Understanding the intricacies of maintaining large-scale transport equipment is essential for ensuring optimal performance and longevity. This section aims to provide comprehensive insights into the various processes involved in keeping such machinery in peak condition. By following systematic approaches, operators can address common issues and enhance the reliability of their vehicles.

Regular upkeep is critical for minimizing downtime and extending the lifespan of transport units. This guide will delve into essential practices, troubleshooting techniques, and preventive measures that can be employed to maintain these vital assets. With detailed information at your disposal, you can navigate the complexities of maintenance effectively.

Moreover, possessing a thorough understanding of operational systems and components allows for informed decision-making when challenges arise. Embracing these guidelines will empower individuals to execute tasks efficiently, ensuring that every unit remains roadworthy and functional.

Essential Guide to Semi Trailer Repairs

This section offers a comprehensive overview of essential maintenance and restoration practices for large transport vehicles. Understanding the intricacies involved in ensuring their longevity and performance is crucial for operators and technicians alike. By familiarizing oneself with common issues and effective solutions, one can significantly enhance the functionality and safety of these crucial assets.

Regular inspections play a vital role in identifying potential problems before they escalate. Key areas to monitor include the structural integrity of the chassis, the condition of axles, and the functionality of braking systems. Attention to detail during these evaluations can prevent costly downtime and ensure compliance with industry standards.

When addressing issues, utilizing quality components for replacements is imperative. Opting for parts that meet or exceed manufacturer specifications can enhance reliability and durability. Additionally, keeping thorough records of all maintenance activities not only aids in tracking the performance history but also assists in future evaluations.

Moreover, investing in ongoing training for personnel can greatly improve repair techniques and safety practices. As technology advances, staying updated on the latest methods and tools ensures efficient and effective servicing. This proactive approach fosters a culture of safety and excellence within the operation.

In conclusion, adhering to a systematic approach in maintaining these vehicles is essential. By prioritizing regular assessments, using quality parts, and fostering continuous learning, operators can ensure that their transport vehicles remain in optimal condition for years to come.

Identifying Common Trailer Issues

Recognizing typical problems that may arise with large transport units is essential for maintaining their efficiency and safety. Various factors can contribute to malfunctions, including wear and tear, environmental conditions, and improper usage. Awareness of these common challenges allows for timely intervention and preventative measures.

Frequent Concerns

Several issues often affect large transport units, leading to potential operational disruptions. Understanding these can help in identifying and addressing them swiftly.

| Issue | Description |

|---|---|

| Brake Malfunctions | Worn-out pads or improper adjustments can lead to inadequate stopping power. |

| Suspension Problems | Worn components may result in uneven weight distribution, affecting stability. |

| Tire Wear | Improper inflation or alignment can cause accelerated tire degradation. |

| Lighting Issues | Faulty connections or blown bulbs can lead to reduced visibility and safety risks. |

Prevention Strategies

Regular inspections and maintenance routines are crucial for avoiding the most common problems. Implementing best practices can prolong the lifespan of the unit and enhance safety during transport.

Inspection Techniques for Trailer Longevity

Regular evaluations play a crucial role in ensuring the extended lifespan of large transport vehicles. By employing systematic assessment methods, owners can identify potential issues early, ultimately saving on costly repairs and enhancing safety during operations.

Visual Examination

A comprehensive visual check is the foundation of any assessment process. Inspecting the exterior surfaces for signs of wear, damage, or corrosion can reveal critical insights about the overall condition. Particular attention should be paid to areas that experience frequent stress or exposure to harsh environments.

Structural Integrity Assessment

Evaluating the frame and support structures is essential for maintaining safety standards. Utilizing tools like a measuring tape or laser level helps ensure all components are aligned correctly and free from deformation. Any irregularities should be documented for further examination.

| Inspection Type | Frequency | Key Focus Areas |

|---|---|---|

| Visual Inspection | Monthly | Exterior surfaces, connections, signs of wear |

| Structural Assessment | Quarterly | Frame alignment, support structure stability |

| Component Testing | Annually | Brake systems, suspension parts, electrical systems |

Step-by-Step Brake System Maintenance

Regular upkeep of the braking mechanism is crucial for ensuring safety and optimal performance. This section provides a comprehensive guide to maintaining these essential components, helping to prevent issues that could arise from neglect.

Follow these steps to effectively manage the maintenance of the braking system:

| Step | Action | Description |

|---|---|---|

| 1 | Visual Inspection | Check for any visible wear, leaks, or damage to brake lines and components. |

| 2 | Fluid Check | Examine brake fluid levels and top up if necessary; replace if contaminated. |

| 3 | Brake Pad Assessment | Inspect brake pads for wear and replace if thickness is below the recommended limit. |

| 4 | Rotor Inspection | Examine rotors for signs of scoring or warping; machine or replace as needed. |

| 5 | System Bleeding | Bleed the brake system to remove air bubbles, ensuring optimal hydraulic pressure. |

| 6 | Test Drive | Conduct a test drive to assess brake performance and responsiveness. |

Adhering to this systematic approach will help maintain the functionality and reliability of the braking apparatus, ultimately contributing to safer operation.

Electrical System Troubleshooting and Repairs

Diagnosing and addressing issues within electrical frameworks is crucial for maintaining optimal performance. This section focuses on identifying common problems, understanding their causes, and implementing effective solutions to ensure reliable operation.

Common Issues and Their Symptoms

Many electrical malfunctions can arise from faulty connections, worn components, or short circuits. Symptoms may include inconsistent power supply, flickering lights, or complete failure of electrical systems. Visual inspections can often reveal loose wires or corrosion that could be contributing to these issues. Regular maintenance checks are essential for preventing minor problems from escalating into significant failures.

Steps for Effective Troubleshooting

Begin by systematically isolating the affected components. Using a multimeter can help measure voltage and continuity, allowing for accurate identification of the source of the malfunction. Once the problem is pinpointed, replace any damaged parts and ensure all connections are secure. Finally, conduct a thorough test of the system to verify that all components function as intended.

Effective Solutions for Suspension Problems

Addressing issues related to support systems is crucial for ensuring the safety and stability of heavy-duty vehicles. These complications can arise from various factors, including wear and tear, improper alignment, or inadequate maintenance. Implementing effective solutions not only improves performance but also extends the lifespan of the vehicle.

First, conducting regular inspections is essential to identify potential weaknesses. Checking components such as leaf springs, shock absorbers, and air bags can reveal signs of damage or excessive wear. By replacing faulty parts promptly, drivers can prevent more severe complications down the line.

Additionally, maintaining proper air pressure in pneumatic systems is vital. Under-inflated components can lead to uneven load distribution, causing further stress on the suspension. Regularly monitoring and adjusting air pressure helps maintain balance and enhances overall stability.

Finally, alignment and adjustment of suspension components should be performed periodically. Properly aligned systems ensure that weight is evenly distributed, which minimizes stress on individual parts. Utilizing professional services for precise alignment can significantly improve handling and ride quality.

Welding and Structural Reinforcement Tips

Effective joining techniques and the enhancement of structural integrity are crucial for ensuring the longevity and safety of large transport units. Understanding the principles behind welding and reinforcement can significantly impact the overall performance of these units under various conditions.

Prior to commencing any welding tasks, it’s essential to prepare the surfaces adequately. Clean the metal components to remove rust, paint, or grease, ensuring a strong bond. Proper fit-up of parts is equally important; gaps should be minimized to achieve a uniform weld. Utilizing appropriate electrodes and settings based on material type can enhance weld quality and durability.

When reinforcing structures, consider strategic placement of additional supports to distribute loads evenly. This can prevent stress concentrations that may lead to failure. Employ techniques such as cross-bracing or adding gussets to enhance stability. Regular inspection of welds and reinforcements after work is completed ensures that any deficiencies are identified and addressed promptly.

Finally, maintaining a consistent welding speed and angle is vital for achieving uniform penetration and strength. Practicing these techniques will result in improved craftsmanship and ultimately extend the lifespan of the unit.

Maintaining Trailer Axles and Bearings

Proper care of the critical components that support the weight and ensure smooth operation of a hauling unit is essential for safety and longevity. Regular attention to these parts can prevent costly breakdowns and enhance overall performance.

To effectively manage these essential elements, consider the following practices:

- Regular Inspection: Conduct thorough checks for signs of wear or damage. Look for cracks, rust, or unusual sounds during operation.

- Lubrication: Ensure that all moving parts are adequately greased. Use the manufacturer’s recommended lubricant to facilitate smooth movement.

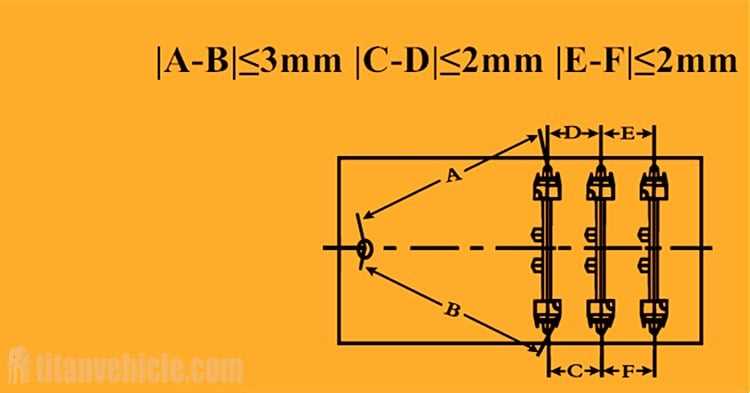

- Alignment Check: Verify that axles are properly aligned to prevent uneven tire wear and ensure stable handling.

- Wheel Bearing Adjustment: Regularly adjust bearings to maintain the correct preload. This helps prevent overheating and failure.

By implementing these maintenance strategies, operators can extend the lifespan of these vital components and enhance the overall reliability of their hauling units.

Optimizing Air System Performance

Ensuring the efficiency of pneumatic systems is crucial for overall functionality and reliability. Various factors contribute to optimal performance, including proper maintenance, component selection, and system design. Enhancing these elements can lead to improved operational effectiveness and longevity.

Regular Maintenance is essential for sustaining system integrity. Periodic inspections should be conducted to identify wear and tear on critical components. This proactive approach helps in preventing unexpected failures and costly downtime.

Component Quality significantly influences performance. Utilizing high-quality parts, such as filters and valves, can enhance airflow and reduce the likelihood of blockages. Investing in durable materials pays off in the long run, contributing to a more reliable setup.

System Design plays a pivotal role in efficiency. Properly sized hoses and fittings ensure minimal pressure loss, facilitating better airflow. Additionally, strategically placing components can help in reducing turbulence and optimizing overall functionality.

Incorporating these practices into routine operations can lead to a marked improvement in air system performance, ensuring that the equipment operates at its best for extended periods.

Repairing and Replacing Trailer Flooring

Maintaining the base surface of your transport unit is crucial for ensuring safety and functionality. Over time, the flooring can sustain damage from various factors, including wear and tear, moisture exposure, and heavy loads. Addressing these issues promptly can prevent further complications and extend the lifespan of the unit.

Assessment of Damage

Before initiating any corrective actions, it is essential to evaluate the extent of the damage. Here are steps to guide the assessment:

- Inspect the surface for visible cracks, warping, or soft spots.

- Check for signs of moisture infiltration, such as mold or rust.

- Examine the structural integrity beneath the flooring, including supports and beams.

Replacement Process

If replacement is necessary, follow these guidelines to ensure a successful installation:

- Remove the damaged sections carefully using appropriate tools.

- Clean the underlying area to remove debris and prepare for new materials.

- Cut new flooring materials to fit the dimensions accurately.

- Secure the new pieces in place using suitable fasteners and adhesives.

- Finish by sealing edges to prevent moisture entry.

By adhering to these steps, you can maintain a robust foundation that ensures the continued safety and effectiveness of your transport unit.

Regular Maintenance for Tires and Wheels

Proper upkeep of rolling components is essential for ensuring safety and enhancing performance. Routine checks and maintenance not only prolong the lifespan of these elements but also improve overall efficiency. This section outlines key practices to maintain optimal condition for tires and wheels.

-

Visual Inspections:

Conduct regular visual assessments to identify any signs of wear, cracks, or foreign objects embedded in the surface.

-

Tire Pressure Checks:

Maintain recommended inflation levels, as incorrect pressure can lead to reduced traction and increased fuel consumption.

-

Alignment and Balancing:

Ensure wheels are properly aligned and balanced to promote even wear and enhance handling capabilities.

-

Rotation:

Regularly rotate tires to ensure even distribution of wear across all tires, typically every 5,000 to 7,500 miles.

-

Depth of Tread:

Monitor tread depth to ensure adequate traction. Replace tires when the tread reaches the minimum legal limit.

-

Cleaning:

Keep wheels clean from dirt and debris. Use appropriate cleaning solutions to prevent corrosion and maintain aesthetics.

Adhering to these maintenance practices will enhance safety, performance, and longevity of wheels and tires, ensuring a smoother experience on the road.

Protecting Against Rust and Corrosion

Ensuring the longevity of metal structures requires a comprehensive strategy to prevent deterioration caused by environmental factors. This involves implementing effective measures to shield surfaces from moisture and other corrosive agents.

Regular maintenance and the application of protective coatings can significantly enhance durability. The following table outlines key practices to mitigate the effects of oxidation and chemical wear:

| Practice | Description |

|---|---|

| Surface Cleaning | Remove dirt, grease, and existing rust using appropriate cleaning agents. |

| Protective Coatings | Apply paints or sealants specifically designed to prevent corrosion. |

| Regular Inspections | Conduct routine checks to identify early signs of damage or corrosion. |

| Environmental Control | Store equipment in controlled environments to minimize exposure to moisture. |

| Use of Sacrificial Anodes | Install anodes that corrode preferentially, protecting underlying materials. |

Implementing these strategies will help maintain the integrity of metal components, extending their lifespan and ensuring optimal performance.