For enthusiasts and professionals alike, maintaining your crafting equipment is essential for optimal performance. This guide provides invaluable insights into troubleshooting and enhancing the functionality of your beloved apparatus. Whether you encounter minor glitches or more complex issues, a clear understanding of the mechanisms at play can empower you to resolve concerns effectively.

Throughout this section, we will explore the intricacies of your device, offering step-by-step instructions to address common challenges. From adjusting settings to replacing components, you’ll find practical advice tailored to elevate your crafting experience. With a little patience and the right knowledge, you can ensure that your apparatus remains a reliable partner in your creative endeavors.

As you delve into the specifics, remember that familiarity with your tool is key to its longevity. This guide not only aims to assist in fixing problems but also seeks to enhance your overall appreciation of the craftsmanship involved in your creative process. Embrace the journey of learning, and you’ll discover the joy of mastering your instrument.

Understanding Janome Sewing Machines

This section aims to provide insights into the intricacies of a popular brand known for its innovative stitching devices. By exploring their features, users can gain a deeper appreciation for their functionality and versatility.

Key aspects to consider include:

- Features: Various models offer distinct capabilities, from basic to advanced options.

- Design: Ergonomic structures enhance usability and comfort during operation.

- Technology: Incorporation of modern innovations improves efficiency and precision.

- Maintenance: Regular care ensures longevity and optimal performance.

Understanding these elements can significantly enhance the user experience, making the operation more enjoyable and effective.

- Explore Different Models: Each variant comes with unique specifications.

- Learn about Accessories: Attachments can expand the capabilities of the devices.

- Utilize Available Resources: Online tutorials and community forums can provide valuable tips.

By delving into these areas, enthusiasts and professionals alike can maximize their potential and creativity in various textile projects.

Common Issues with Janome Models

Many users encounter various challenges when operating their fabric crafting devices. Understanding these frequent problems can help in diagnosing and resolving them efficiently, ensuring a smoother crafting experience.

One of the most prevalent concerns is thread tension that can cause inconsistent stitching. If the thread is either too tight or too loose, it may lead to puckering or thread breakage. Adjusting the tension settings usually resolves this issue.

An additional challenge is the needle getting dull or damaged over time, which can result in skipped stitches or fabric snags. Regularly changing the needle based on the type of fabric being used is essential for optimal performance.

Users often report issues with fabric feeding, where the material does not move smoothly through the apparatus. This can be due to a dirty feed dog or incorrect presser foot pressure. Cleaning and adjusting these components typically rectifies the problem.

Another common situation involves the power supply. If the device fails to turn on or operates intermittently, it may be due to a faulty power cord or a blown fuse. Inspecting these elements can often reveal the source of the problem.

Lastly, inconsistent bobbin winding is frequently mentioned. If the bobbin is not wound correctly, it can lead to poor stitching performance. Ensuring proper winding technique can help alleviate this concern.

Basic Tools for Sewing Machine Repair

Having the right instruments is crucial for maintaining and fixing any textile apparatus. A well-equipped toolkit ensures that any issues can be addressed efficiently, extending the lifespan of your equipment and enhancing its performance.

Here’s a list of essential tools you should have on hand:

- Screwdrivers: Various sizes of flathead and Phillips screwdrivers are necessary for loosening and tightening screws.

- Wrenches: Adjustable wrenches help in managing nuts and bolts, allowing for precise adjustments.

- Pliers: Needle-nose pliers are great for gripping small components or reaching tight spaces.

- Oiler: A small bottle of sewing lubricant keeps moving parts running smoothly and prevents wear.

- Cleaning brushes: A set of brushes helps remove lint and dust from delicate areas, ensuring optimal operation.

In addition to these, consider having:

- Replacement needles: Always keep a variety of needle sizes to accommodate different fabrics.

- Thread: Quality thread in multiple colors can be useful for various fixes and adjustments.

- Fabric scissors: Sharp scissors are essential for cutting threads and fabric as needed.

- Manuals or guides: Reference materials can provide valuable insights into specific issues and solutions.

By assembling these basic tools, you can confidently tackle any challenges that may arise with your textile apparatus.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues that may arise during usage. By following systematic steps, you can efficiently diagnose problems and implement effective solutions, ensuring optimal functionality.

-

Identify the Problem: Begin by observing the symptoms. Common issues may include:

- Unusual noises

- Skipping stitches

- Thread bunching

- Inconsistent tension

-

Check the Threading: Ensure that the thread is correctly threaded through all necessary guides and tension discs. Improper threading can lead to many issues.

-

Inspect the Needle: A bent or dull needle can cause various complications. Replace it with a new, appropriate needle for your tasks.

-

Examine the Bobbin: Remove the bobbin and check for any tangles or improper placement. Rewind or replace the bobbin if necessary.

-

Adjust Tension Settings: Experiment with the tension settings to see if that resolves issues with stitching. Both upper and lower tensions should be adjusted as needed.

-

Clean and Lubricate: Regular maintenance is crucial. Clean the interior and exterior components, and apply lubrication where required to ensure smooth operation.

-

Consult Documentation: If problems persist, refer to the instructional guide for troubleshooting specific issues and follow any provided recommendations.

-

Seek Professional Assistance: If you are unable to resolve the problem, it may be time to consult a professional for further evaluation and support.

Replacing a Broken Needle

When a needle becomes damaged, it can hinder your crafting process significantly. Addressing this issue promptly is essential for maintaining the functionality of your equipment and ensuring a smooth workflow. Below are the steps to effectively substitute a defective needle with a new one.

Follow these guidelines to ensure a successful replacement:

| Step | Description |

|---|---|

| 1 | Unplug the device to ensure safety while working. |

| 2 | Locate the needle holder and gently loosen it using the appropriate tool. |

| 3 | Carefully remove the broken needle from the holder. |

| 4 | Insert the new needle with the flat side facing the correct direction. |

| 5 | Tighten the needle holder securely to ensure stability during use. |

| 6 | Plug the device back in and perform a test to confirm proper operation. |

By following these steps, you can efficiently replace a broken component, helping to enhance your creative experience.

Cleaning and Maintenance Techniques

Regular upkeep and proper cleaning are essential for ensuring the longevity and optimal performance of your equipment. Implementing effective techniques not only enhances functionality but also prevents potential issues that may arise from neglect.

Routine Cleaning Steps

Start by carefully removing any dust and debris that may accumulate in the components. Use a soft brush or a lint-free cloth to gently wipe down surfaces. It’s crucial to pay attention to crevices where particles can gather. Additionally, lubricate moving parts as recommended to maintain smooth operation.

Storage Best Practices

When not in use, store your equipment in a dry and dust-free environment. Consider using a protective cover to shield it from environmental factors. Ensure that the workspace is organized, as this reduces the risk of accidental damage and keeps everything in optimal condition for your next project.

How to Adjust Tension Settings

Finding the right balance in thread tension is crucial for achieving flawless results in your fabric projects. Proper adjustments can significantly enhance stitch quality, ensuring that both the upper and lower threads interlock perfectly.

To begin, locate the tension dial, usually situated on the front or side of the device. This dial typically ranges from a lower to a higher numerical value, indicating varying levels of tightness. If stitches appear loose or uneven, consider increasing the tension by turning the dial clockwise. Conversely, if the fabric puckers, reduce the tension by turning it counterclockwise.

After adjusting the settings, it’s essential to test on a scrap piece of similar material. This practice allows you to observe the results and make further refinements as necessary. Keep in mind that different fabrics may require distinct tension adjustments to achieve optimal outcomes.

Remember, patience is key. It may take several attempts to find the ideal tension that produces clean and professional-looking stitches.

Fixing Bobbin and Thread Problems

Issues with the bobbin and thread can disrupt the flow of any crafting project, leading to frustration and delays. Understanding the common problems associated with these components is essential for a smooth sewing experience. This section will address various concerns and provide effective solutions to ensure consistent performance.

Common Issues and Their Causes

Several factors can contribute to difficulties with the bobbin and thread. Inconsistent tension, improper threading, or a misaligned bobbin can lead to tangled threads or uneven stitches. Regular maintenance and proper setup are crucial for avoiding these challenges.

Solutions for Smooth Operation

To resolve thread-related issues, first check the threading path, ensuring that it is correctly threaded through all necessary guides. Adjust the tension settings according to the fabric type being used. Additionally, ensure that the bobbin is wound evenly and installed properly. For persistent problems, consider replacing worn components to restore optimal functionality.

Upgrading Machine Parts and Accessories

Enhancing the components and add-ons of your equipment can significantly improve its functionality and performance. By carefully selecting upgraded parts, you can tailor your device to better meet your needs and preferences.

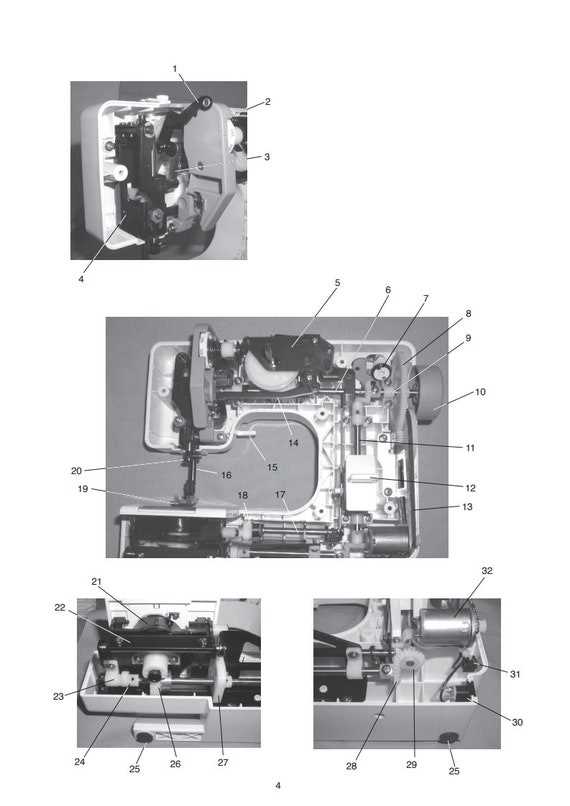

Identifying Key Components is essential when considering upgrades. Focus on parts that directly affect efficiency, such as the needle holder, feed dogs, and presser feet. Each of these elements plays a vital role in the overall operation and can be customized to enhance your experience.

Choosing Quality Add-ons is equally important. Invest in accessories that offer versatility and ease of use, such as specialty feet for various tasks. These enhancements can open up new creative possibilities and streamline your workflow.

Finally, regular maintenance of upgraded parts is crucial to ensure longevity and optimal performance. Establishing a routine check-up schedule can prevent wear and tear, helping your device continue to operate smoothly over time.

When to Seek Professional Help

There are instances when addressing issues on your own may not yield the desired results. Understanding when to reach out for expert assistance can save time and prevent further complications.

Recognizing signs of complex problems is crucial. If you encounter persistent malfunctions that are beyond basic adjustments, it may be time to consult a skilled technician. Additionally, if you notice unusual noises or vibrations, seeking professional insight is advisable.

Do not hesitate to ask for help if you feel uncertain about tackling a specific issue. In some cases, attempting to resolve technical difficulties without proper knowledge can lead to more significant damage. Prioritizing the health of your equipment ensures longevity and optimal performance.

Resources for Janome Owners

This section provides valuable information and tools for individuals who own a particular brand of textile devices. These resources can help users enhance their experience and troubleshoot common issues effectively.

- Official Website: The primary source for the latest updates, user guides, and troubleshooting tips.

- User Forums: Online communities where enthusiasts share experiences, solutions, and creative ideas.

- YouTube Tutorials: Video guides that cover everything from basic operations to advanced techniques.

- Social Media Groups: Platforms where owners connect, share tips, and support each other.

- Local Workshops: In-person classes that offer hands-on training and expert advice.

Utilizing these resources can greatly improve proficiency and enjoyment while working with these versatile devices.

Safety Tips for Sewing Machine Use

Ensuring safety while engaging in textile projects is crucial for a smooth and enjoyable experience. Adhering to certain guidelines can prevent accidents and promote a secure environment.

Workspace Organization

Maintain a clutter-free area to minimize distractions and hazards. Keep tools and materials neatly arranged, ensuring easy access and reducing the risk of tripping or accidental injuries.

Proper Handling Techniques

Always handle equipment with care. Avoid wearing loose clothing or accessories that could become entangled. Additionally, familiarize yourself with the operating procedures and safety features to enhance your confidence and skill.