This section provides essential insights into the upkeep of heavy-duty vehicles, focusing on a specific model known for its durability and efficiency. Understanding the intricacies of these machines ensures longevity and optimal performance.

Key components and systems are examined, offering detailed procedures for addressing common issues that may arise during operation. Knowledge of maintenance practices is vital for anyone involved in the management or ownership of such vehicles.

In this guide, users will find step-by-step instructions that simplify complex tasks, making it accessible for both novice and experienced operators. This resource serves as a valuable reference for achieving peak functionality and reliability in your vehicle.

Freightliner Columbia Overview

This section provides a comprehensive insight into a notable vehicle model known for its reliability and efficiency in long-haul transportation. Designed with advanced engineering, it aims to meet the demanding needs of modern logistics while ensuring comfort and performance.

Key Features

Featuring a robust chassis and an aerodynamic design, this model optimizes fuel consumption and enhances driving stability. The cabin is equipped with modern amenities, providing drivers with a comfortable and productive environment.

Performance and Specifications

Under the hood, this vehicle offers powerful engine options that cater to various hauling requirements. Its transmission system ensures smooth gear shifts, contributing to overall driving efficiency. This combination of power and technology makes it a preferred choice among fleet operators.

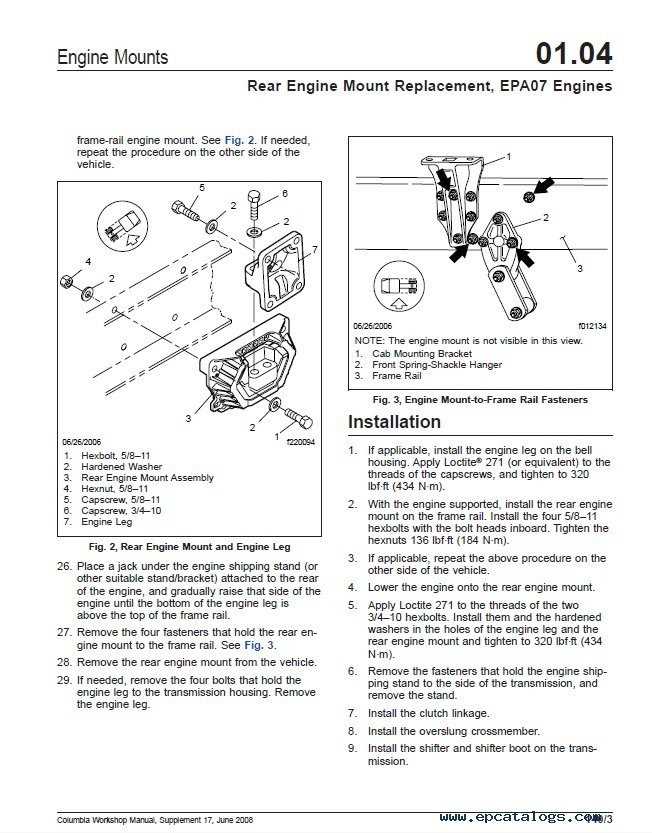

Common Issues and Solutions

This section addresses frequently encountered problems and their respective remedies. Understanding these challenges can greatly assist in maintaining optimal performance and enhancing the longevity of the vehicle.

One prevalent issue is engine performance deterioration, which may manifest as a decrease in power or efficiency. Regular inspections and timely replacement of filters can alleviate this concern.

Another common concern is electrical system malfunctions. Ensuring proper connections and replacing worn-out wiring can resolve many electrical faults.

Transmission difficulties can also arise, often due to fluid leaks or low levels. Regular checks and prompt fluid replacements are crucial to prevent more significant issues.

Lastly, tire wear and alignment problems are frequent. Regular rotations and proper inflation can enhance tire lifespan and improve driving stability.

Maintenance Tips for Longevity

Ensuring the long-term performance of your vehicle requires regular upkeep and attention. By implementing effective maintenance strategies, you can significantly extend the lifespan of your transport machine, reducing the likelihood of unexpected issues and costly repairs.

Routine Inspections

Conducting regular checks on various components is essential. Focus on key areas such as the engine, brakes, and tires. Early detection of wear and tear can prevent more severe problems down the line.

Fluid Levels Management

Maintaining proper fluid levels is crucial for optimal operation. This includes engine oil, coolant, and transmission fluid. Regularly checking and changing these fluids will help ensure smooth functionality and prevent overheating or mechanical failures.

| Fluid Type | Recommended Change Interval | Signs of Issues |

|---|---|---|

| Engine Oil | Every 5,000 miles | Dark color, sludge buildup |

| Coolant | Every 30,000 miles | Overheating, low levels |

| Transmission Fluid | Every 30,000 miles | Slipping gears, discoloration |

Electrical System Troubleshooting

This section focuses on diagnosing issues related to the electrical components of heavy-duty vehicles. Understanding how to identify and resolve common problems can significantly enhance the vehicle’s performance and reliability.

Begin by checking the battery condition, as it is often the root cause of electrical failures. Ensure that connections are clean and secure, and verify that the battery is adequately charged. If symptoms persist, examine the wiring harness for any signs of damage, wear, or corrosion that could interrupt the electrical flow.

Next, test the fuses and relays, which are crucial for protecting circuits from overloads. Replace any blown fuses and ensure that relays are functioning correctly. Utilize a multimeter to measure voltage and continuity, helping to pinpoint any faulty components within the system.

Finally, pay attention to any warning lights or error codes displayed on the dashboard. These indicators provide valuable information about underlying issues, guiding further troubleshooting efforts. By systematically addressing these areas, you can effectively diagnose and remedy electrical system challenges.

Engine Performance Enhancements

Improving the performance of a vehicle’s engine can lead to enhanced efficiency, power, and overall driving experience. Various modifications and upgrades can be implemented to achieve optimal results, catering to both everyday use and specific operational needs.

Common Upgrades

Several enhancements are popular among enthusiasts looking to boost engine capabilities. These include improved air intake systems, upgraded exhaust components, and advanced tuning solutions. Each of these modifications plays a crucial role in enhancing airflow, reducing back pressure, and optimizing fuel delivery.

Benefits of Enhancements

Investing in performance upgrades not only increases power output but can also improve fuel efficiency. Properly tuned engines often run smoother and are more responsive, resulting in a better driving experience. Additionally, enhanced performance can contribute to reduced emissions, benefiting both the environment and regulatory compliance.

| Enhancement | Benefits |

|---|---|

| Cold Air Intake | Increased airflow and horsepower |

| High-Performance Exhaust | Improved engine breathing and sound |

| ECU Tuning | Optimized fuel mapping for better performance |

| Turbocharger Installation | Significant power boost without increasing engine size |

Transmission Care and Repair

Maintaining and servicing the gearbox of heavy vehicles is crucial for optimal performance and longevity. Proper attention to this component can prevent costly breakdowns and ensure smooth operation. Regular inspections and timely interventions play a vital role in the health of the transmission system.

Routine Maintenance Practices

Regular checks of fluid levels and condition are essential. It’s important to replace transmission fluid according to the manufacturer’s recommendations. Additionally, inspecting filters and ensuring that they are clean can prevent debris from causing damage to the internal components.

Troubleshooting Common Issues

Recognizing early signs of transmission problems can save time and resources. Symptoms such as unusual noises, slipping gears, or delayed engagement should prompt immediate investigation. Utilizing diagnostic tools can aid in identifying underlying issues before they escalate.

Suspension System Adjustments

Proper tuning of the suspension mechanism is crucial for optimal vehicle performance and ride comfort. Adjustments may involve various components to ensure that the system functions effectively under different load conditions and road surfaces. This section outlines the key considerations and procedures for achieving the desired settings.

Key Considerations for Adjustments

When modifying the suspension system, it is essential to assess factors such as load distribution, tire pressure, and the overall condition of the components. A balanced setup not only enhances stability but also prolongs the lifespan of the parts involved. Regular inspections and timely adjustments can prevent premature wear and ensure safe operation.

Adjustment Procedures

To initiate adjustments, begin by identifying the specific components that require attention, such as air springs or shock absorbers. Utilize appropriate tools to make necessary modifications, following manufacturer guidelines for specifications. After adjustments are made, conduct a test drive to evaluate the changes and make further refinements as needed.

Brake System Inspection Guidelines

The inspection of the braking mechanism is essential for ensuring optimal performance and safety. Regular checks can help identify potential issues before they escalate, allowing for timely maintenance and repairs.

Begin the examination by assessing the overall condition of the brake components. Look for signs of wear, such as cracks or deformations in the brake pads and discs. It is crucial to verify that all parts are securely attached and functioning as intended.

Next, check the fluid levels in the braking system. Low fluid can indicate leaks or other malfunctions. If necessary, top up the fluid with the recommended type, and inspect the lines for any signs of leakage or damage.

Finally, conduct a test of the braking performance. Ensure that the vehicle stops effectively and promptly when pressure is applied to the brake pedal. Any unusual noises or vibrations during braking should be investigated further.

Bodywork and Exterior Maintenance

Proper upkeep of the vehicle’s outer surfaces is essential for both aesthetics and functionality. Regular attention to the bodywork ensures longevity and preserves the overall value of the machine. This section outlines crucial practices to maintain the integrity and appearance of your vehicle.

Regular Inspections

Conduct frequent checks for any signs of damage, such as dents, scratches, or rust. Addressing these issues promptly can prevent more extensive repairs in the future. Ensure that all seals and weatherstripping are intact to protect the interior from moisture and debris.

Cleaning and Protection

Maintain the exterior by washing it regularly with appropriate cleaning agents. Consider applying a protective coating to safeguard against environmental elements. Waxing can also enhance the shine and provide an additional layer of defense against contaminants.

Cooling System Management

The management of a vehicle’s cooling mechanism is essential for maintaining optimal engine performance and longevity. This section explores the critical components and maintenance practices necessary to ensure the system operates effectively, preventing overheating and related issues.

Key Components of the Cooling System

A well-functioning cooling system consists of several vital elements that work together to regulate temperature. These components include the radiator, water pump, thermostat, hoses, and coolant. Each plays a significant role in ensuring that the engine remains within the appropriate temperature range during operation.

| Component | Function |

|---|---|

| Radiator | Dissipates heat from the coolant |

| Water Pump | Circulates coolant throughout the system |

| Thermostat | Regulates coolant flow based on temperature |

| Hoses | Transport coolant to and from the engine |

| Coolant | Absorbs and dissipates heat |

Maintenance Practices

Interior Comfort Upgrades

Enhancing the comfort of your vehicle’s interior can significantly improve the overall driving experience. By incorporating modern features and thoughtful design elements, you can create a more enjoyable and relaxing environment for both the driver and passengers. This section explores various upgrades that can elevate comfort levels within the cabin.

Consider the following improvements for a more comfortable interior:

| Upgrade | Description |

|---|---|

| Seating Enhancements | Invest in ergonomic seats with adjustable lumbar support and heating options to provide superior comfort during long journeys. |

| Climate Control | Upgrade to an advanced climate control system that offers dual-zone temperature settings, ensuring optimal comfort for all passengers. |

| Sound Insulation | Add soundproofing materials to minimize external noise, creating a quieter and more peaceful cabin atmosphere. |

| Lighting | Incorporate ambient lighting with adjustable brightness to enhance the mood and provide a cozy environment during nighttime driving. |

| Storage Solutions | Implement smart storage options, such as overhead compartments and under-seat bins, to keep the interior organized and clutter-free. |

Safety Features and Checks

Ensuring the reliability and security of a heavy-duty vehicle involves a comprehensive understanding of its safety attributes and routine inspections. Properly functioning safety systems are essential for preventing accidents and enhancing operational efficiency.

Regular Inspections: Conducting systematic checks on critical components such as brakes, lights, and tires is vital. These inspections should be performed before each trip to identify any potential issues that could compromise safety.

Emergency Equipment: It is crucial to equip the vehicle with necessary emergency tools, including a first aid kit, fire extinguisher, and reflective triangles. Ensuring these items are readily available and in good condition can greatly enhance safety in unexpected situations.

Driver Training: Proper training for operators on safety protocols and emergency procedures is essential. Familiarity with the vehicle’s safety features empowers drivers to respond effectively during critical situations.

System Alerts: Monitoring system alerts and notifications regarding vehicle performance can prevent potential malfunctions. Keeping track of these alerts ensures timely maintenance and repairs, promoting a safer driving experience.

Parts Replacement Recommendations

This section provides guidance on the essential components that may require periodic substitution to maintain optimal performance and reliability. Adhering to these recommendations can enhance the longevity of the vehicle and ensure safe operation.

| Component | Replacement Interval | Notes |

|---|---|---|

| Engine Oil Filter | Every 10,000 miles | Replace with OEM filters for best results. |

| Brake Pads | Every 30,000 miles | Inspect regularly for wear and tear. |

| Air Filter | Every 15,000 miles | Consider replacing more often in dusty conditions. |

| Fuel Filter | Every 20,000 miles | Keep fuel quality in check to avoid issues. |