In the realm of automotive engineering, understanding the intricate workings of power transfer systems is essential for enthusiasts and professionals alike. A well-maintained system not only enhances vehicle performance but also extends its lifespan. This guide delves into the vital aspects of servicing and troubleshooting these essential components, ensuring optimal functionality and reliability.

Whether you’re a seasoned mechanic or a DIY enthusiast, possessing the right knowledge can make all the difference. From diagnosing common issues to executing precise adjustments, a thorough grasp of these systems equips individuals to tackle challenges effectively. This resource aims to provide clear, actionable insights for maintaining and optimizing performance.

By exploring various techniques and best practices, readers will learn how to identify potential problems early on, ultimately saving time and costs associated with more significant repairs. Equip yourself with the necessary expertise to ensure that your vehicle remains in peak condition and ready for any journey ahead.

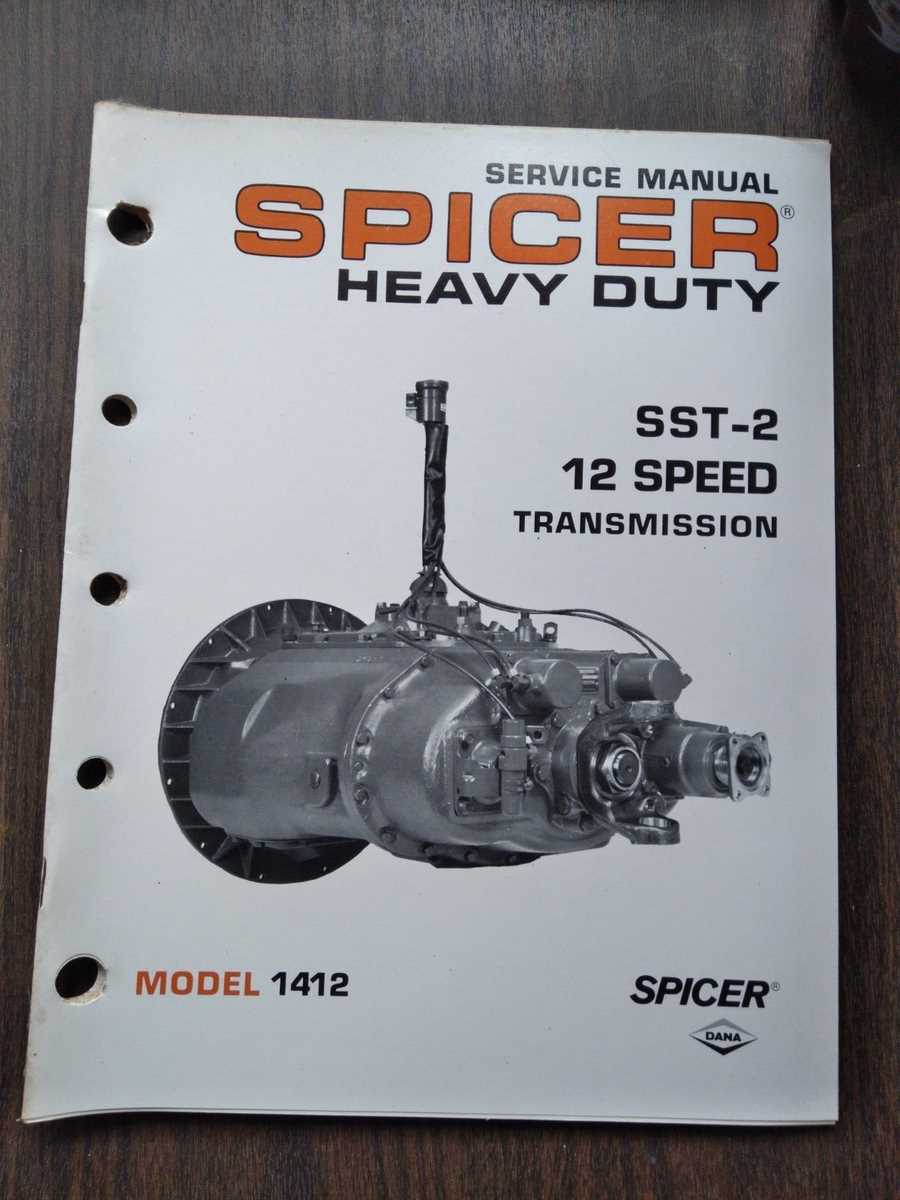

Dana Spicer Transmission Overview

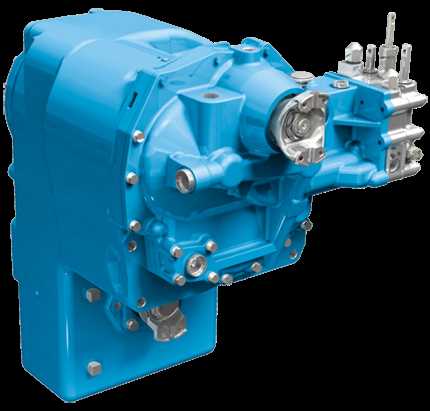

This section provides a comprehensive understanding of a well-known series of automotive gear systems designed for robust performance and reliability. These units are integral to various vehicles, facilitating smooth power transfer and enhancing overall drivability. Their construction and technology have evolved to meet the demands of modern applications, making them a preferred choice for both manufacturers and enthusiasts.

Key Features and Benefits

The highlighted gear systems are characterized by their durability and efficiency. Engineered to withstand significant stress and varying driving conditions, these assemblies ensure optimal functionality. Additionally, they offer features such as advanced fluid management and customizable options to cater to specific performance needs.

Common Applications

Common Issues with Dana Transmissions

When dealing with various power transfer systems, users often encounter a range of challenges that can affect performance and reliability. Understanding these frequent complications is essential for maintaining optimal function and preventing further damage.

One prevalent concern involves overheating, which can stem from insufficient lubrication or excessive load. This issue often leads to premature wear of internal components, resulting in reduced efficiency.

Another common problem is the presence of fluid leaks. These can occur due to worn seals or gaskets, and if not addressed promptly, they may lead to significant fluid loss, impairing overall operation.

Shifting difficulties are also frequently reported. Users may experience hard or delayed shifting, which can be caused by various factors such as cable misalignment or internal wear. Proper diagnostics are crucial to pinpoint the root cause of these issues.

Lastly, abnormal noises during operation often signal underlying mechanical issues. Grinding, whining, or clunking sounds can indicate gear misalignment or damaged components, necessitating immediate attention to avoid catastrophic failures.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to restoring your system to optimal functionality. By following the outlined stages meticulously, you can effectively diagnose and address issues that may arise, ensuring the longevity and performance of your equipment. Each phase is designed to build upon the previous one, offering clear instructions and necessary precautions.

Initial Assessment

Begin by evaluating the condition of the unit. Look for signs of wear or damage, such as leaks or unusual noises. Document any abnormalities and prepare the necessary tools for disassembly. This preliminary analysis is crucial for identifying the root cause of the malfunction.

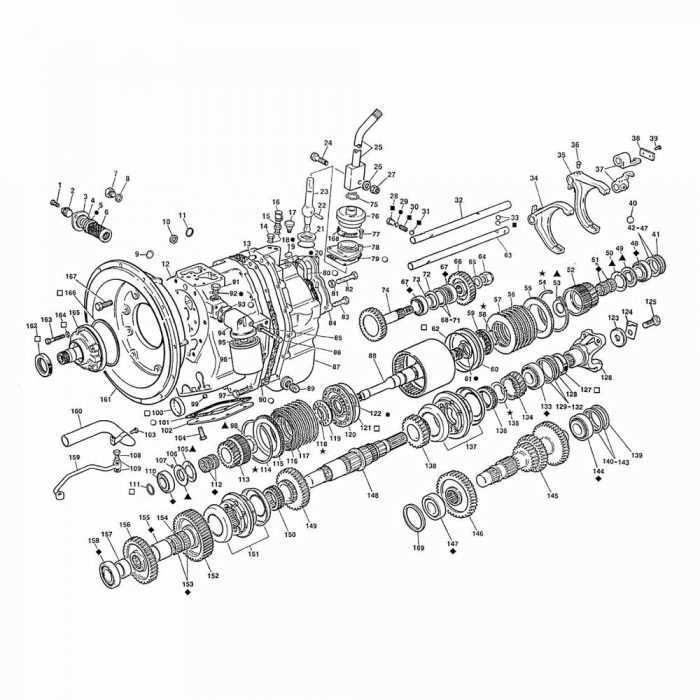

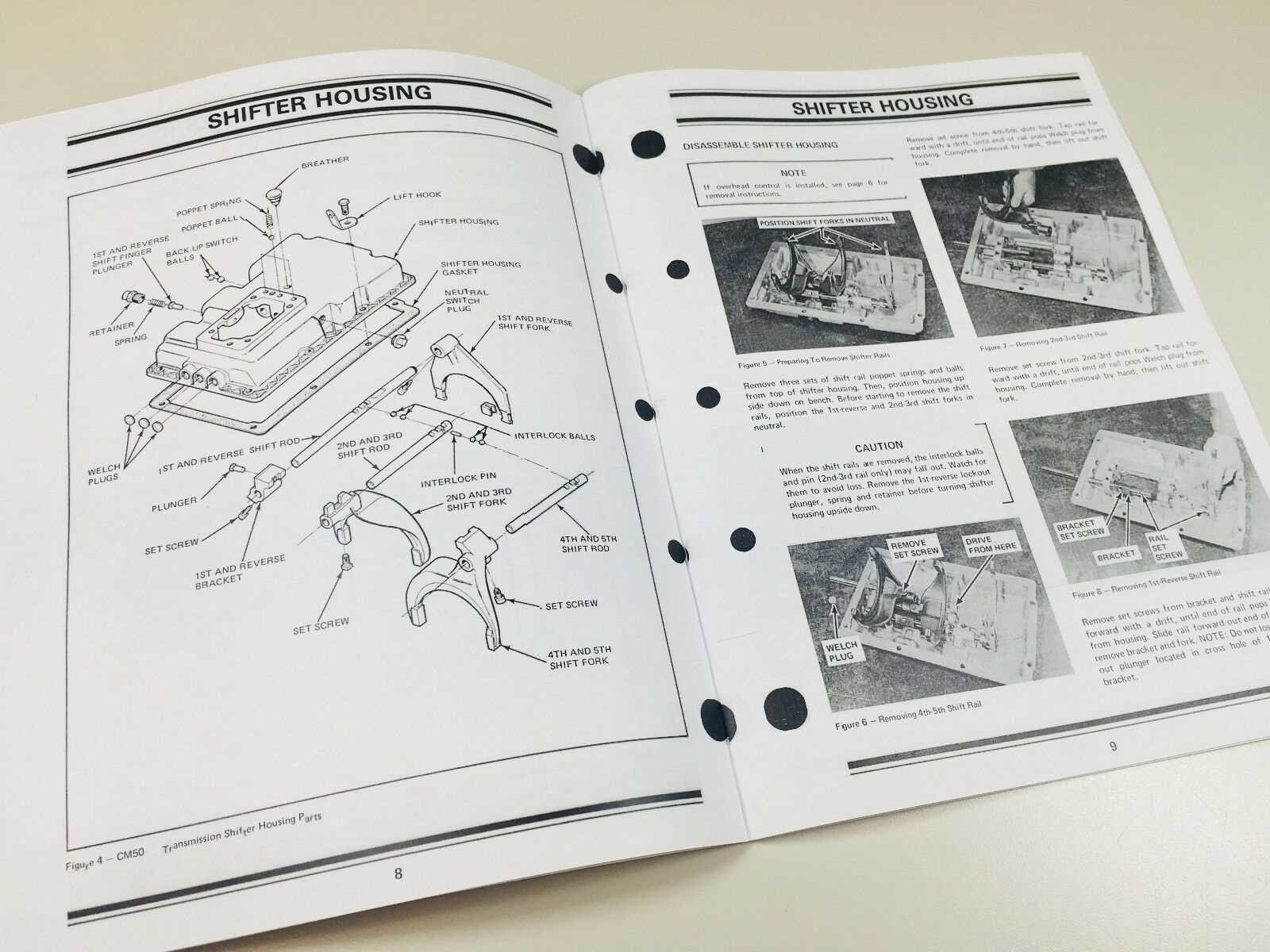

Disassembly and Component Inspection

Carefully disassemble the unit, following the sequence provided in your guide. As you remove components, inspect each part for signs of deterioration. Pay particular attention to seals, gears, and electronic connections. Replace any damaged items with quality replacements to ensure proper operation during reassembly.

Essential Tools for Transmission Repair

When working on complex automotive systems, having the right instruments is crucial for ensuring effective service and maintenance. These tools not only facilitate accurate assessments but also streamline the entire process, making it more efficient and less prone to errors. Understanding the necessary equipment can greatly enhance the quality of your work and improve outcomes.

Basic Hand Tools

Every mechanic should have a comprehensive set of hand tools. Wrenches, sockets, and screwdrivers are fundamental for loosening and tightening components. Additionally, torque wrenches are essential for applying the correct amount of force, which helps prevent damage to sensitive parts. Investing in high-quality hand tools can make a significant difference in both performance and longevity.

Specialized Equipment

Beyond basic tools, specialized equipment is necessary for more intricate tasks. Transmission jacks are invaluable for safely lifting and positioning heavy assemblies. Fluid pumps assist in changing oils and maintaining fluid levels, while diagnostic scanners help identify issues quickly by interfacing with the vehicle’s onboard systems. These tools enable technicians to perform thorough evaluations and ensure optimal functioning of the system.

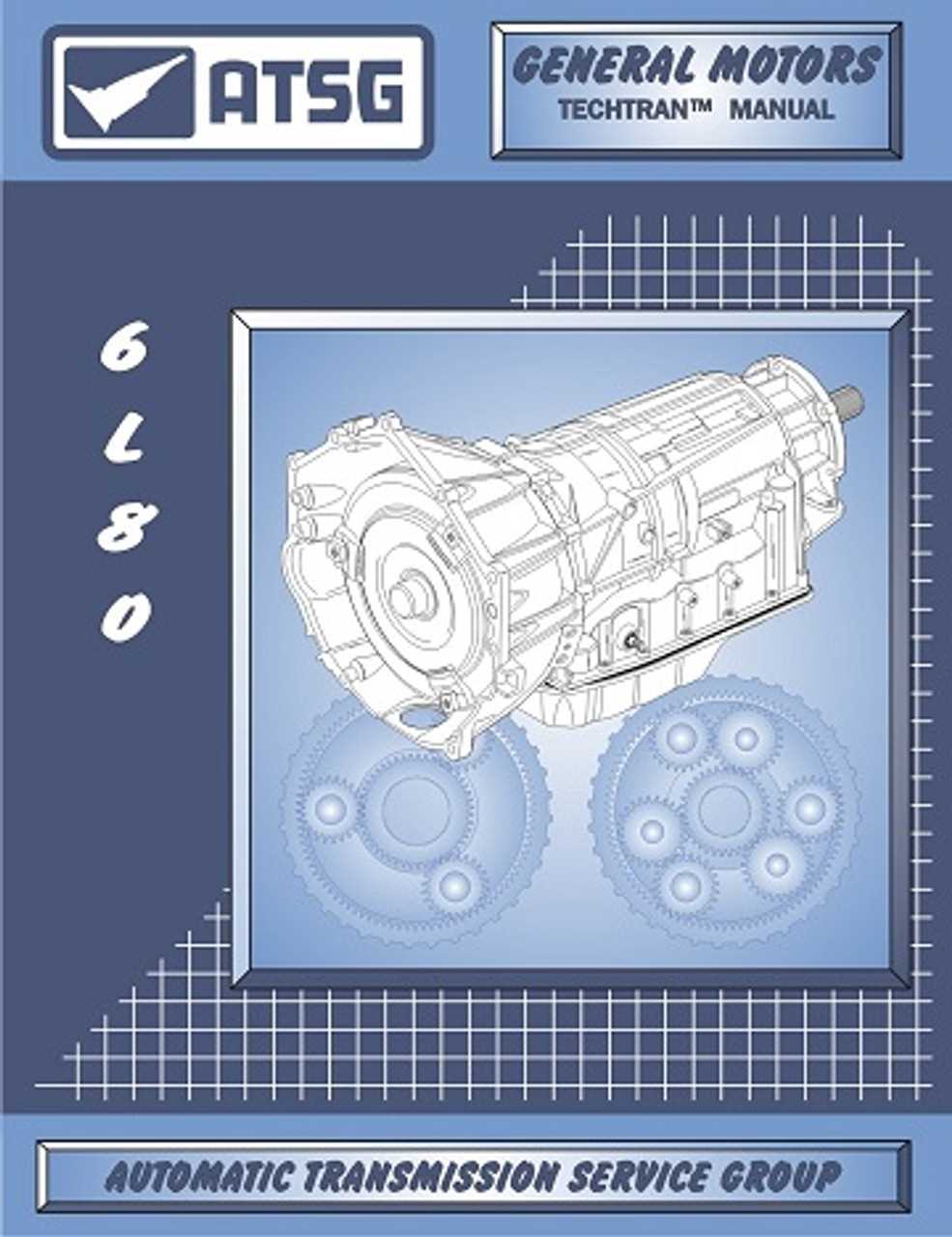

Understanding Transmission Components

The intricate machinery within an automotive system relies on various essential parts working in harmony. Each component plays a vital role in ensuring efficient power transfer from the engine to the wheels, contributing to overall vehicle performance. Grasping the function and interaction of these elements is crucial for anyone involved in automotive maintenance or enhancement.

Gears are fundamental to altering speed and torque, allowing the vehicle to adapt to different driving conditions. Their arrangement and engagement determine how power is effectively transmitted, influencing acceleration and fuel efficiency.

Clutch systems facilitate smooth engagement and disengagement of power, providing the driver with control over the vehicle’s movement. Understanding the mechanisms behind this component is essential for troubleshooting performance issues.

Hydraulic systems utilize fluid pressure to control various functions, including shifting and engaging gears. These systems require careful maintenance to prevent leaks and ensure optimal performance.

Electronic controls have become increasingly important, managing various functions with precision. Familiarity with these technologies can aid in diagnosing problems and enhancing overall system performance.

By comprehending these critical components and their interactions, individuals can better appreciate the complexities of automotive systems and address any challenges that may arise effectively.

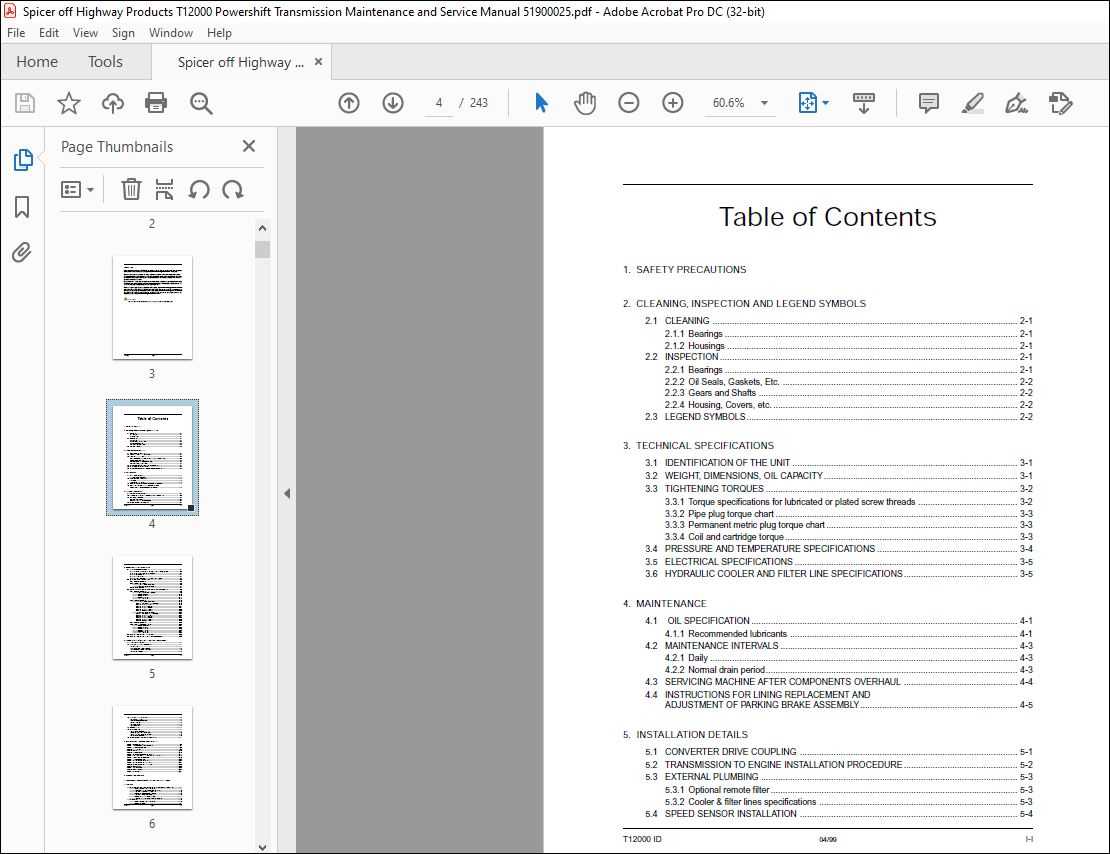

Diagnostic Techniques for Transmission Problems

Identifying issues within the complex system of gear shifting requires a methodical approach. Various strategies can help pinpoint the root causes of malfunction, ensuring effective resolution. By employing specific techniques, technicians can systematically assess and diagnose irregularities.

Key diagnostic methods include:

- Visual Inspection: Examine components for signs of wear, damage, or leaks.

- Fluid Analysis: Check the quality and level of the hydraulic fluid to detect contamination or degradation.

- Scan Tool Diagnostics: Utilize electronic diagnostic tools to retrieve error codes from the control module, providing insight into system failures.

In addition to these initial checks, further techniques can enhance diagnostic accuracy:

- Road Test: Conduct a practical assessment to observe symptoms in real-time, noting any unusual sounds or performance issues.

- Pressure Testing: Measure hydraulic pressures at various points to determine if they fall within manufacturer specifications.

- Electrical Testing: Inspect wiring and connectors for continuity and integrity to ensure proper function of electronic components.

Implementing these approaches allows for a thorough evaluation, ultimately leading to effective interventions and restoring optimal operation.

Maintenance Tips for Longevity

Ensuring the durability of complex mechanical systems requires consistent care and attention. Adopting preventive measures not only enhances performance but also extends the lifespan of vital components. This section outlines essential practices that can help maintain optimal functionality over time.

Regular Inspections

Frequent examinations of your equipment can help identify potential issues before they escalate. Look for signs of wear, unusual noises, or leaks. Addressing minor concerns promptly can prevent more significant problems and costly repairs.

Fluid Quality and Levels

Maintaining appropriate fluid levels and quality is crucial for smooth operation. Check the fluid regularly, and replace it according to the manufacturer’s recommendations. Using high-quality fluids can improve efficiency and safeguard against premature wear.

In conclusion, consistent maintenance practices are key to maximizing the longevity of your machinery. By staying proactive and attentive, you can ensure reliable performance and avoid unexpected failures.

Transmission Fluid: Importance and Types

Fluid plays a crucial role in the functionality and longevity of any vehicle’s gear system. It not only facilitates smooth operation but also protects essential components from wear and tear. Understanding the significance and variety of these fluids is essential for optimal performance and maintenance.

Importance of Fluid

The right fluid serves multiple purposes:

- Reduces friction between moving parts.

- Acts as a coolant to dissipate heat.

- Helps in the smooth engagement of gears.

- Maintains cleanliness by preventing sludge build-up.

Types of Fluid

There are several varieties of fluids available, each designed for specific systems:

- Conventional Fluid: Commonly used in many vehicles, offering basic protection and performance.

- Synthetic Fluid: Engineered for superior performance and longevity, often recommended for high-performance applications.

- High-Mileage Fluid: Formulated for older vehicles, this type includes additives to reduce wear and tear.

- Universal Fluid: Compatible with various systems, making it a versatile choice for mixed fleets.

Selecting the appropriate type is vital for ensuring efficiency and prolonging the lifespan of the components. Regular checks and timely replacements can prevent significant issues down the line.

Upgrading Your Dana Transmission

Enhancing the performance of your vehicle’s gear system can lead to improved efficiency and power. Whether you’re looking to increase towing capacity or improve off-road capabilities, there are several strategies to consider that can significantly boost your setup.

Benefits of Enhancements

- Increased torque and horsepower

- Improved fuel efficiency

- Enhanced durability under heavy loads

- Better overall driving experience

Key Upgrades to Consider

- Advanced Gear Ratios: Changing the gear ratios can optimize your setup for better acceleration or higher top speeds, depending on your needs.

- Performance Components: Upgrading to high-quality clutches and valves can enhance shifting performance and responsiveness.

- Cooling Systems: Installing improved cooling solutions can help prevent overheating during demanding tasks.

- Electronic Controls: Integrating advanced electronic management can provide better tuning and adaptability to various driving conditions.

Consider these options carefully to tailor your vehicle’s gear mechanism to meet your specific performance goals and ensure reliable operation in any situation.

Identifying Different Dana Models

Understanding the various types of gear assemblies is essential for enthusiasts and professionals alike. Each model comes with distinct characteristics and specifications that cater to different applications. Recognizing these differences can enhance the overall performance of your vehicle and ensure proper functionality.

Model Identification can often be determined by examining the serial number or the markings located on the component itself. These identifiers provide valuable information about the design and manufacturing details. Additionally, the physical characteristics such as size, shape, and mounting configurations also play a critical role in distinguishing between different assemblies.

Another aspect to consider is the application of the unit. Some models are tailored for heavy-duty use, while others are designed for light or medium-duty tasks. Understanding the intended application can aid in accurate identification and selection of the appropriate gear assembly for your needs.

Lastly, consulting reliable resources and community forums can provide further insights and support in identifying and differentiating between the various types. Engaging with experienced users can lead to discovering subtle nuances that may not be immediately apparent.

Cost Estimates for Repairs

Understanding the financial implications of maintenance work is crucial for any vehicle owner. Accurately estimating costs allows for better budgeting and preparedness when unexpected issues arise. Various factors influence these expenses, and having a clear picture can significantly ease the process of addressing mechanical problems.

Factors Affecting Costs

- Type of damage: The extent of the malfunction can greatly influence the overall price.

- Labor rates: Different service providers may charge varying hourly rates based on their expertise and location.

- Parts availability: The cost of replacement components can fluctuate based on their availability and demand.

- Vehicle make and model: Specific vehicles may require specialized parts or procedures that could drive up costs.

Typical Cost Ranges

- Minor adjustments: $100 – $300

- Moderate repairs: $400 – $800

- Extensive overhauls: $900 – $2000

By considering these factors and typical ranges, vehicle owners can make informed decisions and prepare for necessary expenses effectively.

Professional vs. DIY Repairs

When it comes to addressing mechanical issues, individuals often face the choice between seeking professional assistance and attempting to resolve the problems themselves. Each approach has its own set of advantages and challenges, influencing both the outcome and the overall experience of the process.

Benefits of Professional Assistance

Engaging an expert can provide numerous benefits, including:

- Expertise: Professionals possess specialized knowledge and experience, enabling them to diagnose and fix problems efficiently.

- Tools and Equipment: Access to advanced tools often unavailable to the average individual can facilitate more effective solutions.

- Warranty and Guarantees: Many professionals offer warranties, ensuring peace of mind and added protection for the customer.

- Time Savings: Experts can typically complete tasks more quickly than someone without training.

Advantages of DIY Approaches

On the other hand, opting for self-repair can also be rewarding. Key advantages include:

- Cost Savings: Performing repairs independently can significantly reduce labor costs.

- Skill Development: Engaging in hands-on work can enhance personal skills and knowledge about mechanical systems.

- Flexibility: DIY projects allow for repairs to be scheduled at one’s convenience, without the need to coordinate with a service provider.

- Personal Satisfaction: Successfully completing a task independently can lead to a sense of accomplishment.

Ultimately, the decision between hiring a professional and tackling the challenge on one’s own depends on various factors, including the complexity of the issue, available resources, and personal comfort with mechanical tasks.

Resources for Further Learning

For those seeking to deepen their understanding of vehicle systems and their intricacies, numerous resources are available. These materials can provide valuable insights into the functioning and maintenance of complex mechanical components.

Online Courses: Websites like Coursera and Udemy offer specialized classes that cover various aspects of automotive technology. These courses often include video lectures, quizzes, and practical assignments to enhance learning.

Books and Guides: A wide array of literature exists that focuses on vehicle mechanics. Look for comprehensive guides that delve into specific areas, providing detailed explanations and diagrams.

Forums and Communities: Engaging with online communities can be beneficial. Platforms such as Reddit and specialized automotive forums allow enthusiasts to share experiences, tips, and solutions to common issues.

Workshops and Seminars: Local educational institutions frequently host workshops and seminars. Participating in these events can offer hands-on experience and direct interaction with experts in the field.

Videos and Tutorials: YouTube hosts numerous channels dedicated to automotive education. Visual demonstrations can clarify complex concepts and provide step-by-step guidance on various tasks.

By utilizing these diverse resources, individuals can expand their knowledge and skills, fostering greater proficiency in the field of vehicle maintenance and repair.