Remove larger components systematically to reveal underlying sections, taking care not to

Inspection and Maintenance of Engine Parts

Consistent inspection and care of internal components play a crucial role in ensuring dependable and smooth performance. Regular checks allow for the early identification of wear, potential faults, and the overall condition of vital mechanisms, helping to prevent more significant issues.

Essential Component Examination

Inspecting core parts such as the pistons, crankshaft, and valves is essential for sustained operation. Over time, these elements can accumulate residue or develop minor wear, which may impact functionality. Cleaning and replacing parts as needed will preserve efficiency and prolong the lifespan of the system.

Routine Lubrication and Adjustments

Proper lubrication minimizes friction and keeps parts working effectively. Regular oil changes and ensuring optimal fluid levels are key in preventing overheating and reducing component stress. Additionally, checking and adjusting parts such as belts and g

Reassembly Instructions for Optimal Performance

Reassembling the components with precision ensures the system operates smoothly and efficiently. Attention to alignment and secure fastening will support the longevity and functionality of all interconnected parts.

Essential Steps for Effective Reassembly

For optimal results, follow these steps to ensure all parts work harmoniously:

- Begin with smaller components, ensuring each is clean and free of debris to avoid operational issues.

- Align parts according to markings or reference points, carefully matching them to their original positions.

- Tighten all bolts and screws incrementally, avoiding over-tightening, which can cause undue stress on the parts.

Final Adjust

Lubrication and Cooling System Maintenance

Proper upkeep of lubrication and cooling mechanisms is essential for ensuring optimal performance and longevity of the vehicle’s power unit. Regular checks and maintenance not only prevent overheating and wear but also contribute to overall efficiency.

Routine inspections should include evaluating fluid levels, assessing for leaks, and replacing any worn components. It is crucial to use the appropriate lubricants and coolants, as specified by the manufacturer, to maintain peak operational conditions.

| Component |

Maintenance Task |

Frequency |

| Oil Level |

Check and top off |

Every 1,000 miles |

| Oil Filter |

Replace |

Every 5,000 miles |

| Coolant Level |

Inspect and refill |

Every 1,000 miles |

| Radiator |

Flush and clean |

Every 30,000 miles |

| Hoses and Belts |

Check for cracks and wear |

Every 5,000 miles |

Ensuring that both lubrication and cooling systems are in good working order will help to avoid unnecessary breakdowns and extend the lifespan of the vehicle’s components.

Electrical Wiring and Connection Details

This section delves into the intricate aspects of electrical circuits and interconnections crucial for optimal performance. Understanding these details ensures that all components function harmoniously, contributing to overall efficiency and reliability.

Wiring Schematics: Comprehensive diagrams illustrate the arrangement and interconnection of various elements. Each connection point plays a pivotal role, facilitating seamless energy flow and communication between parts.

Connector Specifications: Proper connectors are essential for secure and effective communication. Ensure that each connector matches the required specifications to prevent issues related to conductivity and signal integrity.

Grounding Techniques: Effective grounding is vital for safety and performance. Adopting the correct grounding methods minimizes electrical interference and protects sensitive components from potential damage.

Voltage and Current Ratings: Adhering to recommended voltage and current ratings for each component is crucial. Overloading can lead to failures and reduce the lifespan of electrical parts, emphasizing the importance of compliance with guidelines.

Maintenance Practices: Regular checks and maintenance of wiring and connections help identify wear or damage early on. Implementing preventative measures ensures continued functionality and reduces the risk of unexpected failures.

Fuel System Calibration and Adjustment

The calibration and adjustment of the fuel delivery system are crucial for optimal performance and efficiency. Proper tuning ensures that the correct amount of fuel is supplied to the combustion chamber, which is essential for achieving the desired power output and minimizing emissions. This process involves fine-tuning various components to achieve the ideal air-fuel ratio.

Calibration involves setting up the system to deliver fuel at the correct pressure and flow rate, while adjustment focuses on modifying specific parameters to enhance performance. Regular checks and adjustments can prevent issues such as poor fuel economy, excessive emissions, and misfires, ultimately prolonging the lifespan of the components involved.

After calibration, perform a series of tests to evaluate the system’s performance. Monitor the air-fuel mixture using diagnostic equipment to ensure it remains within the ideal range. If necessary, make further adjustments to the injector timing and flow rate to enhance efficiency and performance.

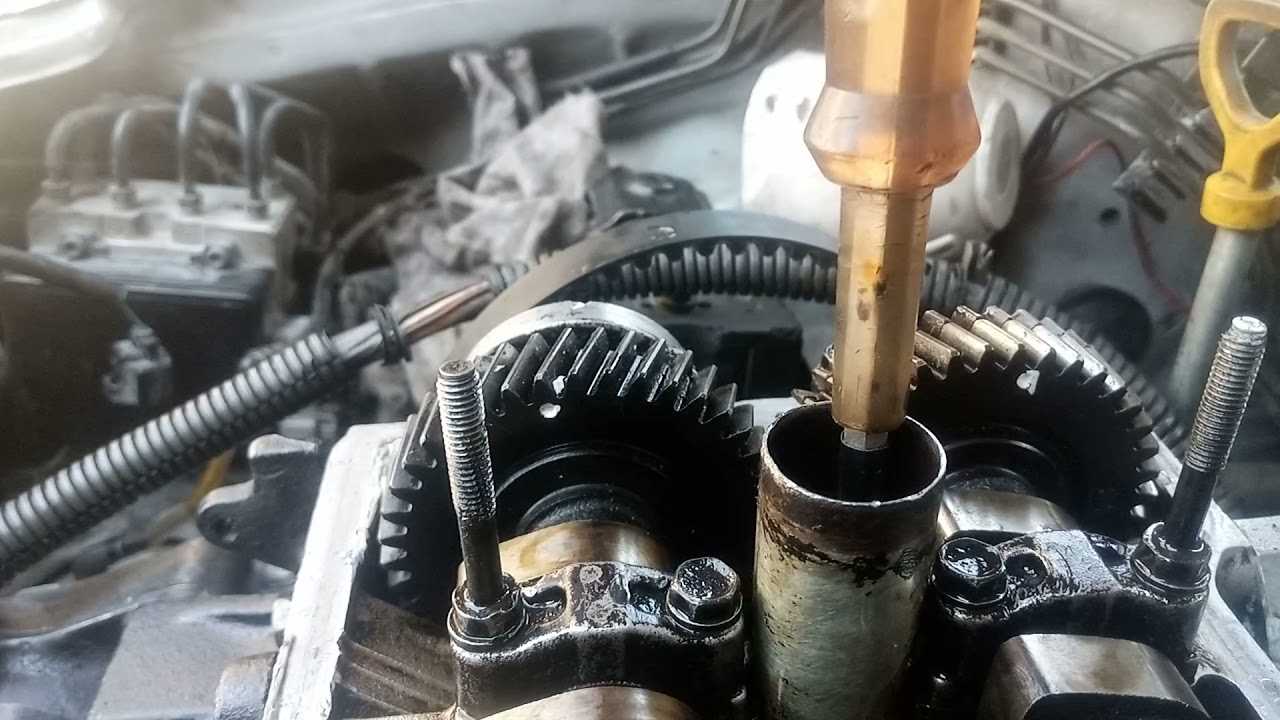

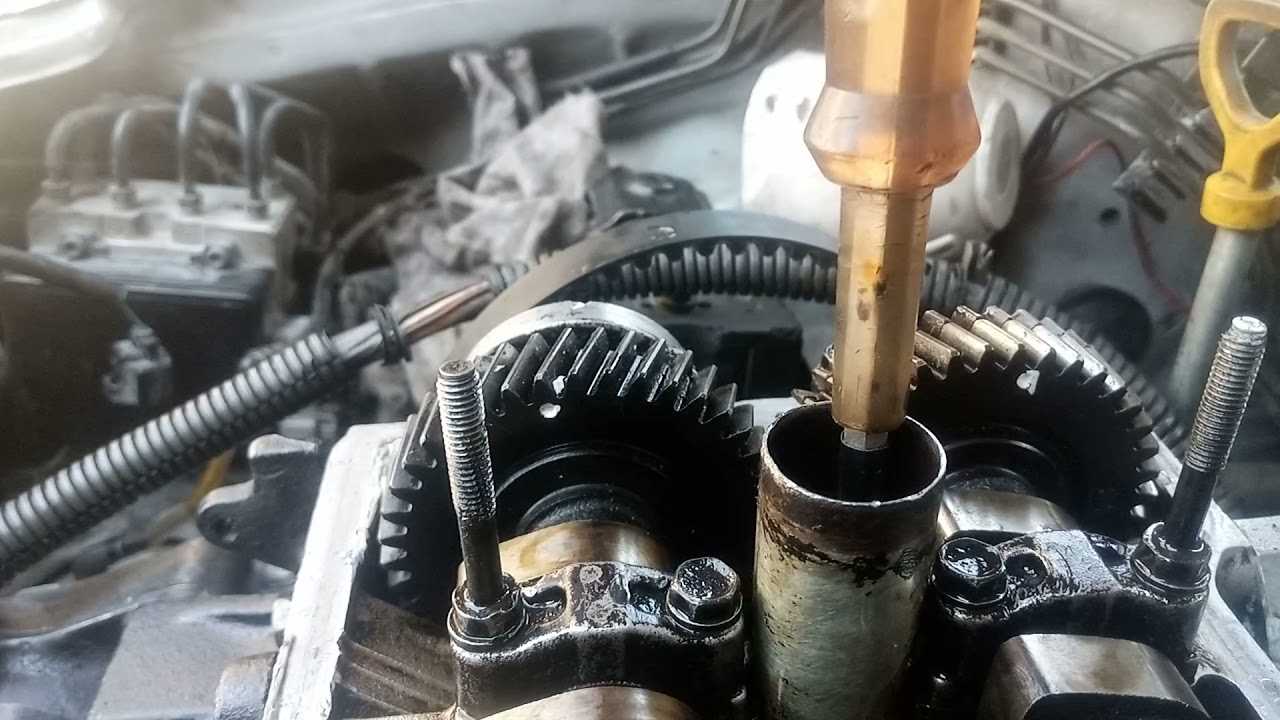

Timing Belt Replacement Procedures

The process of exchanging the timing belt is crucial for maintaining optimal performance and reliability of your vehicle’s powertrain. This task requires careful attention to detail and adherence to specific protocols to ensure proper functioning after the replacement.

Before commencing the procedure, it is essential to gather all necessary tools and components, including the new timing belt, tensioner, and any applicable gaskets. Begin by disconnecting the battery to avoid any electrical mishaps during the process. Then, remove any accessories obstructing access to the belt assembly.

Once the workspace is clear, carefully align the marks on the pulleys and crankshaft to prevent misalignment during reassembly. Loosen the tensioner and remove the old belt, taking note of the routing for accurate installation of the new component. Ensure that the new timing belt is positioned correctly and that the tensioner is appropriately adjusted.

Finally, double-check all alignments and reinstall any accessories that were removed. Reconnect the battery and start the vehicle, observing for any unusual sounds or performance issues. Regularly checking and replacing the timing belt as needed can significantly enhance the longevity and efficiency of your vehicle.

Testing Engine After Repairs

After completing maintenance tasks on a motor, it is essential to assess its performance to ensure that all modifications have been successful and that the unit operates smoothly. This evaluation process helps identify any issues that may have arisen during the work and confirms that the adjustments have restored optimal functionality.

The following steps outline a systematic approach for assessing the performance of the unit:

| Step |

Action |

Notes |

| 1 |

Visual Inspection |

Check for any leaks, loose connections, or irregularities. |

| 2 |

Start-Up Test |

Ensure smooth ignition and listen for abnormal sounds. |

| 3 |

Idle Assessment |

Monitor stability and RPMs during idle conditions. |

| 4 |

Performance Testing |

Conduct acceleration and deceleration tests for responsiveness. |

| 5 |

Diagnostic Check |

Utilize diagnostic tools to identify any error codes or malfunctions. |

Following these steps will help ensure that the motor is functioning correctly and efficiently, allowing for reliable operation moving forward.