Understanding the intricacies of equipment operation is essential for ensuring longevity and optimal performance. This section serves as a valuable resource for those looking to enhance their knowledge in maintaining their machines. By exploring common issues and their solutions, users can develop a deeper appreciation for the mechanics involved.

From routine checks to advanced diagnostic procedures, the information provided here aims to empower users with the skills necessary to tackle various challenges. Whether you are a seasoned operator or a newcomer, this guide offers insights that can significantly improve your troubleshooting capabilities.

Emphasizing the importance of regular upkeep, this section highlights key practices that can prevent minor problems from escalating. Engaging with the material will not only facilitate a smoother experience but also instill confidence in handling equipment effectively.

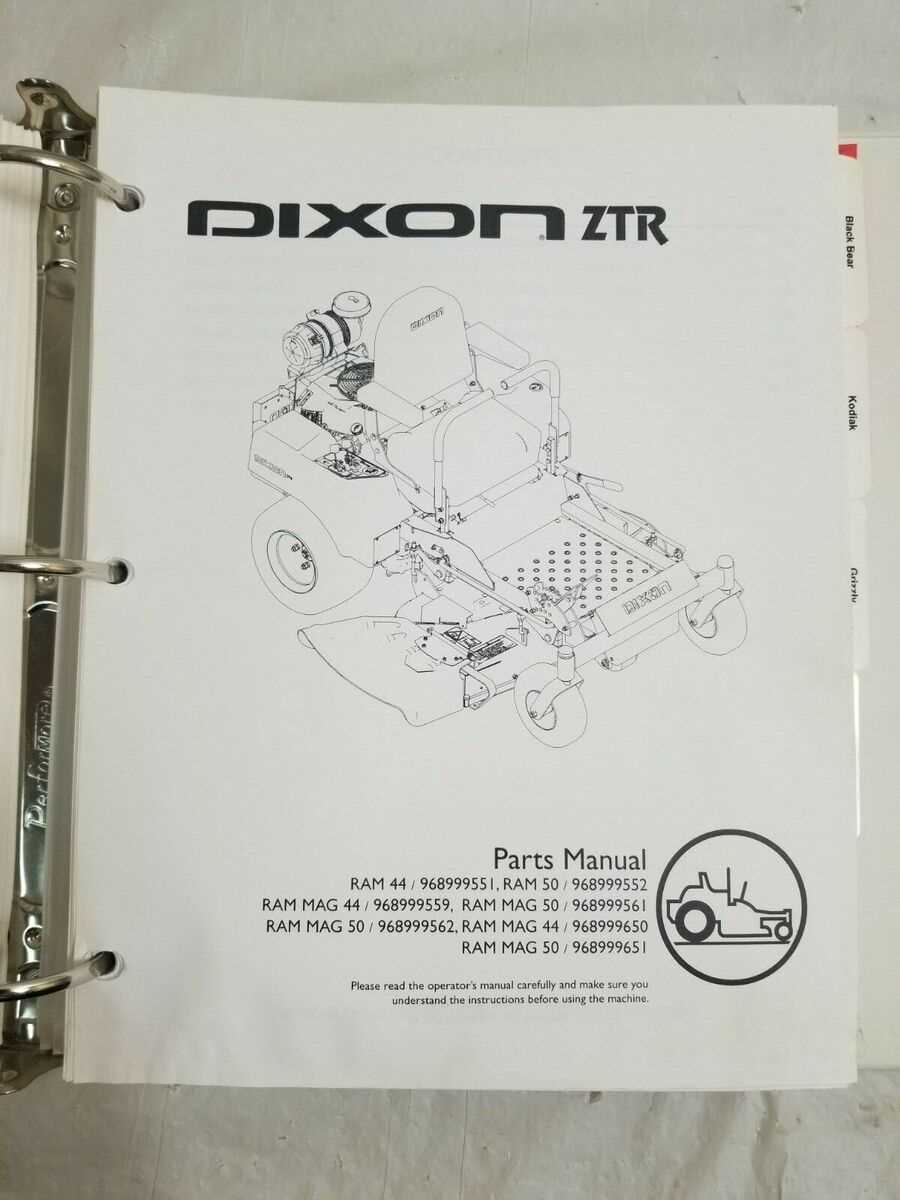

Dixon ZTR Repair Manual Overview

This section provides a comprehensive overview of a resource designed to assist users in the upkeep and troubleshooting of a specific type of mowing equipment. It encompasses essential information, practical guidelines, and helpful tips to ensure optimal performance and longevity of the machinery.

Key Components

- Maintenance schedules

- Common issues and solutions

- Parts identification

- Operational tips

Benefits of Using the Guide

- Enhanced understanding of equipment functionality

- Cost-effective maintenance strategies

- Improved performance and efficiency

- Prolonged lifespan of the machinery

This resource serves as an invaluable tool for both novice and experienced users, facilitating a thorough understanding of essential care practices and technical insights. By utilizing this guide, operators can ensure their equipment runs smoothly and efficiently for years to come.

Essential Tools for Repair

Having the right instruments at your disposal is crucial for maintaining and restoring machinery effectively. A well-equipped toolkit not only enhances efficiency but also ensures that tasks are completed with precision and safety. Selecting appropriate items tailored for specific functions can make a significant difference in the overall outcome of the work.

Basic items such as wrenches, screwdrivers, and pliers form the foundation of any toolkit. These are essential for loosening and tightening various components. Additionally, specialized tools designed for particular tasks, like torque wrenches or socket sets, provide the necessary leverage and fit for more complex adjustments.

Safety equipment should never be overlooked. Protective eyewear and gloves are vital to safeguard against potential hazards during any project. Keeping a clean and organized workspace also contributes to efficiency and reduces the risk of accidents.

Finally, having a reliable source of information, whether in printed form or digital, can aid in understanding procedures and ensuring that every step is followed correctly. This comprehensive approach to tool selection and preparation lays the groundwork for successful maintenance endeavors.

Common Issues with Dixon ZTR

Many users encounter a variety of challenges when operating their high-performance lawn care machines. Understanding these common problems can enhance the user experience and ensure longevity of the equipment. Addressing issues promptly not only saves time but also reduces long-term costs associated with maintenance.

Starting Difficulties: One of the most frequent complaints is related to the starting mechanism. Users may find that the engine struggles to ignite, which can stem from issues with the battery, fuel system, or electrical components. Regular checks of these areas can help mitigate starting problems.

Uneven Cutting: Another prevalent issue is uneven grass trimming. This can result from dull blades, improper deck height settings, or even tire pressure imbalances. Ensuring that blades are sharpened and the deck is level can lead to a more uniform cut.

Overheating: Overheating can be a significant concern, often caused by blocked air filters or insufficient oil levels. Keeping the cooling system clear and monitoring fluid levels are essential steps to prevent this problem.

Vibration and Noise: Excessive vibration or unusual noises during operation can indicate mechanical wear or loose components. Regular inspections and timely repairs of belts, bearings, and other moving parts can help maintain a smooth operation.

Hydraulic Issues: For models equipped with hydraulic systems, users may experience sluggish or unresponsive steering. This can be attributed to low fluid levels or leaks in the hydraulic lines. Ensuring proper fluid maintenance is key to preventing these complications.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues. Following a structured method can save time and ensure effective solutions, leading to optimal performance of your equipment.

Initial Assessment

Before diving into complex diagnostics, conduct a preliminary evaluation to gather essential information.

- Check for visible signs of damage.

- Inspect the fuel levels and quality.

- Examine electrical connections for wear or corrosion.

Systematic Troubleshooting Steps

- Identify the specific symptoms of the issue.

- Refer to the equipment’s specifications for baseline performance indicators.

- Test each component individually, starting from the power source.

- Document any changes or anomalies observed during testing.

- Consult available resources for additional guidance on identified problems.

By following these steps, you can effectively pinpoint the source of the issue and implement appropriate corrective actions.

Maintenance Tips for Longevity

Ensuring the extended life of your equipment involves a series of proactive steps aimed at preserving its functionality and performance. By following best practices and regular upkeep, you can prevent premature wear and maximize efficiency.

Regular Cleaning

Consistent cleaning of your machinery is essential. Remove debris and dirt after each use to prevent buildup that can lead to malfunctions. Pay special attention to hard-to-reach areas, as dirt can accumulate and cause serious issues over time.

Periodic Inspections

Conducting routine inspections allows you to identify potential problems before they escalate. Check belts, filters, and fluid levels regularly to ensure everything operates smoothly. This proactive approach not only saves time but also reduces repair costs.

Parts Replacement Process Explained

Replacing components in machinery is a critical aspect of maintaining efficiency and functionality. This process ensures that equipment operates smoothly, minimizing downtime and enhancing performance. Understanding the sequence and importance of each step can greatly improve the overall effectiveness of maintenance efforts.

Step-by-Step Approach

First, it is essential to identify the specific component that requires attention. Conduct a thorough inspection to determine any signs of wear or malfunction. Once identified, gather all necessary tools and replacement parts before proceeding. This preparation helps streamline the task and reduces the likelihood of interruptions.

Execution and Final Checks

Carefully remove the faulty part, taking note of how it is attached to avoid mistakes during reinstallation. Follow the manufacturer’s guidelines for installing the new component, ensuring a secure fit. After installation, conduct a series of tests to confirm that everything is functioning as intended. Regular checks and maintenance will prolong the lifespan of the equipment and prevent future issues.

Understanding the Electrical System

The electrical system of a machine plays a critical role in its overall functionality and performance. A solid grasp of this system is essential for efficient operation and troubleshooting. It encompasses various components that work together to ensure seamless power distribution, control, and communication throughout the equipment.

Key Components

- Power Source: This is the primary source of energy that fuels the entire system, often consisting of batteries or generators.

- Wiring Harness: A network of wires that transmits electrical signals and power to different parts of the machine.

- Control Modules: These electronic units manage various functions and processes, enabling communication between different system parts.

- Sensors and Switches: Devices that monitor conditions and trigger responses, providing feedback to the control modules.

- Lighting and Indicators: Visual alerts that inform the operator about the machine’s operational status.

Maintenance Tips

- Regularly inspect wiring for signs of wear or damage.

- Ensure connections are secure to prevent electrical failures.

- Test batteries periodically to confirm they hold charge.

- Clean electrical contacts to maintain efficient conductivity.

- Consult schematics to understand the layout and function of the system.

Engine Care and Maintenance

Proper upkeep of the engine is essential for optimal performance and longevity. Regular attention not only enhances efficiency but also prevents potential issues that may arise from neglect. This section outlines key practices to ensure your engine operates smoothly and reliably.

- Regular Inspections: Schedule routine checks to identify any signs of wear or damage. Look for leaks, corrosion, and loose components.

- Oil Changes: Change the oil and oil filter at recommended intervals. Clean oil is crucial for lubrication and overall engine health.

- Cooling System Maintenance: Monitor coolant levels and check for any obstructions in the radiator. Flushing the system periodically can prevent overheating.

- Air Filter Replacement: A clean air filter improves airflow and efficiency. Replace it according to the manufacturer’s recommendations.

- Fuel System Care: Use high-quality fuel and consider adding a fuel system cleaner periodically to maintain performance.

- Battery Maintenance: Inspect battery terminals for corrosion and ensure a secure connection. Regularly test battery performance.

By adhering to these guidelines, you can extend the life of the engine and enhance its performance, ensuring a dependable and efficient experience.

Hydraulic System Basics

Hydraulic systems are essential for various applications, utilizing fluid mechanics to transmit power efficiently. By employing incompressible fluids, these systems can exert force and perform work through a series of interconnected components. Understanding their fundamental principles is crucial for effective operation and maintenance.

Key Components

Several critical elements make up a hydraulic system, each playing a vital role in its overall function. These components work together to ensure that the system operates smoothly and effectively.

| Component | Function |

|---|---|

| Hydraulic Pump | Generates flow and pressure to move fluid through the system. |

| Actuators | Convert hydraulic energy into mechanical motion. |

| Valves | Control the flow and direction of the hydraulic fluid. |

| Reservoir | Stores hydraulic fluid and helps dissipate heat. |

Operating Principles

The operation of hydraulic systems is based on Pascal’s principle, which states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid. This principle allows for the multiplication of force, making hydraulic systems incredibly powerful and efficient for various tasks.

Safety Precautions During Repairs

Ensuring safety while undertaking maintenance tasks is crucial to prevent accidents and injuries. Adhering to specific guidelines helps create a secure working environment, allowing for efficient and effective performance of tasks. This section outlines key precautions that should be observed to protect both the technician and the equipment involved.

Personal Protective Equipment

Utilizing appropriate personal protective gear is essential. Consider the following items:

- Safety goggles to protect your eyes from debris.

- Gloves to shield your hands from sharp objects and chemicals.

- Steel-toed boots to prevent foot injuries from falling items.

- Ear protection when working with loud machinery.

Work Environment Considerations

Maintaining a safe work area is equally important. Follow these recommendations:

- Ensure adequate lighting to avoid accidents.

- Keep the workspace organized to prevent tripping hazards.

- Disconnect power sources before starting any task to avoid electrical shocks.

- Use proper tools for each job to minimize risk of injury.

By prioritizing safety through the use of protective equipment and maintaining a clean work area, individuals can significantly reduce the risk of accidents during maintenance activities.

Seasonal Maintenance Checklist

Regular upkeep is essential for ensuring the longevity and optimal performance of your outdoor equipment. By adhering to a systematic checklist each season, you can identify potential issues before they escalate, ultimately saving time and resources. This guide outlines crucial tasks that should be performed periodically to keep your machinery in top shape.

Spring Tasks

Inspect and Clean: Start by examining all components for wear and tear. Clear away any debris, dirt, or grass clippings that may have accumulated. Pay special attention to air filters and cooling systems, ensuring they are free from obstructions.

Fluids and Lubrication: Check oil levels and replace any fluids that appear dirty or low. Lubricate moving parts to prevent rust and ensure smooth operation throughout the season.

Fall Tasks

Preparation for Storage: Before storing your equipment for the winter, conduct a thorough cleaning. Drain fuel systems and protect parts from corrosion using suitable treatments.

Inspect Belts and Cables: Examine belts for signs of wear or fraying. Tighten or replace any loose or damaged cables to maintain proper function when the machinery is in use again.

By following these seasonal tasks, you can enhance the reliability and efficiency of your outdoor equipment, ensuring it is ready for action when you need it most.

Upgrading Your Dixon ZTR

Enhancing the performance and efficiency of your outdoor equipment can lead to a significantly improved mowing experience. Upgrades can encompass various components, from engine modifications to ergonomic adjustments, all aimed at increasing functionality and comfort.

Consider the following areas for enhancement:

- Engine Performance: Upgrading the engine can provide more power and efficiency, allowing for quicker mowing and less fuel consumption.

- Deck Quality: Installing a higher-quality cutting deck can improve grass cut quality and durability.

- Wheel and Tire Improvements: Opting for better tires can enhance traction and maneuverability on uneven terrain.

- Seat Comfort: Upgrading to a more comfortable seat can reduce fatigue during long mowing sessions.

Each of these modifications can contribute to a more enjoyable and effective mowing experience, ensuring that your equipment meets your specific needs and preferences.

Before making any upgrades, it’s essential to research compatibility and potential impacts on performance. Taking the time to plan your enhancements will result in a more satisfying and efficient outdoor maintenance routine.

Resources for Further Assistance

For those seeking additional help with their equipment, a variety of resources are available to enhance understanding and troubleshooting capabilities. Whether you are facing a specific issue or simply looking to expand your knowledge, these options can provide valuable support.

Online Forums: Engaging with online communities can offer insights from fellow users who have encountered similar challenges. Many enthusiasts and experts share their experiences and solutions, creating a wealth of knowledge at your fingertips.

Official Websites: The manufacturer’s site often contains a treasure trove of information, including FAQs, instructional videos, and product updates. This resource can help you stay informed about the latest best practices and maintenance tips.

Local Workshops: Participating in hands-on workshops can greatly enhance your skills. Many local shops offer classes that cover various aspects of equipment care and operation, allowing for direct interaction with knowledgeable instructors.

User Groups: Joining a local or online user group can facilitate connections with others who share your interests. These groups often organize events, discussions, and knowledge-sharing sessions that can provide practical advice and support.

Help Centers: Some manufacturers maintain dedicated support lines or chat services, providing immediate assistance for any pressing issues. This direct line to professional advice can save time and ensure correct handling of any concerns.

By utilizing these resources, you can enhance your understanding and effectively address any challenges that may arise with your machinery.