Chainsaws are indispensable tools for both professionals and hobbyists, offering power and efficiency for a variety of cutting tasks. However, like any mechanical device, they require regular upkeep to ensure optimal performance. Understanding the intricacies of your equipment can significantly extend its lifespan and enhance its functionality.

In this section, we will explore essential procedures and techniques to troubleshoot common issues and perform necessary adjustments. Whether you are facing minor malfunctions or more significant concerns, having a structured approach can make all the difference in restoring your tool to peak condition.

Equipped with the right knowledge, you will be able to identify problems early, perform basic maintenance tasks, and even execute more complex repairs when needed. This guide aims to empower you with the skills required to keep your chainsaw running smoothly and efficiently.

Understanding the Stihl MS 210

This section aims to provide insights into a popular model of chainsaw that combines efficiency and user-friendliness. This power tool is designed for a range of applications, making it suitable for both novice users and experienced professionals.

Key features of this chainsaw include:

- Lightweight design for easy handling

- Powerful engine that ensures high performance

- Efficient fuel consumption for prolonged usage

- Easy-start mechanism for quick operation

When considering this tool, it’s essential to understand its components:

- Engine: Delivers reliable power for various cutting tasks.

- Guide bar: Available in different lengths, allowing for versatility in cutting.

- Chain: Designed for durability and precision, ensuring clean cuts.

- Safety features: Includes mechanisms to protect the user during operation.

Overall, this chainsaw is an excellent choice for those looking to tackle outdoor projects with ease and efficiency.

Common Issues with Stihl MS 210

Understanding the frequent problems that can arise with certain chainsaw models is essential for effective maintenance and longevity. Users often encounter specific challenges that can hinder performance, leading to frustration during operation. Identifying these issues early on can facilitate timely solutions and enhance the overall experience.

Fuel System Problems: One of the most common complications involves the fuel system. Users may notice difficulty starting the engine or inconsistent running. This can stem from clogged filters, stale fuel, or issues with the carburetor. Regular maintenance and the use of fresh fuel can mitigate these problems.

Ignition Issues: Another prevalent concern relates to the ignition system. If the chainsaw fails to start or has intermittent starting problems, it may indicate a faulty spark plug or ignition coil. Replacing these components can restore reliable operation.

Chain Tension and Bar Wear: Improper chain tension can lead to increased wear on the guide bar and chain. Users should regularly check and adjust tension to ensure optimal cutting performance. Signs of excessive wear include uneven cuts and difficulty in chain movement.

Oil Delivery Failures: Effective lubrication is crucial for maintaining the health of the bar and chain. A malfunctioning oil pump can lead to insufficient lubrication, resulting in overheating and premature wear. Regular inspections and maintenance of the oil system can help prevent this issue.

Air Filter Clogging: Dust and debris can accumulate in the air filter, restricting airflow and impacting engine performance. Cleaning or replacing the air filter as needed is vital for maintaining optimal engine function and efficiency.

By being aware of these typical issues, users can take proactive steps to ensure their equipment remains in top condition, ultimately enhancing performance and reliability during use.

Essential Tools for Repairing Chainsaws

Having the right instruments is crucial for maintaining and fixing power saws effectively. Proper tools not only facilitate the process but also ensure safety and precision during the task. Understanding which implements are essential can significantly enhance the efficiency of any servicing work.

First and foremost, a comprehensive tool kit should include screwdrivers of various sizes, both flat and Phillips. These are necessary for adjusting and securing different components. A torque wrench is also vital for ensuring that bolts are tightened to the manufacturer’s specifications, preventing potential damage.

Another indispensable item is a chain brake tool, which is designed to assist in adjusting or replacing the cutting chain safely. A file set is important for sharpening the chain, while a depth gauge tool ensures optimal performance by maintaining the correct depth of the cutting teeth.

Furthermore, having a set of pliers can aid in grasping small parts, while a cleaning brush helps in removing debris and residue from hard-to-reach areas. Safety equipment, including gloves and goggles, should not be overlooked, as they protect against potential hazards during maintenance tasks.

Ultimately, assembling a well-rounded selection of tools will not only streamline the maintenance process but also contribute to the longevity and performance of your power saw.

Step-by-Step Repair Guide

This section aims to provide a comprehensive approach to troubleshooting and restoring your equipment effectively. By following these detailed instructions, you can address common issues and ensure optimal performance.

Preparation

Begin by gathering all necessary tools and replacement parts. Ensure you have a clean workspace to facilitate an efficient process. Familiarize yourself with the components of your device to streamline the work ahead.

Execution

Carefully disassemble the unit, taking note of each step for reassembly. Inspect all parts for wear or damage, replacing any that are defective. Follow the provided steps meticulously to guarantee a successful outcome.

Replacing the Chain and Bar

Maintaining optimal performance of your cutting tool involves regular attention to its chain and bar. Over time, wear and tear can lead to decreased efficiency and safety. This section outlines the steps necessary to replace these components effectively.

Before you begin, ensure you have the following tools and replacement parts ready:

- Replacement chain

- Replacement bar

- Screwdriver

- Wrench or socket set

- Protective gloves

Follow these steps to complete the replacement:

- Safety First: Disconnect the power source to avoid accidental starts.

- Remove the Old Chain: Loosen the tensioning mechanism using the appropriate tool. Carefully slide the chain off the bar.

- Detach the Bar: Unscrew the bolts securing the bar to the housing and remove it from the tool.

- Install the New Bar: Position the new bar in place and secure it with bolts, ensuring proper alignment.

- Add the New Chain: Thread the new chain around the bar, making sure it follows the correct path, and connect it to the drive sprocket.

- Tighten the Chain: Adjust the tension according to the manufacturer’s specifications, ensuring the chain moves freely without sagging.

- Final Check: Reinspect all connections and ensure everything is secure before reconnecting the power source.

Regularly replacing the chain and bar is essential for maintaining the efficiency and safety of your equipment. Following these steps will help ensure a smooth and effective replacement process.

Maintaining the Fuel System

Proper upkeep of the fuel system is crucial for optimal performance and longevity of your equipment. Regular attention to this area can prevent issues that lead to inefficient operation or costly repairs. Ensuring that fuel flows smoothly and components are in good condition will enhance reliability and functionality.

Here are key steps for maintaining the fuel system:

- Check the fuel filter regularly.

- Inspect fuel lines for cracks or leaks.

- Replace old fuel with fresh gasoline to avoid deterioration.

- Ensure the fuel cap seals properly to prevent contamination.

- Clean or replace the carburetor as needed to prevent clogging.

Following these guidelines can significantly extend the life of your equipment and improve its performance. Consistent monitoring and timely maintenance will help you avoid unexpected breakdowns.

Troubleshooting Ignition Problems

Addressing ignition issues is essential for ensuring optimal performance of your equipment. When your engine fails to start or runs inconsistently, it may be due to problems within the ignition system. This section outlines common symptoms, potential causes, and steps to diagnose and resolve these challenges.

Common symptoms of ignition problems include:

- Engine not starting

- Intermittent firing

- Difficulty in starting after extended use

- Weak or erratic spark

Possible causes for these symptoms might involve:

- Faulty spark plug

- Defective ignition coil

- Worn or damaged wiring

- Issues with the ignition module

To diagnose ignition problems, follow these steps:

- Inspect the spark plug for wear or fouling, and replace if necessary.

- Check the ignition coil for continuity and proper output.

- Examine wiring connections for damage or corrosion.

- Test the ignition module with appropriate tools to ensure it is functioning correctly.

By systematically addressing these areas, you can effectively troubleshoot and resolve ignition issues, restoring your equipment to reliable operation.

Cleaning the Air Filter Effectively

Maintaining optimal airflow is crucial for the performance and longevity of your equipment. A clean air filter not only enhances engine efficiency but also prevents potential damage from debris and contaminants. Regular cleaning is essential to ensure that your machine operates smoothly and reliably.

Here are the steps to effectively clean the air filter:

- Gather Necessary Supplies:

- Soft brush or compressed air

- Warm, soapy water

- Clean, dry cloth

- Protective gloves (optional)

- Remove the Air Filter:

- Locate the air filter cover and remove it carefully.

- Gently take out the air filter, being cautious not to damage any components.

- Clean the Filter:

- If using a brush, lightly sweep away dust and debris from the filter surface.

- For a deeper clean, submerge the filter in warm, soapy water, then rinse thoroughly.

- Allow the filter to dry completely before reinstallation.

- Reinstall the Air Filter:

- Ensure the filter is completely dry and free of any soap residue.

- Carefully place the air filter back into its compartment.

- Secure the air filter cover firmly to prevent any air leaks.

By following these steps, you can maintain a clean air filter, which is vital for optimal performance and extending the lifespan of your equipment.

Adjusting the Carburetor Settings

Proper calibration of the fuel delivery system is essential for optimal engine performance. Adjusting these settings ensures that the mixture of air and fuel is balanced, leading to efficient combustion and reducing emissions. This process can enhance the overall functionality and lifespan of the equipment.

Understanding the Components

Before making any adjustments, it’s important to familiarize yourself with the key components involved:

- Idle Speed Screw: Controls the engine speed when at idle.

- High-Speed Screw: Regulates the fuel mixture during full throttle operation.

- Low-Speed Screw: Affects the mixture at lower speeds and during acceleration.

Adjustment Procedure

Follow these steps to ensure accurate adjustments:

- Start the engine and let it warm up to operating temperature.

- Turn the idle speed screw clockwise to increase the idle speed or counterclockwise to decrease it.

- Adjust the low-speed screw to achieve a smooth acceleration without stalling.

- For high-speed settings, gradually turn the high-speed screw until the engine runs smoothly at maximum throttle.

- After adjustments, check the overall performance and make minor tweaks as necessary.

By taking the time to properly adjust these settings, users can ensure their equipment runs efficiently, providing reliable performance for various tasks.

Safety Precautions During Repairs

When undertaking maintenance tasks on mechanical devices, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions not only protect the individual performing the work but also ensure the longevity and proper functioning of the equipment. Awareness of potential hazards and following established guidelines can significantly reduce risks.

First and foremost, personal protective equipment (PPE) is essential. Always wear appropriate gear, such as gloves, goggles, and ear protection. This minimizes exposure to harmful substances and reduces the chance of physical injury from sharp or moving parts.

Additionally, ensure that the work area is clean and well-lit. A cluttered environment can lead to mishaps, so keeping tools organized and surfaces clear will enhance safety. Ensure that there is adequate ventilation, especially when working with chemicals or fuels.

Furthermore, it is vital to disconnect the power source before beginning any maintenance. This simple step can prevent accidental starts that may cause injury. Familiarize yourself with the equipment’s specifications and follow manufacturer guidelines for safe handling and maintenance practices.

Finally, never hesitate to seek assistance or consult a professional if unsure about a particular procedure. Safety should always be the top priority when engaging in maintenance tasks.

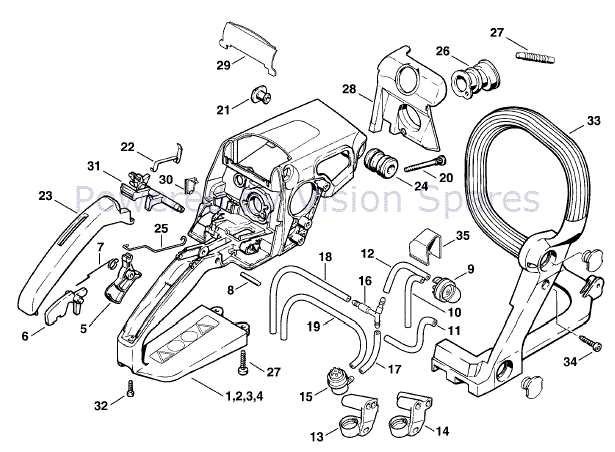

Parts Identification for Stihl MS 210

Understanding the various components of a chainsaw is essential for effective maintenance and troubleshooting. Each part plays a crucial role in the overall performance and efficiency of the tool. Familiarizing oneself with these elements can significantly enhance the user experience and prolong the lifespan of the equipment.

| Part Name | Description | Function |

|---|---|---|

| Chain | A loop of metal links with sharp teeth | Responsible for cutting through wood |

| Guide Bar | A flat metal bar that supports the chain | Directs the chain and provides stability during cutting |

| Engine | The power unit of the chainsaw | Drives the chain and powers the tool |

| Air Filter | A filter that prevents dirt and debris from entering the engine | Maintains engine efficiency by ensuring clean air intake |

| Fuel Tank | A container that holds the fuel mixture | Supplies fuel to the engine for operation |

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing high-quality components is crucial. There are several reliable avenues to explore when searching for necessary parts that ensure optimal performance and longevity.

Authorized Dealers: One of the best places to start is through authorized dealers. These vendors offer a comprehensive selection of original components, guaranteeing compatibility and quality. By purchasing from an official source, you can also benefit from expert advice and customer support.

Online Retailers: The internet hosts a myriad of online platforms that specialize in providing equipment parts. Websites dedicated to outdoor tools often have extensive catalogs, making it easy to find exactly what you need. Look for reputable sites with positive reviews to ensure a reliable shopping experience.

Local Repair Shops: Don’t overlook local repair shops, as they often carry a range of parts and can assist with installation. These businesses usually have knowledgeable staff who can help identify the right component for your needs.

Salvage Yards: For those on a budget, salvage yards can be a treasure trove of usable parts. While it may require some searching, you might find perfectly good components at a fraction of the original cost. Just make sure to inspect items thoroughly before purchasing.

Online Marketplaces: Platforms like eBay or Craigslist may also have listings for parts. While these options can be hit or miss, you can sometimes find great deals. Always check the seller’s ratings and return policies to avoid any disappointments.

By exploring these various sources, you can find the necessary components to keep your equipment in peak condition, ensuring reliability and efficiency in all your tasks.

Tips for Long-Term Maintenance

Ensuring the longevity of your equipment requires consistent care and attention. Regular maintenance not only enhances performance but also prevents unexpected breakdowns. By following a few essential practices, you can keep your tool in optimal condition and extend its lifespan.

Firstly, always clean your device after each use. Removing debris, dirt, and residue helps to prevent corrosion and buildup that can affect functionality. Pay special attention to air filters and spark plugs, as these components directly impact performance.

Additionally, regular lubrication of moving parts is crucial. Using the appropriate oils and greases reduces friction, minimizing wear and tear. Follow the manufacturer’s recommendations for lubrication intervals to maintain efficiency.

It’s also advisable to check and replace any worn or damaged parts promptly. Ignoring small issues can lead to more significant problems down the line. Keep a close eye on chains, bars, and other critical components, ensuring they remain in good working order.

Finally, store your equipment properly when not in use. A cool, dry place protects it from environmental factors that could cause damage. Consider using covers or protective cases for added security.