Proper upkeep of outdoor equipment can significantly enhance its lifespan and performance. This guide provides clear instructions on essential tasks for maintaining a well-functioning, efficient tool, ensuring it stays reliable for garden care. The key lies in following simple steps that improve its resilience and prevent common wear issues.

From regular inspections to addressing small malfunctions, understanding the process of servicing garden equipment at home can save time and money. By incorporating effective techniques, users can restore functionality, maintain sharpness, and improve efficiency, contributing to smoother and safer operation.

We’ll cover the best approaches for cleaning, checking essential components, and addressing minor mechanical adjustments. These practices are designed to help hobbyists and professionals keep their gardening tools in top shape, ensuring optimal performance season after season.

This section focuses on prevalent challenges encountered with various types of cutting devices used for shaping and maintaining outdoor foliage. Understanding these issues is essential for ensuring efficient operation and longevity of the equipment.

Frequent Problems

- Power Supply Failures: Issues related to battery or electrical connections that prevent the device from starting.

- Blade Dullness: Reduced cutting efficiency caused by worn or dull blades.

- Overheating: The equipment may become excessively hot, leading to potential shutdowns or damage.

- Jamming: Occurrences of branches or debris getting stuck in the cutting mechanism.

- Vibration: Excessive shaking during operation, which can indicate misalignment or wear.

Maintenance Tips

- Regularly inspect and clean the cutting edges to prevent rust and improve performance.

- Ensure all electrical connections are secure and free from corrosion.

- Store the equipment in a dry, safe environment to prolong its lifespan.

- Sharpen blades periodically to maintain effective cutting capability.

- Follow manufacturer guidelines for battery care and replacement.

Essential Tools for Repairs

When tackling maintenance tasks on outdoor equipment, having the right instruments is crucial for effective and efficient work. The following tools can help ensure successful upkeep and address any issues that may arise.

- Screwdrivers: A variety of sizes and types, including flathead and Phillips, are essential for loosening and tightening screws.

- Wrenches: Adjustable wrenches and socket sets facilitate the removal of nuts and bolts.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating components.

- Cutters: Sharp cutting tools, such as snips or shears, help in trimming and shaping materials.

- Measuring Tools: A tape measure and ruler ensure precise measurements for replacements or adjustments.

- Cleaning Supplies: Brushes and cloths aid in removing debris and maintaining cleanliness.

Having these essential instruments on hand will greatly enhance the ability to perform necessary tasks and extend the lifespan of your equipment.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues that may arise during the operation of your gardening device. By following a structured methodology, you can efficiently diagnose problems and implement appropriate solutions.

-

Inspect the Power Source: Ensure that the device is properly connected to a power source or that the battery is fully charged.

- Check for damaged cords or loose connections.

- Test the outlet with another device to confirm functionality.

-

Examine the Cutting Mechanism: Look for any obstructions or wear that might affect performance.

- Remove any debris that may be caught in the blades.

- Inspect the blades for dullness or damage.

-

Review Operational Settings: Verify that the settings are correctly adjusted for the task at hand.

- Ensure that the device is set to the appropriate speed and mode.

- Consult the user guide for recommended settings based on the type of material being cut.

-

Check Safety Features: Make sure all safety mechanisms are functioning properly.

- Inspect safety switches and triggers to ensure they are not stuck.

- Confirm that protective guards are in place and secure.

-

Evaluate Overall Performance: After addressing the above steps, test the device to determine if issues persist.

- Perform a trial run in a controlled environment.

- Monitor for any unusual sounds or behaviors during operation.

By systematically addressing each area, you can effectively troubleshoot and restore functionality to your equipment, ensuring optimal performance for your gardening tasks.

Maintenance Tips for Longevity

To ensure the extended life and optimal performance of your gardening tool, regular upkeep is essential. Proper maintenance not only enhances efficiency but also minimizes the risk of unexpected failures. Implementing a few simple practices can greatly contribute to the longevity of your equipment.

First, always keep the cutting edges sharp. Dull blades require more effort and can cause unnecessary wear on the motor. Regularly inspect the blades for signs of damage or dullness, and sharpen them as needed to maintain their effectiveness.

Next, clean the tool after each use. Debris, sap, and dirt can accumulate, potentially affecting performance. Wiping down the surfaces and removing any residues will help prevent corrosion and ensure smooth operation for future tasks.

Additionally, check the motor and electrical components periodically for any signs of wear or fraying. Keeping connections secure and free of moisture is crucial for maintaining safety and functionality.

Lastly, store the equipment in a dry, sheltered area. Protecting it from the elements will reduce the risk of rust and other environmental damage, allowing it to remain in top condition for many seasons to come.

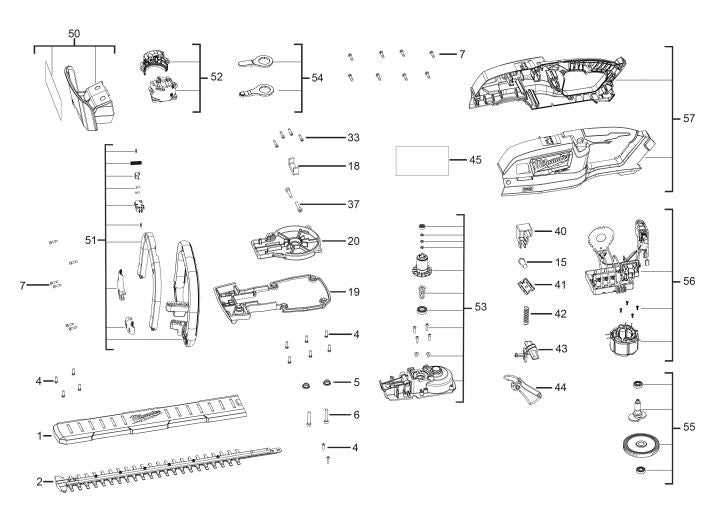

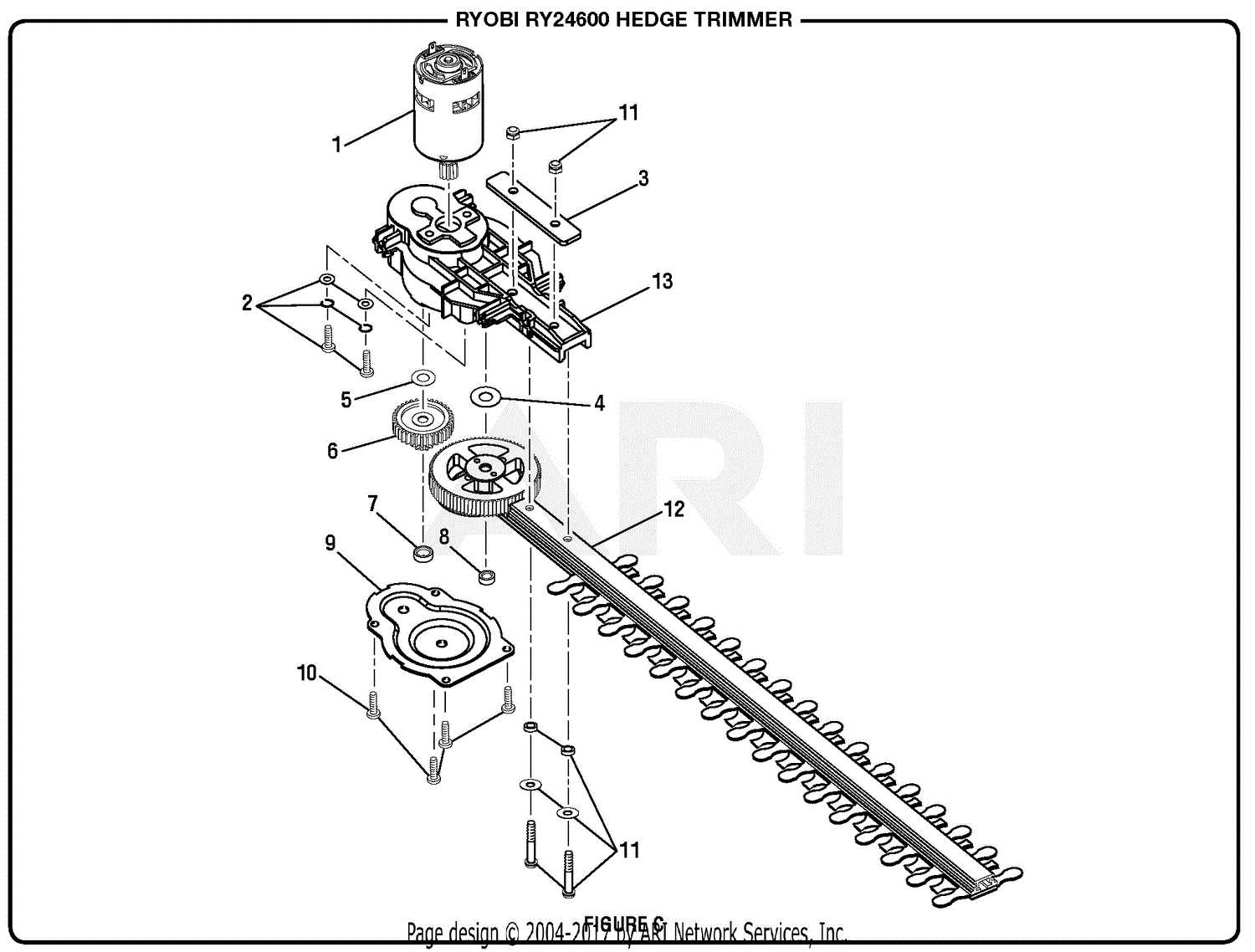

Understanding Trimmer Components

In order to maintain and optimize the functionality of cutting equipment, it is essential to grasp the various parts that contribute to its operation. Each component plays a significant role, affecting performance, durability, and overall efficiency. A thorough understanding of these elements can greatly enhance troubleshooting and maintenance efforts.

Main Parts of Cutting Equipment

The main elements of such devices include the motor, cutting mechanism, and safety features. Each part interacts with the others, making it crucial to understand their individual functions and how they contribute to the whole.

| Component | Function |

|---|---|

| Motor | Powers the equipment, enabling movement and cutting action. |

| Cutting Mechanism | Engages the blades or line, facilitating the trimming process. |

| Handle | Provides control and maneuverability during use. |

| Guard | Ensures safety by covering sharp parts, preventing accidents. |

| Power Source | Supplies energy, either through batteries or electric outlets. |

Importance of Each Component

Understanding the significance of each part not only aids in effective operation but also extends the lifespan of the equipment. Regular inspections and awareness of potential issues with these components can lead to improved performance and safety.

How to Replace Blades Safely

Replacing the cutting elements of your equipment is essential for maintaining optimal performance and ensuring safety during use. Proper handling and precautions can prevent accidents and enhance the longevity of your device. Follow these steps to execute the replacement process efficiently and securely.

Begin by disconnecting the power source to eliminate any risk of accidental activation. Use protective gloves to safeguard your hands from sharp edges. Carefully remove any coverings or guards that may obstruct access to the blades, taking note of their orientation for correct reassembly.

Next, loosen the fastening mechanisms that hold the blades in place. Depending on the design, this may involve unscrewing bolts or unclipping components. Once detached, compare the old blades with the new ones to ensure compatibility. Install the new blades by aligning them precisely and securing them firmly using the original fastening methods.

After ensuring everything is tightly secured, replace any protective coverings or guards that were removed. Finally, reconnect the power source and conduct a brief test to confirm that the equipment operates smoothly without any unusual noises or movements. Regular maintenance of the cutting components will contribute to safer and more effective operation.

Electrical System Diagnostics

Understanding the functionality of the electrical system is essential for ensuring optimal performance and reliability of your device. This section delves into the processes involved in diagnosing issues related to power supply, circuit integrity, and component operation. Proper assessment can help identify faults, allowing for timely interventions and enhancing the longevity of the equipment.

Begin by checking the power source, ensuring that it delivers the correct voltage. Next, examine the wiring for any signs of wear, corrosion, or disconnections that could impede functionality. Additionally, testing switches and connectors is crucial, as these components can often be the source of intermittent issues.

Utilizing a multimeter can provide valuable insights into the electrical flow and help pinpoint discrepancies within the system. Documenting readings and observations will assist in tracking down persistent problems and contribute to a more efficient troubleshooting process.

Proper Cleaning Techniques

Maintaining the cleanliness of your garden tools is essential for their longevity and optimal performance. Regular cleaning helps prevent the buildup of debris and sap, ensuring that the equipment operates efficiently. This section outlines effective methods for keeping your tools in top condition.

Essential Cleaning Steps

Start by removing any visible clippings or dirt using a soft brush or cloth. For stubborn residues, warm soapy water can be used to gently scrub the surfaces. Rinse thoroughly to avoid any soap residue that could affect future usage. It’s important to dry the tools completely to prevent rust and corrosion.

Preventative Measures

To enhance the cleaning process, consider applying a light lubricant after cleaning. This not only protects the surfaces but also ensures smooth operation. Storing tools in a dry, sheltered area will further reduce the risk of dirt accumulation and damage.

Seasonal Maintenance Checklist

Regular upkeep of your gardening tools ensures optimal performance and longevity. Following a seasonal checklist helps to identify necessary tasks that keep your equipment in top shape, making it ready for use when you need it most.

Spring Preparation

- Inspect blades for sharpness and damage.

- Clean all components to remove debris and dirt.

- Check for any loose screws or fittings.

- Lubricate moving parts to ensure smooth operation.

- Replace any worn-out parts as needed.

Autumn Storage

- Thoroughly clean the equipment to prevent rust.

- Drain any fuel to avoid residue buildup.

- Store in a dry location away from extreme temperatures.

- Cover the equipment to protect it from dust and moisture.

- Perform a final inspection before the off-season.

Upgrades and Modifications Options

Enhancing and customizing garden tools can significantly improve their performance and usability. By exploring various upgrade options, users can tailor their equipment to better suit specific tasks, increase efficiency, or even extend the lifespan of the device. Below are some popular modifications that enthusiasts often consider.

Blade Upgrades: One of the most effective ways to enhance cutting performance is by replacing the standard blades with high-quality alternatives. This can lead to cleaner cuts and reduced wear on the motor, making tasks easier and more efficient.

Power Enhancements: Upgrading the power source or battery can greatly affect performance. Opting for a more robust battery or a higher-capacity engine can result in longer operating times and better overall strength for tackling tougher vegetation.

Handle Modifications: Comfort and control can be improved by customizing the handles. Adding ergonomic grips or extending handle lengths can help reduce fatigue and allow for better maneuverability during prolonged use.

Noise Reduction: Implementing sound-dampening materials or modifications can make operation quieter, which is particularly beneficial in residential areas or during early morning tasks.

Considering these upgrades not only enhances functionality but also provides an opportunity for users to personalize their equipment, ultimately leading to a more satisfying gardening experience.