The upkeep of a telescopic pruner is essential for ensuring its longevity and optimal performance. Understanding the components and functions of this versatile tool will help you tackle common issues effectively. Whether you are an avid gardener or a professional landscaper, proper care can enhance productivity.

In this section, we will explore practical insights and step-by-step guidance to address frequent challenges faced by users. By delving into troubleshooting techniques and maintenance tips, you will gain the ultimate knowledge needed to keep your equipment in top shape.

From routine inspections to specific repairs, our comprehensive approach will empower you to manage your pruner with confidence. With the right strategies, even complex problems can be resolved efficiently, ensuring that your tool remains a reliable companion for years to come.

Overview of Stihl HT 101

The telescopic pruner is an essential tool for maintaining gardens and landscapes. Designed for both professional landscapers and avid gardeners, it offers a combination of power, versatility, and user-friendly features. This equipment allows users to effortlessly reach high branches without the need for ladders, enhancing safety and efficiency.

Equipped with a robust engine, this device delivers reliable performance, ensuring that even the toughest cutting tasks can be accomplished with ease. The lightweight design enhances maneuverability, making it ideal for prolonged use without causing undue strain. Additionally, the adjustable shaft length enables users to customize their reach, ensuring optimal results in various situations.

Features such as ergonomic handles and low vibration technology contribute to a comfortable user experience, allowing for extended periods of operation. Furthermore, the easy-to-access controls simplify adjustments and maintenance, making this pruner a practical choice for those seeking efficiency in their gardening endeavors.

Overall, this telescopic pruner represents a blend of innovation and functionality, making it an indispensable tool for anyone serious about garden care.

Common Issues and Troubleshooting

When operating a telescopic pole saw, users may encounter various challenges that can hinder performance. Understanding these common problems and their solutions is essential for maintaining the tool’s efficiency and ensuring a smooth cutting experience. Below are some frequent issues along with troubleshooting tips to help you resolve them.

Frequent Problems

- Engine Failure to Start: This can be caused by several factors, including fuel issues, spark plug problems, or air filter blockages.

- Insufficient Power: A lack of power may arise from a dull chain, improper tension, or a clogged exhaust.

- Excessive Vibration: Vibration can indicate loose components or an unbalanced cutting head.

- Chain Slippage: This issue may result from improper chain tension or worn sprockets.

Troubleshooting Tips

- Check Fuel Quality: Ensure that you are using fresh fuel and that the mixture is correct.

- Inspect the Spark Plug: Look for wear or deposits; replace if necessary.

- Clean or Replace the Air Filter: A clogged filter can restrict airflow, leading to performance issues.

- Sharpen or Replace the Chain: Regular maintenance of the cutting chain is vital for optimal performance.

- Tighten Loose Components: Regularly inspect and tighten screws and bolts to prevent excessive vibration.

By following these guidelines and addressing common issues promptly, users can enhance the longevity and effectiveness of their pole saw, ensuring a reliable tool for their gardening and trimming needs.

Essential Tools for Repairs

When tackling maintenance tasks, having the right equipment is crucial for achieving optimal results. Various tools not only streamline the process but also enhance safety and efficiency. Below is a list of indispensable items that should be part of any toolkit when engaging in equipment upkeep.

Basic Tool Kit

A foundational set of tools is essential for any maintenance work. This includes items that assist in loosening, tightening, and adjusting parts effectively.

| Tool | Purpose |

|---|---|

| Screwdrivers | Used for fastening and unfastening screws. |

| Wrenches | Ideal for gripping, turning, tightening, and loosening nuts and bolts. |

| Pliers | Useful for gripping objects and bending wires. |

| Hex Keys | Designed for driving bolts and screws with hexagonal sockets. |

Safety Equipment

Ensuring personal safety while conducting maintenance is paramount. The following items provide protection during various tasks.

| Safety Gear | Function |

|---|---|

| Safety Glasses | Protect eyes from debris and chemicals. |

| Gloves | Prevent cuts and abrasions during handling. |

| Ear Protection | Safeguard hearing when working with loud equipment. |

| Dust Mask | Reduce inhalation of harmful particles and fumes. |

Step-by-Step Repair Guide

This section provides a comprehensive approach to fixing common issues that may arise with your equipment. By following these detailed instructions, you can troubleshoot effectively and restore functionality to your tool.

Preparation

- Gather necessary tools: screwdrivers, wrenches, and safety gear.

- Find a clean, well-lit workspace to avoid losing small parts.

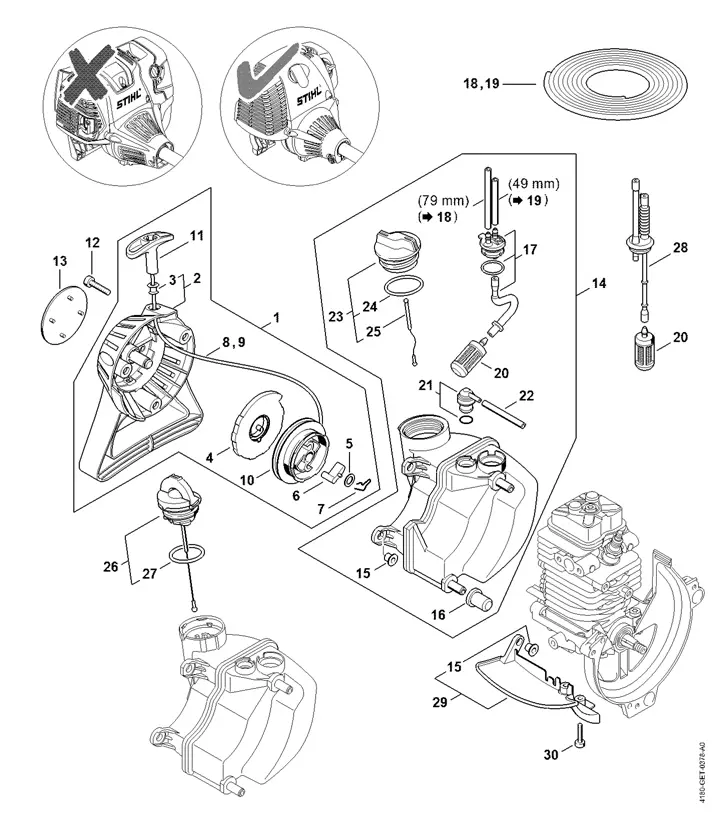

- Consult the user guide for specific component information.

Troubleshooting Process

- Identify the problem: listen for unusual noises or check for performance issues.

- Disconnect the power source for safety before beginning any work.

- Examine external parts for visible damage or wear.

- Remove covers or shields to access internal components as needed.

- Inspect key areas:

- Fuel lines for clogs or leaks.

- Electrical connections for corrosion.

- Moving parts for lubrication or wear.

- Replace any faulty components with appropriate replacements.

- Reassemble the equipment carefully, ensuring all parts are secure.

- Reconnect the power source and conduct a test run to ensure proper operation.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its durability and optimal performance. By following a few straightforward practices, you can extend its lifespan and maintain its efficiency, allowing you to get the most out of your investment.

- Regular Cleaning: Keep the exterior and moving parts clean from dirt and debris. This helps prevent wear and promotes better operation.

- Check and Replace Filters: Ensure that air and fuel filters are clean and replace them as needed to maintain proper airflow and fuel efficiency.

- Inspect Spark Plug: Regularly examine the spark plug for signs of wear or carbon buildup. Replace it if necessary to ensure smooth ignition.

- Lubrication: Apply appropriate lubricants to moving parts as specified in the guidelines. This minimizes friction and reduces wear.

Additionally, following a consistent maintenance schedule can help catch potential issues early, preventing costly repairs in the long run.

- Weekly Checks: Inspect the equipment for loose bolts or components and tighten as needed.

- Seasonal Overhaul: Before and after heavy use seasons, perform a thorough checkup to ensure everything is in optimal condition.

By implementing these simple strategies, you can ensure your equipment remains reliable and efficient for years to come.

Replacing Worn-Out Parts

Maintaining the functionality of your equipment is crucial for optimal performance and longevity. Over time, certain components may wear down, leading to decreased efficiency and potential operational issues. Identifying and replacing these parts can significantly enhance performance and ensure safe usage.

Here are key steps to consider when replacing worn-out components:

- Identify Worn Parts:

- Inspect for visible damage, cracks, or excessive wear.

- Listen for unusual noises during operation that may indicate malfunctioning components.

- Monitor performance metrics, such as power output and cutting efficiency.

- Obtain Replacement Components:

- Source parts from authorized dealers or trusted suppliers to ensure compatibility.

- Consider OEM (Original Equipment Manufacturer) parts for reliable performance.

- Check for warranties or guarantees on replacement items.

- Follow Installation Guidelines:

- Refer to the equipment documentation for specific instructions on part replacement.

- Use appropriate tools to avoid damage during installation.

- Ensure all connections are secure to prevent operational issues.

- Test Functionality:

- Run the equipment briefly to confirm proper installation.

- Check for any leaks, vibrations, or unusual sounds.

- Monitor performance during initial use to ensure everything operates smoothly.

Regular maintenance and timely replacement of worn components are essential practices for anyone looking to maximize the efficiency and lifespan of their equipment.

Fuel System Cleaning Procedures

Maintaining the fuel system is essential for optimal performance and longevity of any engine-powered equipment. A clean fuel system ensures that fuel flows efficiently, reducing the risk of clogging and improving combustion. This section outlines the necessary steps to thoroughly clean the fuel system, enhancing reliability and functionality.

Necessary Tools and Materials

Before beginning the cleaning process, gather the following tools and materials:

| Tool/Material | Description |

|---|---|

| Fuel Line Cleaner | A specialized solvent designed to dissolve deposits in fuel lines. |

| Cleaning Brushes | Small brushes for scrubbing components like filters and carburetors. |

| Protective Gloves | To ensure safety while handling chemicals. |

| Fuel Filter Replacement | A new filter to ensure cleanliness after the procedure. |

Cleaning Steps

Follow these steps for an effective cleaning procedure:

- Disconnect the fuel lines and remove the fuel filter.

- Apply the fuel line cleaner to the lines and let it sit for the recommended time.

- Use cleaning brushes to scrub the interior of the lines and other components.

- Rinse the parts with clean fuel to remove any remaining debris and cleaner.

- Install the new fuel filter and reconnect all lines securely.

Regular cleaning of the fuel system will not only enhance performance but also extend the lifespan of the equipment, ensuring reliable operation for years to come.

Electrical Components Diagnosis

Diagnosing electrical systems in outdoor power equipment is crucial for ensuring optimal performance and longevity. Understanding the function of each component and the symptoms of potential failures can help users identify issues early and implement effective solutions. This section focuses on common electrical components, their roles, and techniques for troubleshooting various problems.

Common Issues and Symptoms

Electrical malfunctions can manifest in various ways, such as erratic operation, failure to start, or unexpected shutdowns. Common components like switches, wiring, and ignition systems may be the source of these problems. For instance, a faulty switch may prevent power from reaching the engine, while damaged wiring could lead to intermittent performance issues. Recognizing these symptoms early is essential for effective diagnosis.

Testing and Troubleshooting Techniques

To diagnose electrical problems, several testing methods can be employed. Using a multimeter, one can check for continuity in wires and components, ensuring that electrical pathways are intact. Additionally, inspecting connectors for corrosion or loose fittings is vital, as poor connections often lead to operational failures. Systematic testing, starting from the power source and moving towards the load, can help isolate issues effectively.

Safety Precautions During Repair

When undertaking maintenance tasks on any equipment, ensuring personal safety and preventing accidents is paramount. Proper measures can protect both the individual and the machinery, leading to a successful outcome. This section outlines essential guidelines to follow before and during maintenance work.

| Precaution | Description |

|---|---|

| Personal Protective Equipment | Always wear appropriate safety gear, including gloves, goggles, and sturdy footwear to safeguard against injuries. |

| Work Environment | Ensure the workspace is clean, dry, and well-lit to minimize risks of slips, trips, or falls. |

| Power Source Disconnection | Before starting any work, disconnect the power source to avoid accidental activation of the machinery. |

| Tool Inspection | Examine all tools and equipment for damage or wear. Using faulty tools can lead to accidents. |

| Follow Manufacturer Guidelines | Adhere to the instructions provided by the manufacturer to ensure safe and effective procedures. |

| Assistance | Don’t hesitate to seek help if needed. Having a second person can enhance safety during complex tasks. |

By following these essential precautions, individuals can significantly reduce the risk of accidents and ensure a more efficient process when working on machinery. Prioritizing safety leads to better results and protects both the user and the equipment.

Stihl HT 101 Accessories Overview

This section provides an insightful look into the various attachments and enhancements available for enhancing performance and versatility. Understanding the additional components can significantly improve the functionality of your equipment, making it more efficient for different tasks.

Popular Attachments

Among the most sought-after accessories are extension poles, which allow users to reach higher branches and foliage without the need for ladders. Additionally, specialized cutting heads can be employed to tackle various types of vegetation, ensuring optimal results in every scenario.

Maintenance and Safety Gear

Proper maintenance tools and safety equipment are essential for prolonging the life of your gear and ensuring safe operation. Protective helmets, gloves, and eye protection are vital, while maintenance kits containing lubricants and cleaning solutions help keep the machinery in peak condition.

When to Seek Professional Help

Determining when to call in an expert can be challenging for many individuals. While some issues may appear manageable, certain circumstances warrant the assistance of a skilled technician. Recognizing these situations can save time and prevent further complications.

Here are some indicators that it may be time to seek professional assistance:

- Persistent Problems: If the issue continues despite your efforts to resolve it, professional insight may be necessary.

- Unusual Sounds: Any strange noises during operation can signal deeper mechanical problems that require expert evaluation.

- Lack of Knowledge: If you’re unsure about the repair process or lack the proper tools, seeking help is advisable.

- Safety Concerns: If you notice potential safety hazards, such as leaks or excessive vibrations, it’s best to consult a professional.

- Complex Repairs: Tasks that involve intricate components or specialized knowledge should be handled by trained individuals.

By being aware of these signs, you can ensure that your equipment remains in optimal condition while minimizing risks associated with improper handling.

Cost Estimation for Repairs

Estimating expenses for maintenance tasks is crucial for efficient budgeting and resource allocation. Understanding potential costs helps in making informed decisions regarding the necessary services and parts.

When evaluating the costs, consider the following factors:

- Parts Replacement: Identify components that may need substitution. Research prices for both original and aftermarket options.

- Labor Costs: Calculate the charges associated with professional assistance, if required. This may vary based on complexity and location.

- Diagnostic Fees: Some technicians may charge a fee for assessing the issue before commencing any work.

- Additional Supplies: Factor in costs for tools, lubricants, and cleaning agents that may be needed during the process.

To create a more accurate estimate, follow these steps:

- List all potential issues based on previous performance.

- Research prices for needed parts through various suppliers.

- Contact local service providers to gather quotes on labor.

- Summarize all findings to develop a comprehensive budget.

By thoroughly evaluating these aspects, you can effectively plan for maintenance expenses and ensure that your equipment remains in optimal condition.

User Reviews and Experiences

This section gathers insights from users who have interacted with the product. By sharing their personal journeys, individuals provide valuable perspectives on functionality, ease of use, and overall satisfaction. Their feedback can assist potential buyers in making informed decisions.

Common Praise

- Efficiency: Many users appreciate the high performance, noting that it effectively handles various tasks.

- Durability: Several reviewers highlight the robust build quality, indicating that the tool withstands regular use.

- User-Friendly: Customers often commend the straightforward operation, making it accessible for both beginners and seasoned users.

Areas for Improvement

- Weight: Some users mention that the tool can feel heavy during extended use, impacting comfort.

- Maintenance: A few reviewers express the need for clearer guidelines on upkeep to ensure longevity.

- Noise Level: Several users suggest that reducing noise output would enhance the overall experience.