For enthusiasts and those devoted to classic automotive upkeep, tackling the intricate details of vintage transmission systems can be both a challenge and a rewarding experience. This guide provides valuable insights and essential steps for bringing life back to a cherished component of older vehicles. By understanding the structure and functions of each part, anyone can achieve a smooth and precise outcome.

From assessments to adjustments, this article will walk you through each step necessary to breathe new life into an iconic transmission. Detailed instructions, helpful illustrations, and practical advice ensure clarity, enabling readers to approach each phase with confidence. With patience and care, your classic vehicle will perform with renewed precision and reliability on the road.

Essential Guide to Saginaw 4-Speed Repairs

Maintaining and restoring a four-gear transmission can be a rewarding experience, offering both performance benefits and improved longevity. Understanding how to approach various challenges in these components can be crucial for anyone working with them. This guide covers the key methods and techniques to help ensure smooth operation and extend the life of these mechanical systems.

Understanding Component Wear

Over time, gears and other internal parts can suffer from wear and tear, which may lead to decreased efficiency and potential breakdowns. Regularly inspecting each part for signs of deterioration is essential. Look for any unusual marks or signs of wear on the gears and other surfaces, as these can indicate problems that may require attention. Early intervention often prevents the need for extensive work later.

Effective Methods for Reassembly

After disassembly, ensuring that each part is clean and correctly positioned is vital for optimal functioning. Using proper tools and ensuring precise alignment can prevent common issues, such as misalignment and improper engagement. Additionally, lubricating each part adequately can reduce friction and improve the unit’s overall performance.

Understanding 4-Gear Mechanics

Exploring the inner workings of a 4-gear transmission system provides valuable insight into how the complex arrangement of gears and linkages contributes to efficient power transfer. This type of gearbox is appreciated for its simplicity and reliability, making it a popular choice in many vehicle models from earlier decades.

The key to mastering this system lies in understanding how the gears interact with one another, each designed to handle specific ranges of vehicle performance. From engaging smoothly at low speeds to handling higher loads, each gear plays a unique role. The assembly’s components must align precisely, ensuring the seamless operation and longevity of the entire mechanism.

Properly synchronized movement within the 4-gear system is crucial, as it balances power and torque effectively. Familiarity with the arrangement and function of each gear helps in troubleshooting common issues, particularly in classic car restoration. By gaining a thorough understanding of this mechanical process, enthusiasts and mechanics alike can achieve both optimal performance and preservation of these enduring automotive systems.

Common Issues with Saginaw 4-Speed Transmissions

Many drivers encounter specific challenges with these older four-gear setups, especially when exposed to extended use or heavy workloads. These components, while robust, may exhibit wear or mechanical inconsistencies over time, often affecting the ease and efficiency of operation.

| Issue | Description |

|---|---|

| Gear Slipping | One prevalent problem is slipping between gears, particularly when moving between first and second. This issue is often caused by worn synchronizers or gear teeth. |

| Difficulty Shifting | Shifting problems may arise, especially when shifting to reverse or higher gears. This can be due to worn linkages or misaligned shift forks. |

| Leaking Fluid | Leaks around seals and gaskets are common, often due to aging seals or cracks in the casing. This leads to decreased fluid levels, impacting performance. |

| Grinding Sounds | Grinding noise, particularly in lower gears, may indicate worn bearings or damaged synchronizers, usually stemming from prolonged use or improper lubrication. |

| Excessive Vibration | Vibrations during operation can be linked to misaligned shafts or wear in the bearings. Left unchecked, this can lead to further component damage. |

Identifying Gearbox Symptoms

Understanding the signs of wear or malfunctions in a gearbox is essential for maintaining smooth vehicle operation. Recognizing early indications of trouble can help prevent further issues and ensure reliable performance over time.

Unusual Noises

A common sign of internal issues is the appearance of unusual noises. If there are grinding, whining, or clunking sounds, especially during gear shifts, it may indicate that certain parts are wearing down. These sounds can stem from misaligned components, lack of lubrication, or bearing wear.

Shifting Difficulties

Another sign to watch for is difficulty when shifting between gears. If gears feel resistant, “stick,” or there’s a delayed response when changing positions, internal adjustments or replacements might be needed. This symptom often suggests that components are not properly engaging, which can lead to more significant problems if not addressed.

Step-by-Step Transmission Disassembly

Disassembling a transmission involves carefully separating its components to diagnose or refurbish each part. This process requires attention to detail and methodical steps to ensure the system is dismantled safely and without damage. Below is a structured guide to help with each phase of disassembly, listing essential tasks and tips to make the process more efficient.

Initial Preparation

Before starting, prepare your workspace and ensure that all required tools are within reach. Having a clean area will help keep parts organized and prevent any mix-ups.

- Place the transmission on a stable work surface.

- Gather tools, including socket wrenches, pliers, and a cleaning cloth.

- Prepare labeled containers or trays for small parts like bolts and clips.

Main Disassembly Steps

Follow these steps to dismantle the transmission efficiently, taking care with each component to avoid accidental damage.

- Remove the outer casing: Start by loosening the bolts and carefully lifting off the housing. Ensure all bolts are kept in order for reassembly.

- Detach the gears: Using appropriate tools, pull each gear free, noting their placement for future reference. Handle gears with care to avoid chipping.

- Disassemble the shaft: Take off any clips or fasteners and slide the shaft components out one by one. Label each item to ensure proper reassembly.

- Extract bearings and seals: Carefully pry out the bearings and seals, placing them aside if replacement is needed.

Completing these steps will result in a fully disassembled tra

Cleaning and Inspecting Internal Components

Proper maintenance of internal mechanisms is crucial for ensuring optimal performance and longevity. This section focuses on the essential steps for cleaning and examining various components within the assembly. Regular upkeep can help identify potential issues early and maintain the functionality of the unit.

Before beginning the cleaning process, gather the necessary tools and materials:

- Solvent or degreaser

- Brushes (various sizes)

- Lint-free cloths

- Magnifying glass or inspection tool

- Protective gloves

The following steps outline an effective approach to cleaning and inspecting internal parts:

- Disassembly: Carefully disassemble the unit, ensuring that all components are kept organized to facilitate reassembly.

- Initial Cleaning: Use a suitable solvent to remove any grime or debris from the surfaces of the parts. A soft brush can be helpful in reaching intricate areas.

- Detailed Inspection: Examine each component closely for signs of wear, cracks, or other damage. Pay attention to areas that experience friction or stress during operation.

- Final Cleaning: Wipe down all parts with a lint-free cloth to ensure they are free of any residues before reassembly.

- Documentation: Record any findings regarding wear or necessary replacements, which can aid in future maintenance efforts.

By following these procedures, you can effectively maintain the internal components, enhancing their reliability and performance.

Reassembly Tips for Optimal Performance

When putting components back together, ensuring precision and care is crucial for achieving top functionality. This section provides essential advice to enhance the efficiency of your assembly process, ensuring that every part fits seamlessly and operates at its best.

To facilitate a successful reassembly, consider the following guidelines:

| Tip | Description |

|---|---|

| Clean All Components | Before reassembly, thoroughly clean each part to remove dirt, oil, and old lubricant. This helps prevent contamination and ensures better performance. |

| Use Quality Lubricants | Apply high-quality lubricants to moving parts. This reduces friction and wear, enhancing overall efficiency and lifespan. |

| Follow Torque Specifications | Adhere to the manufacturer’s torque specifications when tightening bolts and screws. This helps prevent damage and ensures that all parts are secured correctly. |

| Inspect Seals and Gaskets | Check all seals and gaskets for wear or damage. Replacing these parts during reassembly is vital to avoid leaks and maintain optimal performance. |

| Double-Check Alignment | Ensure that all components are aligned properly before final assembly. Misalignment can lead to premature failure and inefficiency. |

By following these tips, you can significantly improve the performance and reliability of your assembled components, ensuring they function effectively for years to come.

Lubrication and Maintenance Recommendations

Proper upkeep and lubrication are essential for ensuring optimal performance and longevity of transmission systems. Regular maintenance routines help in minimizing wear and tear, thus enhancing overall efficiency. Understanding the right procedures and intervals for maintenance can significantly extend the lifespan of these mechanical components.

Recommended Lubricants

Choosing the right lubricants is crucial. It’s advisable to use high-quality fluids that meet the specifications outlined by the manufacturer. These fluids help reduce friction, preventing overheating and potential damage. Ensure that the selected lubricant is compatible with the materials used in the transmission.

Maintenance Schedule

Establishing a consistent maintenance schedule is vital. It is recommended to inspect fluid levels regularly and replace the lubricant at specified intervals to prevent contamination and ensure effective performance. Additionally, checking for leaks and worn seals should be part of routine checks, as these issues can lead to significant operational problems.

Adjusting Saginaw 4-Speed Linkage

Properly calibrating the transmission linkage is essential for achieving smooth gear shifts and optimal performance in your vehicle. This process ensures that the connection between the gear shifter and the transmission components functions effectively, allowing for precise engagement and disengagement of gears.

To begin, identify the linkage assembly and inspect for any signs of wear or damage. Ensure that all components are securely fastened and free of debris. If necessary, clean the linkage to eliminate any buildup that may hinder its operation.

Next, adjust the linkage by following the manufacturer’s specifications, which typically involve positioning the gear shifter in the neutral position and aligning the linkage accordingly. Utilize any available adjustment screws or nuts to fine-tune the alignment, ensuring that the shifter moves freely and accurately engages each gear.

After making adjustments, test the linkage by shifting through all gears to confirm smooth transitions. If any issues persist, further refinement may be required, or it may be necessary to consult a professional for assistance. Regular maintenance of the linkage system will contribute to the longevity and reliability of the transmission.

Preventing Future Transmission Wear

Maintaining the longevity of a vehicle’s transmission system is essential for optimal performance and reliability. By adopting proactive measures, vehicle owners can significantly reduce the risk of wear and tear, ensuring a smoother driving experience and extending the lifespan of the transmission components.

Regular maintenance is one of the most effective ways to prevent premature wear. This includes routine inspections, timely fluid changes, and addressing minor issues before they escalate into major problems. Adhering to a maintenance schedule can help identify potential concerns early on and mitigate damage.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Fluid Replacement | Every 30,000 miles | Prevents fluid degradation and ensures optimal lubrication |

| Filter Inspection | Every 15,000 miles | Reduces contaminants and maintains fluid cleanliness |

| Seals and Gaskets Check | Annually | Prevents leaks and maintains pressure |

| Fluid Level Check | Monthly | Ensures adequate lubrication and cooling |

Additionally, adopting smooth driving habits can greatly impact transmission longevity. Avoiding sudden accelerations, harsh braking, and excessive idling helps minimize strain on the system. Moreover, using the appropriate gear ratios for various driving conditions can further enhance performance and reduce wear.

Troubleshooting Saginaw Shifting Problems

Addressing issues related to gear transitions can be a complex task that requires careful examination of various components. Understanding the common symptoms and their potential causes is crucial for efficient resolution. This section provides insights into diagnosing and fixing these problems effectively.

One frequent issue is difficulty in engaging or disengaging gears. This may stem from misaligned linkages or worn-out components. Inspecting the linkage system for any signs of wear or damage is essential. If adjustments are necessary, ensure they are made according to specifications.

Another common symptom is grinding noises during shifts, which often indicate improper synchronization. Checking the transmission fluid is vital; low fluid levels can lead to inadequate lubrication, exacerbating wear on internal parts. Replenishing fluid to the recommended level can significantly improve performance.

Additionally, slipping out of gear while driving is a serious concern. This may result from excessive wear on the clutch or internal gears. Monitoring the clutch’s functionality and replacing any worn components will help maintain proper engagement and prevent further complications.

Lastly, regular maintenance checks can prevent many of these issues from arising. Keeping a close eye on fluid levels, linkage adjustments, and component conditions will ensure the smooth operation of the transmission system over time.

Finding Quality Replacement Parts

When it comes to maintaining and enhancing the performance of your vehicle, sourcing top-notch components is crucial. Quality replacement parts not only ensure optimal functionality but also extend the lifespan of your machinery. Whether you’re looking for individual pieces or complete assemblies, understanding where to find reliable options can make a significant difference.

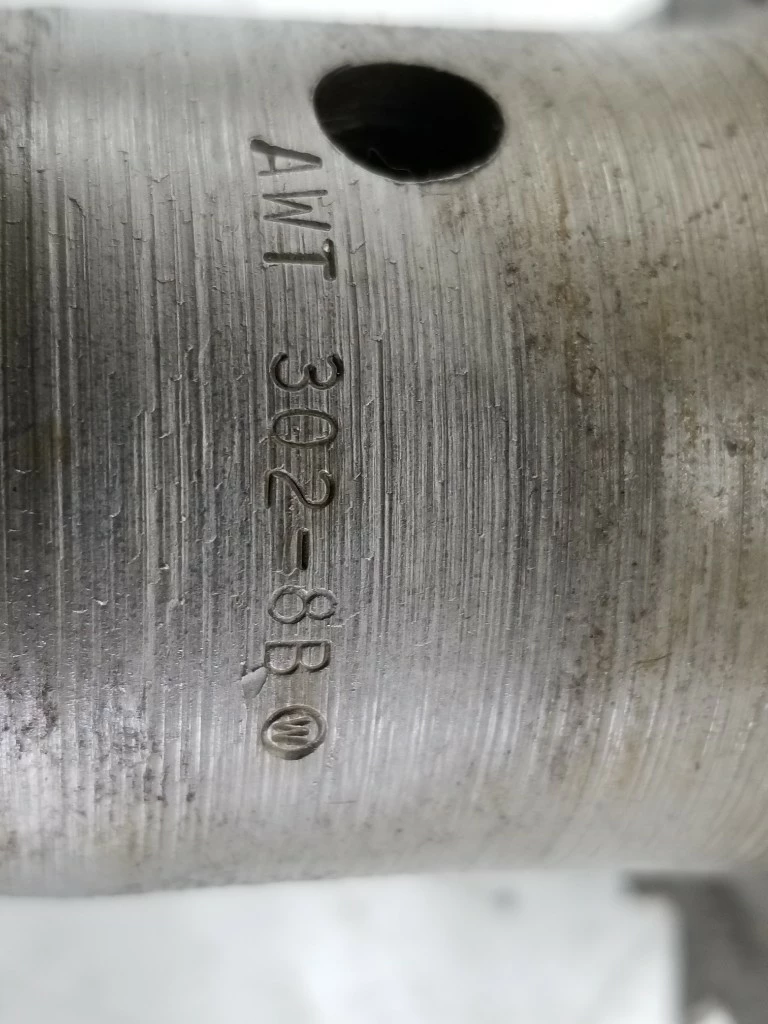

Understanding Compatibility

Before purchasing any component, it’s essential to verify its compatibility with your specific model. Each vehicle has unique specifications that require attention to detail. Researching part numbers and consulting expert resources can help in identifying the correct fit.

Reputable Sources for Components

Consider visiting trusted suppliers that specialize in automotive parts. Online platforms can also offer a vast selection, but ensure to check customer reviews and ratings. Additionally, local auto parts stores often provide personalized assistance and can help you find exactly what you need.

Quality assurance is paramount when selecting parts. Look for warranties or guarantees, as these can provide peace of mind regarding the durability of your investment. Ultimately, investing time in finding the right components pays off in the long run.

Testing Transmission Performance Post-Repair

After addressing issues within the gearbox, it is essential to evaluate its functionality to ensure optimal operation. This evaluation helps identify any remaining problems and confirms that all repairs have been effective. A systematic approach to testing will provide a clear understanding of how well the transmission performs under various conditions.

Initial Check and Fluid Inspection

Begin by examining the transmission fluid. Ensure it is at the correct level and free of contaminants. Fluid quality directly impacts performance, so any signs of discoloration or particles may indicate underlying issues. Additionally, conduct a visual inspection of the casing and surrounding components for any leaks or damage that could affect performance.

Performance Evaluation on the Road

Once the initial checks are complete, take the vehicle for a test drive. Pay attention to shifting smoothness and responsiveness. Note any unusual noises or delays during gear transitions, as these may signal further adjustments are necessary. Monitoring the vehicle’s behavior under different driving conditions will provide valuable insights into the transmission’s overall health.