Hair trimming devices are essential tools for grooming, and keeping them in peak condition is vital for achieving precise results every time. This guide covers practical insights on diagnosing common issues, as well as steps to maintain and extend the lifespan of these popular grooming tools. You’ll find detailed approaches to ensure your device remains in top working order, offering consistently reliable performance.

Our goal is to assist both first-time users and seasoned technicians with effective solutions to typical mechanical and functional concerns. From troubleshooting motor inconsistencies to addressing dull blades, this guide provides clear instructions designed to help you restore your trimming device to its original efficiency. Whether you’re dealing with an occasional fault or performing regular maintenance, following these steps can save time and effort.

In addition, we’ve included preventive care tips that help keep your trimming tool in excellent condition, reducing the likelihood of future malfunctions. Regular upkeep not only preserves the device’s functionality but also ensures each trim remains sharp and precise. Explore this guide to maintain, troubleshoot, and optimize your grooming tool for continued reliable use.

Wahl Clipper Repair Manual

This section provides a comprehensive overview for maintaining and troubleshooting electric grooming tools. Here, you’ll find structured guidance to address common performance issues, extend the tool’s lifespan, and ensure it operates smoothly with minimal interruptions.

| Issue | Cause | Solution |

|---|---|---|

| Unusual noise | Loose internal parts or debris | Tighten screws, remove cover, and clean thoroughly |

| Poor trimming performance | Dull or misaligned blades | Realign or replace blades as necessary |

| Overheating | Continuous use without lubrication | Allow to cool, clean, and apply oil to blades |

| Battery issues | Old or weak battery | Charge fully, or replace if necessary |

With regular upkeep, it’s possible to maintain the device’s efficiency, ensuring reliable, long-term use. A little preventive care will go a long way in avoiding unexpected malfunctions.

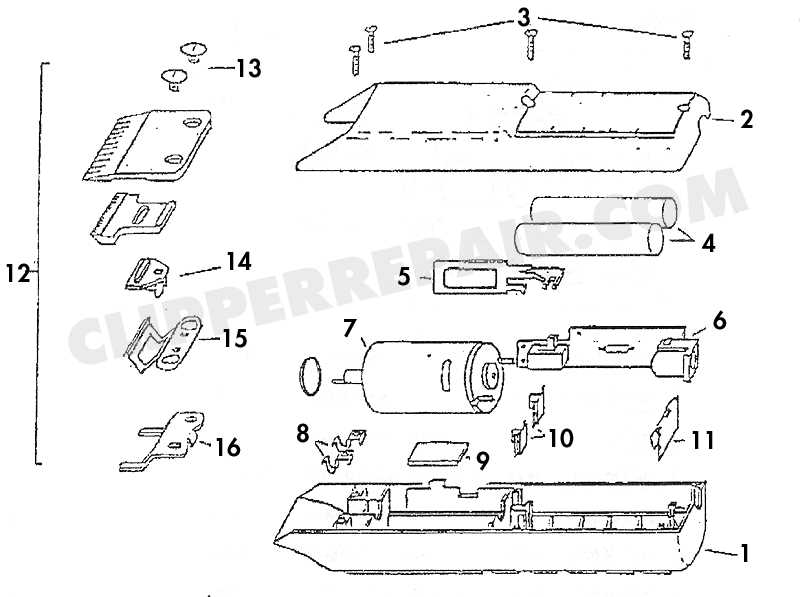

Understanding Wahl Clipper Components

Modern grooming devices consist of several integral parts that work together to provide precise trimming and longevity. Familiarity with these elements not only aids in effective usage but also extends the life of the equipment, making upkeep simpler and more efficient.

Primary Mechanical Parts

The device operates through a set of key mechanical elements, including the motor, which drives the blades, and a set of movable and stationary blades that create the cutting action. The alignment of these blades and the sharpness of their edges directly impact performance and ensure smooth, consistent results.

Electrical and Power Elements

Power sources, usually rechargeable batteries or a direct power cord, ensure continuous operation, while an internal circuit controls the current to maintain safety and efficiency. The power switch and any speed settings also play a role, allowing users to adjust the device for various styling needs.

Regular understanding of these components allows users to better handle maintenance needs, avoid common issues, and make adjustments that preserve the device’s quality and functionality over time.

Common Signs of Clipper Malfunctions

Regular use of grooming tools can sometimes lead to issues that affect their efficiency and longevity. Recognizing early signs of wear and tear can help ensure that these tools function optimally, prolonging their lifespan and maintaining consistent performance.

1. Unusual Noise During Operation

One common symptom of underlying issues is a sudden increase in noise or a strange buzzing sound during use. This could indicate loose components, blade misalignment, or internal wear. Consistently loud sounds are often a clear sign that a check-up is necessary.

2. Decline in Cutting Performance

A noticeable decrease in cutting precision, where the device pulls or snags hair, may suggest that the blades are dull or that there’s a build-up of debris inside. Reduced cutting efficiency often requires attention to avoid further damage or discomfort during use.

Keeping these common issues in mind helps maintain equipment quality and efficiency, preventing small problems from developing into larger, more costly repairs.

Tools Needed for Clipper Repair

Performing maintenance on grooming devices requires a set of specialized tools to ensure efficient and accurate work. Equipped with the proper instruments, you can handle common adjustments and address technical issues that may arise, restoring the device to optimal function.

Essential Tools for Disassembly and Cleaning

To start, a precision screwdriver set is essential for carefully removing screws without damaging them. Tweezers are useful for handling small parts during disassembly. A soft brush or compressed air can help remove hair and debris, keeping internal components clean and preventing buildup.

Maintenance and Reassembly Instruments

For lubricating moving parts, light machine oil is recommended to reduce friction and extend the device’s lifespan. An alignment gauge helps ensure that all parts are realigned correctly during reassembly. Lastly, a small hammer and punch can assist with more intricate adjustments if necessary, aiding in a smooth and balanced operation.

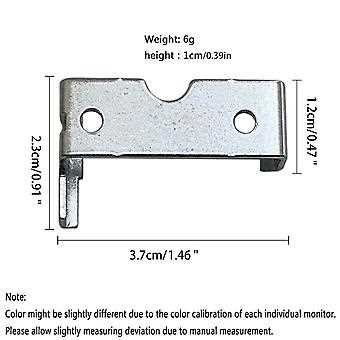

Step-by-Step Blade Replacement Guide

This guide will help you effectively replace the blades, ensuring optimal performance and a smooth cut. Following each step carefully allows for a safe and efficient replacement process, so you can get back to using your device with confidence.

1. Prepare the Device

Begin by turning off and unplugging the unit. It’s important to avoid any accidental activation during the blade change process. Set up a clean, well-lit workspace where you can handle small components easily.

2. Remove the Old Blade

Using a screwdriver, loosen the screws holding the existing blade in place. Once the screws are removed, carefully lift the blade assembly away from the device. Keep the screws and any other small parts in a secure location to prevent loss.

3. Clean the Blade Area

Before installing the new blade, wipe away any dust, hair, or oil residue from the exposed area. This will help ensure that the new blade fits securely and functions smoothly. A small brush or cloth can be helpful for cleaning in tight spaces.

4. Attach the New Blade

Position the new blade correctly, aligning it with the screw holes. Carefully insert and tighten the screws until the blade is firmly attached. Avoid overtightening, as this can damage the screws or misalign the blade.

5. Test the Blade

Once the

Cleaning and Maintaining Clipper Blades

Proper upkeep of cutting tools is essential for achieving optimal performance and longevity. Regular maintenance ensures that the blades remain sharp and free from debris, which in turn facilitates a smooth cutting experience. This section outlines effective methods for cleaning and maintaining these essential components.

Step-by-Step Cleaning Process

To ensure the best results, follow these steps for cleaning:

| Step | Description |

|---|---|

| 1 | Disconnect the tool from the power source to ensure safety. |

| 2 | Remove the blades according to the manufacturer’s instructions. |

| 3 | Use a soft brush to remove hair and debris from the blades. |

| 4 | Wash the blades in warm, soapy water, then rinse and dry thoroughly. |

| 5 | Apply a few drops of lubricant to keep the blades moving smoothly. |

Maintenance Tips

In addition to regular cleaning, consider these maintenance tips to enhance the lifespan of your cutting tools:

- Store blades in a dry, cool place to prevent rust.

- Sharpen blades periodically to maintain cutting efficiency.

- Check for any signs of wear and replace blades as necessary.

Troubleshooting Clipper Motor Issues

Addressing motor difficulties is essential for maintaining the performance of your grooming tool. Identifying and resolving common problems can enhance longevity and efficiency. Below are typical concerns and their solutions to help restore functionality.

Common Motor Problems

- Inconsistent power

- Excessive noise

- Overheating

- Unresponsive device

Solutions to Motor Issues

- Check the power source to ensure a proper connection and eliminate any interruptions.

- Inspect for any obstructions or debris that may hinder movement.

- Examine the blades for dullness, which can lead to increased strain on the motor.

- Ensure ventilation is adequate to prevent overheating during prolonged use.

Regular maintenance, including cleaning and lubrication, can prevent many of these issues. Adopting a proactive approach will ensure optimal performance for your grooming tool.

Fixing Power Supply Problems

Electrical issues are common in grooming devices and can often lead to operational failures. Addressing these problems requires a systematic approach to ensure proper functionality and longevity of the device. This section will guide you through identifying and resolving typical electrical malfunctions.

- Check the Power Source:

Begin by verifying that the outlet is functioning. Test it by plugging in another device. If the outlet works, proceed to inspect the device itself.

- Inspect the Power Cord:

Examine the cord for any visible signs of damage, such as fraying or cuts. A damaged cord can disrupt power flow and must be replaced if found defective.

- Examine the Connection Points:

Ensure that all connections between the power cord and the device are secure. Loose connections can hinder power transfer.

- Test the Battery (if applicable):

If the device operates on batteries, check their condition. Replace any old or depleted batteries to restore power.

- Utilize a Multimeter:

A multimeter can help measure voltage and continuity. Use it to identify issues within the circuitry by testing various points in the electrical system.

By following these steps, you can effectively troubleshoot and resolve electrical problems, ensuring your grooming device operates smoothly once again.

How to Lubricate Clippers Properly

Maintaining the performance of your grooming tools is essential for ensuring longevity and optimal functionality. Regular lubrication is a critical aspect that helps reduce friction, prevents overheating, and enhances the overall efficiency of the device. This section will guide you through the essential steps to properly lubricate your tools for the best results.

Essential Supplies for Lubrication

Before you begin, gather the necessary items to ensure a smooth process. You will need:

| Supplies | Purpose |

|---|---|

| High-quality oil | Reduces friction and ensures smooth operation |

| Clean cloth | For wiping excess oil and debris |

| Brush | To remove hair and dirt from the blades |

Steps for Proper Lubrication

Follow these simple steps to effectively lubricate your grooming tools:

- Ensure the device is turned off and unplugged for safety.

- Use a brush to clean the blades thoroughly, removing any accumulated hair and dirt.

- Apply a few drops of high-quality oil to the blades, focusing on the pivot points and areas where metal surfaces contact.

- Turn the device on for a few seconds to allow the oil to distribute evenly across the blades.

- Wipe away any excess oil with a clean cloth to prevent buildup.

Preventing Overheating During Use

Ensuring optimal performance during operation requires attention to various factors that can lead to excessive heat build-up. By implementing effective strategies, users can extend the lifespan of their devices and maintain consistent functionality.

- Regular Maintenance: Keeping equipment clean is crucial. Debris and hair can accumulate and hinder airflow, causing the motor to overheat. Regularly inspect and clean the blades and vents.

- Proper Lubrication: Applying appropriate lubricants to the blades reduces friction, which in turn minimizes heat generation. Ensure that you use recommended oils for best results.

- Take Breaks: Continuous use can lead to overheating. Schedule short breaks during longer sessions to allow the motor to cool down.

- Choose the Right Settings: Adjusting the speed settings according to the task can help prevent the device from working harder than necessary, reducing heat production.

- Store Properly: When not in use, store the device in a cool, dry place to prevent any damage that could contribute to overheating when used again.

By following these precautions, users can effectively prevent overheating, ensuring their tools remain in excellent working condition and enhancing their overall experience.

Adjusting Blade Alignment

Proper alignment of the cutting components is essential for achieving optimal performance and longevity of your grooming device. Misalignment can lead to uneven cuts, increased wear, and potential damage. This section outlines the necessary steps to ensure the blades are correctly positioned for effective operation.

Importance of Correct Alignment

When the cutting edges are not aligned, the device may struggle to operate efficiently. This misalignment can cause snagging, pulling of hair, and an overall unsatisfactory grooming experience. By ensuring the blades are correctly aligned, you can enhance the performance and extend the lifespan of your tool.

Steps for Adjustment

To adjust the alignment, first, ensure the device is turned off and unplugged. Locate the adjustment screws, typically found near the blades. Loosen the screws slightly without removing them. Gently move the cutting edges until they are aligned properly, with a minimal gap between them. Once positioned correctly, tighten the screws securely. Test the alignment by running the device through a small section of hair, making further adjustments as needed.

DIY Tips for Long-lasting Performance

Maintaining tools for grooming can significantly enhance their lifespan and efficiency. By following simple yet effective practices, users can ensure that their devices operate at peak performance over the years. These tips aim to help you maximize the longevity and functionality of your grooming equipment.

Regular Cleaning and Maintenance

One of the most crucial aspects of preserving your grooming tools is regular cleaning. After each use, gently remove hair and debris to prevent buildup. Use a soft brush to reach tight spaces and ensure that every part is free from obstructions. Additionally, periodic lubrication of moving parts can reduce friction and wear, contributing to smoother operation.

Proper Storage Solutions

How you store your grooming equipment can greatly impact its condition. Keep your tools in a dry, cool place to prevent moisture damage. Consider using a dedicated case or pouch to protect against dust and accidental drops. Proper storage not only safeguards your tools but also makes them readily accessible for future use.