This section provides an insightful overview of the intricate processes involved in maintaining and restoring the functionality of a specific type of automotive system. Understanding the mechanisms and components at play is crucial for anyone looking to enhance their knowledge in vehicle maintenance and performance enhancement.

Equipped with the right techniques and tools, even complex tasks can be approached with confidence. This guide serves as a resource for enthusiasts and professionals alike, aiming to simplify intricate procedures and offer clarity on essential practices. By delving into the various aspects of the overhaul process, readers will gain valuable insights that promote effective and safe vehicle operation.

Moreover, learning about common issues and solutions can empower individuals to tackle challenges independently. This resource emphasizes the importance of thorough understanding, preparation, and attention to detail, ensuring that every step contributes to the overall success of the project.

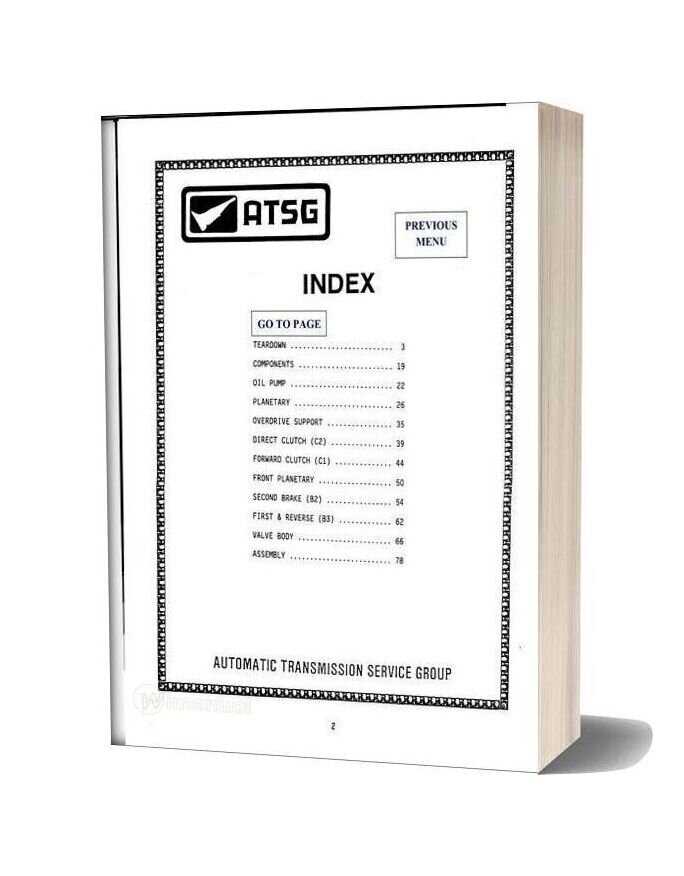

A340F Transmission Repair Guide

This section provides essential insights into the maintenance and restoration of a specific gear-shifting mechanism, ensuring optimal performance and longevity. By understanding the fundamental components and processes, enthusiasts and professionals alike can effectively address common issues.

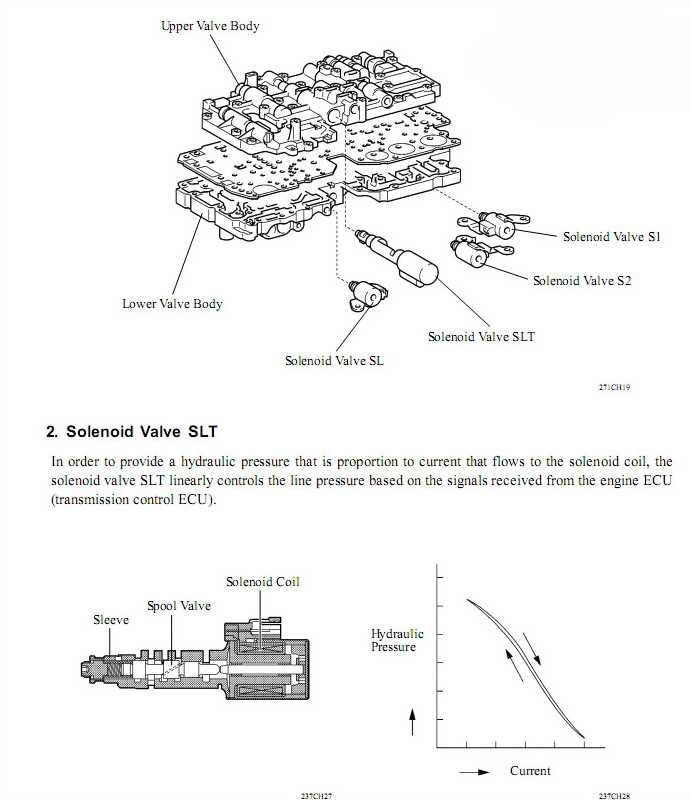

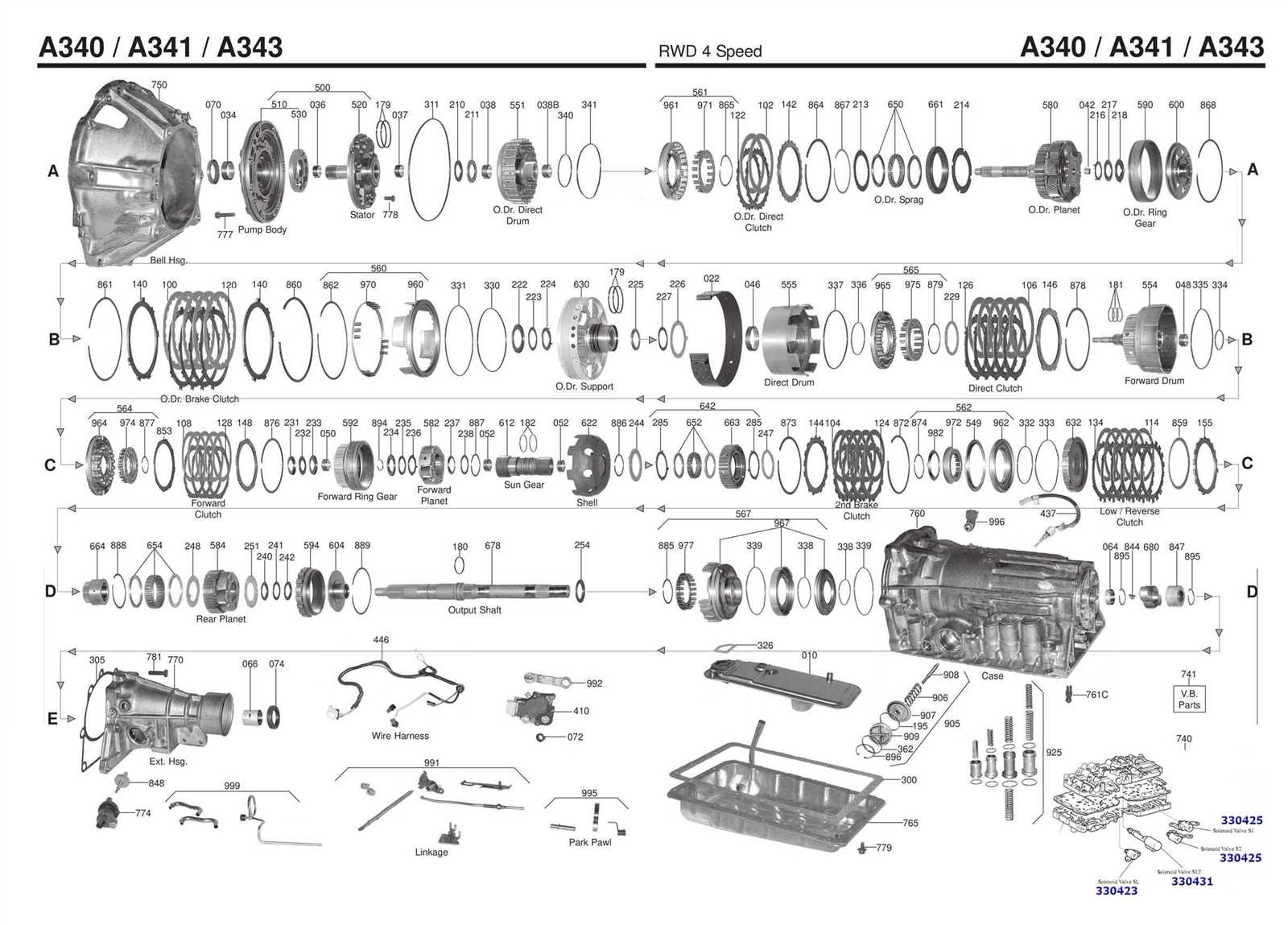

Understanding the Components

The system comprises various intricate parts that work harmoniously. Familiarity with elements such as clutches, gears, and hydraulic systems is crucial for diagnosing problems and implementing solutions. Regular inspection can prevent minor concerns from escalating.

Maintenance Best Practices

Implementing a proactive approach to upkeep is vital. Regular fluid checks, timely replacements, and careful monitoring of performance can significantly enhance functionality. Adhering to these guidelines can lead to a more efficient and reliable operation.

Understanding A340F Transmission Basics

This section explores the essential features and functions of a specific type of vehicle gearbox, highlighting its design and operational characteristics. Knowledge of this system is crucial for those looking to maintain or troubleshoot issues effectively.

Key Components

The unit comprises several critical parts that work together to ensure smooth functionality. Each component plays a vital role in the overall performance, and understanding these elements can aid in effective maintenance.

| Component | Description |

|---|---|

| Gear Set | Responsible for changing speeds and torque. |

| Fluid Pump | Maintains fluid circulation, ensuring lubrication. |

| Valve Body | Controls the flow of hydraulic fluid to different parts. |

| Torque Converter | Facilitates smooth engagement between engine and gearbox. |

Operational Principles

The functionality of this gearbox involves intricate hydraulic systems that respond to driving conditions. Understanding how these systems interact can significantly improve diagnosis and intervention during service.

Common Issues with A340F Transmissions

Understanding the typical problems associated with these vehicle components can significantly enhance maintenance and longevity. Various factors can lead to performance issues, and being aware of them is crucial for any owner or technician.

Fluid Leaks

One of the most frequent concerns is the presence of fluid leaks. These can arise from deteriorated seals or gaskets, leading to inadequate lubrication and potential overheating. Regular inspections are vital to catch these issues early and prevent further damage.

Shifting Difficulties

Another common symptom is difficulty in shifting gears. This can manifest as hesitation or a complete failure to change gears. Possible causes include contaminated fluid or issues with the internal components. Addressing these problems promptly can help maintain optimal performance.

Essential Tools for Repair Process

Having the right equipment is crucial for a successful restoration task. A well-equipped workspace not only facilitates the procedure but also ensures safety and efficiency. Below are some of the vital instruments that will assist in achieving a smooth operation.

- Wrenches: Various sizes are necessary for loosening and tightening fasteners.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is essential for handling screws.

- Pliers: Useful for gripping and twisting wires or components.

- Socket Set: Ideal for reaching tight spots and providing torque.

- Torque Wrench: Ensures that fasteners are tightened to the manufacturer’s specifications.

Utilizing these instruments effectively can significantly impact the outcome of the project. Proper maintenance of tools is equally important to ensure longevity and reliability.

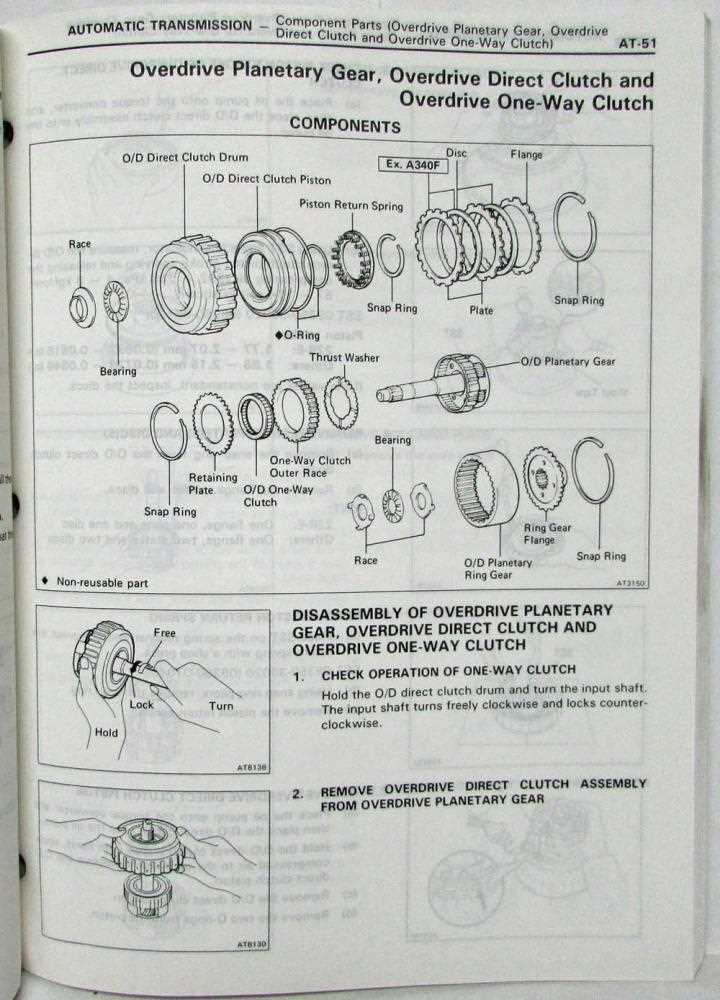

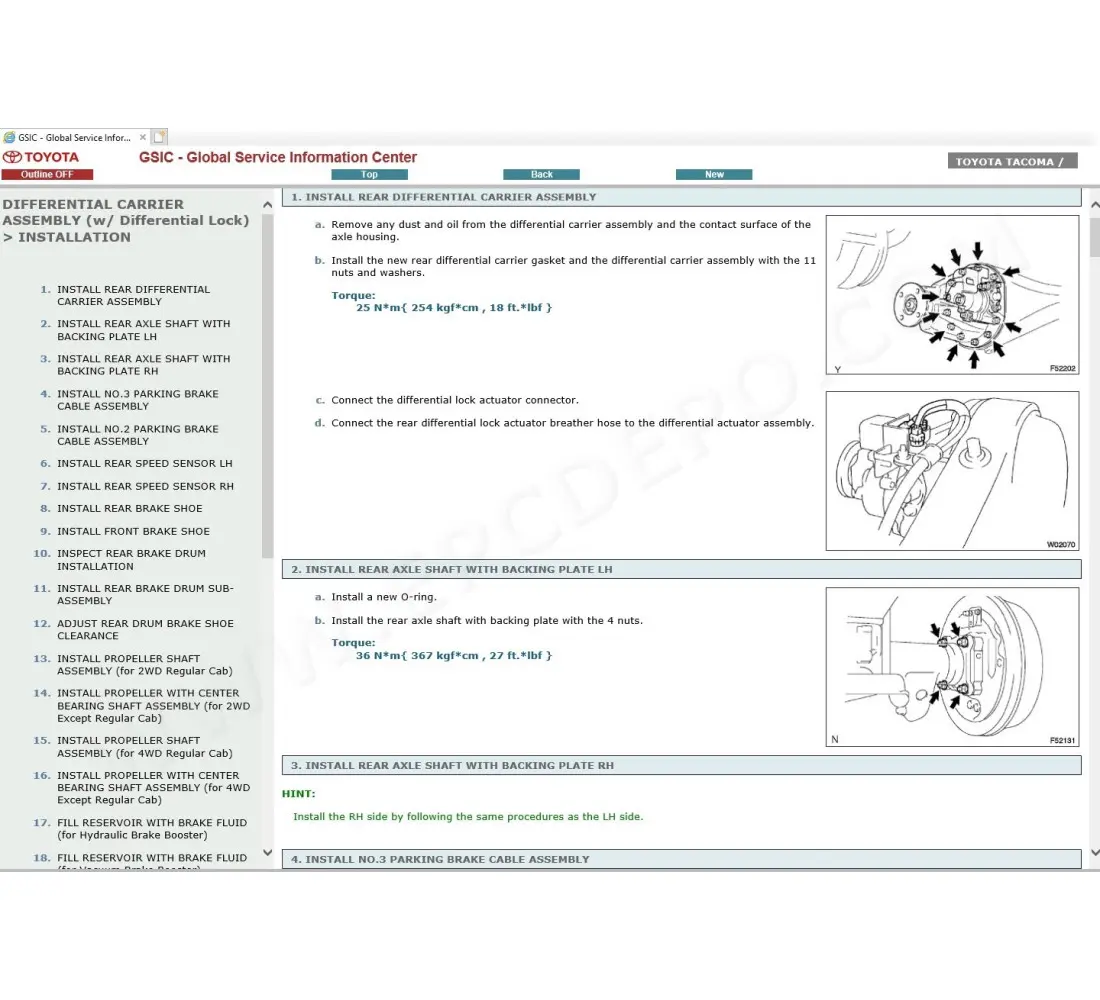

Step-by-Step Disassembly Instructions

This section provides detailed guidance for systematically dismantling the unit. Following these steps will ensure that each component is carefully removed, preventing damage and facilitating future reassembly.

-

Preparation:

- Gather all necessary tools and equipment.

- Ensure a clean and organized workspace.

- Review safety protocols to protect yourself and the components.

-

Initial Inspection:

- Examine the outer casing for any signs of damage.

- Document any irregularities for future reference.

-

Component Removal:

- Start with the outer panels, removing screws and clips.

- Proceed to detach smaller components such as sensors and connectors.

- Label each part as it is removed to aid in reassembly.

-

Internal Dismantling:

- Carefully extract internal assemblies, following the designated order.

- Keep track of all fasteners and their locations.

-

Final Steps:

- Inspect all removed parts for wear or damage.

- Clean the components to prepare for maintenance or replacement.

Completing these steps will provide a thorough disassembly, laying the groundwork for any necessary work on the unit.

Inspecting Components for Damage

Careful evaluation of parts is crucial to ensure optimal functionality and longevity of the system. Identifying any signs of wear or failure can prevent larger issues down the line.

Begin by examining the various elements for visible defects. Look for:

- Cracks or fractures

- Discoloration indicating overheating

- Unusual wear patterns on surfaces

- Looseness or instability in mounting points

After the visual inspection, proceed with a more detailed analysis. Consider the following steps:

- Use appropriate tools to measure tolerances and clearances.

- Check for fluid leaks that may indicate compromised seals.

- Assess the alignment of components to prevent operational issues.

- Test for functionality through manual or automated methods.

Document any findings meticulously to aid in decision-making for maintenance or replacement needs.

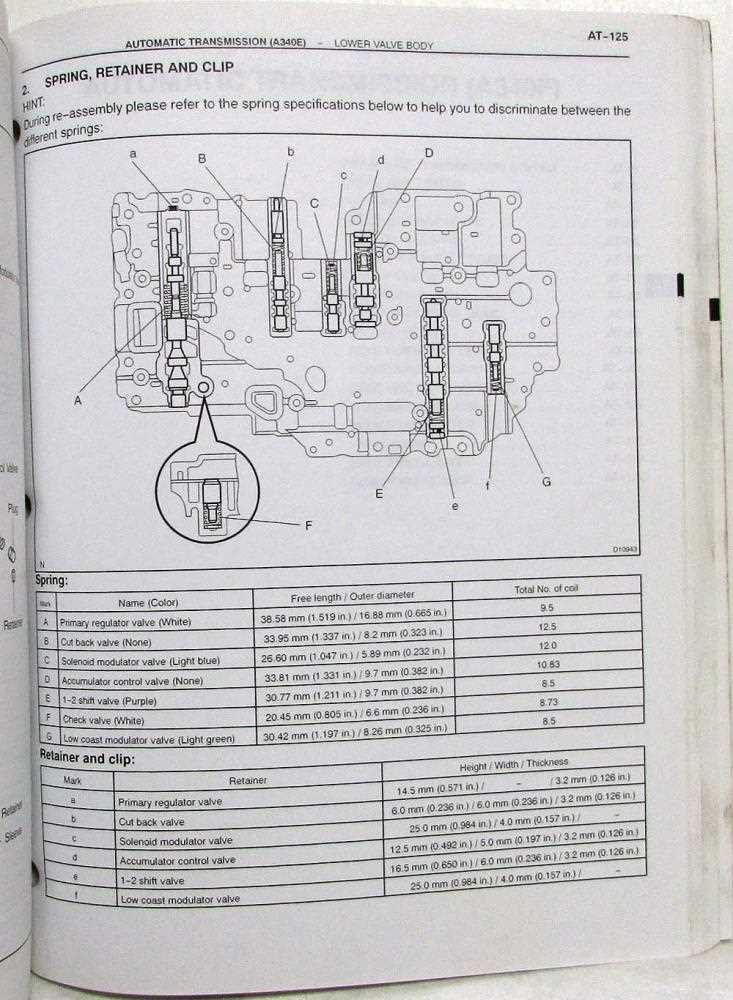

Reassembly Techniques for A340F

Reassembling a complex mechanical system requires precision and an understanding of the components involved. This section focuses on effective methods to ensure that every part is correctly positioned and secured, resulting in optimal performance and longevity.

Preparation Steps

Before beginning the reassembly process, it’s crucial to organize all components and tools. Clean each part thoroughly to remove any debris or old lubricants that could hinder functionality. Reviewing any previous documentation can provide insights into specific sequences and techniques relevant to the assembly.

Assembly Process

During the reassembly, start by carefully aligning larger components, ensuring they fit snugly together. Gradually incorporate smaller elements, verifying that each piece is positioned accurately. Utilize torque specifications to secure fasteners appropriately, as improper tension can lead to failure or inefficient operation. Regularly check alignment and functionality as you progress through the assembly, making adjustments as necessary.

Fluid Specifications and Maintenance Tips

Maintaining optimal performance in your vehicle’s drivetrain involves understanding the essential fluids that keep it running smoothly. Proper fluid selection and regular maintenance can significantly enhance longevity and efficiency.

Fluid Types: It’s crucial to use the recommended fluids that meet specific standards for viscosity and formulation. Always refer to your vehicle’s guidelines to choose the right products, as different systems may require distinct types of fluids.

Regular Checks: Routine inspections of fluid levels are vital. Ensure that all necessary fluids are topped up and in good condition. Look for signs of contamination or degradation, as these can indicate the need for replacement.

Change Intervals: Adhere to the manufacturer’s recommendations regarding fluid change intervals. Regularly replacing old fluids helps prevent wear and tear, promoting smoother operation and reducing the risk of damage.

Proper Disposal: When changing fluids, ensure to dispose of old fluids responsibly. Many service centers and recycling centers offer safe disposal options, which helps protect the environment.

Diagnosing Electrical Problems

Identifying issues related to electrical systems is crucial for maintaining optimal vehicle performance. This process involves a systematic approach to detect malfunctions that may disrupt the functionality of various components. By understanding the signs and employing the right techniques, one can effectively troubleshoot and resolve these complications.

The first step in diagnosing electrical faults is to observe any unusual behavior in the system. This could include erratic responses, warning lights on the dashboard, or unexpected failures. Gathering information from the vehicle’s onboard diagnostic system can provide valuable insights, highlighting specific areas that require further investigation.

Next, it is important to inspect all wiring and connections. Look for signs of wear, corrosion, or loose terminals that could hinder the flow of electricity. Utilizing a multimeter can help measure voltage and continuity, enabling the identification of breaks or shorts in the circuit.

Additionally, testing individual components, such as relays and sensors, is essential. By isolating these parts, one can determine if they are functioning correctly or need replacement. Ensuring that all components are working together seamlessly will help restore proper operation.

Upgrading Performance in A340F

Enhancing the efficiency of your vehicle’s power delivery system can significantly improve its overall performance. By focusing on key areas of modification, drivers can experience a noticeable boost in responsiveness and power output.

One effective method is to optimize fluid dynamics within the system. This can be achieved by using high-quality lubricants that reduce friction and heat buildup, leading to smoother operation. Additionally, upgrading internal components can provide improved durability and performance under stress.

Another approach involves adjusting electronic controls. Fine-tuning the software can enhance shift timing and responsiveness, resulting in a more dynamic driving experience. Finally, incorporating performance parts designed specifically for these systems can lead to enhanced reliability and efficiency.

Preventative Measures to Avoid Failures

Implementing proactive strategies can significantly enhance the longevity and reliability of complex systems. By understanding potential issues and addressing them before they escalate, users can prevent costly breakdowns and maintain optimal performance.

Regular Maintenance Checks

Consistent evaluations are essential to identify wear and tear early. Key tasks include:

- Inspecting fluid levels and quality.

- Checking for leaks or signs of deterioration.

- Ensuring all components are properly secured.

Using Quality Components

Utilizing high-quality parts is crucial in minimizing the risk of failure. Consider the following:

- Choose reputable manufacturers for replacement items.

- Ensure compatibility with existing systems.

- Adhere to specifications outlined by experts.

Cost Analysis of A340F Repairs

This section delves into the financial implications associated with addressing issues in a specific automotive component. Understanding the potential expenses can help vehicle owners make informed decisions regarding maintenance and troubleshooting.

Factors Influencing Costs

Several elements contribute to the overall expenses involved in addressing malfunctions. Labor rates, availability of parts, and the complexity of the task all play significant roles in determining the final price. Additionally, the location of the service center can greatly impact the total cost, as urban areas may have higher labor charges compared to rural regions.

Estimating Overall Expenses

When estimating the costs for fixing issues, it’s essential to consider both direct and indirect expenses. Direct costs include parts and labor, while indirect costs might encompass downtime and potential loss of vehicle functionality. By taking a comprehensive approach to budgeting, owners can better prepare for any necessary financial outlays.

When to Seek Professional Help

Understanding when to enlist the expertise of a specialist can be crucial for maintaining your vehicle’s functionality. There are certain indicators that suggest it may be time to consult a trained technician rather than attempting to address issues on your own.

If you notice unusual sounds, such as grinding or whining, it’s a sign that something may be amiss. Additionally, if you experience unexpected vibrations or difficulties in shifting gears, these symptoms warrant immediate attention. It is advisable to avoid driving the vehicle further in these situations, as doing so can exacerbate the problem.

Another key factor is the presence of warning lights on your dashboard. Ignoring these signals could lead to more severe complications. Furthermore, if you find that the performance of your vehicle has declined noticeably, it is wise to seek assistance from a qualified professional.

Ultimately, timely intervention can save you from extensive repairs and ensure your vehicle operates smoothly for years to come. If you are unsure about the severity of the issue, it is always better to consult with an expert.