Maintaining an espresso machine in excellent working condition is essential for consistently enjoying quality brews at home. This guide provides an insightful look into key maintenance practices, common technical challenges, and methods to restore your coffee maker’s efficiency. Whether it’s about cleaning, recalibrating settings, or addressing occasional malfunctions, understanding how to approach each aspect will significantly extend the life of your machine.

Here, we’ll explore various processes that keep your machine in optimal shape, from simple adjustments to in-depth troubleshooting steps. Essential insights on how to diagnose specific issues and apply practical solutions will be shared to enhance your coffee experience. With detailed guidance and step-by-step explanations, this resource equips you with the knowledge to perform hands-on care effectively and responsibly.

Each section covers a unique aspect of machine upkeep, focusing on proactive and corrective actions. By the end of this guide, you will gain the confidence to handle routine care tasks as well as address minor issues that could arise over time. Dive in to discover how to keep your espresso maker running smoothly and producing high-quality coffee every day.

Comprehensive Guide for Delonghi Magnifica ESAM 3300 Repairs

In this guide, we provide an in-depth look into maintaining and troubleshooting common issues for this popular coffee machine model. Whether it’s achieving consistent brewing results, managing occasional functionality disruptions, or cleaning critical parts, these steps will assist in keeping your machine in optimal condition.

- Cleaning and Maintenance Tips: Regular upkeep is essential for consistent operation. We cover easy cleaning methods for key components, like the brew group and water tank, which can prevent issues and extend your machine’s lifespan.

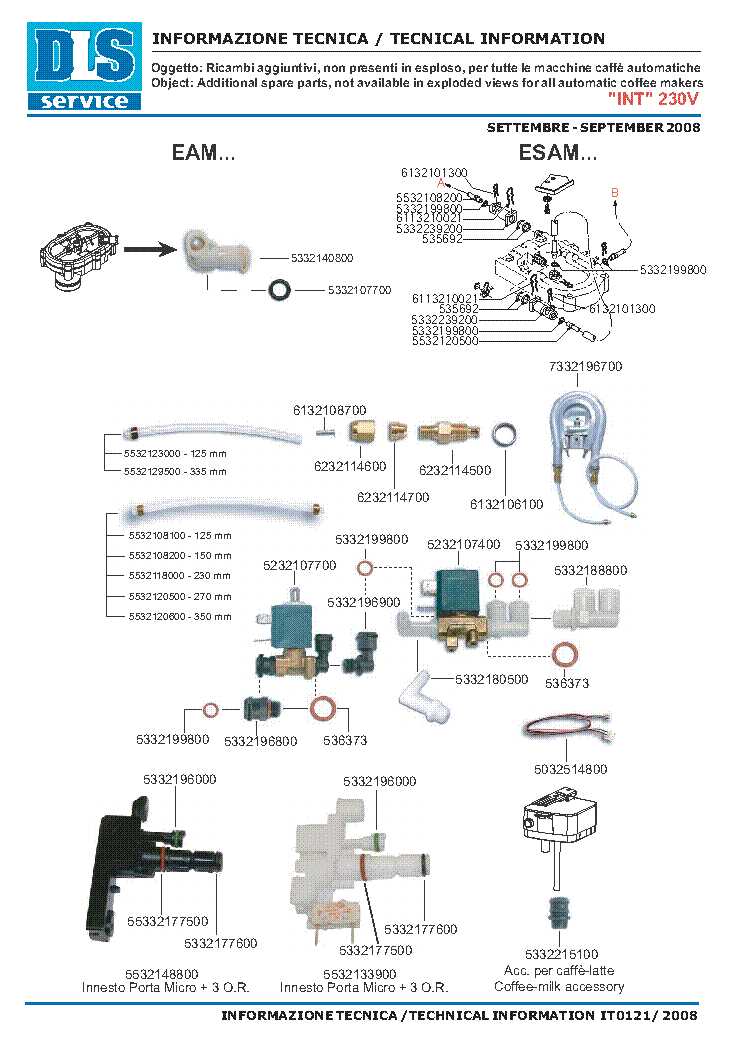

- Common Component Checks: Recognize the signs of wear and tear on frequently used parts. Learn how to inspect hoses, seals, and grinder components for any visible damage or blockages, as these can affect performance.

- Troubleshooting Power and Display: Address common problems with startup, such as display errors or power issues. Understand basic fixes that may resolve these disruptions without the need for professional intervention.

- Adjusting Grinder Settings: Fine-tunin

Identifying Common Malfunctions in ESAM 3300

Understanding frequent issues with this appliance can help improve its functionality and extend its life span. Recognizing early signs of potential problems may also prevent more serious breakdowns, saving time and effort in maintenance. Below, we explore some recurring challenges users might encounter with this model.

Water Flow Disruptions

A common concern involves interruptions in water flow, which could be due to blockages in the internal water system or wear on essential components. This issue often manifests through reduced output or irregular operation. Regularly checking for obstructions and cleaning the system can alleviate this problem, enhancing the overall performance of the appliance.

Temperature Control Fluctuations

Inconsistent temperature regulation can affect the quality of output, especially if the internal heating elements or sensors are malfunctioning. Fluctuating temperatures may indicate a need for recalibration or, in some cases, part replacement. Periodic assessment of temperature consistency helps maintain optimal output and may prevent further issues down the line.

Essential Tools for Repairing Coffee Makers

To maintain and restore coffee makers, a specific set of tools is essential for efficient work and effective results. Each tool plays a role in diagnosing issues, making adjustments, and replacing worn parts. Having the right equipment can simplify the entire process and save valuable time.

Screwdrivers and Hex Keys: Many coffee maker models are held together by a variety of screws, so a comprehensive set of screwdrivers and hex keys is crucial. These tools allow easy access to internal components, enabling thorough inspection and adjustments.

Needle-Nose Pliers: This tool is indispensable for handling small parts and removing connectors in tight spaces. Its slender design helps reach awkward spots without causing damage to sensitive components.

Multimeter: For assessing electrical performance, a multimeter is essential. It allows for accurate testing of power levels, identifying any irregularities in electrical connections or components.

Descaling Solution and Brushes: Cleaning tools like descaling solutions and fine brushes are crucial for maintaining water flow and removing mineral buildup that can impact the machine’s efficiency and taste quality.

Silicone Grease: Proper lubrication is key for smooth operation. Applying silicone grease to moving parts helps reduce wear, particularly in areas exposed to high heat and frequent use.

Having these basic tools at hand not only facilitates troubleshooting but also contributes to the longevity of the machine. Proper maintenance ensures consistently high performance and keeps coffee machines

Step-by-Step Breakdown for Cleaning Process

Regular maintenance is essential for optimal performance and extending the lifespan of your appliance. A thorough cleaning routine ensures each component remains in top condition, free from buildup and residues. Follow these steps to maintain a spotless and smoothly functioning machine.

1. Empty the Grounds Container: Begin by removing the container where used grounds collect. Discard any leftover grounds, then wash the container with warm water and mild soap, rinsing thoroughly before drying.

2. Clean the Drip Tray: Remove the drip tray and wash it with a soft sponge to eliminate any spills or residues. Make sure it’s completely dry before placing it back to avoid moisture buildup.

3. Rinse the Water Tank: Detach the water tank and rinse it under cool, running water. If there is any mineral residue, use a gentle brush to scrub the interior lightly. Refill with fresh water when finished.

4. Wipe the Exterior: With a damp, lint-free cloth, wipe down the exterior surfaces. Pay special attention to areas that may have accumulated fingerprints or spills, leaving the machine looking polished and clean.

5. Descale

Diagnosing Issues with Water Flow

Proper water flow is essential for optimal performance and quality. Over time, reduced flow or blockages may affect the device’s functionality, making it important to identify and address these issues early. This guide will help in pinpointing common causes of restricted water movement and in taking steps to ensure smooth operation.

Several factors may contribute to water flow complications. These can range from clogging within the pipes, buildup in essential components, or wear on internal mechanisms. By isolating each factor, a more effective resolution can be achieved.

Common Issue Possible Cause Solution Weak Water Stream Partial blockages in tubes or connectors Clean or replace affected tubing No Water Flow Pump malfunction or severe blockage Inspect pump, clean or replace as needed Inconsistent Flow Air trapped in system or buildup Prime system, clear air and clean components Regular maintenance, such as flushing the system and inspecting connections, can prevent most water flow issues. By keeping all parts clear of debris and buildup, consistent

Replacing Grinder Components in ESAM 3300

When it comes to maintaining the functionality of a coffee maker, ensuring that the grinding system operates smoothly is crucial. Over time, various parts of the grinder may wear out or become inefficient, necessitating their replacement. This section will guide you through the process of swapping out the essential components of the grinding mechanism to restore optimal performance.

Identifying Components for Replacement

Before beginning the replacement process, it’s important to identify which parts may need attention. Common components that often require replacement include:

- Burrs

- Grinder motor

- Hopper

- Grind adjustment knob

Steps for Replacing Grinder Components

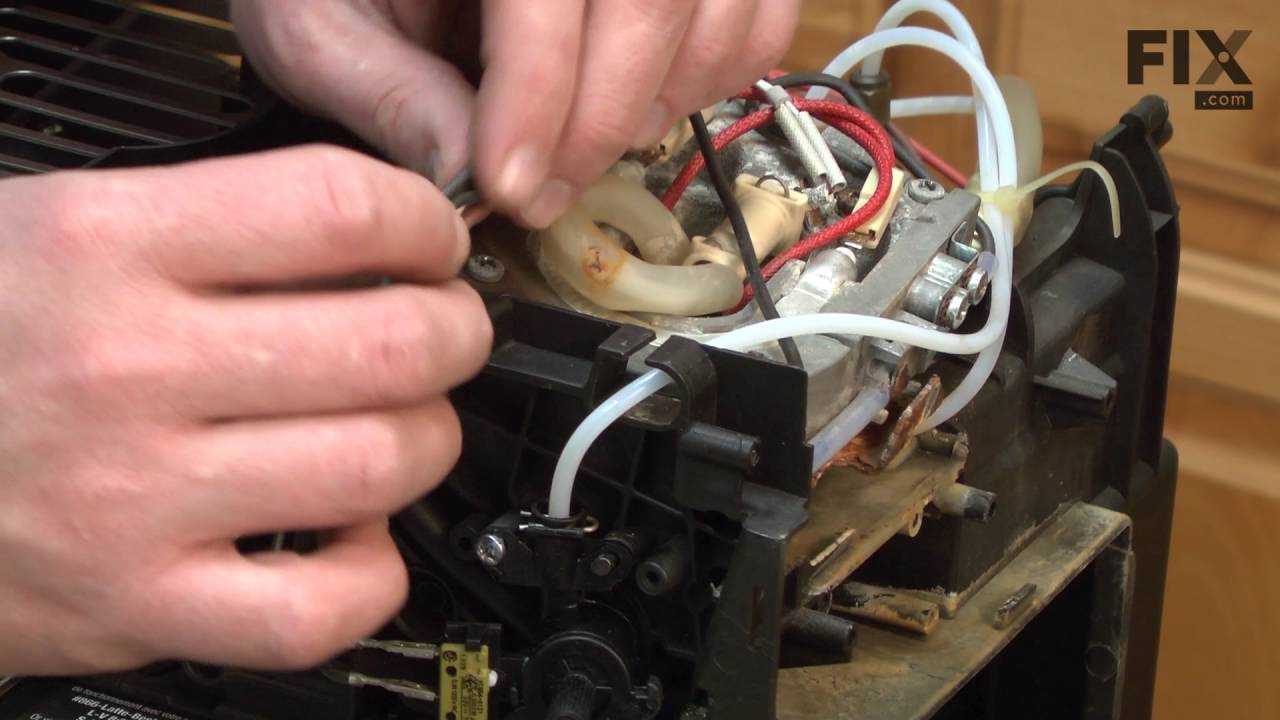

- Unplug the machine: Always ensure that the device is disconnected from power to avoid any electrical hazards.

- Remove the water reservoir: Take out the water container to gain access to the grinder area.

- Take out the grinder assembly: Depending on the model, you may need to unscrew or unclip the grinder to detach it from the machine.

- Replace the worn components: Carefully remove the damaged parts and install the new ones, ensuring they are securely fitted.

- Reassemble the grinder: Once the replacements are in place, reattach the grinder assembly and ensure all components are aligned correctly.

- Test the grinder: Plug in the coffee maker and run a test to ensure the grinding system operates efficiently.

By following these steps, you can effectively replace the grinder components and maintain the quality of your coffee preparation process.

Maintaining Optimal Steam Pressure Levels

Achieving and sustaining the correct steam pressure is essential for the performance of espresso machines. Proper maintenance ensures that your equipment delivers rich, frothy milk and consistently brewed beverages. By following a few simple steps, you can ensure that your machine operates efficiently and produces high-quality results.

Key Factors Influencing Steam Pressure

- Water Quality: Using filtered or distilled water can prevent mineral buildup that affects pressure.

- Temperature Settings: Ensure that the temperature is set correctly to facilitate steam generation.

- Regular Cleaning: Routine cleaning of the steam wand and boiler is vital to prevent blockages.

- Component Wear: Check for worn or damaged parts that may hinder pressure stability.

Steps to Optimize Steam Pressure

- Perform regular descaling to remove any calcium deposits.

- Inspect and clean the steam wand after each use to avoid clogs.

- Monitor water levels and ensure the reservoir is filled to the recommended capacity.

- Test the pressure gauge regularly for accuracy and replace it if necessary.

By prioritizing these maintenance practices, you can maintain optimal steam pressure levels, leading to better brewing outcomes and prolonged equipment life.

Calibrating Temperature for Brew Consistency

Achieving the perfect brew requires precise temperature control, as it significantly influences the flavor and aroma of the coffee. By ensuring that the brewing temperature remains consistent, one can enhance the extraction process, leading to a richer and more balanced cup. This section will guide you through the essential steps to calibrate the temperature settings for optimal brewing results.

First, it is important to understand the ideal brewing temperature range, which typically falls between 195°F and 205°F (90°C to 96°C). Start by measuring the current brewing temperature using a reliable thermometer. If the temperature deviates from the recommended range, adjustments must be made. This can often be accomplished through the machine’s settings or control panel.

Next, make the necessary adjustments to the temperature settings, allowing the machine to stabilize before testing again. After calibrating, run a test brew and monitor the temperature closely. This process may require several iterations to achieve the desired consistency.

Lastly, keep in mind that environmental factors, such as water temperature and machine condition, can impact brewing performance. Regularly checking and calibrating your brewing temperature will ensure that each cup of coffee maintains its intended quality, providing an exceptional experience every time.

Fixing Power Supply Problems in ESAM 3300

Power issues can be a common challenge faced by many users of espresso machines. Understanding the potential sources of electrical malfunctions and knowing how to address them is crucial for maintaining optimal performance. This section will outline essential steps and troubleshooting methods to resolve these challenges effectively.

Identifying Symptoms: The first step in diagnosing power supply issues is to observe the machine’s behavior. Common indicators include failure to power on, unusual noises, or intermittent operation. These signs can often point to underlying electrical faults.

Checking Connections: Ensure that all power connections are secure. A loose or damaged power cord can lead to insufficient energy supply. Inspect the plug and socket for any signs of wear or damage that could interrupt the flow of electricity.

Fuses and Circuit Breakers: A blown fuse or tripped circuit breaker is a frequent culprit for power disruptions. Locate the fuse box and check if any fuses have blown. Replacing them may resolve the issue, but persistent problems may indicate deeper electrical issues.

Power Supply Unit Examination: If initial checks do not reveal the source of the problem, the power supply unit itself may require inspection. Look for signs of overheating or burn marks, which could indicate component failure. Testing the unit with a multimeter can help determine if it is functioning correctly.

Consulting Technical Support: If the problem persists despite these efforts, seeking assistance from technical support or a qualified technician may be necessary. Professional guidance can provide valuable insights and solutions tailored to specific issues, ensuring the machine returns to optimal working condition.

Reassembling Parts After Troubleshooting

Once you have successfully identified and resolved the issues with your coffee brewing appliance, it’s time to put everything back together. This process is crucial for ensuring the proper functionality of the machine and maintaining its overall performance. Taking care during reassembly will help you avoid future complications and extend the lifespan of your equipment.

Steps for Reassembly

Follow these steps to ensure a smooth reassembly process:

Step Description 1 Gather all components and ensure they are clean and dry before reassembly. 2 Refer to the disassembly guide to remember the order of reassembling parts. 3 Carefully fit each component back into place, making sure they align correctly. 4 Tighten any screws or fasteners securely to prevent any loose parts during operation. 5 Perform a final inspection to ensure all parts are properly reinstalled and nothing is left out. Final Testing

After reassembly, it’s essential to conduct a test run. This allows you to verify that the appliance operates as expected. Pay attention to any unusual sounds or functions, which could indicate improper reassembly or remaining issues. If everything works smoothly, you can confidently continue enjoying your freshly brewed beverages.

Prolonging the Life of Your Machine

Ensuring the longevity of your appliance involves adopting certain practices that enhance its performance and durability. By following a few essential maintenance tips, you can avoid common issues and enjoy optimal functionality for years to come.

Here are some key strategies to keep your device in top condition:

- Regular Cleaning: Periodically clean the various components, including the brew unit and water tank, to prevent the buildup of coffee oils and mineral deposits.

- Descaling: Implement a descaling routine every few months, especially if you live in an area with hard water, to maintain proper water flow and prevent scaling.

- Use Quality Ingredients: Always utilize fresh, high-quality coffee beans and filtered water to enhance flavor and reduce wear on the machine.

- Monitor Usage: Pay attention to the frequency of use and adjust settings accordingly to avoid overworking the appliance.

- Professional Servicing: Consider periodic professional maintenance checks to address any potential issues before they escalate.

By implementing these practices, you can significantly extend the lifespan of your coffee-making device, ensuring it continues to deliver delightful beverages for many years.