Maintaining your outdoor power equipment is essential for ensuring optimal performance and longevity. Proper care not only enhances efficiency but also extends the life of the machine, reducing the likelihood of unexpected breakdowns. In this guide, we will delve into essential upkeep practices that will keep your device in top condition.

Every piece of machinery requires attention to detail and understanding of its components. By familiarizing yourself with the intricacies of your equipment, you can tackle common issues with confidence. This resource will provide you with step-by-step instructions, useful tips, and insights to help you navigate the maintenance process effectively.

Whether you are a seasoned user or new to the world of outdoor tools, knowing how to manage routine checks and repairs is invaluable. From troubleshooting minor glitches to executing essential adjustments, this guide aims to equip you with the knowledge needed to maintain your equipment successfully. Embrace the challenge and take control of your device’s upkeep with this informative resource.

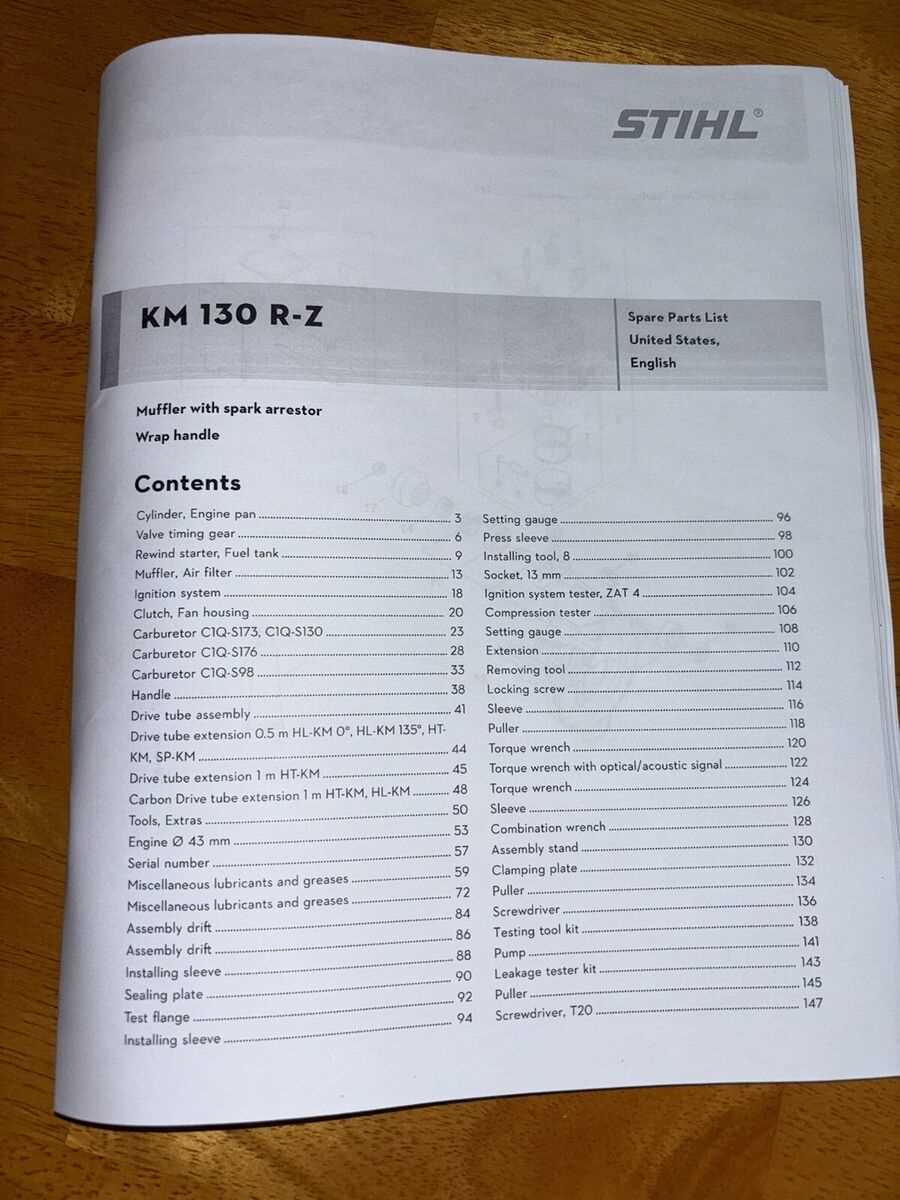

Understanding the Stihl KM 90 R

The KM 90 R is a versatile piece of outdoor equipment designed for a variety of landscaping tasks. Its robust construction and powerful engine make it a reliable choice for both professionals and enthusiasts alike. This machine excels in delivering efficient performance while ensuring ease of use, making it a favorite in the gardening and maintenance community.

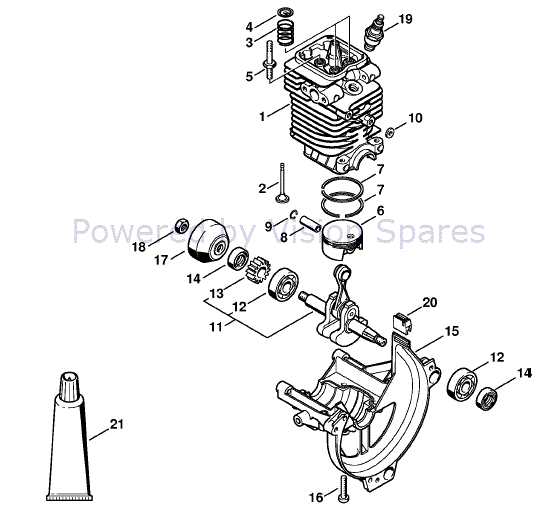

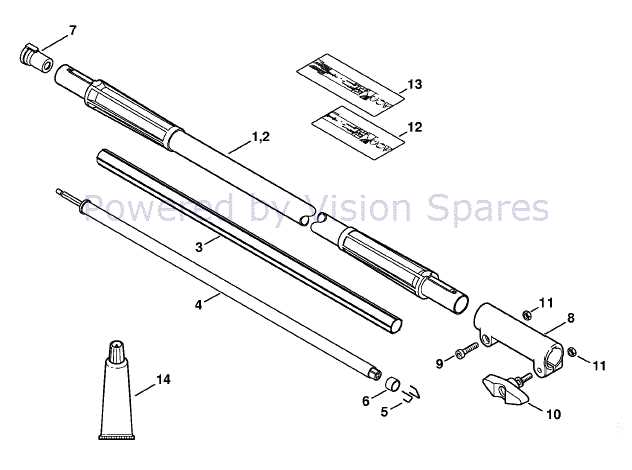

At the heart of this tool is a strong engine that provides impressive power, allowing users to tackle tough jobs with confidence. Its modular design supports various attachments, enabling it to transform into different types of equipment based on specific needs. This adaptability not only enhances functionality but also improves efficiency, as users can switch between tasks without needing multiple machines.

Regular maintenance is crucial for keeping this equipment in optimal condition. Understanding its components and how they work together can significantly extend its lifespan and performance. Users should familiarize themselves with basic operational procedures and safety protocols to ensure a smooth experience.

In summary, the KM 90 R represents a blend of power, versatility, and user-friendly features. Whether for professional landscaping or personal projects, mastering this tool can greatly enhance productivity and satisfaction in outdoor tasks.

Key Features of KM 90 R

The KM 90 R is designed to offer versatility and efficiency for various outdoor tasks. This tool combines power and practicality, making it suitable for both professionals and enthusiasts alike. Here are some of its standout characteristics:

- Powerful Engine: Equipped with a robust engine, it delivers exceptional performance for heavy-duty tasks.

- Modular Design: The interchangeable attachments allow users to customize the tool for specific jobs, enhancing its usability.

- Lightweight Construction: Its design minimizes fatigue during extended use, making it comfortable for users.

- User-Friendly Controls: The intuitive control layout simplifies operation, even for those who are new to outdoor power equipment.

- Durability: Built with high-quality materials, it ensures longevity and reliable performance under various conditions.

These features collectively contribute to making the KM 90 R an invaluable asset for managing landscaping and maintenance tasks efficiently.

Common Issues and Troubleshooting

Understanding typical problems that may arise with outdoor power equipment can significantly enhance its longevity and performance. By familiarizing yourself with common symptoms and their corresponding solutions, you can effectively address minor setbacks before they escalate into major concerns.

1. Difficulty Starting

If the unit fails to start, first check the fuel level and ensure it is fresh. Stale fuel can lead to starting issues. Additionally, inspect the spark plug for wear or damage; replacing it may resolve the problem. Lastly, ensure that all switches are in the correct positions, as an incorrectly set throttle can prevent ignition.

2. Poor Performance

Experiencing a lack of power during operation can be frustrating. This may be caused by a clogged air filter, which restricts airflow. Regularly cleaning or replacing the air filter can improve performance. Additionally, inspect the fuel filter for blockages, as this can affect fuel delivery to the engine.

3. Excessive Vibration

Unusual vibrations during use can indicate a loose component or unbalanced attachment. Check for any loose bolts and tighten them as necessary. Inspect the attachment for wear or damage, as uneven surfaces can lead to excessive shaking. Proper maintenance of these parts is crucial for smooth operation.

4. Leaking Fuel

Fuel leaks can pose safety risks and should be addressed immediately. Examine all fuel lines and connections for cracks or deterioration. If a leak is detected, replace the affected components to prevent further issues. Ensure that the fuel cap is secure, as an improperly sealed cap can also lead to spills.

5. Engine Overheating

Overheating can result from inadequate cooling or overworking the machine. Ensure that the cooling fins are clean and free from debris. If the engine frequently overheats, consider reducing the workload or allowing for more frequent breaks to prevent damage.

By being aware of these common challenges and their solutions, you can maintain optimal functionality and extend the lifespan of your equipment. Regular inspection and proactive care are key to avoiding many of these issues.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right equipment is crucial for achieving optimal results. A well-equipped toolkit not only simplifies the process but also enhances efficiency and precision. The following items are fundamental for anyone looking to ensure their equipment remains in peak condition.

First, a set of screwdrivers in various sizes and types is indispensable for loosening and tightening screws. Additionally, wrenches, both adjustable and fixed, will allow for the handling of nuts and bolts effectively. Pliers are also essential, providing grip and leverage for more intricate tasks.

Next, consider a quality socket set, which offers versatility for different fasteners, and a torque wrench to apply the correct amount of force. Don’t forget about cutting tools such as utility knives or shears, which can aid in handling components with precision.

Finally, safety gear, including gloves and goggles, is necessary to protect yourself during the process. With these tools on hand, you will be well-prepared to tackle any maintenance challenge that arises.

Step-by-Step Maintenance Guide

Regular upkeep of your equipment is essential to ensure its longevity and optimal performance. This section provides a comprehensive approach to maintaining your tools, allowing you to identify issues early and keep everything running smoothly.

Daily Checks

Start each day with a quick inspection. Look for any visible damage, ensure that all components are securely attached, and check fluid levels. A clean machine operates better, so remove any debris or buildup from the exterior and working parts.

Periodic Servicing

In addition to daily checks, schedule more thorough maintenance at regular intervals. This includes changing filters, inspecting spark plugs, and examining belts for wear. Keeping a log of these tasks can help you stay organized and proactive in your maintenance efforts. Always refer to the specific guidelines for your equipment to understand the recommended timelines for each task.

Remember: Preventative care is key to avoiding major issues down the line. By following these steps diligently, you can ensure your tools remain reliable and effective for years to come.

Replacing the Air Filter

Maintaining optimal performance in outdoor power equipment involves regular checks and maintenance of essential components, such as the air filtration system. A clean air filter ensures that the engine receives adequate airflow, promoting efficiency and longevity. This section outlines the steps to effectively change the air filter, a task that can enhance the overall functionality of your device.

Steps for Replacement

To begin the process, ensure that the machine is turned off and disconnected from any power source. Locate the air filter housing, which is typically secured with screws or clips. Carefully remove the housing to access the filter.

Once exposed, take out the old filter and inspect the housing for any debris or dirt. Clean the area if necessary. Insert the new filter, ensuring it fits snugly into place. Reattach the housing securely, making certain that all screws or clips are fastened correctly.

Post-Replacement Check

After replacing the filter, it’s important to perform a quick check. Start the engine and observe its operation. A properly installed filter should allow for smooth performance without any irregular noises or issues. Regularly inspecting and replacing the air filter will contribute significantly to the efficiency and reliability of your equipment.

Inspecting the Fuel System

Ensuring the optimal performance of your outdoor equipment involves a thorough examination of the fuel delivery components. Regular checks can help identify issues that may impede functionality, leading to smoother operation and prolonged service life. A systematic approach is essential for maintaining efficiency and reliability.

Key Components to Examine

During your inspection, focus on the following critical parts of the fuel system:

| Component | Inspection Method | Common Issues |

|---|---|---|

| Fuel Tank | Check for cracks or leaks | Cracks, dirt buildup |

| Fuel Lines | Inspect for wear and damage | Leaks, blockages |

| Filter | Remove and clean or replace | Clogs, contamination |

| Pump | Test for proper function | Failure to deliver fuel |

Maintenance Tips

To ensure your fuel system operates efficiently, follow these maintenance tips:

- Regularly clean the fuel tank to prevent sediment buildup.

- Replace filters as recommended by the manufacturer.

- Store fuel in a cool, dry place to avoid degradation.

- Inspect fuel lines periodically for signs of wear.

Electrical Components Overview

This section delves into the essential electrical parts that play a critical role in the operation of power equipment. Understanding these components is vital for ensuring efficient functioning and longevity of the machinery. Each element contributes to the overall performance and reliability, making it crucial to familiarize oneself with their characteristics and maintenance needs.

- Ignition System: Responsible for starting the engine, this system ignites the fuel-air mixture, ensuring smooth operation.

- Wiring Harness: A network of wires that connects various electrical components, facilitating communication and power distribution throughout the unit.

- Battery: Supplies electrical energy for starting the engine and powering various electronic elements.

- Switches: Control the flow of electricity, allowing users to turn the machine on and off as needed.

- Regulator: Maintains consistent voltage levels, preventing damage to the electrical system from fluctuations.

Each of these components has specific functions and requires periodic checks to ensure they are in good condition. Regular maintenance can help avoid electrical failures and enhance the efficiency of the equipment.

Servicing the Spark Plug

The spark plug plays a crucial role in the overall performance of small engines, ensuring efficient ignition of the air-fuel mixture. Regular maintenance of this component is essential to maintain optimal engine function and longevity.

First, it’s important to disconnect the ignition source to prevent any accidental starts during servicing. Carefully remove the spark plug using a suitable wrench, taking care not to damage the surrounding area. Inspect the plug for signs of wear, such as carbon buildup or electrode erosion. A clean and well-maintained plug promotes better combustion and engine efficiency.

If necessary, clean the spark plug using a wire brush or appropriate solvent to remove deposits. Ensure that the electrode gap is within the manufacturer’s specified range; adjustments can be made using a feeler gauge. Finally, reinstall the spark plug by hand to avoid cross-threading, and tighten it securely, but avoid over-torquing, which could damage the threads.

By keeping the spark plug in good condition, you contribute to the engine’s performance and reliability, ensuring it runs smoothly for longer periods.

Guidelines for Gear Head Maintenance

Proper upkeep of gear heads is essential for optimal performance and longevity of your equipment. Regular attention to this component can prevent premature wear and ensure smooth operation, ultimately enhancing productivity and reducing the risk of breakdowns.

Start by cleaning the gear head regularly to remove dirt and debris that can hinder performance. Use a soft brush and cloth to access hard-to-reach areas, ensuring that no contaminants are trapped inside. Inspect the gear teeth for signs of damage or excessive wear, and address any issues promptly to avoid further complications.

Lubrication is crucial for maintaining functionality. Apply the appropriate lubricant as specified by the manufacturer, ensuring even coverage without overfilling. Regularly check the oil levels and replace old lubricant to maintain efficiency and protect the internal components.

Lastly, ensure that all fasteners are secure and not showing signs of rust or corrosion. Tighten any loose screws or bolts, and replace any damaged parts immediately to maintain the integrity of the gear head. Following these guidelines will help keep your equipment running smoothly and extend its lifespan.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is essential for both the technician and the equipment. Adhering to proper protocols minimizes risks and enhances efficiency. It is crucial to implement precautionary measures before starting any servicing activities.

Personal Protective Equipment

Utilizing personal protective equipment (PPE) is vital for safeguarding against potential hazards. This includes wearing safety goggles to protect your eyes from debris, gloves to prevent cuts and abrasions, and sturdy footwear to provide support and protection. Always ensure that your clothing is appropriate and free from loose ends that could get caught in moving parts.

Work Environment Safety

Creating a secure workspace is equally important. Make sure the area is well-lit and free of clutter. Positioning tools and materials properly can prevent accidents. Additionally, always disconnect the power source before beginning any service to avoid unintended start-ups. Regularly inspect your tools for any wear or damage, as faulty equipment can lead to injuries.

Finding Genuine Stihl Parts

When maintaining and restoring outdoor power tools, sourcing authentic components is crucial for ensuring optimal performance and longevity. Genuine parts are specifically designed to meet the original specifications, providing the reliability that aftermarket alternatives often lack. This section will guide you through the process of locating these essential items, ensuring your equipment operates efficiently.

Where to Look for Authentic Components

To find genuine components, start with authorized dealers or service centers. These locations often carry a comprehensive inventory of parts that adhere to the manufacturer’s standards. Additionally, visiting the official website can provide valuable information on availability and the latest updates. It’s essential to avoid unauthorized vendors, as their products may not meet the necessary quality criteria.

Identifying Original Parts

When searching for components, familiarize yourself with the markings and packaging that indicate authenticity. Genuine products typically have specific logos or part numbers that differentiate them from imitations. Always cross-reference these details with the manufacturer’s documentation to ensure compatibility. Investing time in finding the right parts will ultimately save you money and frustration in the long run.

Tips for Preventative Care

Maintaining your equipment is essential to ensure its longevity and optimal performance. Regular upkeep not only prevents unexpected breakdowns but also enhances efficiency, allowing you to achieve the best results in your tasks. Here are some key practices to keep in mind for effective preventative maintenance.

Regular Cleaning

Keeping your tools clean is crucial. After each use, remove any debris, dirt, or residue that may have accumulated. This prevents build-up that could interfere with performance and leads to rust or corrosion over time. Utilize a soft brush or cloth to wipe down surfaces and check for any signs of wear.

Routine Inspections

Conducting frequent inspections helps identify potential issues before they escalate. Look for loose parts, frayed wires, or cracks in components. Pay attention to fluid levels and replace them as necessary. Establishing a consistent check-up schedule will ensure that your equipment remains in top condition.