Proper upkeep of equipment is essential for ensuring longevity and optimal performance. This section delves into essential practices that can help maintain machinery in peak condition. By following recommended procedures, users can prevent common issues and enhance the overall functionality of their devices.

Detailed instructions and troubleshooting tips will be explored to equip users with the knowledge necessary for effective care. Emphasizing the importance of routine checks and timely interventions can significantly impact the reliability of your equipment.

Learning about maintenance strategies can empower users to tackle minor challenges independently. By being proactive, individuals can save time and resources, fostering a more efficient and enjoyable experience with their machinery.

This section provides an introduction to the specific model, highlighting its design features and overall functionality. Understanding these elements is essential for users seeking to maintain or troubleshoot their equipment effectively.

Key Features

- Durable construction for longevity

- User-friendly controls for ease of operation

- Efficient performance tailored for various tasks

Intended Use

The model is designed for a range of applications, making it suitable for both residential and commercial use. Its versatility allows users to tackle different projects with confidence.

Common Issues and Solutions

In any mechanical device, users may encounter various challenges that can hinder performance or functionality. This section aims to provide insights into frequently observed problems and their corresponding remedies. By understanding these issues, users can enhance the longevity and efficiency of their equipment.

One common issue is difficulty in starting the engine, which may stem from fuel supply problems or battery issues. Ensuring that the fuel is fresh and the battery is fully charged can often resolve this concern.

Another frequent problem involves uneven cutting, which can result from dull blades or incorrect height settings. Regular maintenance of blades and proper adjustment of cutting heights will help achieve a uniform cut.

Users may also experience issues with overheating. This can be addressed by checking the cooling system and ensuring that vents are clear of debris, allowing for proper airflow.

By addressing these common problems proactively, users can maintain optimal performance and extend the lifespan of their machinery.

Maintenance Tips for Longevity

Ensuring the durability of your equipment involves regular upkeep and attention to detail. By following simple yet effective practices, you can significantly extend the lifespan and efficiency of your machinery.

Regular Cleaning

Keeping your equipment clean is essential. Accumulated dirt and debris can lead to malfunctions and reduce performance. Schedule periodic cleaning sessions to remove any buildup, focusing on critical components to maintain optimal functionality.

Periodic Inspections

Conducting routine checks allows you to identify potential issues before they escalate. Look for signs of wear and tear, and address any concerns immediately. By being proactive, you can avoid costly repairs and ensure smooth operation for years to come.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of any machinery. A well-equipped toolkit not only streamlines the process but also enhances efficiency, ensuring that tasks are completed with precision and ease.

Basic Equipment Needed

To start, a selection of fundamental tools is necessary. These include items that cater to various functions, enabling users to tackle different issues that may arise.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For fastening and loosening screws |

| Wrench | For tightening or loosening nuts and bolts |

| Pliers | For gripping, twisting, and cutting |

Advanced Tools for Complex Tasks

In addition to basic tools, having access to specialized equipment can greatly assist in more intricate tasks. These tools provide enhanced functionality and precision, which can be vital in complex situations.

| Tool | Use |

|---|---|

| Multimeter | For measuring voltage, current, and resistance |

| Torque Wrench | For applying specific torque to fasteners |

| Diagnostic Scanner | For identifying issues in electronic systems |

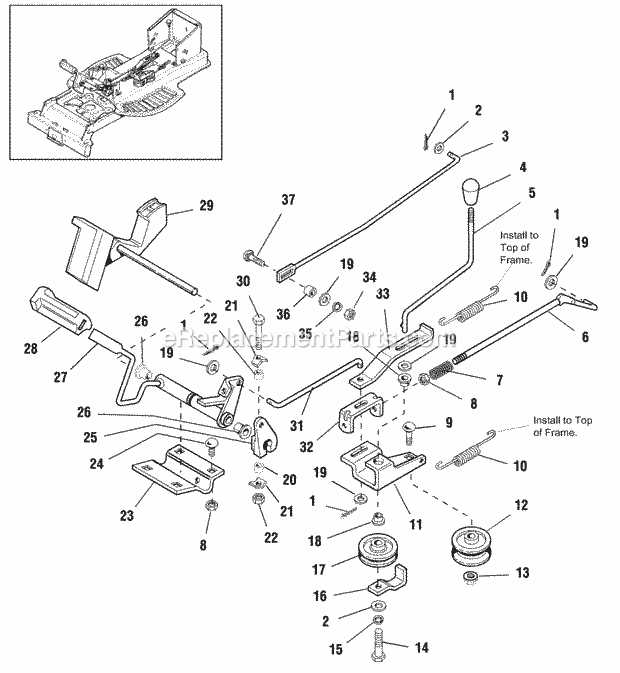

Step-by-Step Repair Procedures

This section provides a comprehensive guide for performing necessary maintenance tasks. Each stage is outlined clearly to ensure that individuals can follow along easily, facilitating a smooth process.

Begin by gathering all essential tools and components. Ensure that the workspace is organized and free from any distractions. Following this, identify the areas that require attention and assess the situation thoroughly.

Next, carefully disassemble the relevant parts, taking note of each step to avoid confusion during reassembly. It is crucial to handle each component with care to prevent damage. Once disassembly is complete, inspect each piece for wear or faults.

After inspection, clean the components thoroughly to remove any debris or buildup. This will help ensure optimal functionality once everything is reassembled. Replace any damaged parts with new ones, making sure they fit correctly.

Finally, reassemble the unit by reversing the disassembly steps. Double-check that all components are securely in place and function as intended before concluding the process. This methodical approach will contribute to the longevity and efficiency of the equipment.

Parts Replacement Guide

This section provides essential information for the effective exchange of components in your equipment. Understanding the replacement process can enhance the performance and longevity of your device.

When considering the swap of any part, ensure you have the correct specifications and tools at hand. Begin by consulting the relevant documentation to identify compatible components.

Once you have the necessary parts, proceed with caution. Disconnect the power source and carefully remove the old component, taking care not to damage surrounding areas. Install the new part by reversing the removal process, ensuring all connections are secure.

After installation, perform a thorough check to confirm functionality. Regular maintenance and timely replacements can prevent further issues and maintain optimal performance.

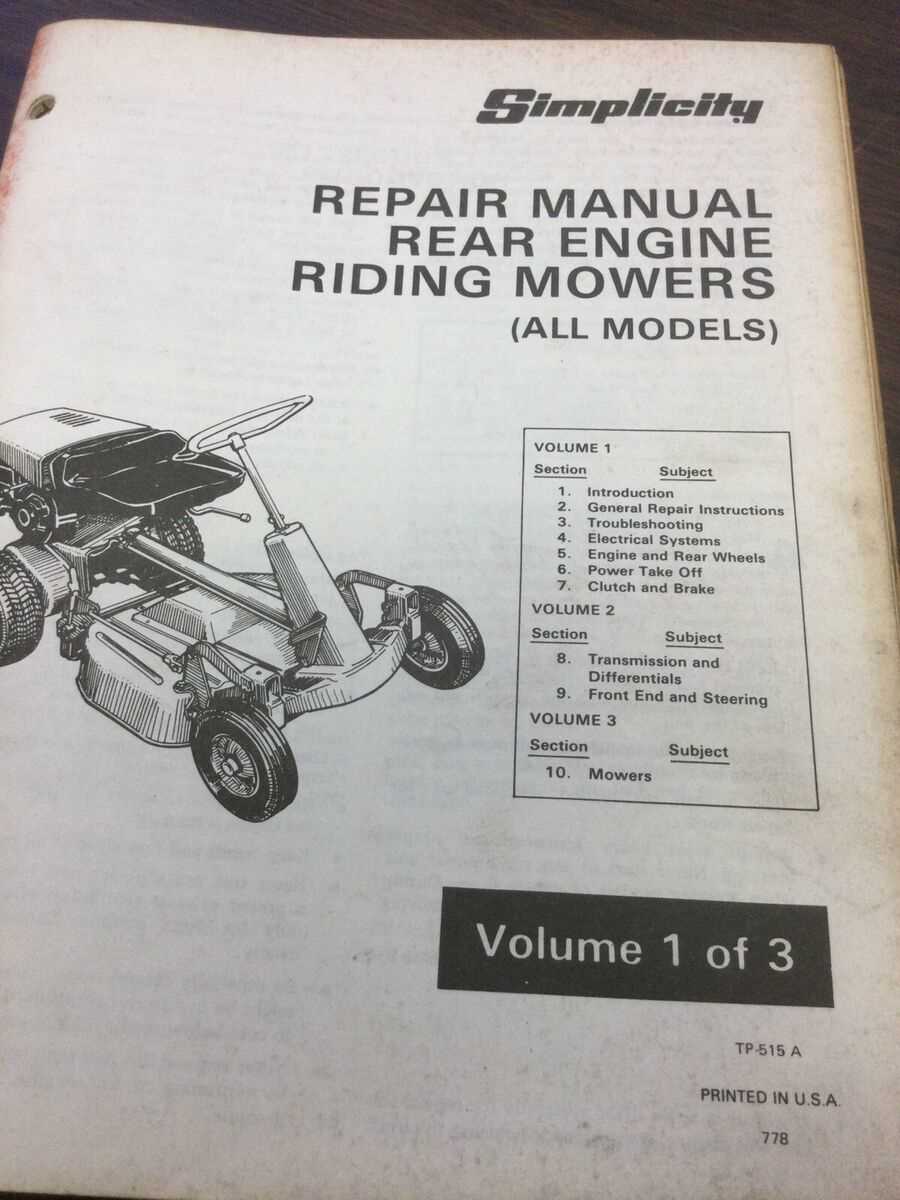

Understanding the User Manual

This section aims to provide clarity on how to navigate the instructional document effectively. By grasping its structure and the information presented, users can ensure they fully utilize the features and functionalities of the product.

Key Components

Each section of the document serves a specific purpose, guiding the user through various aspects of the device. Familiarity with these components can enhance the overall experience.

| Component | Description |

|---|---|

| Introduction | An overview of the product and its main features. |

| Setup Instructions | Step-by-step guidelines for initial configuration. |

| Troubleshooting | Common issues and their solutions. |

| Maintenance Tips | Recommendations for keeping the device in optimal condition. |

Navigating the Document

Understanding how to locate specific information quickly can save time and effort. Users are encouraged to familiarize themselves with the table of contents and index to enhance their efficiency.

Frequently Asked Questions

This section aims to address common inquiries that users may have regarding the maintenance and troubleshooting of their equipment. Understanding these aspects can greatly enhance the overall experience and functionality of the device.

What should I do if the device does not start?

If you encounter issues with powering on the unit, first ensure that it is properly connected to a power source. Check for any visible damage to the cord and ensure that any switches are in the correct position. If the problem persists, consulting the guidelines may provide additional troubleshooting steps.

How often should I perform maintenance?

Regular upkeep is essential for optimal performance. It is generally recommended to carry out maintenance checks at least once every season. This includes cleaning components and inspecting for wear and tear. Adhering to a consistent maintenance schedule can help prolong the life of the device.

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking maintenance tasks. Proper precautions help prevent accidents and injuries, creating a secure environment for all involved.

Before starting any work, it’s essential to wear appropriate personal protective equipment. This includes gloves, goggles, and sturdy footwear to safeguard against potential hazards.

Additionally, always ensure that the equipment is turned off and disconnected from any power source. This simple step significantly reduces the risk of electric shocks and other dangerous situations.

It’s advisable to maintain a clean workspace, free of clutter and distractions, to promote focus and efficiency. Lastly, familiarizing yourself with the tools and their proper usage is crucial for a successful and safe procedure.

Troubleshooting Electrical Problems

Identifying and resolving electrical issues is crucial for maintaining optimal functionality. This section outlines common challenges and effective strategies for diagnosis and resolution, ensuring that your equipment operates smoothly.

Common Symptoms and Diagnosis

Electrical malfunctions can manifest in various ways, such as inconsistent power supply or unexpected shutdowns. Observing these signs is essential for pinpointing the root cause. Start by checking the connections and ensuring that all components are properly secured. Visual inspections can reveal loose wires or signs of wear that may contribute to the problem.

Effective Solutions

Once the issue is identified, several steps can be taken to remedy it. For instance, replacing faulty components may restore functionality. Additionally, ensuring that all electrical connections are clean and secure can prevent future disruptions. Regular maintenance and periodic checks are vital for avoiding recurring issues.

Finding Professional Help

When facing challenges with your equipment, seeking assistance from experts can be crucial. Professional support ensures that any issues are diagnosed accurately and resolved efficiently. Understanding when to turn to skilled technicians can save time and prevent further complications.

Signs You Need Expert Assistance

- Persistent problems that do not resolve with basic troubleshooting.

- Unusual noises or smells emanating from the machine.

- Components that appear damaged or worn out.

- Frequent breakdowns or performance issues.

How to Choose the Right Professional

- Research local service providers and read reviews.

- Check for certifications and experience in handling similar equipment.

- Request estimates to compare costs and services offered.

- Ask for recommendations from trusted sources.

Warranty and Service Information

This section provides essential details regarding the coverage and maintenance support for your equipment. Understanding the terms of your warranty and the available service options is crucial for ensuring optimal performance and longevity of your device.

Coverage Details

The warranty typically includes protection against manufacturing defects and may cover repairs or replacements during the specified period. It is important to review the specific terms to know what is included and any actions that may void the warranty.

Service Options

For servicing your equipment, authorized service centers are available to provide expert assistance. Regular maintenance and prompt repairs can enhance the operational efficiency of your device. Be sure to keep all documentation for warranty claims and service records.