Ensuring the optimal performance of heavy machinery is crucial for efficient operations in various industries. Understanding the intricacies of these robust systems allows operators and technicians to maintain equipment effectively, minimizing downtime and enhancing productivity.

The following sections delve into essential practices and strategies for maintaining specific engine models. By familiarizing oneself with the nuances of these systems, users can better troubleshoot issues and implement preventative measures that extend the life of their equipment.

Whether you are a seasoned professional or a newcomer to the field, this guide offers valuable insights that cater to your needs. A comprehensive approach to understanding engine components and their functions will empower you to achieve superior results in your maintenance efforts.

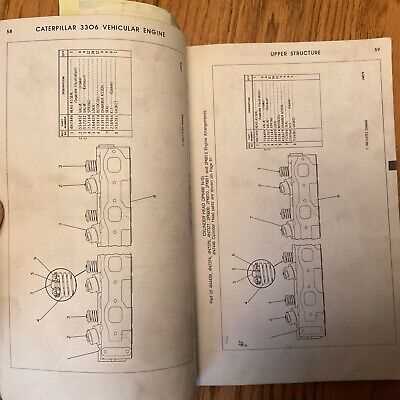

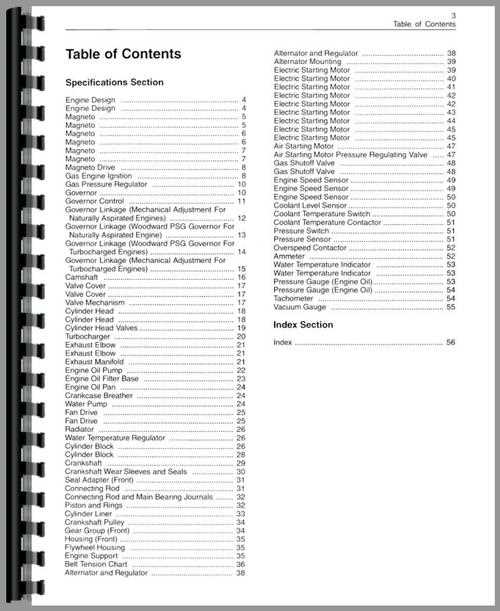

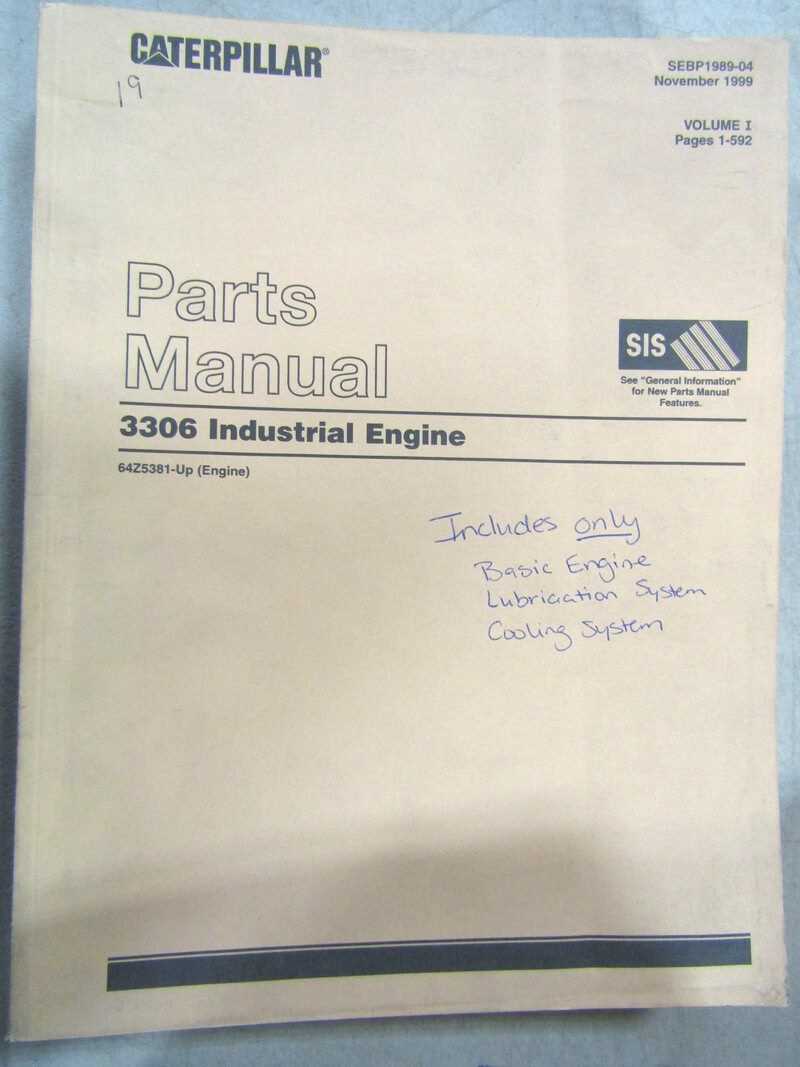

Engine Overview

This section provides a comprehensive insight into a specific engine type known for its reliability and performance in various applications. Understanding the essential features and functionalities of this engine is crucial for effective maintenance and troubleshooting.

The following table summarizes key characteristics of this engine model:

| Feature | Description |

|---|---|

| Type | Six-cylinder, four-stroke engine |

| Displacement | Approximately 10.5 liters |

| Power Output | Ranging from 170 to 300 horsepower |

| Application | Commonly used in construction and industrial equipment |

| Fuel Type | Diesel |

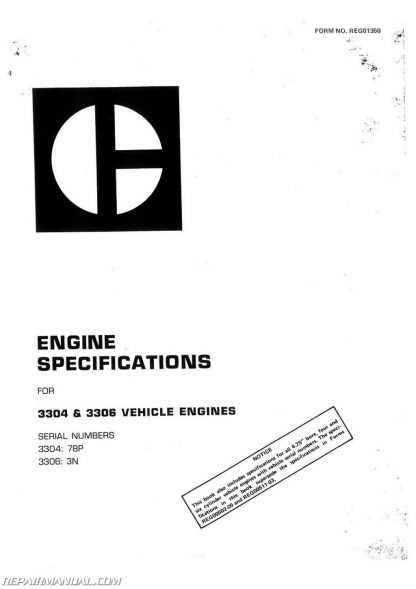

Engine Specifications and Features

This section provides an overview of the vital characteristics and attributes associated with a specific diesel engine model. Understanding these specifications is crucial for optimizing performance and ensuring longevity, making it essential for users and technicians alike.

Engine Type: The power unit is a four-stroke, inline configuration designed for robust performance. It is known for its reliability and efficiency under various operational conditions.

Cylinders: Featuring a specific number of cylinders, this engine type allows for smooth power delivery and enhanced torque characteristics, making it suitable for heavy-duty applications.

Displacement: The engine’s displacement is a critical factor that influences its power output and efficiency. This measurement indicates the total volume of all cylinders and is an essential aspect of engine design.

Power Output: The rated horsepower of this engine model ensures it meets the demands of various machinery and equipment, providing the necessary strength for demanding tasks.

Torque: Maximum torque is achieved at a specific RPM, providing the necessary force for effective operation in challenging environments.

Fuel System: The engine employs a high-pressure fuel injection system, which enhances combustion efficiency and performance, contributing to reduced emissions and improved fuel economy.

Cooling System: A liquid cooling mechanism ensures optimal operating temperatures, preventing overheating and maintaining engine integrity during extended use.

Weight: The overall weight of the unit affects the installation and operational parameters, making it important for users to consider in their specific applications.

Understanding these elements is vital for effective maintenance and operation, enabling users to maximize the potential of their equipment.

Common Issues and Symptoms

Understanding typical challenges encountered with heavy machinery can enhance operational efficiency and prolong service life. Recognizing the signs of potential problems is crucial for timely interventions and maintenance.

- Engine Performance Degradation:

A noticeable decline in power output or acceleration may indicate underlying issues.

- Unusual Noises:

Strange sounds such as knocking or grinding often signal mechanical wear or component failure.

- Excessive Smoke:

Smoke emissions, particularly if they are black or blue, can be indicative of fuel or oil-related problems.

- Overheating:

Consistently high operating temperatures may point to cooling system inefficiencies or blockages.

- Fluid Leaks:

Visible fluid leaks around seals and gaskets can lead to significant operational disruptions if not addressed.

- Starting Difficulties:

Challenges in starting the engine could stem from electrical or fuel delivery system issues.

Addressing these common concerns promptly can prevent further complications and ensure reliable performance.

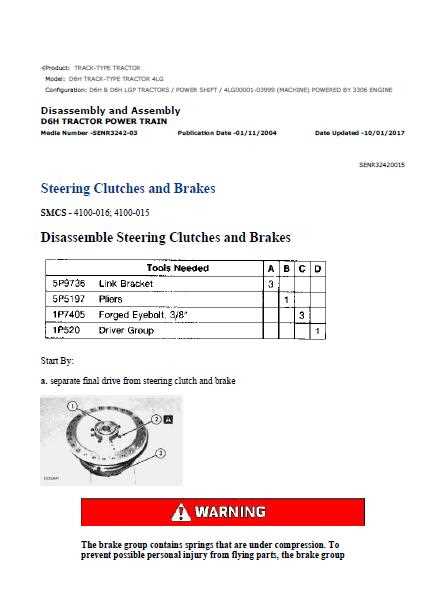

Tools Required for Repairs

When undertaking maintenance tasks, having the right instruments is crucial for achieving optimal results. A well-equipped toolkit enhances efficiency and ensures that each operation can be performed smoothly. Below is an overview of essential tools that facilitate various types of work.

Basic Hand Tools

Starting with the basics, a set of hand tools is fundamental for any mechanical project. This includes wrenches, screwdrivers, and pliers. Each of these tools serves a specific purpose, allowing for precise adjustments and assembly tasks. Investing in high-quality hand tools can significantly improve durability and performance during use.

Diagnostic Equipment

In addition to hand tools, diagnostic instruments are vital for identifying issues effectively. Tools such as multimeters and compression gauges provide valuable insights into the condition of various components. These devices help technicians troubleshoot and resolve problems efficiently, ensuring that machinery operates at peak performance.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of machinery. Following systematic procedures can help prevent issues and maintain efficiency. This section outlines crucial steps to effectively conduct maintenance tasks.

Preparation for Maintenance

- Gather necessary tools and safety equipment.

- Review operational guidelines to understand specific requirements.

- Ensure the machine is turned off and adequately secured.

Maintenance Steps

- Inspect fluid levels, including oil and coolant, and top off as needed.

- Examine filters and replace them if they appear dirty or clogged.

- Check belts and hoses for signs of wear, replacing any damaged components.

- Clean external surfaces to remove dirt and debris, improving cooling and visibility.

- Test all operational functions to ensure everything is working smoothly.

Fuel System Troubleshooting Tips

Effective troubleshooting of the fuel system is essential for maintaining optimal engine performance. Understanding the various components and potential issues can significantly enhance efficiency and reliability. Below are several tips to identify and address common fuel-related problems.

Identifying Fuel Flow Issues

- Check for clogs in fuel filters, which can restrict flow and affect performance.

- Inspect fuel lines for leaks or damage that may lead to pressure loss.

- Ensure the fuel tank has sufficient supply to avoid running on empty.

Examining Fuel Quality

- Test the fuel for contamination, as impurities can hinder proper combustion.

- Verify the fuel grade used matches the engine specifications to ensure compatibility.

- Monitor for signs of water in the fuel, which can lead to serious operational issues.

Electrical System Diagnostics

The evaluation of the electrical system in heavy machinery is crucial for ensuring optimal performance and reliability. Proper diagnostics allow technicians to identify issues, prevent potential failures, and maintain operational efficiency. This section outlines the fundamental principles and methodologies for assessing electrical components.

Common Issues and Symptoms

Several common problems may arise within the electrical framework of machinery. These issues can manifest as inconsistent starting, erratic behavior of gauges, or complete power failure. Recognizing these symptoms early is essential for effective troubleshooting.

Diagnostic Techniques

Utilizing specialized tools and techniques is vital for accurate assessment. Multimeters are indispensable for measuring voltage, current, and resistance, while oscilloscopes can provide insights into waveforms and signal integrity. Additionally, following a systematic approach, including visual inspections and component testing, enhances the likelihood of identifying underlying issues.

Cooling System Maintenance Guidelines

Maintaining the cooling system is essential for optimal performance and longevity of any engine. Regular checks and preventive measures can significantly reduce the risk of overheating and related issues, ensuring smooth operation during use.

Routine Inspection

Frequent inspections of the cooling components are vital. Focus on the following:

- Check coolant levels and top up if necessary.

- Inspect hoses for signs of wear or leaks.

- Examine the radiator for blockages or debris.

- Look for any signs of corrosion or damage on cooling components.

Coolant Quality and Replacement

Using the correct type of coolant is crucial for effective heat transfer and protection against freezing or boiling. Follow these guidelines:

- Use a high-quality coolant suitable for the engine’s specifications.

- Replace coolant according to the recommended schedule or if it appears discolored.

- Flush the cooling system periodically to remove contaminants.

Replacement Parts and Recommendations

When maintaining heavy machinery, ensuring the use of high-quality components is essential for optimal performance and longevity. Selecting appropriate substitutes not only enhances efficiency but also minimizes downtime caused by mechanical failures.

Quality Components

It is advisable to choose parts that meet or exceed original specifications. This guarantees compatibility and reliability. Aftermarket options can be a cost-effective alternative, but careful consideration should be given to the manufacturer’s reputation and product reviews.

Maintenance Tips

Regular inspections and timely replacements of worn components can prevent larger issues down the line. Establish a routine to check vital systems and replace any failing parts promptly. Additionally, utilizing genuine parts whenever possible ensures that machinery operates as intended.

Preventive Measures for Longevity

Ensuring the extended lifespan of machinery involves implementing strategic actions that promote optimal performance and minimize wear and tear. Regular maintenance routines, along with careful monitoring of operational conditions, are essential to achieving this goal.

Regularly inspecting components and systems can help identify potential issues before they escalate into significant problems. Keeping all parts well-lubricated and free from debris contributes to smoother operation and reduces the risk of breakdowns. Additionally, adhering to recommended service intervals enhances reliability and efficiency.

Training operators on proper usage techniques is vital for preventing misuse that could lead to premature damage. Utilizing quality fuels and lubricants is another key factor, as inferior products can compromise performance and lead to costly repairs. Maintaining a clean working environment further supports longevity by preventing contaminants from affecting sensitive areas.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and troubleshooting for heavy machinery engines. Here, you’ll find valuable insights to assist you in resolving typical issues and enhancing the longevity of your equipment.

- What are the signs that maintenance is needed?

Common indicators include unusual noises, decreased performance, or warning lights on the dashboard. Regular checks can help identify issues early.

- How often should I perform routine inspections?

It is advisable to conduct inspections at regular intervals, typically every 250 to 500 hours of operation, depending on the manufacturer’s guidelines.

- What type of oil should be used?

Using the correct oil type is crucial for optimal performance. Always refer to the equipment specifications for the recommended oil viscosity and grade.

- How can I improve fuel efficiency?

Fuel efficiency can be enhanced through regular maintenance, proper calibration, and ensuring that the engine is not overloaded.

- What should I do if I encounter an error code?

First, consult the diagnostic guide to understand the error. If necessary, seek assistance from a qualified technician for further evaluation.