Understanding the basics of keeping your leaf blower in optimal condition can significantly extend its life and ensure peak performance. This guide provides a detailed look at essential maintenance practices, enabling you to prevent common issues and handle technical tasks effectively. Here, you’ll find insights into parts, diagnostics, and tips for consistent upkeep.

For anyone looking to enhance the efficiency of their leaf blower, recognizing and addressing minor issues before they escalate is key. This section includes step-by-step solutions for typical challenges, ensuring you have the knowledge to address mechanical and operational concerns confidently.

From maintaining the motor to ensuring all components are aligned and clean, regular attention to these devices helps them run smoothly through seasons of use. Delve into practical advice on preserving functionality and discover efficient ways to troubleshoot so you can get back to your outdoor tasks without unnecessary delays.

Troy-Bilt TB320BV Repair Manual

Understanding the maintenance and care of garden tools is essential for anyone looking to keep equipment performing efficiently season after season. Regular upkeep ensures optimal functionality and extends the lifespan of outdoor devices. In this section, you’ll find insightful tips on diagnosing common issues, along with guidelines to help you address them effectively. Clear instructions, paired with careful handling, can simplify any adjustments and replacements needed over time.

Among the most frequent concerns are engine performance issues and component wear, which can affect reliability. We’ll walk through how to identify potential causes, such as clogged filters, dull blades, or faulty spark plugs, all of which impact performance. With step-by-step guidance, these adjustments can be completed smoothly, making it easier to tackle any challenges that arise in your outdoor tasks.

Overview of Key Features

This section highlights the essential functionalities and components that make this device efficient and user-friendly. Whether you’re looking for reliable performance in yard maintenance or versatility in outdoor tasks, these key elements are designed to support a seamless operation experience.

Powerful Engine and Enhanced Efficiency

At the heart of this model is a robust engine, delivering consistent power for a range of tasks. Built to maximize energy efficiency, it combines performance and longevity, allowing users to manage extensive outdoor areas without interruptions. The efficient fuel system ensures longer operation times with minimal emissions, supporting an eco-friendly approach.

User-Friendly Design and Versatility

Featuring an ergonomic design, the device emphasizes comfort during prolonged use. Its intuitive controls and lightweight structure enable easy handling, enhancing

Common Issues and Troubleshooting Tips

This section provides solutions for frequent issues that may arise during the operation of outdoor power tools. With clear, step-by-step advice, these tips will help users quickly identify and resolve typical problems, ensuring equipment continues to perform reliably and efficiently.

Engine Won’t Start

If the engine fails to start, check the following common causes and solutions:

- Fuel Level: Ensure there’s enough fuel in the tank. Old or contaminated fuel should be replaced with fresh gasoline.

- Spark Plug Condition: Inspect the spark plug for damage or wear. Clean or replace it if necessary.

- Air Filter: A clogged air filter can restrict airflow. Clean or replace it regularly to maintain proper engine function.

Loss of Power During Use

If the tool loses power or performs poorly while in operation, consider the following

Step-by-Step Engine Maintenance Guide

Regular engine upkeep is essential to ensure optimal performance and longevity. This guide provides clear and actionable steps to keep your engine running smoothly, addressing common maintenance needs without specialized knowledge. By following these instructions, you’ll promote efficiency and reduce the likelihood of future issues.

1. Check the Oil Level: Begin by inspecting the oil level, as adequate lubrication is vital for engine health. Use a dipstick to gauge the current

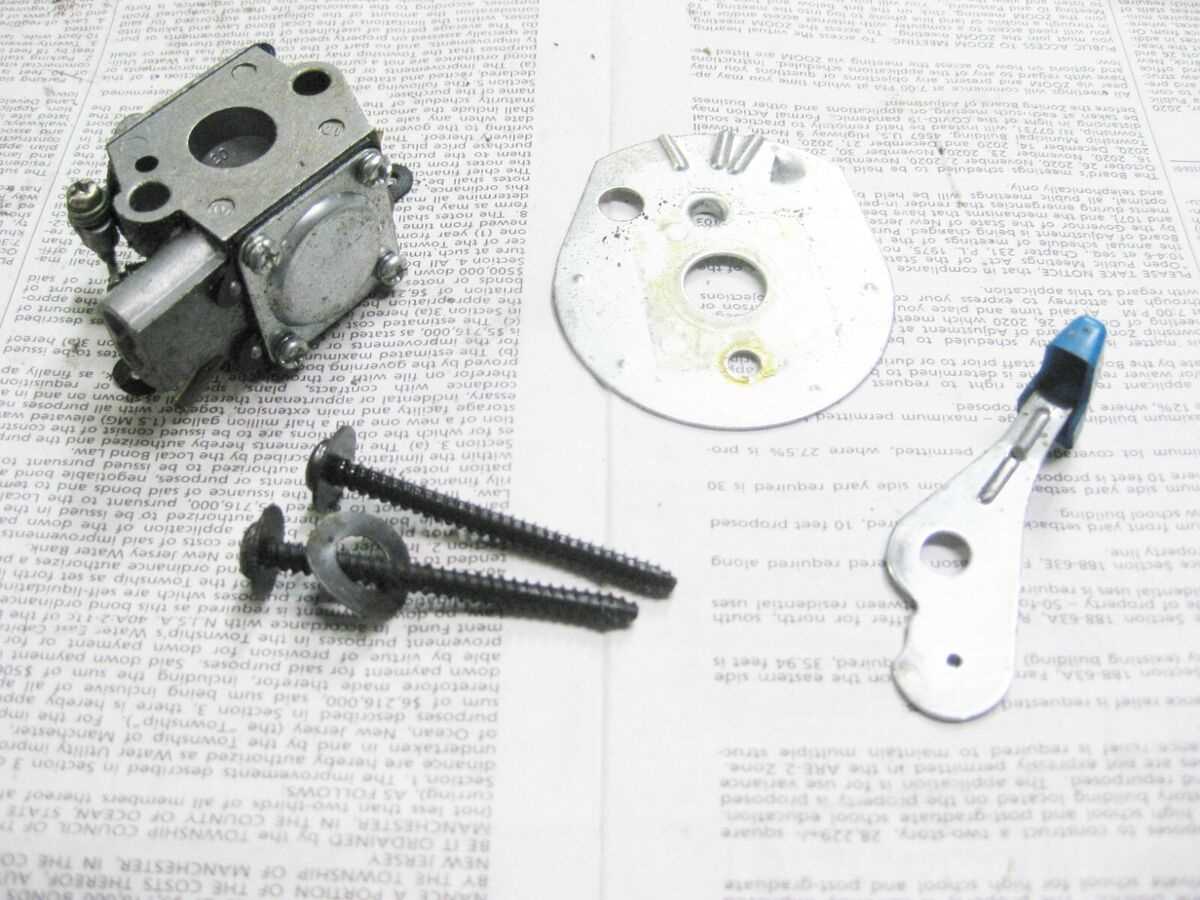

Essential Tools for Repairing TB320BV

To efficiently maintain and restore functionality, having the right set of equipment is crucial. Each tool serves a unique purpose, ensuring that every component can be adjusted or replaced with precision.

One of the primary tools is a well-fitting screwdriver set, ideal for disassembling various parts. Alongside screwdrivers, adjustable wrenches and socket sets help in loosening or tightening bolts and

Cleaning and Lubrication Procedures

Regular maintenance is essential for the optimal performance and longevity of your equipment. This section outlines the recommended practices for cleaning and lubrication to ensure your machinery operates smoothly and efficiently.

Follow these guidelines for effective cleaning:

- Always disconnect the power source before starting any cleaning process.

- Use a soft brush or cloth to remove debris and dirt from all surfaces.

- Avoid using harsh chemicals that may damage the equipment’s components.

- For stubborn grime, a mixture of mild soap and water can be used. Ensure all residues are rinsed off thoroughly.

Lubrication is equally important for reducing friction and wear on moving parts. Adhere to the following lubrication steps:

- Refer to the manufacturer’s specifications for the type of lubricant suitable for your machine.

- Apply lubricant to all specified points, ensuring even coverage.

- Do not over-lubricate, as excess grease can attract dirt and lead to malfunctions.

- Inspect lubricated areas regularly and reapply as necessary to maintain optimal function.

By following these cleaning and lubrication procedures, you can enhance the efficiency and lifespan of your equipment, ensuring it remains in top working condition.

Replacing Air Filters and Spark Plugs

Maintaining optimal performance in small engines requires regular attention to vital components such as air filters and spark plugs. These elements play a crucial role in ensuring efficient operation and longevity of your equipment. Over time, they can become clogged or worn out, leading to reduced efficiency and potential engine issues.

Importance of Clean Air Filters

Air filters prevent dirt and debris from entering the engine, promoting better airflow and combustion. A clean filter enhances performance and fuel efficiency, while a clogged filter can cause the engine to work harder, leading to potential damage.

Replacing Spark Plugs

Spark plugs ignite the air-fuel mixture in the engine’s combustion chamber. Worn or fouled plugs can result in misfires, poor acceleration, and increased emissions. Regularly replacing spark plugs is essential for maintaining engine health and ensuring smooth operation.

| Component | Signs of Wear | Replacement Frequency |

|---|---|---|

| Air Filter | Clogged, dirty appearance | Every 25-50 hours of use |

| Spark Plug | Cracked insulator, carbon buildup | Every 50-100 hours of use |

Regularly checking and replacing these components will help maintain your equipment’s performance and extend its lifespan, ensuring it operates smoothly for years to come.

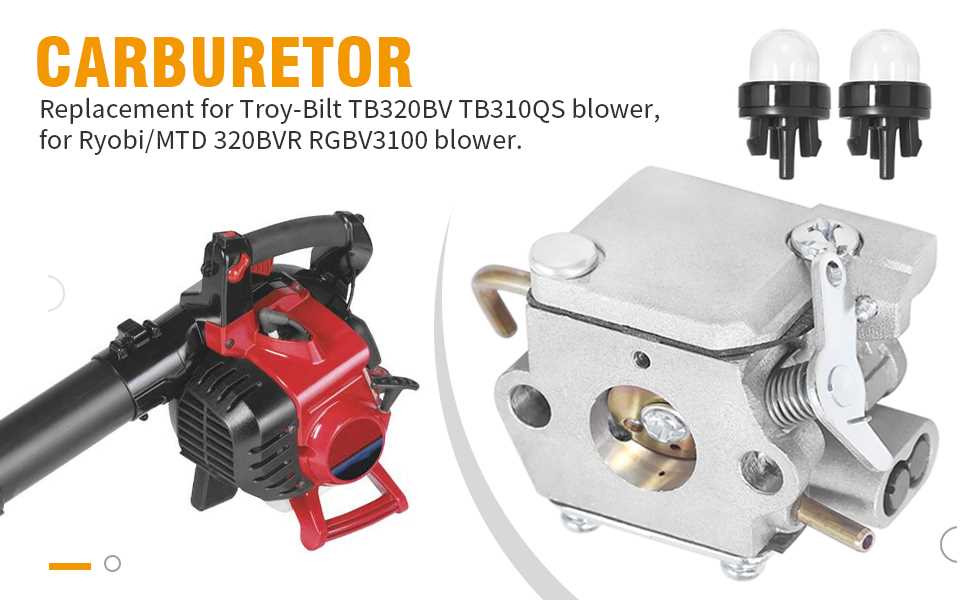

Carburetor Adjustment and Fine-Tuning

Proper calibration of the carburetor is essential for optimal engine performance. This process involves adjusting the air-fuel mixture to ensure efficient combustion and smooth operation. Correct tuning not only enhances power output but also improves fuel efficiency and reduces emissions.

To achieve accurate settings, it is important to first locate the adjustment screws, typically found on the side of the carburetor. These screws control the idle speed and mixture ratio. Start by warming up the engine to its normal operating temperature before making any adjustments. This ensures the carburetor components are functioning correctly.

Begin with the idle speed screw, which regulates how fast the engine runs when not under load. Slowly turn the screw clockwise to increase the idle speed or counterclockwise to decrease it, listening for a smooth and steady idle. Once the desired speed is reached, move on to the mixture adjustment.

The mixture screw fine-tunes the balance of air and fuel. Turn the screw gradually, pausing to observe engine response after each adjustment. Aim for a slightly rich mixture, which provides better throttle response. If the engine begins to sputter or stall, it may be too rich, requiring a slight adjustment in the opposite direction.

After making these adjustments, it is advisable to take the equipment for a short test run. Observe how it performs under load and check for any irregularities. If necessary, return to the carburetor and repeat the adjustments until the engine runs smoothly and efficiently.

Guide to Electrical Component Checks

This section provides essential insights into evaluating electrical components within various machinery. Understanding how to properly inspect and test these parts is crucial for ensuring optimal performance and preventing potential issues.

Follow the outlined steps to conduct thorough assessments of electrical elements, which can significantly enhance the reliability of your equipment.

| Component | Check Method | Expected Result |

|---|---|---|

| Batteries | Measure voltage with a multimeter | Voltage should match specifications |

| Wires | Inspect for visible damage | No frays or breaks present |

| Connectors | Ensure tight connections | All connectors should be secure |

| Fuses | Check for continuity | Fuse should show continuity if functional |

| Switches | Test with a multimeter | Switch should operate smoothly |

Fuel System Inspection and Care

Maintaining the fuel system of your equipment is essential for optimal performance and longevity. Regular checks can prevent potential issues that might disrupt operations and ensure that the engine runs smoothly. This section will provide insights into the components of the fuel system and guidelines for their upkeep.

Begin by examining the fuel tank for any signs of contamination or rust. Ensure that the fuel is clean and free from debris, as impurities can affect combustion efficiency. It is advisable to use fuel stabilizers to prolong the life of gasoline, especially during periods of inactivity.

Inspect the fuel lines for cracks or leaks, which can lead to fuel loss and safety hazards. Replace any damaged sections promptly to maintain integrity. Additionally, check the fuel filter; a clogged filter can hinder fuel flow and impair engine performance. Regular replacement of the filter is recommended according to the manufacturer’s guidelines.

Lastly, keep an eye on the carburetor or fuel injectors, depending on the engine type. Clean these components regularly to ensure proper fuel atomization and efficient combustion. Addressing these areas will enhance the reliability and efficiency of the equipment.

Blade and Impeller Maintenance

Proper upkeep of the cutting mechanism and impeller is essential for ensuring optimal performance and longevity of your equipment. Regular inspections and maintenance can prevent wear and tear, enhancing efficiency and reducing the risk of malfunctions.

Inspection Guidelines

Start by examining the blade and impeller for any signs of damage or accumulation of debris. Look for cracks, chips, or bends that may affect performance. It is important to clean these components thoroughly to prevent clogging and to maintain cutting efficiency.

Maintenance Procedures

Once inspected, sharpening the blade is crucial for effective operation. Use a sharpening tool or file to restore the blade’s edge. Additionally, check the impeller for any blockages and ensure that it spins freely. Lubricate any moving parts to reduce friction and enhance functionality.

| Component | Maintenance Action | Frequency |

|---|---|---|

| Blade | Sharpen | Every 10 hours of use |

| Impeller | Clean and inspect | After each use |

| Moving Parts | Lubricate | Monthly |

Seasonal Storage and Protection Tips

Proper seasonal storage is essential for extending the lifespan of your outdoor equipment. Taking the time to prepare your tools for periods of inactivity can prevent deterioration and ensure they are ready for use when needed. By following a few simple guidelines, you can safeguard your investments and keep them in optimal condition.

Cleaning and Maintenance

Before storing your equipment, it’s crucial to thoroughly clean all surfaces to remove dirt, debris, and any residual materials. Pay special attention to blades and other components that may accumulate grime. Additionally, perform necessary maintenance tasks such as sharpening blades, changing oil, and checking fuel systems. This preparation will help prevent corrosion and mechanical issues during storage.

Storage Environment

Choosing the right environment for storage is equally important. Ideally, your tools should be kept in a dry, temperature-controlled area to avoid exposure to harsh elements. If storing outdoors, consider using protective covers to shield against moisture and sunlight. Organizing your equipment in a way that allows for easy access will also facilitate smoother operations when it’s time to retrieve them for use.