In the realm of antique writing instruments, the artistry and craftsmanship of these mechanical wonders captivate enthusiasts and collectors alike. Understanding their intricate workings and the nuances of their design is essential for anyone looking to maintain or rejuvenate these historical devices. A detailed exploration into the methods of preserving these cherished items can provide invaluable insights and practical knowledge.

Whether you’re a seasoned restorer or a curious novice, the journey of bringing an old writing device back to life is both rewarding and enlightening. This guide offers comprehensive strategies to tackle common challenges faced during the revitalization process, ensuring that your treasured machine can continue to serve its purpose for years to come.

Through a careful examination of each component, users will discover techniques that enhance functionality while respecting the original aesthetics. Emphasis will be placed on best practices that not only safeguard the mechanical integrity but also celebrate the unique character inherent in these timeless artifacts.

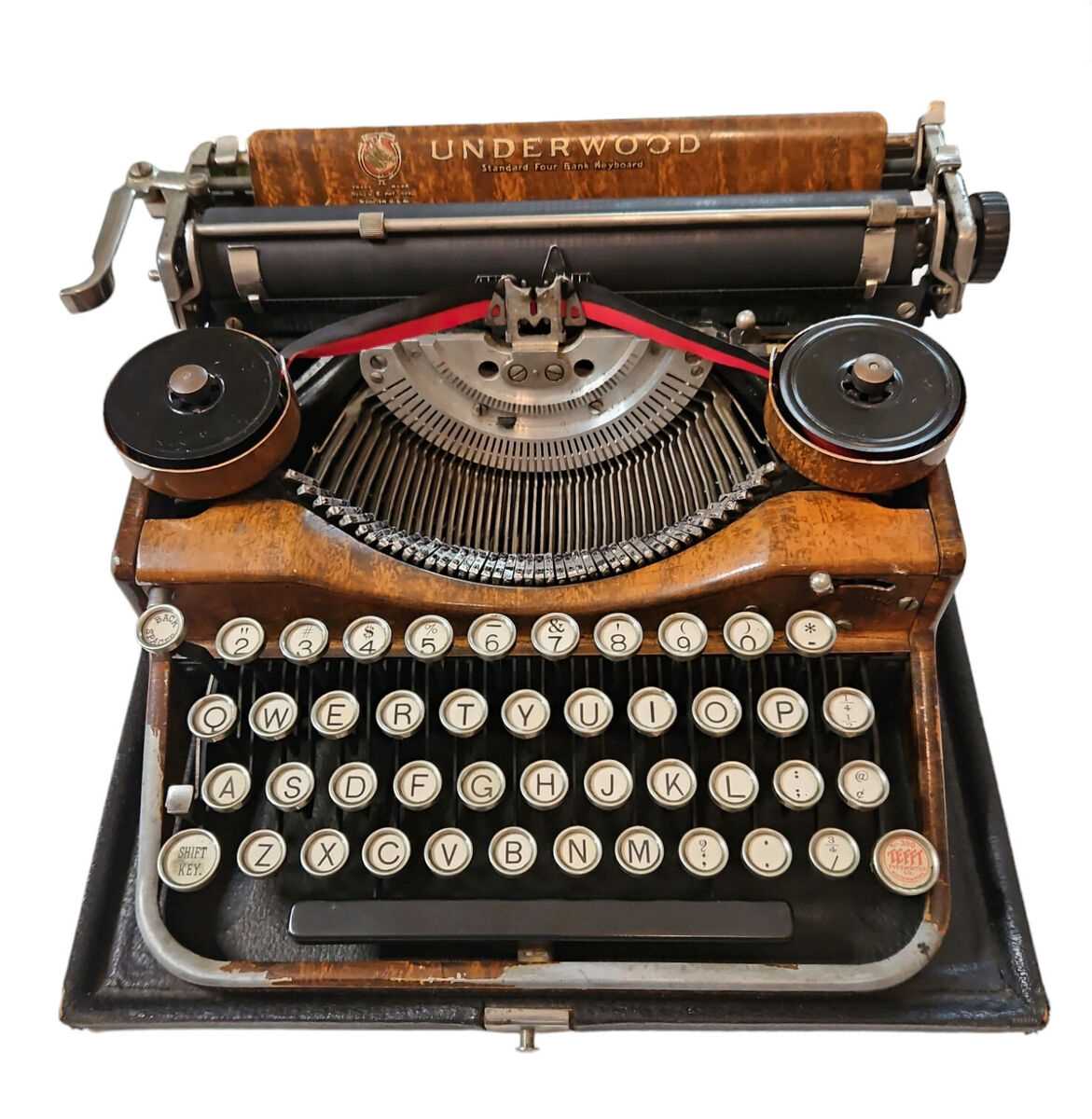

Understanding the Underwood Typewriter

Exploring the intricacies of vintage writing machines reveals a fascinating blend of craftsmanship and innovation. These devices, renowned for their mechanical precision and elegant design, played a pivotal role in shaping the way we communicate through written language. This section aims to delve into the essential features and historical significance of these remarkable instruments.

Mechanics and Design are at the heart of these writing tools. Each component is meticulously engineered to ensure smooth operation and reliability. The arrangement of keys, hammers, and ribbons reflects a thoughtful approach to user experience, allowing for fluid typing and clarity in print. Understanding these elements is crucial for anyone interested in the legacy of written communication.

Historical Context adds another layer to the appreciation of these machines. Emerging in the late 19th century, they became symbols of progress and productivity. Writers, journalists, and everyday users relied on their functionality, making them an integral part of both personal and professional expression. Examining their evolution provides insight into societal changes and technological advancements over time.

By grasping the mechanics and historical impact of these devices, enthusiasts and collectors can better appreciate their significance in the realm of written expression. This understanding fosters a deeper connection with the artistry and ingenuity that defined an era of communication.

Common Issues with Underwood Models

Various challenges can arise when using vintage writing machines. Understanding these common problems can help users troubleshoot effectively and maintain optimal performance. Here are some frequent difficulties encountered with these classic models:

- Jamming Mechanism: Keys may stick or jam, often due to misalignment or debris accumulation.

- Ink Ribbon Issues: Ribbons can dry out or break, leading to inconsistent ink flow and faded impressions.

- Alignment Problems: Text may appear misaligned, necessitating adjustments to the carriage or platen.

- Worn Components: Over time, parts may wear down, affecting overall functionality and requiring replacement.

- Sticky Keys: Oil or dust buildup can cause keys to become unresponsive, needing cleaning or lubrication.

Being aware of these common issues can aid users in maintaining their devices and ensuring a smoother writing experience.

Essential Tools for Repairs

Maintaining and restoring mechanical writing devices requires a specific set of instruments to ensure efficiency and precision. Understanding the essential tools can make the process smoother and more effective, allowing enthusiasts to breathe new life into vintage equipment.

Basic Tools

- Small Screwdrivers: A variety of sizes, particularly Phillips and flathead, are crucial for accessing different components.

- Tweezers: Useful for handling small parts and springs that require delicate manipulation.

- Cleaning Brushes: Soft-bristled brushes help remove dust and debris from intricate mechanisms.

- Lubricants: Lightweight oils or greases designed for mechanical devices keep moving parts functioning smoothly.

Advanced Equipment

- Magnifying Glass: Enhances visibility for intricate details, making it easier to diagnose issues.

- Calipers: Precision measurement tools ensure that parts fit correctly and function as intended.

- Replacement Parts: Stocking common components such as ribbons and rollers is essential for effective restoration.

- Workbench: A sturdy surface provides ample space for working on projects and organizing tools.

Having these instruments on hand not only facilitates the restoration process but also enhances the overall experience of working with these remarkable machines.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring the longevity and optimal performance of your writing instrument. By following a systematic approach, you can easily maintain its functionality and preserve its charm. This guide will walk you through the necessary steps to keep your device in top condition.

Begin by gathering the required tools, including a soft cloth, a small brush, and appropriate lubricants. Carefully disassemble the unit, paying attention to the arrangement of components for easy reassembly later. Clean all parts thoroughly to remove dust and debris that may hinder operation.

Next, inspect the moving parts for wear and tear. Replace any damaged components to avoid further issues. Apply lubricant to the joints and gears to ensure smooth movement. Avoid over-lubrication, as this can attract dirt and lead to buildup.

After reassembly, conduct a functional test to confirm everything is working correctly. Make any necessary adjustments to alignment or tension. Finally, store the device in a protective case to shield it from environmental factors that could cause damage.

Replacing Typewriter Ribbons

Ensuring optimal performance of your writing device often requires periodic updates to its ink supply. This process not only enhances the quality of your impressions but also prolongs the lifespan of the machine. In this section, we will explore the steps involved in exchanging these essential components efficiently.

Choosing the Right Ink Supply

Before beginning the replacement, it is crucial to select the appropriate ink supply for your device. Different models may require specific sizes and types. Check the documentation or consult with a reputable supplier to find the correct option. Using an incompatible ink supply may lead to poor print quality or even damage to the mechanism.

Step-by-Step Replacement Process

1. Prepare Your Workspace: Clear your area of any clutter to ensure a smooth process. Having tools such as scissors and a clean cloth handy can be beneficial.

2. Remove the Old Ink Supply: Locate the mechanism holding the ink supply. Carefully detach it from the device, paying attention to how it is positioned for easier reinstallation.

3. Install the New Ink Supply: Take the new component and align it according to the markings or guides in the device. Ensure it is securely fastened and positioned correctly.

4. Test the Installation: After replacing the ink supply, perform a test print. Check for clarity and consistency in the impressions to confirm successful installation.

Following these steps will not only keep your writing instrument functioning at its best but also ensure that each written word stands out beautifully.

Fixing Sticking Keys Effectively

Addressing unresponsive or sluggish levers can greatly enhance the writing experience. This issue often arises from dust accumulation or mechanical misalignment. Implementing a few straightforward techniques can restore functionality and ensure smooth operation.

Begin by disassembling the unit to access the affected components. A careful cleaning will eliminate debris, while lubrication will provide necessary fluidity. Always test each lever after treatment to confirm improvement.

| Step | Action |

|---|---|

| 1 | Disassemble the unit carefully. |

| 2 | Clean all surfaces and mechanisms. |

| 3 | Apply suitable lubricant to moving parts. |

| 4 | Reassemble and test each key. |

Cleaning Your Underwood Typewriter

Maintaining the functionality and appearance of your vintage writing machine is essential for optimal performance. Regular cleaning not only enhances its aesthetic appeal but also ensures smooth operation, extending its lifespan.

To begin the cleaning process, gather the following materials:

- Soft, lint-free cloths

- Compressed air canister

- Isopropyl alcohol or mild cleaning solution

- Small brush or toothbrush

- Cotton swabs

Follow these steps for effective maintenance:

- Dust Removal: Use the compressed air canister to blow away dust and debris from hard-to-reach areas, such as between keys and around levers.

- Surface Cleaning: Dampen a cloth with isopropyl alcohol and gently wipe down the exterior surfaces. Avoid saturating any parts.

- Key Care: Use a small brush to clean around the keys. For stubborn grime, lightly scrub with a damp cloth.

- Interior Attention: Carefully lift the cover and use compressed air to remove dust from the internal components, being cautious not to damage any delicate parts.

- Final Touches: Check for any remaining dirt using cotton swabs dipped in the cleaning solution, ensuring all surfaces are pristine.

By following these guidelines, you will ensure that your writing device remains in excellent condition, allowing for a seamless writing experience for years to come.

Adjusting the Margin Stops

Proper alignment of the stopping points is essential for achieving consistent results while composing. Ensuring these limits are accurately set allows for neat and organized text layout, enhancing the overall appearance of the final output.

To effectively modify the margin settings, follow these simple steps:

| Step | Action |

|---|---|

| 1 | Locate the margin adjustment levers on the device. |

| 2 | Move the left margin stop to the desired position. |

| 3 | Repeat the process for the right margin stop. |

| 4 | Test the adjustments by typing a sample text. |

| 5 | Make any necessary fine-tuning based on the test results. |

By taking the time to adjust these settings, users can ensure that their written work is polished and professional, ultimately enhancing readability and presentation.

Replacing the Platen and Rollers

Maintaining the functionality of your writing machine often involves replacing essential components that wear out over time. Among these, the platen and rollers play a crucial role in ensuring smooth operation and high-quality output. This section will guide you through the steps necessary to effectively swap these components, enhancing the overall performance of your device.

Understanding the Components

The platen is the cylindrical part that holds the paper in place, while the rollers help feed the paper through the mechanism. Over time, these parts can become worn, leading to uneven impressions or paper jams. Identifying when it’s time to replace them is essential for preserving the quality of your work.

Gathering the Necessary Tools

Before you begin, ensure you have all the required tools at hand. You will need a screwdriver, replacement platen and rollers, and perhaps a cleaning cloth. Having everything ready will streamline the process and minimize interruptions.

Step-by-Step Replacement

Start by carefully removing any covers or panels to access the internal components. Unscrew the existing platen and gently pull it free from its mounts. Take note of how the rollers are positioned; this will aid in correctly installing the new ones. After replacing the platen, position the new rollers in their respective places, ensuring they are secure and aligned properly.

Testing the New Components

Once the new parts are installed, reassemble any covers and test the machine with a few sheets of paper. Check for proper alignment and functionality. Make adjustments if necessary, ensuring a seamless writing experience.

Conclusion

Regularly updating key components like the platen and rollers can greatly enhance the longevity and efficiency of your equipment. By following these steps, you can ensure that your device continues to produce crisp, clear text for years to come.

Lubrication Tips for Longevity

Proper maintenance is essential for ensuring the durability and smooth operation of mechanical devices. Regular lubrication can prevent wear and tear, enhance performance, and extend the life of the equipment. Here are some helpful tips to keep in mind for effective lubrication.

- Select the Right Lubricant: Use a high-quality lubricant that suits the specific materials and mechanisms involved. Consider options like light machine oil or graphite for optimal results.

- Frequency of Application: Establish a regular schedule for applying lubricant. Frequent checks will help catch any signs of wear early and ensure that all moving parts are adequately coated.

- Application Techniques: Apply lubricant sparingly and precisely. Over-lubricating can attract dust and debris, leading to buildup that hinders performance.

- Clean Before Lubrication: Always clean the components before applying any lubricant. This removes dirt and old residue, allowing the new lubricant to work effectively.

- Inspect for Damage: During lubrication, inspect the mechanisms for any signs of damage or misalignment. Addressing these issues early can prevent further complications.

By following these practices, you can help maintain optimal functionality and extend the lifespan of your mechanical equipment, ensuring it continues to operate smoothly for years to come.

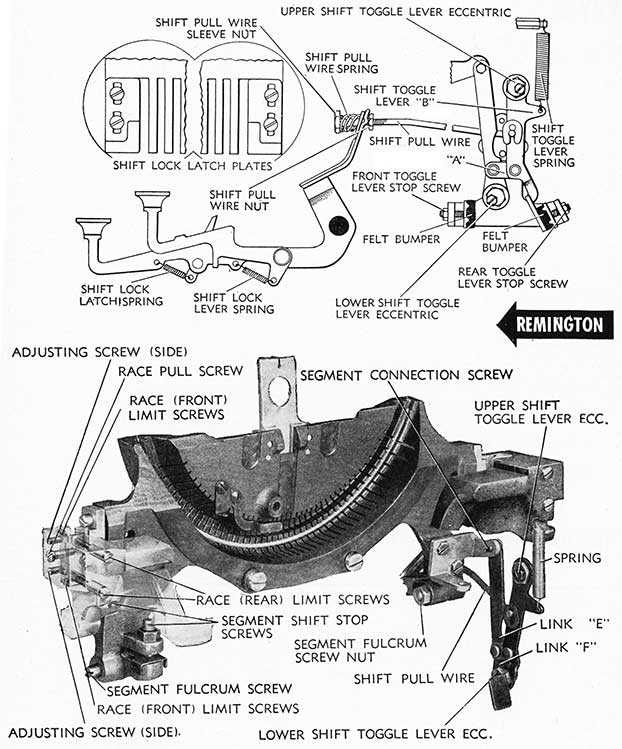

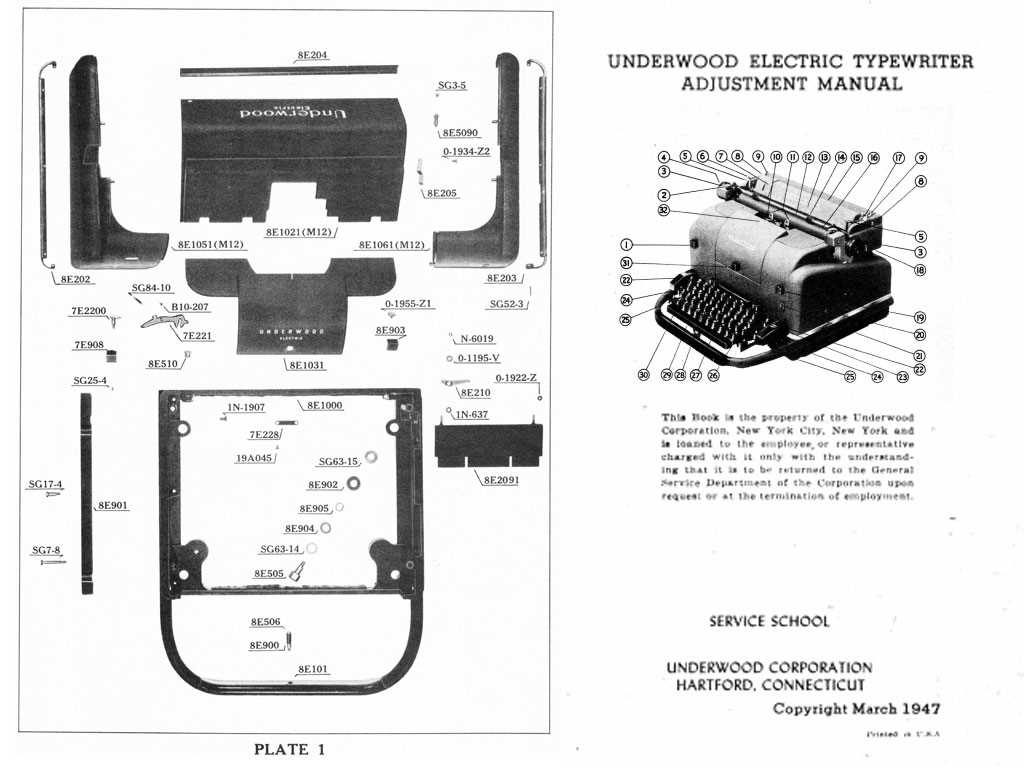

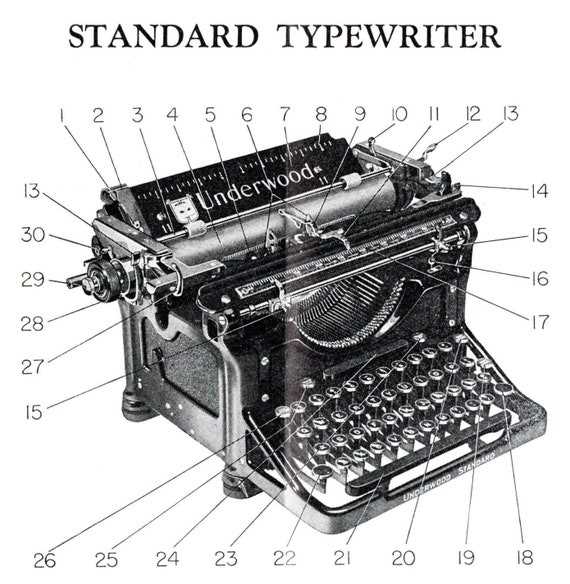

Identifying Parts and Components

Understanding the various elements and their functions within a mechanical writing device is essential for effective maintenance and troubleshooting. Each part plays a critical role in the overall performance, and recognizing these components can greatly enhance your ability to address any issues that may arise.

Below is a table that outlines some of the key components, their descriptions, and common functions:

| Component | Description | Function |

|---|---|---|

| Carriage | The sliding mechanism that holds the paper. | Moves horizontally to advance the writing position. |

| Keyboard | The array of keys representing letters and symbols. | Used to input text by pressing corresponding keys. |

| Ribbon Spool | Holds the inked ribbon used for printing. | Feeds the ribbon through the mechanism for inking characters. |

| Platen | The cylindrical roller that supports the paper. | Provides a surface against which the ribbon impacts. |

| Feed Mechanism | The system that advances the paper after each line. | Moves the paper up to prepare for the next line of text. |

| Shift Mechanism | The assembly that allows for uppercase and lowercase letters. | Changes the position of the keys for different letter cases. |

Familiarity with these components not only aids in better understanding of the device but also improves troubleshooting efficiency and ensures smoother operation.

Resources for Typewriter Enthusiasts

For those captivated by vintage writing machines, a wealth of information and community support is readily available. Enthusiasts can explore various platforms that provide insights into maintenance, history, and craftsmanship. These resources serve as invaluable tools for both novices and seasoned aficionados, fostering a deeper appreciation for the art of mechanical writing.

Online Communities

Numerous forums and social media groups exist where lovers of these mechanical wonders gather to share tips, tricks, and experiences. Participants often exchange advice on upkeep, discuss rare finds, and celebrate the unique characteristics of their collections. Engaging with these communities can lead to friendships and a shared passion for preservation.

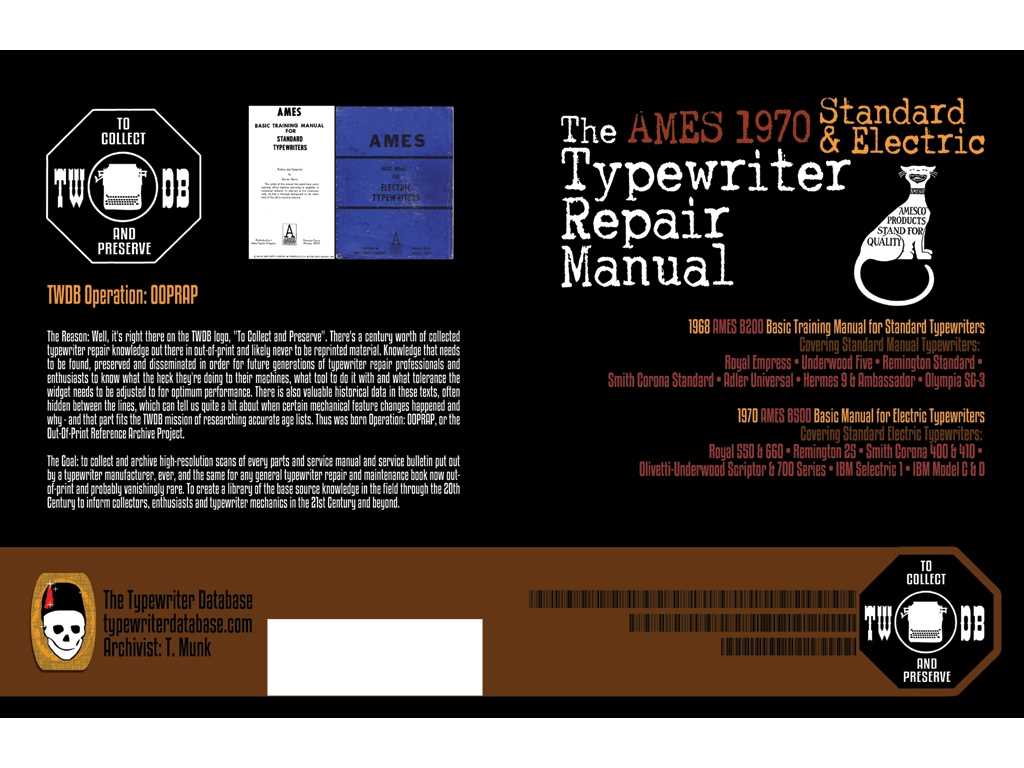

Literature and Guides

Books and digital publications dedicated to the history and functionality of these devices provide essential knowledge. Many authors and experts compile guides that cover everything from basic care to advanced restoration techniques. These resources not only enhance understanding but also inspire creativity in utilizing these charming machines.