The efficient operation of heavy-duty vehicles largely depends on the robustness and reliability of their gear systems. Proper understanding of these complex assemblies is essential for ensuring longevity and peak performance. This section delves into crucial aspects of maintaining and troubleshooting advanced gear mechanisms.

By exploring the intricacies of these mechanical wonders, users can gain valuable insights into their functionality. Knowledge of the various components and their roles is fundamental to addressing common issues that may arise during use. A well-informed approach not only enhances operational efficiency but also minimizes the risk of unexpected breakdowns.

Effective upkeep practices are vital in extending the lifespan of these essential parts. The following content offers detailed guidance on best practices, including diagnostics, common pitfalls, and strategies for ensuring optimal performance. By adhering to these recommendations, users can confidently navigate the complexities of gearbox care.

This section provides a comprehensive look into a complex mechanical system designed for heavy-duty vehicles. Understanding the functionality and components of this gear arrangement is crucial for effective maintenance and troubleshooting. The focus here is on the unique features that distinguish this assembly in the world of automotive engineering.

| Feature | Description |

|---|---|

| Gear Configuration | This arrangement enhances operational efficiency, allowing for a variety of driving conditions. |

| Durability | Constructed to withstand heavy use, ensuring longevity and reliability. |

| Maintenance Requirements | Regular upkeep is essential for optimal performance and longevity. |

| Common Issues | Identifying frequent malfunctions can aid in swift troubleshooting and repairs. |

| Component Identification | Familiarity with the parts is vital for effective repairs and enhancements. |

Common Issues with Eaton Transmissions

Many vehicle owners encounter various challenges with heavy-duty gear systems. Understanding these common problems can help in timely identification and resolution, ensuring smoother operation and longevity.

Frequent Problems Encountered

One prevalent issue involves gear shifting difficulties, which may stem from inadequate lubrication or worn components. These factors can lead to hard engagements and increased wear over time.

Maintenance Challenges

Regular upkeep is crucial to prevent premature failures. Neglecting routine inspections can result in unnoticed damage that exacerbates the condition. Additionally, overheating can be a significant concern, often caused by improper fluid levels or contamination.

Essential Tools for Repairs

When it comes to maintaining and fixing complex mechanical systems, having the right equipment is crucial. A well-equipped toolkit can significantly streamline the process, ensuring that each task is performed efficiently and accurately. This section highlights the indispensable tools that every technician should consider having at their disposal.

Wrenches: A variety of wrenches, including adjustable and socket types, are fundamental for loosening and tightening fasteners. These tools provide the necessary leverage to handle stubborn bolts and nuts.

Screwdrivers: A set of screwdrivers in different sizes and types is essential for accessing various components. Flathead and Phillips screwdrivers should be included to accommodate a range of screw types.

Pliers: Pliers are versatile tools that aid in gripping, bending, and cutting wires or small parts. Needle-nose pliers are especially useful for reaching tight spaces.

Torque Wrench: Ensuring that fasteners are tightened to the correct specifications is vital. A torque wrench allows for precise adjustments, preventing damage from over-tightening.

Impact Gun: An impact gun can significantly reduce the effort required to remove stubborn fasteners, making it an invaluable addition to any toolkit.

Measuring Tools: Calipers and rulers are important for measuring components accurately. This ensures that replacements fit perfectly and function correctly.

Equipping yourself with these essential tools will not only enhance your efficiency but also contribute to the longevity and performance of the machinery you are working on.

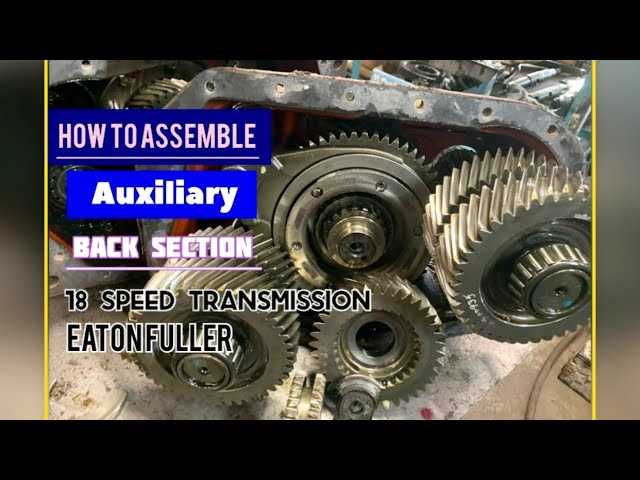

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to taking apart a complex mechanical unit. Following these steps ensures that you can successfully access internal components for inspection, maintenance, or replacement. Proper disassembly is crucial to avoid damaging parts and to facilitate efficient reassembly.

Preparation

- Gather necessary tools such as wrenches, screwdrivers, and pliers.

- Ensure you have a clean workspace to organize parts.

- Refer to the schematics or diagrams if available.

Disassembly Steps

- Start by removing any external covers and shields.

- Disconnect all electrical connectors and hoses carefully.

- Loosen and remove bolts securing the main housing.

- Gently separate the housing to access internal mechanisms.

- Document the arrangement of components for reference during reassembly.

- Remove individual parts, taking care not to force any components.

- Inspect each part for wear or damage as you proceed.

Inspecting Internal Components

Thorough examination of internal mechanisms is crucial for ensuring optimal functionality and longevity of the system. Regular checks can help identify wear, damage, or misalignment that may compromise performance. Understanding the components’ condition can prevent costly failures and extend service life.

Visual Assessment: Begin with a detailed visual inspection of all internal parts. Look for signs of corrosion, cracks, or abnormal wear patterns. Any visible damage should be documented and addressed promptly.

Operational Testing: Conduct functional tests to assess how each component interacts with others. Listen for unusual noises or vibrations that may indicate underlying issues. Ensure that all parts operate smoothly and without hesitation.

Measurement and Tolerance Checks: Utilize precision tools to measure critical dimensions. Compare these measurements against the manufacturer’s specifications to determine if any components fall outside acceptable tolerances. This step is essential for maintaining performance and reliability.

Regular inspections, combined with a proactive approach to maintenance, will significantly enhance the overall effectiveness and durability of the unit.

Repairing Gear and Shaft Problems

Addressing issues with gears and shafts is crucial for ensuring the efficient operation of heavy machinery. These components are integral to the overall functionality, and any malfunction can lead to significant performance degradation. Understanding common problems and their solutions is essential for maintaining optimal performance.

Identifying Common Issues

Gear and shaft complications often manifest as unusual noises, vibrations, or difficulty in engaging gears. Common issues include wear, misalignment, and insufficient lubrication. Regular inspections can help detect these problems early, allowing for timely intervention.

Effective Solutions

To rectify gear and shaft problems, begin with a thorough examination of the components. Replace worn gears and ensure shafts are aligned correctly. Applying appropriate lubricants can also mitigate friction and extend the lifespan of these parts. Implementing these strategies will enhance the reliability and efficiency of the machinery.

Sealing and Gasket Replacement

Maintaining optimal performance in heavy-duty machinery requires attention to various components, including seals and gaskets. These parts play a crucial role in preventing leaks and ensuring the efficient operation of the system. Proper replacement and maintenance can significantly extend the lifespan of the equipment.

Identifying Wear and Damage

Before proceeding with the replacement, it is essential to examine the existing seals and gaskets for signs of wear, such as cracks or deformation. Regular inspection helps identify potential issues early, allowing for timely intervention and avoiding costly downtime.

Replacement Process

When replacing seals and gaskets, it is vital to choose high-quality materials that meet or exceed the original specifications. Ensure that all surfaces are clean and free from debris before installation. Carefully position the new parts, applying the correct torque to avoid future leaks.

Testing for Leaks

After the replacement is complete, conducting a thorough test is crucial. Monitor the system for any signs of leakage during operation, and make adjustments as necessary. This proactive approach helps maintain the integrity of the machinery and ensures reliable performance.

Reassembly Techniques and Tips

Reassembling complex mechanical components requires attention to detail and a systematic approach. Ensuring that each part is correctly placed and secured is essential for optimal performance and longevity.

Follow these guidelines for effective reassembly:

- Organize Parts: Keep all components arranged in an orderly fashion. Use labeled containers for small items to prevent confusion.

- Refer to Documentation: Consult any available guides or schematics to verify the correct sequence and orientation of parts.

- Inspect Each Component: Before reassembly, thoroughly check each piece for wear or damage. Replace any faulty parts to avoid future issues.

- Use Proper Tools: Ensure that you have the correct tools at hand. Using inappropriate tools can lead to damage or improper assembly.

- Follow Torque Specifications: Adhere to the specified torque settings for fasteners to ensure a secure fit without over-tightening.

By adhering to these techniques, you can enhance the reliability and efficiency of the assembled unit.

Fluid Types and Maintenance Practices

Maintaining optimal performance in heavy-duty gear systems relies heavily on the choice of lubricants and adherence to proper upkeep routines. Understanding the different categories of fluids available and their specific properties is crucial for ensuring longevity and reliability.

Types of Lubricants: Various formulations exist, including synthetic and mineral oils, each designed to provide specific benefits under different operational conditions. Synthetic fluids often offer enhanced protection against wear and improved thermal stability, making them ideal for rigorous applications. In contrast, mineral oils may be more suitable for standard usage scenarios, providing adequate protection at a lower cost.

Maintenance Practices: Regular checks and timely changes of lubricants are essential practices to uphold system efficiency. Establishing a maintenance schedule that includes periodic inspections can help identify potential issues before they escalate. Always refer to the manufacturer’s guidelines to determine the correct fluid type and change intervals for optimal results.

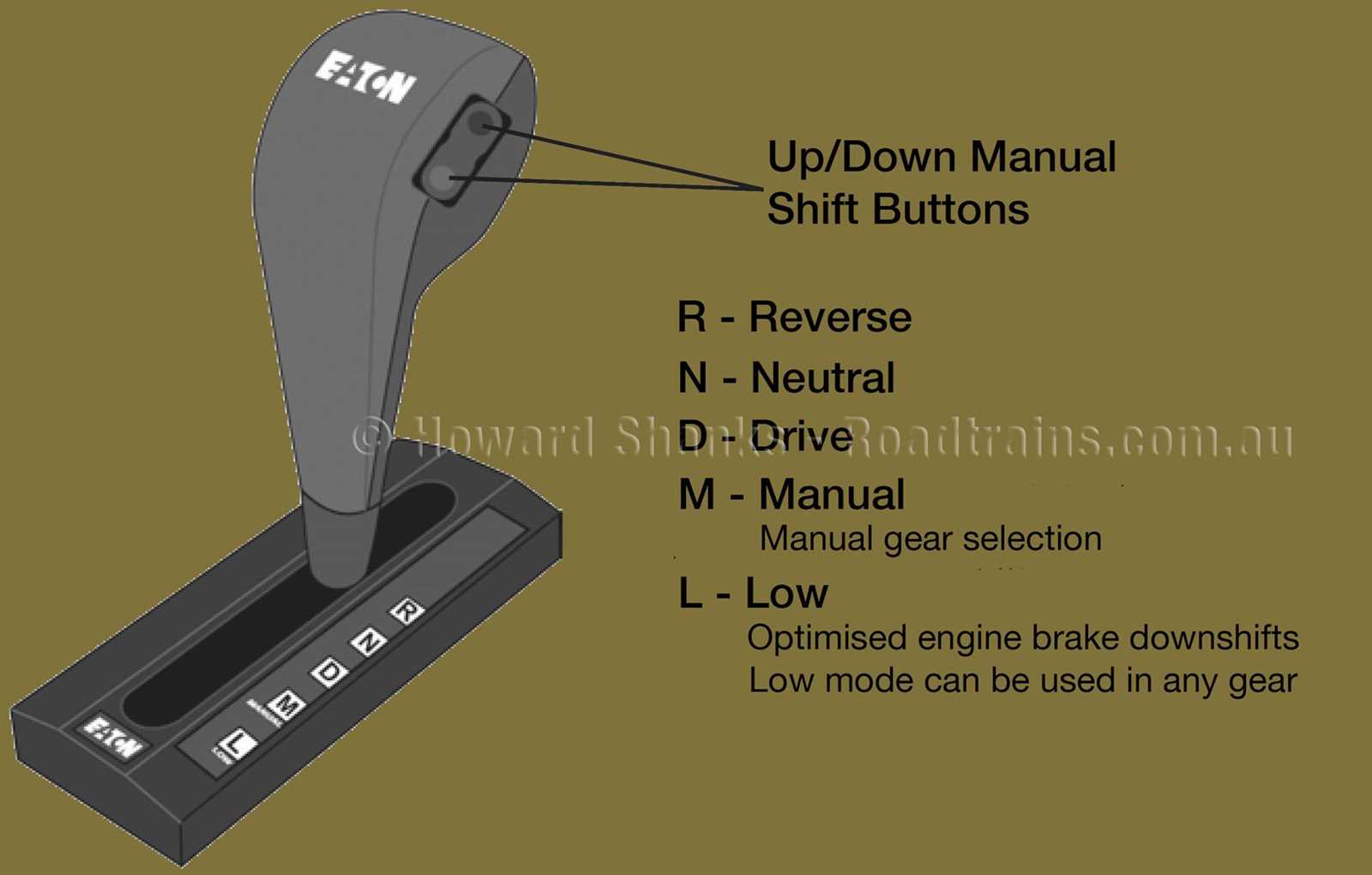

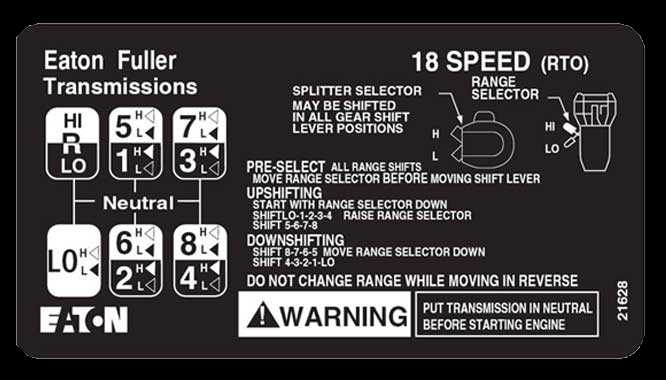

Testing Transmission Performance

Evaluating the efficiency and functionality of a gear-shifting system is crucial for ensuring optimal operation. This process involves several key steps to assess how well the mechanism engages and disengages under various conditions.

- Initial Inspection: Begin by visually checking for any obvious signs of wear or damage.

- Fluid Level Check: Ensure that the lubricant is at the appropriate level to avoid excessive friction and overheating.

- Engagement Test: Operate the system through all available settings to confirm smooth transitions between gears.

- Load Assessment: Test under different load conditions to observe how the mechanism responds and maintains performance.

Following these steps will provide insights into the overall health of the gear system and help identify any necessary adjustments or replacements.

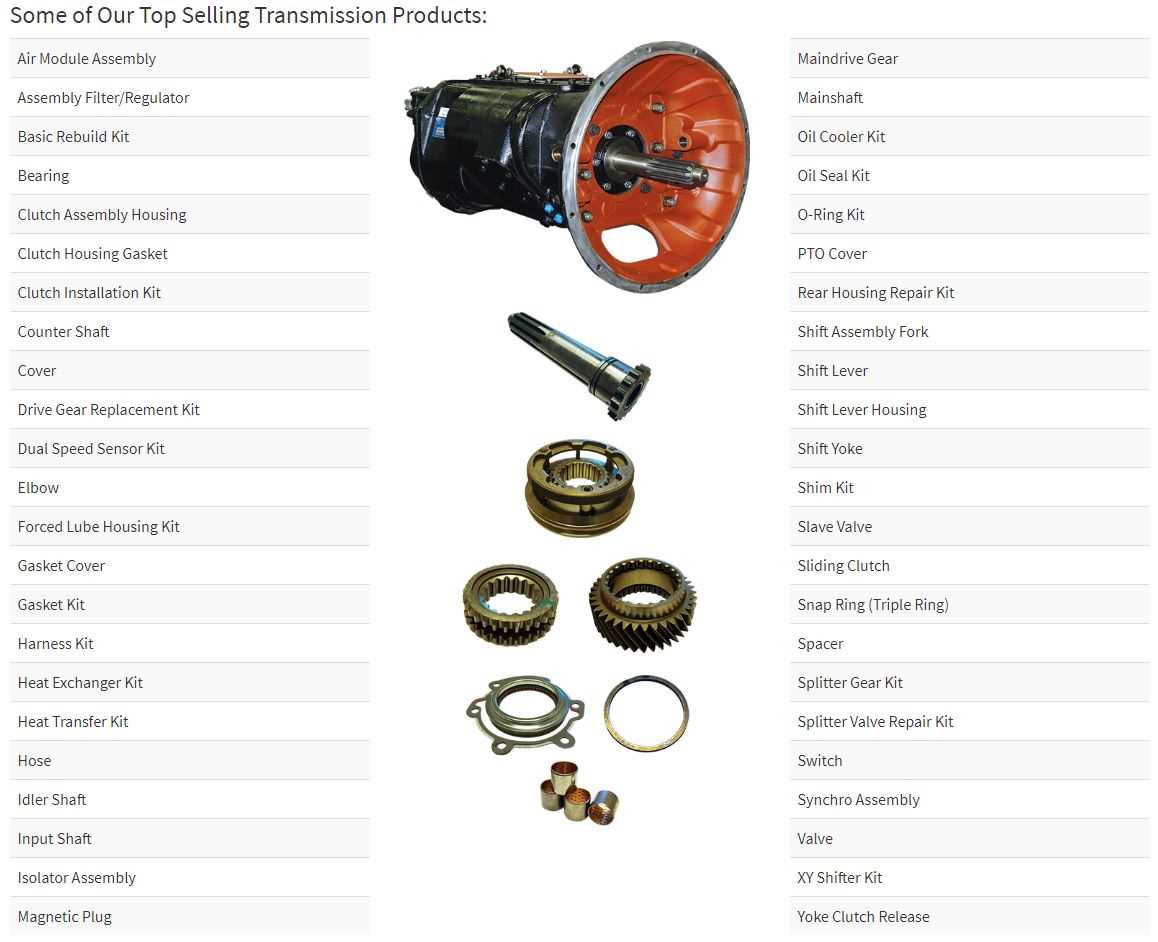

Upgrading Components for Durability

Enhancing the resilience of essential vehicle systems is crucial for maintaining optimal performance and longevity. By focusing on component upgrades, operators can significantly improve reliability and reduce the likelihood of unexpected failures.

Choosing high-quality materials is the first step in this process. Utilizing robust parts made from superior alloys or advanced composites can greatly enhance strength and wear resistance. This choice minimizes the impact of stress and prolongs the lifespan of critical assemblies.

Another important aspect is regularly inspecting and replacing wear-prone components. Items such as seals, gaskets, and bushings are vital to system integrity. Upgrading these parts with more durable alternatives can lead to better sealing and reduced friction, ultimately enhancing overall system efficiency.

Additionally, considering advanced engineering solutions can offer significant benefits. Implementing upgraded design features, such as reinforced casings or improved lubrication systems, contributes to greater operational stability. This strategic approach not only enhances performance but also ensures smoother functionality under demanding conditions.

Resources for Further Assistance

When encountering challenges with complex mechanical systems, accessing additional resources can be invaluable. Various organizations and platforms provide support, guidance, and detailed insights to enhance your understanding and troubleshooting capabilities.

Online Forums and Communities

Joining online forums and communities dedicated to mechanical systems can provide a wealth of shared knowledge. Participants often share their experiences, solutions, and tips that can help you navigate specific issues effectively.

Professional Services

In some cases, enlisting the expertise of professionals can lead to more efficient resolutions. Many services offer specialized support for mechanical systems, ensuring that you receive accurate and reliable assistance.

| Resource Type | Details |

|---|---|

| Online Forums | Communities where users discuss issues and solutions. |

| Technical Websites | Websites offering tutorials, guides, and troubleshooting tips. |

| Professional Services | Consultants or shops specializing in mechanical systems. |