This section provides essential insights into the upkeep and restoration of small engine equipment. Understanding the intricacies of your machinery can enhance performance and prolong its lifespan.

Delving into specific components and common issues empowers users to tackle repairs with confidence. Familiarity with various tools and techniques is crucial for effective resolutions.

Whether you’re dealing with routine maintenance or unexpected breakdowns, having a reliable source of information at your fingertips is the ultimate advantage. This guide aims to equip you with the knowledge needed for successful interventions.

Poulan P3314 Overview

This section provides a comprehensive look at a popular model in the outdoor power equipment category. Known for its reliability and performance, this device is designed to tackle a variety of cutting tasks efficiently. Whether you are a homeowner looking to maintain your yard or a professional landscaper, understanding the features and capabilities of this equipment is essential for optimal use.

Key Features

- Powerful engine for efficient operation

- Lightweight design for easy handling

- Durable construction for long-lasting performance

- Adjustable settings for various cutting needs

- Safety features to ensure user protection

Applications

- Trimming trees and bushes

- Cutting firewood

- Landscaping tasks

- General maintenance of outdoor spaces

Understanding these aspects can significantly enhance the user experience and ensure the equipment is used to its full potential.

Common Issues with Poulan Chainsaws

Chainsaws are essential tools for many outdoor tasks, yet they can encounter various problems that hinder performance. Understanding these common difficulties can help users troubleshoot effectively and maintain optimal functionality. Here are some prevalent concerns faced by owners of these powerful devices.

Starting Problems

One frequent issue involves difficulties in starting the machine. This can stem from several factors, including fuel quality, ignition system failures, or carburetor blockages. Ensuring that fresh, appropriate fuel is used and that the spark plug is in good condition can often resolve these starting challenges.

Chain Issues

An improperly functioning chain can lead to reduced efficiency and increased safety risks. Common symptoms include dullness, misalignment, or even chain derailment. Regular maintenance, including sharpening and proper tensioning, is essential to keep the chain operating smoothly. Additionally, checking the bar for wear and tear can prevent further complications.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for achieving efficient and effective outcomes. A well-equipped workspace can significantly simplify the process, ensuring that each task is completed with precision and care. Understanding the necessary instruments can empower individuals to handle various challenges with confidence.

Basic Toolkit

Every repair enthusiast should start with a foundational set of tools that can tackle a wide range of issues. This toolkit typically includes items that facilitate both assembly and disassembly, making it versatile for different situations.

| Tool | Purpose |

|---|---|

| Screwdriver Set | To tighten or loosen screws of various sizes. |

| Wrench Set | For gripping, fastening, and loosening nuts and bolts. |

| Hammer | To drive nails or fit parts together. |

| Pliers | For gripping and bending materials. |

Advanced Tools

For more complex tasks, advanced instruments can enhance precision and efficiency. These tools often cater to specific functions, allowing for a more refined approach to maintenance activities.

| Tool | Purpose |

|---|---|

| Torque Wrench | To apply a specific torque to fasteners. |

| Multimeter | For measuring electrical properties such as voltage and resistance. |

| File Set | To smooth or shape materials. |

| Drill | For creating holes or driving screws. |

Step-by-Step Maintenance Guide

Regular upkeep of your outdoor power equipment is essential for optimal performance and longevity. Following a structured approach to maintenance not only ensures reliability but also enhances safety during operation. This guide provides a detailed process for maintaining your device effectively.

| Step | Description |

|---|---|

| 1 | Clean the Equipment – Remove dirt, debris, and residue from the exterior to prevent rust and maintain visibility. |

| 2 | Inspect the Blade – Check for dullness or damage. Sharpen or replace as necessary to ensure efficient cutting. |

| 3 | Check Fuel and Oil Levels – Ensure proper fuel mixture and oil levels. Replace old fuel to prevent engine issues. |

| 4 | Examine the Air Filter – Clean or replace the air filter to maintain airflow and engine efficiency. |

| 5 | Inspect Cables and Hoses – Look for wear and tear on any cables and hoses. Replace if damaged to avoid malfunctions. |

| 6 | Check Spark Plug – Inspect for carbon buildup or damage. Clean or replace to ensure smooth ignition. |

| 7 | Lubricate Moving Parts – Apply lubricant to joints and moving components to minimize friction and wear. |

| 8 | Store Properly – Ensure the device is stored in a dry, clean area to protect it from environmental factors. |

By adhering to this maintenance routine, you can ensure that your outdoor equipment remains in excellent condition, providing reliable service for years to come.

Replacing the Chain and Bar

Maintaining the cutting components of your tool is essential for optimal performance. Over time, wear and tear can compromise effectiveness, making it necessary to replace both the chain and the bar. This process ensures that your equipment operates smoothly and safely, enhancing your overall experience.

To begin, ensure that your device is powered off and disconnected from any power source. This is a crucial step for safety. Next, locate the tensioning mechanism and release it to loosen the existing chain. Carefully remove the chain from the bar, and then detach the bar itself from the drive assembly.

Once you have removed the old components, it’s time to install the new chain and bar. Start by positioning the new bar in place, aligning it with the drive mechanism. Next, thread the new chain around the bar, ensuring that it fits snugly within the grooves. Pay attention to the direction of the teeth; they should face the correct way for effective cutting.

After securing the new components, adjust the tension of the chain according to the manufacturer’s guidelines. A properly tensioned chain is vital for performance and safety. Finally, check all connections to ensure everything is securely fastened before powering on your tool again.

By following these steps, you can effectively replace the cutting elements, prolonging the lifespan of your equipment and maintaining its efficiency.

Troubleshooting Engine Problems

When dealing with issues related to the power unit of a chainsaw, it’s essential to identify the underlying causes that may hinder its performance. A systematic approach can help pinpoint the source of the trouble and facilitate effective solutions. This section outlines common engine issues and steps to diagnose and resolve them.

Common Symptoms

- Engine fails to start

- Unusual noises during operation

- Loss of power while cutting

- Frequent stalling

- Excessive vibration

Diagnostic Steps

- Check Fuel Supply: Ensure the fuel tank is filled with the correct mixture and that fuel lines are free from blockages.

- Inspect the Air Filter: A clogged air filter can restrict airflow, leading to performance issues. Clean or replace it as needed.

- Examine the Spark Plug: A damaged or dirty spark plug can cause ignition problems. Inspect, clean, or replace it to ensure proper function.

- Assess the Carburetor: Clogged jets or improper adjustments can lead to fuel delivery issues. Clean or tune the carburetor for optimal performance.

- Look for Leaks: Check for any fuel or oil leaks around seals and gaskets, which can affect engine efficiency.

By following these troubleshooting steps, you can identify and address many common problems associated with the engine, ensuring reliable operation and extending the life of your equipment.

Cleaning the Air Filter

Maintaining a clean air filter is crucial for ensuring optimal performance of your outdoor equipment. A clogged filter can hinder airflow, affecting the engine’s efficiency and longevity. Regular inspection and cleaning of the filter can prevent potential issues and keep your device running smoothly.

Steps for Cleaning the Air Filter

Follow these simple steps to effectively clean the air filter:

| Step | Description |

|---|---|

| 1 | Remove the air filter cover carefully to access the filter. |

| 2 | Gently take out the air filter, taking care not to damage it. |

| 3 | Tap the filter lightly to remove loose dirt and debris. |

| 4 | Wash the filter with warm, soapy water if it is heavily soiled. |

| 5 | Rinse thoroughly and let it dry completely before reinserting. |

| 6 | Replace the air filter and secure the cover properly. |

Maintenance Tips

To prolong the life of your air filter, check it regularly for signs of wear or damage. Replace it if it appears excessively dirty or compromised. Following these guidelines will help maintain the efficiency and performance of your equipment, ensuring it operates at its best.

Adjusting the Carburetor Settings

Fine-tuning the air-fuel mixture is essential for optimal engine performance. Proper adjustments can enhance efficiency, improve starting, and reduce emissions. This process requires attention to detail and a basic understanding of engine functions.

1. Gather Necessary Tools: To begin, assemble a set of tools, including a screwdriver and a tachometer if available. Having the right instruments on hand ensures a smoother adjustment process.

2. Locate the Adjustment Screws: Typically, there are two or three screws that control the idle speed and the mixture. Consult the specific engine documentation to identify their locations accurately.

3. Adjust the Idle Speed: Start the engine and allow it to warm up. Turn the idle speed screw clockwise to increase RPMs, or counterclockwise to decrease them. Aim for a steady idle that suits your operational needs.

4. Tune the Air-Fuel Mixture: Next, adjust the mixture screws. Turn them slowly while observing engine response. If the engine runs rough, you may need to tweak the settings further until you achieve a smooth operation.

5. Test and Finalize: After making adjustments, test the engine under various loads to ensure it performs well. Fine-tune as necessary, keeping an eye on how the adjustments affect power and efficiency.

By carefully adjusting these settings, you can enhance performance and prolong the lifespan of the engine, ensuring reliable operation for future tasks.

Understanding Fuel and Oil Requirements

Proper maintenance of small engines relies heavily on the correct types of fuel and lubricants. Ensuring that the right substances are used not only promotes optimal performance but also prolongs the lifespan of the equipment. Selecting the appropriate fuel and oil can significantly affect efficiency and reliability during operation.

Fuel Specifications

Using high-quality fuel is essential for maintaining engine health. Typically, it is recommended to use unleaded gasoline with an octane rating of 87 or higher. Avoid mixing fuel with ethanol content exceeding 10%, as it can lead to operational issues. Fresh fuel is crucial; old or stale gasoline can cause starting problems and diminished performance.

Oil Requirements

The choice of oil is equally important. For most small engines, a high-quality 2-stroke oil is recommended, mixed in the proper ratio with fuel. Always consult the specifications to determine the correct mixing ratio for your engine. Using the right lubricant not only minimizes wear and tear but also enhances the overall efficiency of the machinery.

Safety Tips for Chain Saw Use

Operating a chain saw requires careful attention to safety practices to prevent accidents and injuries. Understanding the proper techniques and precautions is essential for anyone who intends to use this powerful tool, ensuring both personal safety and that of others nearby.

Essential Safety Gear

- Always wear a helmet with a face shield or safety goggles to protect against flying debris.

- Use protective gloves to enhance grip and safeguard your hands.

- Wear sturdy boots with non-slip soles to prevent slipping and provide ankle support.

- Don chaps or leg protection to shield against cuts and injuries.

- Consider ear protection to reduce noise exposure.

Pre-Use Safety Checks

- Inspect the chain saw for any signs of damage or wear before use.

- Ensure that the chain is properly tensioned and lubricated.

- Check that all safety features are functional, including the chain brake.

- Clear the work area of any obstacles or hazards.

- Familiarize yourself with the operation and handling of the equipment.

Identifying Wear and Tear Signs

Recognizing signs of deterioration is essential for maintaining the efficiency and longevity of your equipment. Various indicators can reveal the condition of components, helping to prevent more significant issues and ensuring optimal performance. Regular inspection can save time and resources in the long run.

| Indicator | Description |

|---|---|

| Cracks and Fractures | Visible breaks or fissures in the body of the tool can signal structural weakness. |

| Excessive Wear | Signs of abrasion on moving parts indicate that they may be nearing the end of their lifespan. |

| Rust or Corrosion | Any signs of oxidation on metal components can compromise functionality and safety. |

| Loose Connections | Parts that are not securely fastened can lead to inefficiency and potential hazards. |

| Unusual Noises | Strange sounds during operation often point to internal issues that need immediate attention. |

Storage Recommendations for Longevity

Proper storage techniques are essential for ensuring the longevity and optimal performance of your equipment. By following a few key guidelines, you can protect your tools from environmental factors and wear, ultimately extending their lifespan and maintaining functionality.

Firstly, always clean your equipment thoroughly before storing it. Remove any dirt, debris, or residue that may have accumulated during use. This prevents corrosion and buildup that can affect performance. After cleaning, apply a light coating of oil to metal surfaces to further protect against rust.

Secondly, consider the storage environment. Keeping your tools in a dry, temperature-controlled space is vital. Avoid areas prone to humidity, extreme temperatures, or direct sunlight, as these conditions can lead to deterioration over time.

Additionally, use protective covers or cases whenever possible. This adds an extra layer of defense against dust and physical damage. Organizing your tools in a way that minimizes movement and friction can also prevent unnecessary wear.

Finally, perform regular inspections during storage. Check for signs of wear, rust, or other issues that may arise. Addressing these concerns early can save you from larger problems down the line, ensuring your equipment remains in excellent condition for years to come.

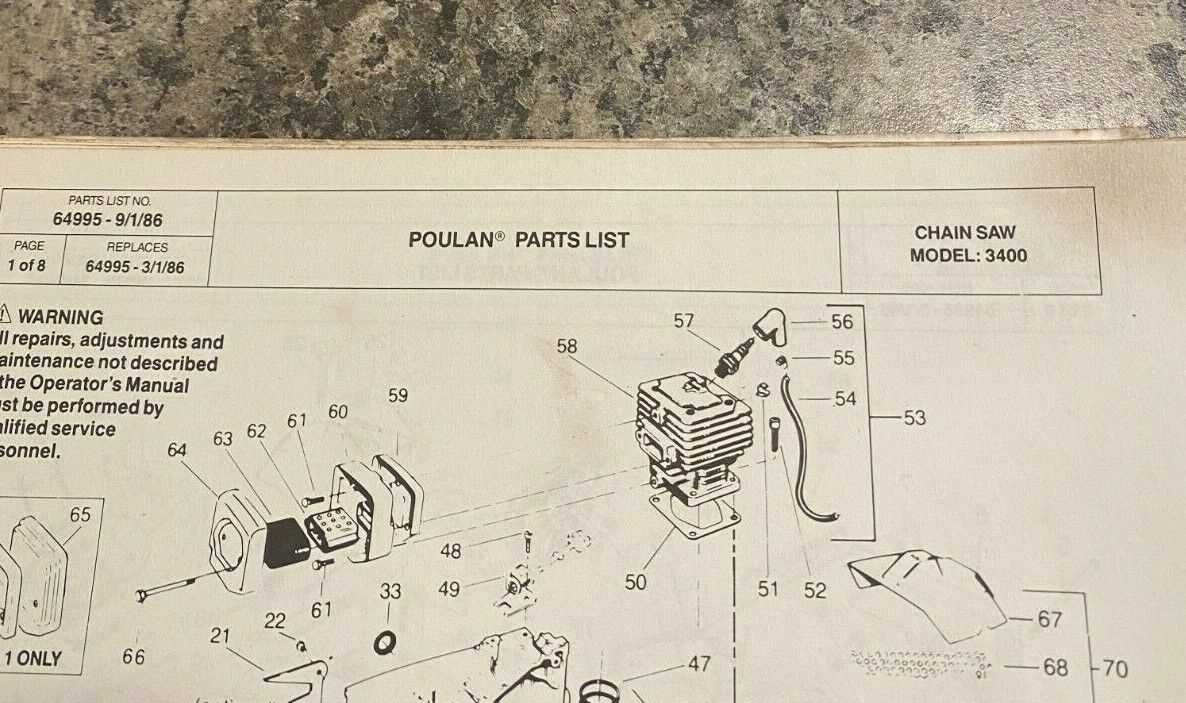

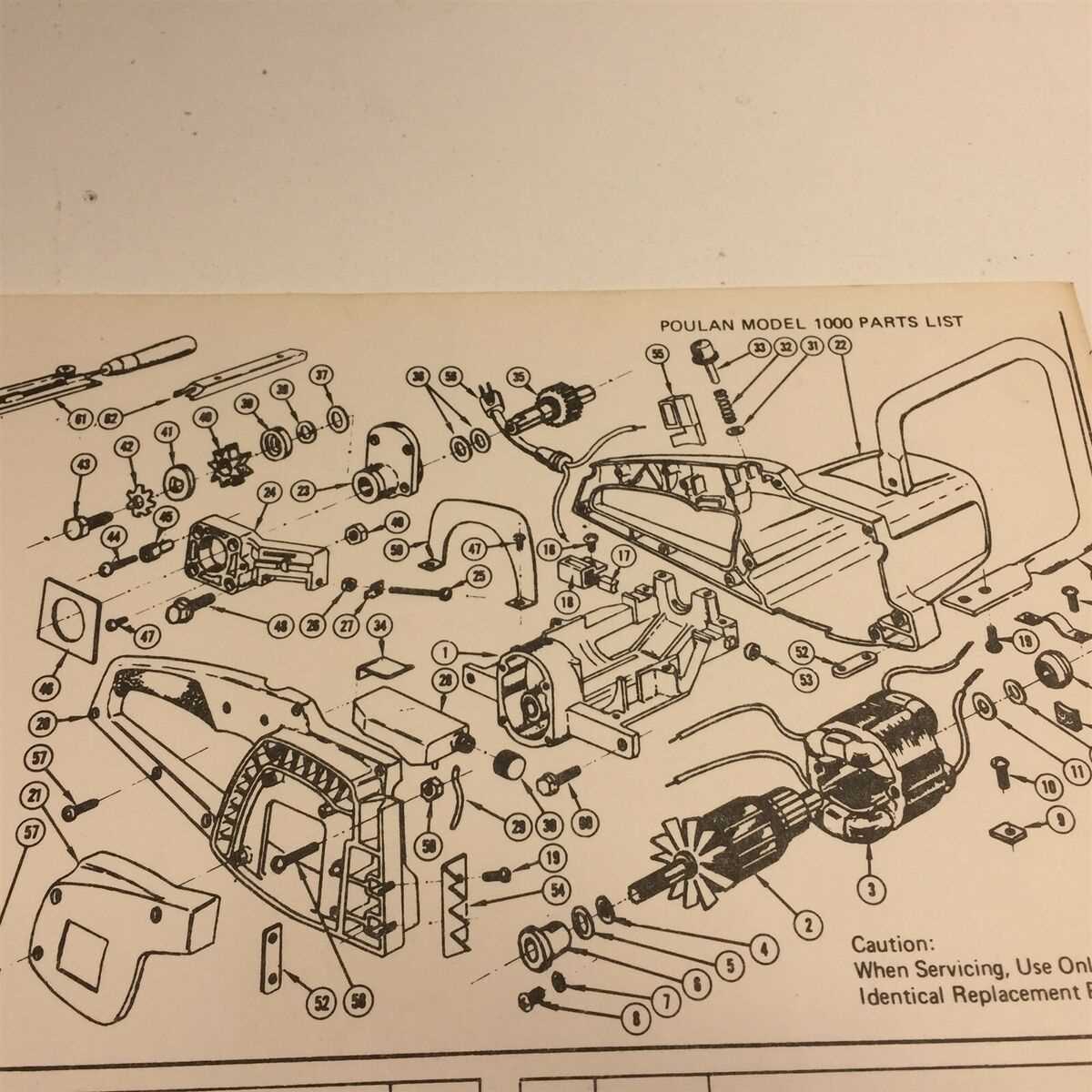

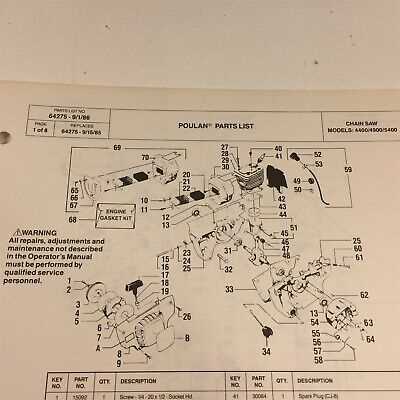

Finding Replacement Parts Online

Locating suitable components for your equipment can be a straightforward process with the right approach. The internet offers a vast array of resources, making it easier to source high-quality parts that ensure optimal performance and longevity of your tools.

Start by exploring specialized online retailers that focus on outdoor machinery and tools. These platforms often provide a comprehensive selection of parts, along with detailed descriptions to help you identify the exact item you need. Additionally, check for customer reviews and ratings to gauge the reliability of the products and the seller.

Another effective method is to visit manufacturer websites. They typically have dedicated sections for replacement parts, where you can enter your model details to find compatible options. This ensures that you are purchasing genuine components designed specifically for your equipment.

Don’t overlook auction sites and classified ads, where you might find new or gently used parts at competitive prices. Always verify the condition and compatibility before making a purchase to avoid any future complications.

Lastly, consider joining online forums or communities related to your equipment. Members often share insights and recommendations for trusted suppliers, making it easier to find what you need while also connecting with fellow enthusiasts.