Understanding the intricacies of a specific type of automatic gearbox can greatly enhance your ability to perform effective maintenance and restoration. This section offers a comprehensive overview of the essential processes involved in overhauling a complex assembly. By gaining insight into the various components and their functions, you will be better equipped to tackle issues that may arise over time.

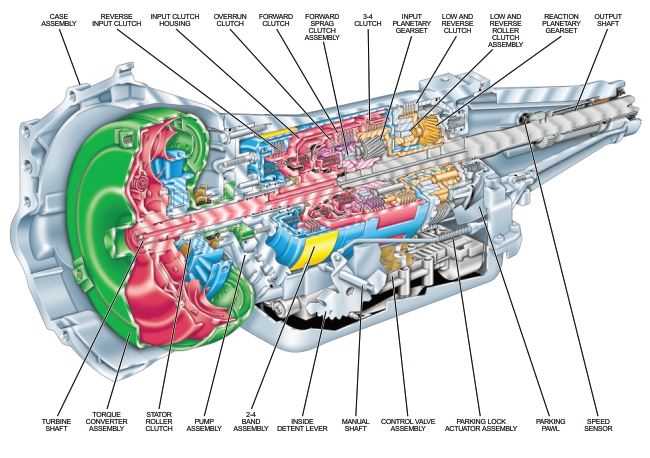

Preparation and Knowledge are crucial when delving into the intricacies of a gearbox system. Familiarizing yourself with the assembly, including gears, clutches, and hydraulic components, can facilitate a smoother restoration process. With the right approach, you can ensure that your efforts lead to a reliable and efficient outcome.

In addition to technical knowledge, having the right tools at your disposal is vital for any successful project. Proper equipment will not only streamline the process but also enhance the precision of your work. This guide aims to provide you with the foundational information necessary to navigate the complexities of such systems and execute effective repairs with confidence.

Overview of 4L60E Transmission

The system discussed here is a crucial component in many vehicles, known for its versatility and performance. It plays a vital role in enhancing driving experiences through efficient gear shifting and power management. This particular assembly is engineered to handle various conditions, making it a popular choice among automotive enthusiasts and professionals alike.

Key Features: This unit is designed with a focus on durability and adaptability, allowing it to excel in both everyday driving and demanding environments. Its ability to deliver smooth transitions between gears is one of its standout characteristics.

Common Issues: While it is a robust piece of machinery, it may encounter specific challenges over time. Regular maintenance and awareness of potential problems can significantly extend its lifespan and ensure optimal functionality.

Common Issues and Symptoms

When dealing with automotive shifting systems, several recurring problems may arise, often signaling the need for attention. Recognizing these signs early can prevent more extensive damage and costly repairs. This section outlines typical challenges encountered with these mechanisms.

Slipping Gears: One of the most noticeable issues is the inability to maintain gear engagement, which may cause unexpected changes in speed or acceleration. This can result from various factors, including fluid levels or component wear.

Unusual Noises: Strange sounds such as grinding, whining, or clunking can indicate internal complications. These noises often emerge during shifts or acceleration, suggesting that components may be misaligned or damaged.

Delayed Engagement: A delay in response when shifting from park to drive can signify problems within the system. This symptom might be linked to low fluid levels or contamination affecting performance.

Fluid Leaks: Visible fluid leakage beneath the vehicle is a clear warning sign. Low levels of hydraulic fluid can lead to inadequate operation and should be addressed promptly to avoid further issues.

Warning Lights: The illumination of dashboard warning indicators can point to underlying complications. It’s essential to consult a professional for diagnostics when these alerts are triggered.

By being aware of these common challenges and their symptoms, vehicle owners can take proactive steps to maintain optimal functionality and prolong the lifespan of their automotive systems.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing common issues found in automatic gear systems. Following a systematic procedure ensures that all components are inspected and repaired efficiently, leading to a successful restoration of functionality.

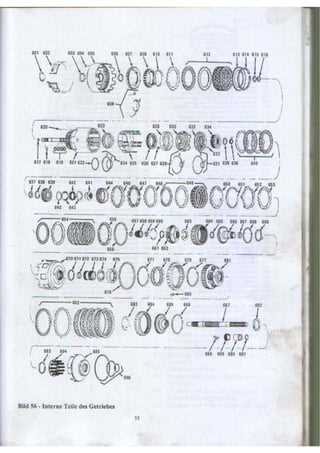

Preparation and Disassembly

Begin by gathering the necessary tools and safety equipment. Ensure the workspace is organized and well-lit. Carefully detach the assembly from the vehicle, taking note of any connections and fasteners. Document each step, as this will aid in reassembly later. Once removed, proceed to disassemble the unit, examining each part for signs of wear or damage.

Inspection and Replacement

After disassembly, conduct a thorough evaluation of all components. Look for cracks, discoloration, or any irregularities that may indicate failure. Replace any damaged elements with high-quality substitutes. It’s crucial to use compatible parts to maintain the integrity of the system. After replacing the necessary components, reassemble the unit, ensuring all connections are secure and in the correct order.

Tools Required for Repair

Successful maintenance and restoration of automotive components demand a specific set of instruments and equipment. Having the right tools ensures efficiency and accuracy, minimizing the risk of damage during the process. Below is a list of essential tools to facilitate the task.

Essential Hand Tools

Basic hand tools are crucial for any mechanical project. This includes wrenches, sockets, and screwdrivers. These instruments allow for effective loosening and tightening of various fasteners. Additionally, pliers and hammers may come in handy for more delicate adjustments.

Specialized Equipment

In some cases, specialized tools enhance the process significantly. A torque wrench is vital for ensuring that all components are tightened to the manufacturer’s specifications. Moreover, a fluid pump can assist in transferring essential fluids without spills, while a repair stand provides stability during disassembly and assembly.

Replacing Clutches and Gaskets

Maintaining optimal performance in an automotive system often requires the replacement of critical components such as friction elements and sealing materials. This process ensures that the mechanism operates smoothly and efficiently, preventing leaks and enhancing overall reliability.

Tools and Materials Needed

- Socket set

- Torque wrench

- Clutch kits

- Gasket material or pre-cut gaskets

- Sealing compound

- Cleaning supplies

Step-by-Step Replacement Process

- Start by disconnecting the battery and ensuring the work area is safe.

- Remove any covers or components obstructing access to the clutches and gaskets.

- Carefully take out the existing friction elements and gaskets, noting their positions for reassembly.

- Clean the surfaces thoroughly to remove old material and debris.

- Install the new clutches and gaskets, ensuring they fit securely and are aligned correctly.

- Reassemble any components that were removed, tightening them to the manufacturer’s specifications.

- Reconnect the battery and test the system to confirm proper operation.

Following these guidelines will help ensure that the elements are replaced effectively, contributing to the longevity and functionality of the entire assembly.

Checking Valve Body Functionality

The valve body plays a crucial role in the operation of an automotive fluid coupling system, regulating the flow of hydraulic fluid and enabling various gear shifts. Ensuring its proper functionality is essential for maintaining optimal performance and preventing operational issues.

Signs of Malfunction

Recognizing the symptoms of a failing valve body can help identify the need for further inspection. Common indicators include:

- Unresponsive gear shifts

- Delayed or harsh shifting

- Fluid leaks around the valve assembly

- Erratic or inconsistent performance

Inspection Procedure

To effectively check the functionality of the valve body, follow these steps:

- Ensure the vehicle is on a level surface and secure it with jack stands.

- Remove the pan to access the valve body assembly.

- Inspect for visible damage or debris inside the assembly.

- Test the solenoids and check for electrical continuity.

- Clean any accumulated debris and check for proper fluid flow through the channels.

- Reassemble and refill with appropriate fluid before testing the system under various operating conditions.

Fluid Changes and Maintenance Tips

Regularly maintaining the internal workings of your vehicle’s powertrain is essential for optimal performance and longevity. One crucial aspect of this upkeep involves the periodic replacement of the lubricant, which plays a vital role in ensuring smooth operation and preventing wear and tear.

Importance of Regular Fluid Changes

Changing the lubricant at recommended intervals helps to remove contaminants and prevents the buildup of harmful deposits. Over time, fluid can become degraded, losing its ability to lubricate effectively. Neglecting this task can lead to increased friction and heat, ultimately resulting in costly damage.

Maintenance Best Practices

To maintain peak efficiency, consider the following tips:

- Check Fluid Levels: Regularly inspect fluid levels to ensure they are within the recommended range.

- Use Quality Products: Always choose high-quality lubricants that meet or exceed the manufacturer’s specifications.

- Monitor Performance: Pay attention to any changes in shifting behavior or unusual noises, as these can be early signs of issues.

- Consult Professionals: When in doubt, seek advice from a qualified technician for any concerns regarding performance.

By adhering to these practices, you can significantly enhance the reliability and efficiency of your vehicle’s mechanical systems.

Testing for Performance After Repair

After completing service on a vehicle’s shifting mechanism, it is essential to ensure that it operates smoothly and efficiently. This section outlines key steps and considerations for evaluating functionality, ultimately confirming that the system meets performance standards.

Initial Checks and Observations

Begin by conducting a visual inspection to identify any visible leaks or abnormalities. Ensure that all components are securely fastened and that the fluid levels are adequate. Once the initial checks are complete, start the vehicle and listen for unusual noises, which could indicate underlying issues.

Road Testing Procedures

Perform a series of controlled road tests to assess the responsiveness and behavior of the system under various conditions. Pay attention to shifting patterns, ensuring that transitions are smooth and timely. Acceleration tests should also be conducted to evaluate power delivery and overall efficiency. If any irregularities arise during testing, further diagnostics may be necessary.

Finally, after conducting these assessments, document the findings to establish a performance baseline. Regular evaluations help maintain optimal functionality and prolong the lifespan of the system.

Upgrading Components for Better Performance

Enhancing the efficiency and capability of your vehicle’s system involves a strategic approach to component upgrades. By selecting high-quality parts, you can significantly improve power delivery and responsiveness. This section will explore various options that can lead to a noticeable increase in performance.

Key Components to Consider

When upgrading, focus on elements such as the valve body, pump, and clutches. A performance-oriented valve body can improve shift timing and firmness, providing a more engaging driving experience. Upgrading the pump ensures adequate fluid pressure, which is crucial for optimal operation and longevity.

Benefits of High-Performance Clutches

Investing in superior clutches enhances durability and torque handling. These components are designed to withstand higher temperatures and pressures, which translates to improved reliability under demanding conditions. With robust clutches, you can enjoy smoother shifts and a more engaging connection to the road.

Incorporating these enhancements not only boosts performance but also contributes to the overall longevity of the system, ensuring a rewarding driving experience for years to come.