This resource serves as an invaluable tool for individuals seeking to enhance their knowledge about the upkeep and troubleshooting of specific automotive engines. Understanding the intricacies of your vehicle’s powertrain is essential for ensuring optimal performance and longevity. This guide is tailored to provide insights that are crucial for both seasoned mechanics and enthusiastic DIYers.

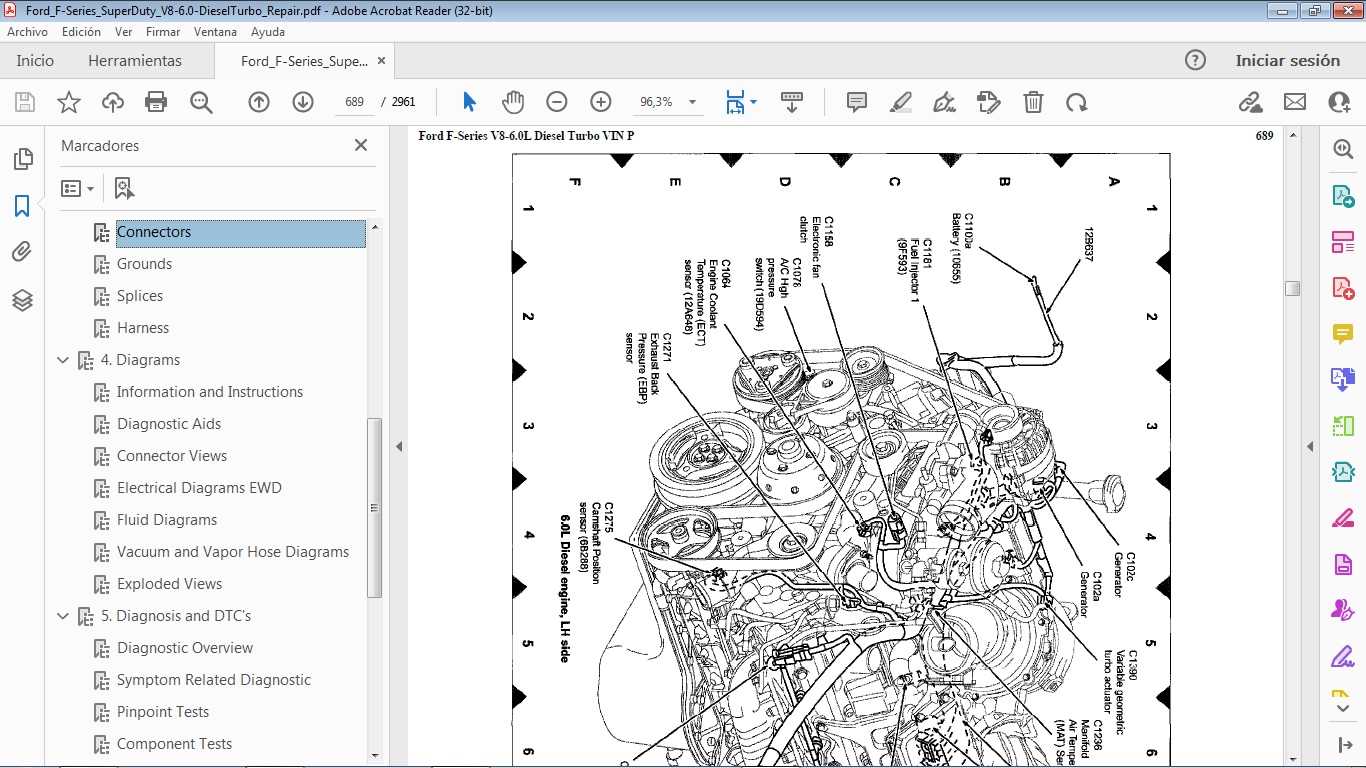

Within these sections, you will discover detailed instructions, diagrams, and tips that address common issues and solutions related to the engine in question. Whether you are looking to perform routine checks or tackle more complex challenges, the information provided will equip you with the necessary skills and confidence. Mastering the intricacies of your engine will not only save time and resources but also deepen your appreciation for the engineering behind it.

As you navigate through this guide, you will find an array of topics ranging from basic maintenance techniques to in-depth troubleshooting strategies. Each chapter is designed to progressively build your understanding, ensuring you can confidently address various situations as they arise. This resource ultimately aims to empower you, fostering a deeper connection with your vehicle’s inner workings.

Overview of Ford 6.0 Diesel Engine

The engine in question is a robust power unit known for its performance and durability. Designed to cater to the demanding requirements of heavy-duty applications, it features advanced technologies that enhance both efficiency and power output. This overview aims to highlight the key characteristics and operational capabilities of this formidable engine.

In terms of architecture, the engine utilizes a V8 configuration, which is complemented by turbocharging. This combination provides significant torque, making it well-suited for towing and hauling. Additionally, the inclusion of direct fuel injection allows for improved combustion efficiency, contributing to better fuel economy and lower emissions.

Maintenance and common issues associated with this engine type are also important for owners and technicians. Regular servicing is essential to ensure longevity and optimal performance. Understanding the typical concerns that may arise, such as head gasket failures and fuel system complications, can aid in timely interventions.

| Feature | Description |

|---|---|

| Engine Type | V8 Turbocharged |

| Fuel System | Direct Injection |

| Torque Output | High Torque for Towing |

| Common Issues | Head Gasket Failures, Fuel System Problems |

Common Issues with Ford 6.0 Engines

The powertrain in question has garnered attention due to a range of prevalent challenges that owners may face. Understanding these issues can help in identifying symptoms early and ensuring optimal performance over time.

One frequent problem involves coolant leaks, which can lead to overheating and subsequent damage if not addressed promptly. These leaks are often traced back to faulty head gaskets or worn components within the cooling system.

Additionally, issues with the fuel delivery system can cause poor performance and starting difficulties. Clogged injectors or a malfunctioning fuel pump can significantly impact engine efficiency and reliability.

Another common concern is related to the electrical system. Problems with sensors, particularly the oil pressure and temperature sensors, can result in incorrect readings and may lead to operational complications.

Furthermore, excessive exhaust emissions are often linked to turbocharger malfunctions or issues within the exhaust gas recirculation system. Regular inspection and maintenance can mitigate these risks and prolong the engine’s lifespan.

Essential Tools for Repairs

Having the right equipment is crucial when tackling any maintenance task. A well-stocked toolbox can significantly enhance efficiency and ensure that jobs are completed effectively. Whether you’re dealing with routine upkeep or more complex fixes, familiarity with essential instruments is key to successful outcomes.

Basic Hand Tools

Starting with the fundamentals, a selection of hand tools is indispensable. Wrenches, screwdrivers, and pliers form the backbone of any toolkit. These instruments are vital for loosening and tightening fasteners, enabling access to various components.

Power Tools and Diagnostics

In addition to hand tools, incorporating power tools can drastically reduce time spent on tasks. Tools such as impact wrenches and drills facilitate quicker disassembly and assembly. Furthermore, diagnostic equipment plays an essential role in troubleshooting issues effectively, allowing for precise identification of problems.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to diagnosing and resolving issues that may arise in your vehicle’s performance. By following these organized steps, you can identify potential problems and implement effective solutions, ensuring optimal functionality and longevity.

Initial Assessment

Begin by performing a thorough evaluation of the symptoms you are experiencing. Note any unusual noises, vibrations, or warning lights. Check the fluid levels and inspect for leaks or signs of wear. Document your observations, as they will be crucial for pinpointing the underlying issue.

Systematic Diagnosis

Utilize a logical process for troubleshooting. Start with the most accessible components, checking electrical connections, fuses, and wiring for damage. Use diagnostic tools to read error codes from the onboard computer system. If necessary, refer to specific component specifications to verify proper operation. This step-by-step method will help you narrow down the potential sources of the problem efficiently.

Replacing the Fuel Injector

In this section, we will explore the essential steps involved in swapping out the fuel delivery component of your vehicle’s engine. A malfunctioning fuel injector can lead to various performance issues, including poor acceleration, increased emissions, and rough idling. Understanding the replacement procedure can help restore optimal functionality and efficiency to your engine.

Preparation and Tools Needed

Before starting the replacement process, gather the necessary tools and components. You will typically need a ratchet set, wrenches, a fuel line disconnect tool, and a new fuel injector. Additionally, make sure to have safety goggles and gloves to protect yourself during the procedure. It is also advisable to work in a well-ventilated area to avoid inhaling harmful fuel vapors.

Steps to Replace the Fuel Injector

Begin by disconnecting the negative battery terminal to ensure safety. Next, relieve the fuel system pressure by removing the fuel pump fuse and starting the engine until it stalls. Once the pressure is relieved, disconnect the fuel lines and electrical connectors from the faulty injector. Remove the securing bolts and gently extract the injector from the intake manifold. Install the new injector by reversing the removal steps, ensuring all connections are secure. Finally, reconnect the battery and test the vehicle for proper operation.

Maintaining the Cooling System

The efficiency of any engine largely depends on its temperature regulation. A well-functioning cooling mechanism prevents overheating and ensures optimal performance. Proper upkeep of this system is essential for longevity and reliability, as it minimizes the risk of damage from excessive heat.

To maintain an effective cooling apparatus, regular inspections are crucial. Check the coolant levels frequently, and top off if necessary. Use the appropriate mixture of antifreeze and water, typically recommended as a 50/50 blend, to ensure proper heat transfer and protection against freezing. Replacing the coolant at specified intervals will also help in removing contaminants that may affect performance.

Inspect the radiator for any signs of corrosion or leaks. Ensure that the hoses connecting the radiator to the engine are intact and free from cracks. Any signs of wear should prompt immediate replacement to avoid coolant loss. Furthermore, regularly check the thermostat, as a malfunction can lead to improper temperature regulation.

Lastly, it is important to monitor the water pump, which plays a pivotal role in circulating coolant throughout the system. Look for any signs of leakage or unusual noise, as these may indicate that it requires attention. Keeping the cooling system in optimal condition is vital for the overall health of the engine.

Upgrading Exhaust Components

Enhancing the exhaust system is a popular modification for those seeking improved performance and efficiency from their vehicles. Upgrading these elements can lead to better airflow, reduced back pressure, and a more aggressive sound. In this section, we will explore various components that can be modified to achieve these benefits.

Benefits of Upgrading

- Increased horsepower and torque

- Improved fuel efficiency

- Enhanced engine sound

- Weight reduction in some cases

Components to Consider

- Headers: Replacing stock headers with performance headers can significantly improve exhaust flow and reduce restrictions.

- Cat-back Exhaust Systems: Upgrading to a cat-back system allows for better airflow from the catalytic converter to the exhaust tip.

- Mufflers: Performance mufflers can enhance sound while maintaining or improving flow rates.

- Exhaust Tips: Aesthetic upgrades can also be made with stylish exhaust tips, contributing to a vehicle’s overall appearance.

In conclusion, upgrading exhaust components is an effective way to boost vehicle performance while providing a personalized touch. Consider your goals and budget to select the right enhancements for your setup.

Diagnosing Electrical Problems

Troubleshooting electrical issues can be a challenging yet essential aspect of vehicle maintenance. Identifying and resolving these complications not only improves performance but also enhances safety and reliability. Understanding the fundamental concepts of automotive electrical systems is crucial for effective diagnosis and repair.

Common Symptoms of Electrical Issues

- Inconsistent starting or no start at all

- Dim or flickering lights

- Malfunctioning accessories, such as power windows or radio

- Warning lights on the dashboard

Steps for Effective Diagnosis

- Check the battery: Inspect connections and charge level.

- Examine fuses: Look for blown fuses and replace as necessary.

- Test wiring: Use a multimeter to check for continuity and shorts.

- Assess ground connections: Ensure all grounds are secure and corrosion-free.

By following these guidelines, one can systematically approach electrical troubleshooting, leading to more efficient solutions and a well-functioning vehicle.

Oil Change Procedures Explained

Regular maintenance of engine lubrication is essential for optimal performance and longevity. Understanding the process involved in refreshing the lubricant is crucial for any vehicle owner. This section outlines the necessary steps to effectively carry out this maintenance task, ensuring that your engine operates smoothly.

The procedure involves several key stages, including preparation, draining the old fluid, replacing the filter, and refilling with new oil. Each step plays a significant role in maintaining the engine’s health and functionality.

| Step | Description |

|---|---|

| 1. Gather Materials | Collect necessary tools and supplies, including a wrench, oil filter, new lubricant, and a drain pan. |

| 2. Warm Up the Engine | Start the engine and let it run for a few minutes to warm up, ensuring better fluid drainage. |

| 3. Drain Old Oil | Locate the drain plug beneath the engine and remove it to let the old lubricant flow into the drain pan. |

| 4. Replace Oil Filter | Remove the old filter using an appropriate tool and install the new one, ensuring a tight seal. |

| 5. Refill with New Oil | Using a funnel, pour the new lubricant into the designated opening, monitoring the level with the dipstick. |

| 6. Check for Leaks | After refilling, run the engine briefly and inspect for any leaks around the drain plug and filter. |

| 7. Dispose of Old Oil | Properly dispose of the used lubricant and filter at a designated recycling center. |

Following these outlined steps will help ensure that your engine remains well-lubricated and functions efficiently, contributing to its overall performance and durability.

Understanding the Turbocharger System

The turbocharger system is a vital component in enhancing engine performance and efficiency. This mechanism works by utilizing exhaust gases to increase the intake air pressure, which ultimately leads to a more powerful combustion process. By compressing the incoming air, it allows the engine to burn more fuel, resulting in greater power output without significantly increasing engine size.

Components of the Turbocharger System

The turbocharger system consists of several key components, including the turbine, compressor, and the wastegate. The turbine captures exhaust gases produced by the engine, causing it to spin rapidly. This motion drives the compressor, which draws in ambient air and compresses it before sending it into the engine’s intake manifold. The wastegate regulates the amount of exhaust flow entering the turbine, preventing overboost and ensuring optimal engine performance.

Benefits of Turbocharging

Implementing a turbocharger offers multiple advantages, such as improved acceleration and enhanced fuel economy. By increasing the air density in the combustion chamber, the engine can achieve higher power levels without requiring larger displacement. Additionally, turbocharged engines often produce lower emissions, making them more environmentally friendly. Overall, understanding the intricacies of the turbocharger system can lead to better maintenance practices and improved vehicle performance.

Preparing for Engine Rebuilds

Undertaking an engine overhaul requires meticulous planning and preparation to ensure a successful outcome. The process involves several crucial steps that not only facilitate a smoother rebuild but also enhance the overall performance and longevity of the engine. Understanding the essential elements of this undertaking is vital for both novice and experienced mechanics.

Gathering Necessary Tools and Parts

Before beginning the rebuild process, it is imperative to assemble all the necessary tools and components. This includes specialized instruments for disassembly, inspection, and reassembly, as well as replacement parts such as gaskets, seals, and bearings. Having everything on hand minimizes downtime and prevents interruptions during the project.

Creating a Work Environment

A well-organized workspace is essential for effective engine reconstruction. Ensure the area is clean, well-lit, and spacious enough to accommodate the engine and tools. Proper organization helps in tracking components and facilitates efficient workflow, which is crucial for completing the task in a timely manner.

Recommended Maintenance Schedule

Establishing a consistent upkeep routine is crucial for ensuring the longevity and optimal performance of your vehicle. Adhering to a systematic schedule helps prevent issues, enhances reliability, and can ultimately save you money on repairs. Below is a guideline for regular maintenance tasks to consider.

Every 3,000 to 5,000 Miles

- Oil change and filter replacement

- Inspect fluid levels (brake, transmission, coolant, etc.)

- Check tire pressure and tread depth

- Examine wiper blades for wear

Every 15,000 Miles

- Replace air filter

- Inspect and clean the battery terminals

- Rotate tires to ensure even wear

- Check brake pads and rotors

Every 30,000 Miles

- Replace fuel filter

- Inspect belts and hoses for signs of wear

- Flush and replace coolant

- Inspect suspension components

Every 60,000 Miles

- Replace timing belt (if applicable)

- Inspect transmission fluid condition

- Change spark plugs

- Check alignment and suspension settings

Following this schedule can significantly improve the vehicle’s performance and safety. Regular checks and timely replacements ensure that your vehicle operates smoothly and efficiently.

Resources for Further Assistance

Accessing reliable resources can greatly enhance your understanding and troubleshooting skills. Whether you are seeking guidance on specific issues or general maintenance tips, numerous platforms offer valuable information for vehicle enthusiasts.

- Online Forums: Engaging with communities can provide insights from experienced individuals. Websites dedicated to automotive discussions often feature sections for specific models, allowing for targeted advice.

- YouTube Channels: Video tutorials can be extremely helpful for visual learners. Many creators specialize in vehicle maintenance, showcasing step-by-step processes that can assist you in your projects.

- Technical Websites: Various sites provide detailed specifications, diagrams, and troubleshooting guides. These resources can be beneficial for understanding the intricacies of vehicle systems.

- Local Workshops: Consider visiting nearby automotive repair shops or community colleges. Many offer classes or workshops that focus on practical skills and techniques.

- Manufacturer Support: Official websites often have customer service lines, FAQs, and downloadable resources that can help address specific inquiries.

Utilizing these resources can empower you with the knowledge needed to effectively manage your vehicle’s maintenance and resolve any challenges you may encounter.