, ensuring that the vehicle functions as intended.

Upgrading A442F Performance Features

Enhancing the capabilities of a specific gear system can significantly improve overall vehicle performance. By focusing on various modifications, enthusiasts can achieve better acceleration, responsiveness, and durability. This section delves into essential upgrades that can transform the functionality and efficiency of your setup.

Several components contribute to the performance enhancement of a gear mechanism. Here are some key areas to consider when planning your upgrades:

| Upgrade Component | Description | Benefits |

|---|---|---|

| Improved Torque Converter | Upgrading to a high-performance torque converter allows for increased torque multiplication. | Better acceleration and power delivery. |

| Performance Clutch Kits | Installing a high-friction clutch can handle increased power levels. | Enhanced grip and reduced slip during hard acceleration. |

| Fluid Cooling Systems | Adding an auxiliary cooler helps maintain optimal operating temperatures. | Increased reliability and longevity of components. |

| Control Module Tuning | Tuning the electronic control unit can optimize shift points and improve responsiveness. | Smoother and quicker gear changes. |

| Heavy-Duty Bands and Seals | Using upgraded bands and seals ensures better retention of pressure. | Increased durability and efficiency in power transfer. |

By carefully selecting and implementing these enhancements, you can unlock a new level of performance and reliability from your gear system, tailored to your driving style and needs.

Finding Professional Repair Services

Locating qualified assistance for vehicle issues can be a daunting task. Ensuring that you choose experienced technicians is crucial for maintaining the efficiency and longevity of your automobile. This section aims to guide you through the process of identifying reliable service providers in your area.

Evaluating Potential Candidates

When searching for skilled professionals, consider several key factors. Look for certifications, customer reviews, and the range of services offered. Recommendations from friends or family can also be invaluable in making your decision.

| Criteria | Importance |

|---|---|

| Certifications | High |

| Customer Reviews | High |

| Experience | Medium |

| Range of Services | Medium |

Ensuring Quality Service

Once you have shortlisted potential providers, it is wise to inquire about warranties and guarantees on their work. A reputable business will stand by its services, providing peace of mind for customers. Additionally, ask about the diagnostic tools they use, as modern equipment can significantly impact the quality of service received.