Keeping your outdoor machinery in optimal condition is essential for ensuring a lush and healthy lawn. Understanding the various components and their functions allows you to tackle issues effectively, enhancing the longevity and performance of your tools. This section serves as a comprehensive overview to assist you in navigating common challenges that arise with your gardening equipment.

Whether you are dealing with minor glitches or more significant malfunctions, having a systematic approach can simplify the troubleshooting process. The insights provided here aim to empower you with the knowledge necessary to identify problems swiftly and implement practical solutions. With the right information at hand, even the most daunting tasks can become manageable.

Equipped with essential tips and strategies, you will learn how to maintain and restore your machinery with confidence. By focusing on straightforward techniques and preventative measures, you can keep your equipment running smoothly, ultimately leading to a more enjoyable and efficient gardening experience.

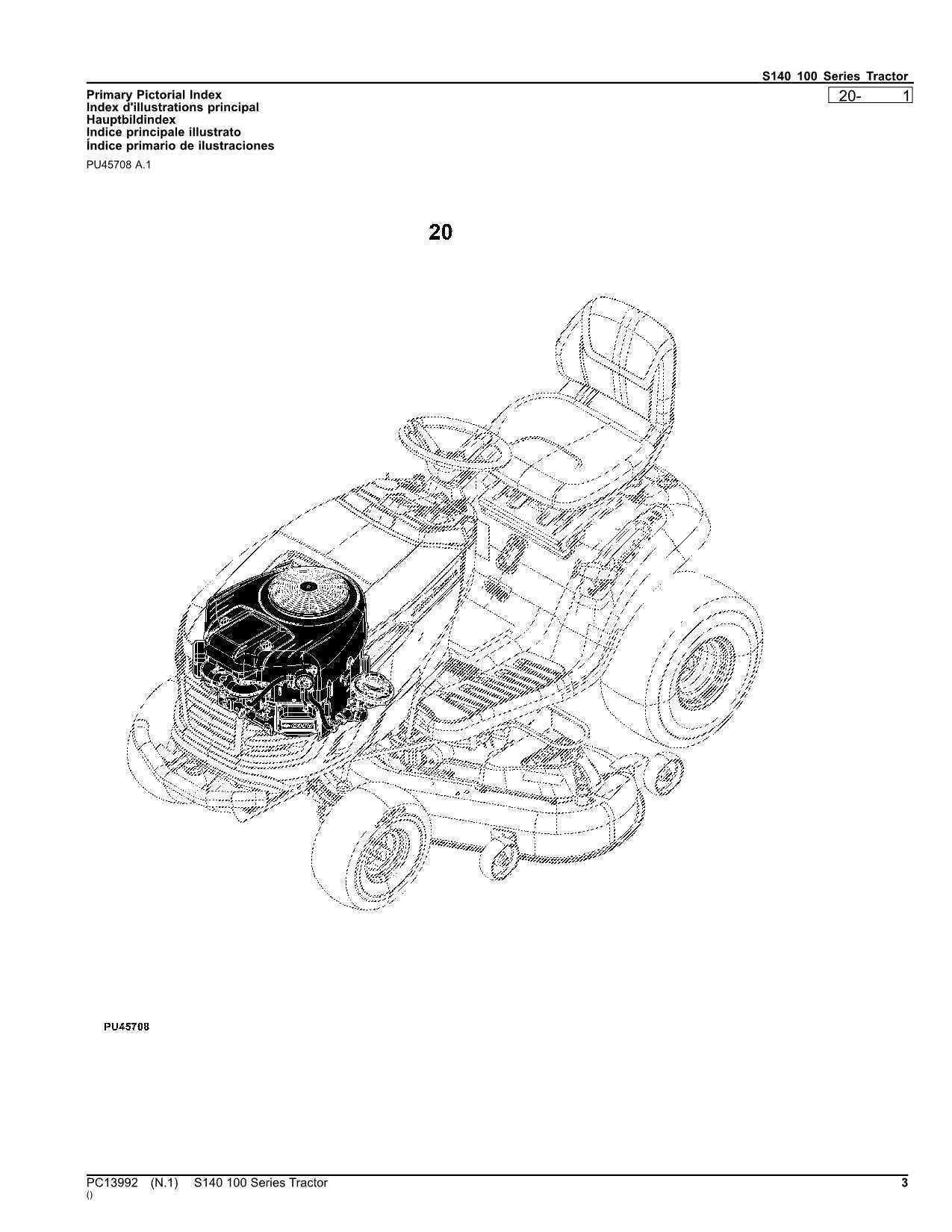

Simplicity Mower Repair Manual Overview

This section provides a comprehensive guide aimed at helping users maintain and troubleshoot their lawn equipment. Understanding the basics can significantly extend the lifespan of your machine and enhance its performance.

Key topics covered include:

- Common issues and their solutions

- Essential tools for maintenance

- Step-by-step guidance for various tasks

- Safety precautions to keep in mind

Whether you’re a seasoned user or a beginner, this resource is designed to empower you with the knowledge needed for effective care and enhancement of your equipment.

Regular upkeep can prevent major malfunctions, ensuring that your device operates smoothly throughout the season. By familiarizing yourself with the intricacies of your equipment, you can tackle minor problems before they escalate.

Consider the following tips for effective management:

- Inspect your equipment regularly for wear and tear.

- Follow the manufacturer’s guidelines for maintenance schedules.

- Keep a log of any issues and repairs performed.

- Utilize recommended parts and fluids for optimal performance.

In summary, this guide serves as a valuable asset for anyone looking to enhance their skills in caring for lawn machinery, ensuring it remains in peak condition for years to come.

Essential Tools for Mower Repair

When it comes to maintaining outdoor equipment, having the right instruments is crucial for effective upkeep and troubleshooting. Whether you’re tackling routine tasks or addressing specific issues, a well-equipped toolkit can make all the difference.

Here’s a list of indispensable items you should consider having on hand:

- Wrenches: A set of both standard and metric wrenches is essential for loosening and tightening various components.

- Screwdrivers: Flathead and Phillips screwdrivers in various sizes are necessary for accessing and adjusting parts.

- Socket Set: A quality socket set allows for quick removal of nuts and bolts, saving time during maintenance tasks.

- Plier Set: Needle-nose and regular pliers help in gripping and manipulating small parts.

- Torque Wrench: Ensures that fasteners are tightened to the correct specifications, preventing damage.

- Cleaning Supplies: Brushes, cloths, and solvents will help maintain cleanliness and functionality.

- Safety Gear: Gloves and goggles are essential to protect yourself during any hands-on work.

By equipping yourself with these fundamental tools, you can effectively handle maintenance tasks and enhance the longevity of your outdoor machinery.

Common Mower Issues and Solutions

Maintaining a lawn care machine is essential for ensuring optimal performance and longevity. However, various challenges may arise during operation, affecting efficiency and results. Understanding these common problems and their respective solutions can help users address issues promptly and effectively.

1. Engine Won’t Start

If the engine fails to ignite, it may be due to several factors, such as a drained battery, faulty spark plug, or clogged fuel line. Begin by checking the battery charge and connections. If those are fine, inspect the spark plug for wear and replace if necessary. Lastly, ensure that fuel is flowing freely to the engine.

2. Uneven Cutting

When grass is not cut uniformly, it can indicate an issue with the blade height or the condition of the blades themselves. Verify that all blades are set to the same height and sharpen or replace them as needed. Additionally, check for any debris or obstacles that may be obstructing proper movement.

3. Excessive Vibration

Unusual vibrations during operation often suggest that the blades are unbalanced or that components are loose. Examine the blades for damage and ensure they are correctly aligned. Tightening any loose parts can also help eliminate excessive movement.

4. Overheating

Overheating can be caused by inadequate oil levels or blocked cooling fins. Regularly check and maintain appropriate oil levels, and clean any debris from the cooling fins to allow for proper airflow.

5. Stalling

If the machine frequently stalls, it could be a sign of fuel delivery issues or a dirty air filter. Inspect the fuel system for blockages and replace any clogged filters to restore smooth operation.

Addressing these prevalent issues can lead to a more efficient and enjoyable experience when maintaining your outdoor space. Regular inspections and preventative measures can significantly reduce the likelihood of encountering these problems in the first place.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. Following a structured approach to maintenance not only enhances efficiency but also prevents potential issues. This guide provides a series of straightforward steps to help you keep your machine in excellent condition.

Tools and Supplies Needed

- Wrench set

- Screwdrivers

- Oil and lubricant

- Air filter replacement

- Safety goggles

- Cleaning rags

Maintenance Steps

- Begin with a thorough inspection of all components.

- Check and change the oil as needed, ensuring to use the correct type.

- Clean or replace the air filter to maintain airflow.

- Sharpen or replace the cutting blades to ensure effective operation.

- Inspect the belts and cables for wear and tear; replace if necessary.

- Clean the exterior and undercarriage to remove debris.

- Finally, test the equipment to ensure everything operates smoothly.

How to Change Mower Blades

Replacing the cutting edges of your equipment is essential for maintaining optimal performance and ensuring a clean cut. Regularly checking and changing these components can enhance the longevity of your tool and improve its efficiency. Follow these steps to successfully carry out the task.

- Gather Your Tools

- Wrench or socket set

- Safety gloves

- Protective eyewear

- Grease or lubricant

- Prepare the Equipment

- Ensure the engine is off and the spark plug is disconnected to avoid accidental starting.

- Elevate the unit securely using jack stands or a ramp.

- Remove the Old Blades

- Locate the fasteners securing the blades.

- Use the wrench or socket to loosen and remove the bolts.

- Carefully detach the blades from the mounting area.

- Install New Cutting Edges

- Position the new blades onto the mounting area.

- Align the holes and secure them with bolts.

- Use the wrench to tighten the fasteners securely.

- Final Checks

- Reconnect the spark plug.

- Check the tightness of the bolts again.

- Lower the equipment and ensure everything is in place.

By following these steps, you can ensure that your tool is equipped with sharp, efficient cutting edges, allowing for a precise and effective job every time.

Troubleshooting Engine Problems

When your outdoor equipment exhibits performance issues, diagnosing the engine is crucial for restoring its functionality. Various symptoms can arise, ranging from difficulties in starting to irregular operation during use. Understanding these common issues can help you identify the root cause and take appropriate action.

Common Symptoms and Causes

One of the most prevalent problems is failure to start. This can be attributed to several factors, such as an empty fuel tank, clogged filters, or worn-out spark plugs. Additionally, if the engine runs erratically, it may indicate fuel quality issues or air intake obstructions. Always check for these elements before proceeding to more complex troubleshooting.

Steps for Diagnosis

Begin by inspecting the fuel system. Ensure that the tank is filled with fresh fuel and that there are no blockages in the lines. Next, examine the ignition components, particularly the spark plug for signs of wear or damage. Cleaning or replacing these parts can often resolve operational difficulties. Finally, check for any visible leaks or damaged seals that could affect performance.

By systematically addressing these areas, you can effectively pinpoint and resolve engine-related issues, ensuring smooth operation of your equipment.

Fuel System Cleaning Tips

Maintaining the cleanliness of the fuel system is essential for optimal performance and longevity of any engine. Regular attention to this area can prevent issues such as clogging and inefficiency. Below are some effective strategies to ensure your fuel system remains in excellent condition.

Routine Maintenance Steps

- Inspect and replace fuel filters as needed to ensure proper flow.

- Check fuel lines for cracks or leaks that could affect performance.

- Keep the fuel tank clean and free from debris to prevent contamination.

Cleaning Techniques

- Use a specialized cleaning solution designed for fuel systems to remove deposits.

- Run the engine with the cleaner according to the manufacturer’s instructions for optimal results.

- Consider using compressed air to blow out any debris from lines and injectors.

Implementing these tips can significantly enhance the functionality of your equipment, ensuring a smoother operation and extending its lifespan.

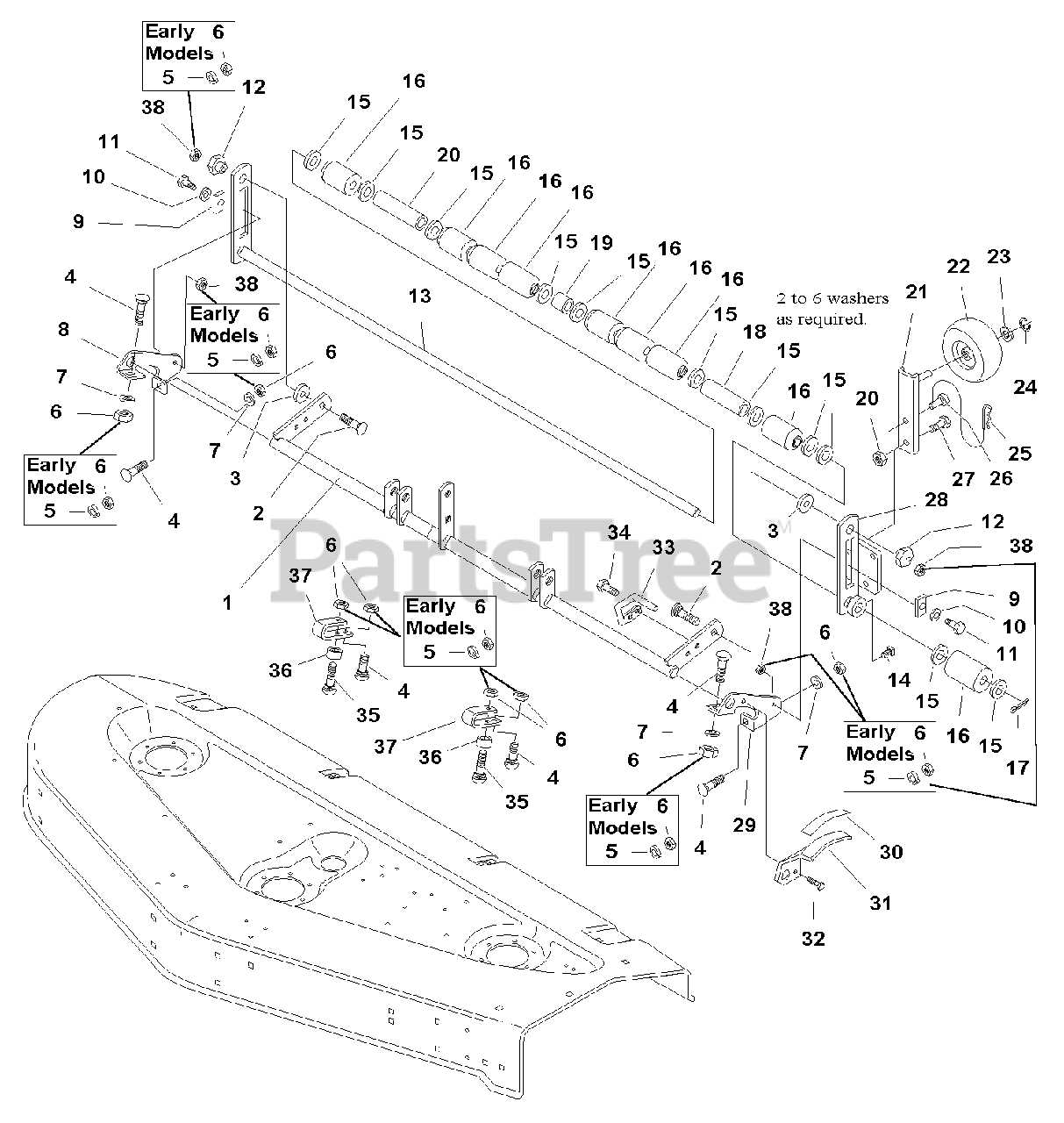

Replacing Belts and Cables

Maintaining the efficiency of your equipment often involves addressing wear and tear on components such as belts and cables. These elements play a crucial role in the overall functionality, ensuring smooth operation and optimal performance. Regular checks and timely replacements can prevent further issues and extend the lifespan of your machinery.

When replacing belts and cables, it is essential to follow a systematic approach. Here are the key steps involved in the process:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and replacement parts. Ensure you have the correct specifications for belts and cables required for your specific model. |

| 2 | Disconnect the power source to prevent any accidental start-ups while working on the equipment. |

| 3 | Remove the old belt or cable. This may involve loosening certain components or brackets that hold them in place. |

| 4 | Install the new belt or cable, making sure to follow the correct routing as indicated in the guidelines. |

| 5 | Reconnect any components you may have detached and ensure everything is secured properly. |

| 6 | Reconnect the power source and test the equipment to confirm that the new parts are functioning correctly. |

By following these steps, you can ensure that your equipment remains in optimal condition, ready to tackle any task at hand. Regular maintenance checks will help identify when belts and cables need replacing, allowing for proactive care and minimizing downtime.

Electrical System Diagnostics

Understanding the intricacies of the electrical framework is essential for troubleshooting issues effectively. This section delves into methods for evaluating and diagnosing common electrical problems that may arise, ensuring optimal performance and reliability.

To initiate the diagnostic process, it’s crucial to gather the necessary tools and perform a systematic inspection. Below is a table outlining the common components to check and the corresponding symptoms that may indicate potential faults.

| Component | Symptoms |

|---|---|

| Battery | Weak or no power, difficulty starting |

| Wiring Connections | Corrosion, loose connections, intermittent power |

| Fuses | Blown fuses, electrical failures |

| Ignition System | Engine not firing, stalling |

| Starter Motor | Clicking noise, no engagement |

By systematically addressing these areas, one can identify and resolve electrical challenges, ensuring the machinery operates efficiently and safely.

Seasonal Care for Longevity

Regular maintenance is essential for extending the lifespan of your outdoor equipment. By following a structured seasonal care routine, you can ensure that your tools remain efficient and reliable. This section outlines key practices to adopt throughout the year, helping you to avoid costly repairs and downtime.

Spring Preparations

As the weather warms up, it’s time to prepare your equipment for the upcoming busy season. Start by inspecting the condition of the blades and ensuring they are sharp and free of debris. Clean the air filters and check the fuel system for any signs of deterioration.

Autumn Shutdown

As the season changes, proper storage is crucial to prevent damage from cold weather. Before storing, thoroughly clean the equipment and change the oil. It’s also advisable to remove any residual fuel to avoid corrosion and clogs in the fuel system.

| Season | Maintenance Task |

|---|---|

| Spring | Inspect blades, clean air filters, check fuel system |

| Summer | Regular cleaning, monitor performance, replace spark plugs if necessary |

| Autumn | Clean equipment, change oil, remove residual fuel |

| Winter | Store in a dry place, cover to protect from dust and moisture |

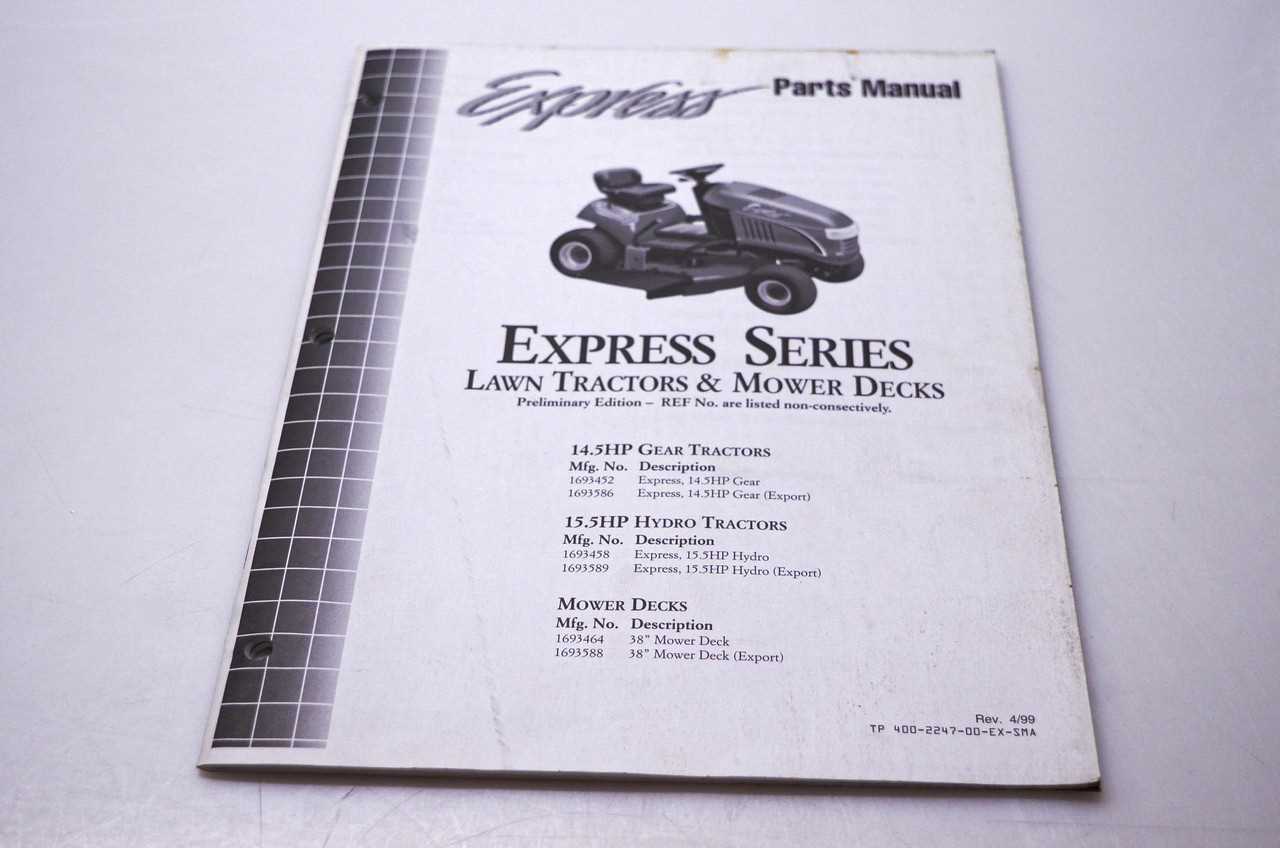

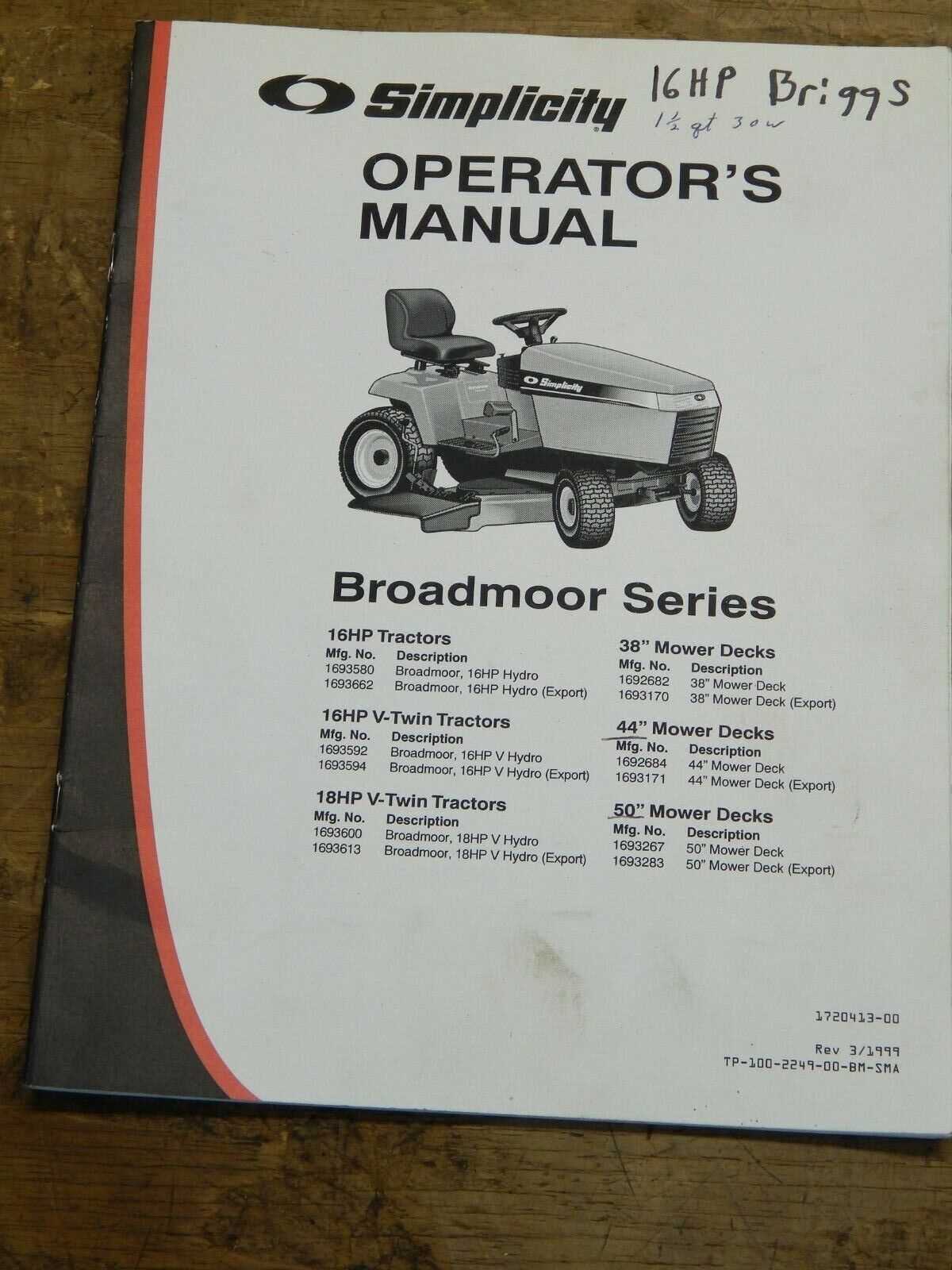

Finding Replacement Parts Online

Locating components for lawn care equipment can be a straightforward process if you know where to look. The internet offers a plethora of resources that simplify the task of sourcing necessary items. Whether you need blades, belts, or other vital pieces, a well-structured approach can save time and ensure you find the right fit for your machine.

Start by utilizing specialized websites that focus on outdoor equipment. These platforms often have extensive catalogs and search functions, allowing you to enter your model number for precise results. Additionally, many sites provide detailed descriptions and images to help you confirm compatibility.

Consider checking online marketplaces where users buy and sell equipment parts. These venues can offer both new and used options at competitive prices. However, it’s crucial to verify the seller’s reputation and the condition of the items before making a purchase.

Lastly, don’t overlook the power of forums and online communities. Engaging with fellow enthusiasts can lead to recommendations for reputable suppliers and even insights into hard-to-find components. By leveraging these resources, you can enhance your chances of successfully sourcing the parts you need.