When it comes to ensuring the longevity and performance of your car, having access to detailed instructions is crucial. Many owners are eager to tackle their own projects but often need a reliable resource that covers every aspect of maintaining and fixing common issues. Understanding how to approach these tasks correctly not only saves time and money but also instills confidence in handling various technical challenges.

This guide provides clear and thorough explanations, empowering car enthusiasts and owners with the essential knowledge to keep their vehicle in top condition. With a focus on accuracy and user-friendliness, the instructions here are designed to help you easily follow each step, preventing costly mistakes and enhancing your understanding of your vehicle’s mechanics.

Pontiac Sunfire 1997 Repair Guide

The following guide provides essential information for the upkeep and troubleshooting of a mid-90s vehicle. This section is aimed at helping owners identify common issues and perform basic maintenance tasks to extend the lifespan of their vehicle. By following these steps, users can address a range of problems effectively, ensuring safe and reliable operation.

Maintenance Essentials

Regular servicing is key to keeping any car in optimal condition. Performing routine checks on vital components like the engine, brakes, and suspension helps in preventing unexpected breakdowns. Monitoring fluid levels, such as engine oil and coolant, and replacing them when necessary, ensures smooth operation. Paying attention to warning signs, such as unusual noises or vibrations, allows for early detection of potential issues.

Troubleshooting Common Issues

Addressing recurring faults can be challenging, but a proactive approach makes all the difference. Begin by inspecting electrical connections and examining any loose or corroded wiring. If symptoms like stalling or poor acceleration are evident, focus on the ignition system and fuel delivery. It’s also crucial to perform periodic checks on key parts, like belts and hoses, which can deteriorate over time.

Engine Troubleshooting and Fixes

Identifying and addressing issues under the hood requires a careful approach, as various components must work in harmony for smooth vehicle operation. Understanding the common symptoms and their underlying causes is crucial to ensuring consistent engine performance and reliability.

Common Signs of Engine Problems

There are several indicators that can signal underlying mechanical issues. Recognizing these early can help prevent more significant damage and costly repairs. Below are some common symptoms:

- Unusual Noises: Knocking, tapping, or hissing sounds often indicate problems such as worn-out bearings, loose belts, or issues with the cooling system.

- Power Loss: A noticeable decrease in acceleration or difficulty maintaining speed can point to issues with fuel delivery or spark plugs.

- Smoke from the Exhaust: Different colors of smoke–blue, white, or black–can provide clues to potential problems like oil leakage, coolant issues, or incorrect fuel-air mixture.

- Warning Lights: Engine warning lights often indicate specific sensor-detected problems, making diagnostics more straightforward when checked with a scanning tool.

Step-by-Step Solutions to Address Issues

Once you identify the problem, it’s essential to follow a structured approach for repairs. Below are some basic steps for common engine issues:

- Check Fluids: Low levels of oil or coolant can lead to overheating or friction, damaging internal parts. Regularly inspect and top up essential fluids.

- Inspect Electrical Connections: Ensure all electrical components, including the ignition system, are free from corrosion and tightly connected to avoid misfires or starting issues.

- Examine Belts and Hoses: Over time, belts can become loose or cracked, and hoses may deteriorate

Electrical System Diagnosis Tips

Understanding how to effectively diagnose issues within a vehicle’s electrical framework is crucial to maintaining optimal performance. A systematic approach can help in identifying faulty connections, malfunctioning components, and underlying problems that might otherwise go unnoticed. With a solid strategy and the right tools, even complex electrical challenges can be resolved efficiently.

Inspect Wiring and Connections – A thorough examination of all visible cables and connectors is essential. Look for signs of wear, corrosion, or loose attachments, as these can cause intermittent issues or failures. Replacing worn-out wires or connectors can often restore proper functionality.

Use Diagnostic Tools Efficiently – Utilize multimeters and circuit testers to measure voltage, continuity, and resistance in critical areas. This helps in narrowing down the problem to a specific segment or component. Ensure to follow safety procedures when working with live circuits.

Check Grounding Points – Faulty grounding can lead to numerous electrical problems. Inspect all grounding locations to confirm they are secure and free from rust or dirt buildup. Clean and tighten these points as needed to maintain a reliable electrical connection.

Test Key Electrical Components – Assess key elements like the alternator, battery, and fuses, as these are often central to common failures. Testing these parts helps ensure they are providing adequate power and functioning within specified limits.

By following these steps, troubleshooting an electrical setup can become more efficient, reducing the time spent on identifying and fixing issues while enhancing the reliability of the entire system.

Transmission Maintenance Essentials

Proper upkeep of the transmission system is vital for ensuring smooth performance and longevity of any vehicle. This crucial component plays a key role in transferring power from the engine to the wheels, making regular inspection and care essential to avoid issues that could affect the driving experience.

Key Practices for Transmission Care

One of the fundamental practices is checking the fluid levels consistently. Low or degraded fluid can lead to overheating and damage to internal components. It’s advisable to use a high-quality transmission fluid that matches the system’s requirements. Also, remember to monitor for leaks, which could be early signs of potential issues.

Importance of Regular Inspections

Scheduling periodic inspections with a qualified technician can prevent costly repairs in the future. Regular evaluations help identify worn-out components, such as seals and gaskets, which, if left unchecked, could cause more significant damage. Additionally, timely replacements of filters and fluids contribute to a well-functioning system.

Following these guidelines ensures a longer lifespan and smoother operation of the transmission, reducing the risk of unexpected breakdowns and costly repairs.

Suspension and Steering Adjustments

The precision and stability of a vehicle’s suspension and steering systems are vital for maintaining both safety and comfort on the road. Understanding and properly adjusting these components helps ensure a smooth ride, reliable handling, and better response to driving conditions. Fine-tuning these systems enhances overall vehicle performance and durability, minimizing wear and tear on crucial parts.

Inspecting and Tuning the Suspension

Regular inspection of the suspension is essential to detect signs of wear, such as worn bushings or leaking shocks. Adjustments should focus on achieving optimal ride height, alignment, and damping characteristics. Key elements include the alignment of wheels, balancing of the ride height, and ensuring the proper function of shock absorbers and struts. This can involve replacing damaged components and fine-tuning the suspension geometry for a balanced driving experience.

Steering Calibration and Adjustments

The steering system requires precise calibration to maintain directional stability and reduce driver fatigue. Key adjustments include ensuring that the steering wheel is centered, the alignment is accurate, and there is no excess play in the steering column. Fine-tuning the steering response also involves inspecting the tie rods, adjusting the power steering system, and checking for any worn or loose components that may impact handling.

Component Inspection Focus Adjustment Recommendations Shock Absorbers Check for leaks and wear Replace if leaking or unresponsive Wheel Alignment Inspect toe, camber, and caster angles Adjust to manufacturer’s specifications Steering Linkages Test for excessive play or wear Tighten or replace worn components Braking System Repairs and Upgrades

The braking system is crucial for vehicle safety, requiring regular maintenance and timely enhancements to ensure optimal performance. Upgrading components not only improves responsiveness but also enhances overall driving experience. This section delves into essential procedures for maintaining and upgrading your vehicle’s stopping mechanisms.

Essential Maintenance Procedures

Regular inspection and maintenance of the braking system can prevent more significant issues and prolong its lifespan. Key procedures include checking brake pads, rotors, and fluid levels. It’s advisable to follow a consistent schedule to ensure all components function correctly.

Component Recommended Action Frequency Brake Pads Inspect and replace if worn Every 20,000 miles Brake Rotors Check for warping and replace if necessary Every 30,000 miles Brake Fluid Flush and replace Every 2 years Upgrading Brake Components

Consider upgrading to high-performance brake pads and rotors for improved stopping power and reduced fade during intense driving conditions. Additionally, installing stainless steel brake lines can enhance pedal feel and responsiveness. Evaluate your driving habits to determine the most beneficial upgrades.

Fuel System Inspection Guidelines

Ensuring the optimal performance of the fuel system is vital for the overall efficiency of the vehicle. Regular examination of various components can prevent potential issues and maintain the engine’s functionality. This section outlines essential procedures for evaluating the fuel delivery system.

Component Inspection Criteria Recommended Action Fuel Pump Check for unusual noises or vibrations during operation. If issues are detected, consider replacement. Fuel Filter Inspect for clogs or contamination. Replace if any blockages are found. Fuel Injectors Examine for leaks and proper spray pattern. Clean or replace as necessary. Fuel Lines Look for signs of wear, cracks, or leaks. Replace damaged lines immediately. Regular inspections of these components will contribute to a smoother operation and extend the lifespan of the engine. Follow these guidelines to ensure a reliable fuel system.

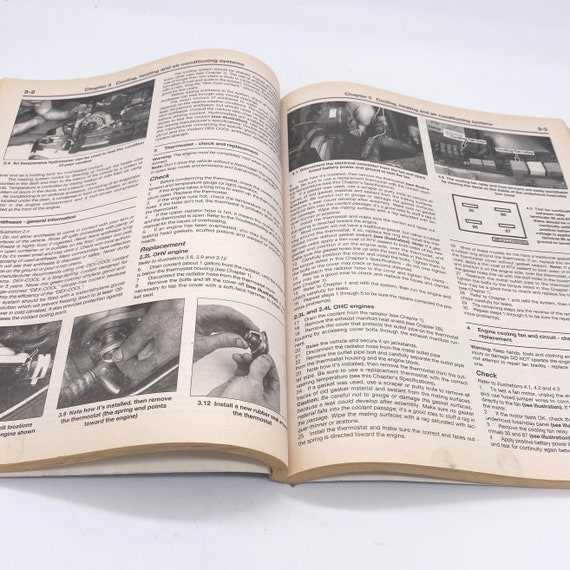

Cooling System Checks and Repairs

The cooling system is vital for maintaining optimal engine temperature and preventing overheating. Regular inspections and timely interventions can enhance performance and extend the lifespan of the vehicle. Understanding the components involved and recognizing signs of potential issues are crucial for effective maintenance.

Inspecting Coolant Levels

Begin by checking the coolant levels in the reservoir. Ensure that the liquid is within the recommended range, as low levels can lead to insufficient cooling and engine damage. If the coolant is depleted, refill it with the appropriate mixture of antifreeze and water, following manufacturer specifications.

Examining Hoses and Connections

Next, inspect the hoses and connections for signs of wear or leaks. Look for cracks, bulges, or discoloration, as these can indicate deterioration. Tighten loose connections and replace any damaged hoses to prevent coolant loss and ensure a secure flow within the system.

Exterior and Bodywork Restoration

Restoring the exterior and bodywork of a vehicle involves a comprehensive approach to enhance its aesthetic appeal and structural integrity. This process not only revives the original charm but also protects the vehicle from environmental elements that can lead to deterioration over time.

The first step in this rejuvenation journey typically includes a thorough inspection of the body panels, trim, and paintwork. Identifying areas with rust, dents, or scratches is crucial, as these imperfections can affect the overall appearance and performance of the vehicle.

Restoration Step Description Surface Preparation Cleaning and sanding the exterior to remove old paint and rust, ensuring a smooth surface for new applications. Body Repairs Addressing any structural damages such as dents and rust spots using fillers and proper techniques to restore original shapes. Painting Applying high-quality paint that matches the vehicle’s original color, followed by clear coating for added protection and shine. Finishing Touches Adding new trim, polishing surfaces, and ensuring all elements are securely reattached to achieve a polished look. By following these essential steps, one can effectively breathe new life into a vehicle’s exterior, ensuring it remains visually appealing while standing the test of time.

Interior Components Maintenance

Ensuring the proper upkeep of the interior elements of your vehicle is essential for both functionality and comfort. Regular attention to these components can prevent wear and tear, enhance the overall aesthetic, and maintain a pleasant driving environment. This section outlines the key practices to keep the interior in optimal condition.

Start by routinely inspecting and cleaning surfaces, including the dashboard, seats, and floor mats. Use appropriate cleaning solutions to avoid damage and preserve the materials. Pay special attention to any spills or stains, addressing them promptly to prevent permanent discoloration.

Additionally, check the functionality of essential features such as window controls, door locks, and lighting systems. Ensure that all electrical components operate smoothly, replacing any burnt-out bulbs or malfunctioning switches as needed. Regular lubrication of moving parts can also enhance performance and extend lifespan.

Lastly, consider the importance of maintaining a clean air system. Regularly replace the cabin air filter to ensure fresh air circulation within the vehicle. This practice not only improves air quality but also contributes to the overall comfort during your travels.

Exhaust System Replacement Techniques

Replacing the exhaust system is a crucial maintenance task that ensures optimal vehicle performance and compliance with emissions regulations. Proper techniques can help achieve a successful installation, enhancing both efficiency and longevity of the components.

Preparation and Safety

Before starting the replacement process, it’s essential to prepare adequately:

- Ensure the vehicle is parked on a level surface.

- Gather necessary tools, including wrenches, sockets, and a jack.

- Wear safety gear such as gloves and goggles to protect against potential hazards.

Removal and Installation Steps

The following steps outline the removal and installation process:

- Begin by removing the old exhaust components, starting from the rear and working towards the front.

- Use penetrating oil on stubborn bolts to facilitate easier removal.

- Inspect all new parts for damage before installation.

- Align the new exhaust components carefully, ensuring proper fitment with hangers and brackets.

- Secure all connections using the appropriate fasteners, and double-check for any leaks after installation.

Following these techniques will contribute to a smoother operation of the vehicle’s exhaust system and maintain its overall performance.

Lighting and Signal System Repairs

Proper functionality of the illumination and signaling components is essential for ensuring safe driving conditions. This section will explore the essential procedures for maintaining and troubleshooting these vital systems, enabling drivers to enhance visibility and communicate effectively with other road users.

To successfully address issues related to lighting and signaling, consider the following common components:

- Headlights

- Taillights

- Turn signals

- Brake lights

- Interior lights

When encountering problems, it is important to perform systematic checks. Follow these steps:

- Inspect all bulbs for any signs of damage or burnout.

- Examine the wiring and connections for corrosion or loose fittings.

- Test the switches for proper operation.

- Ensure the fuses related to the lighting system are intact.

- Assess the battery voltage and connections for any power supply issues.

For each component, specific troubleshooting techniques may apply. Regular inspections can prevent future malfunctions and ensure optimal performance of the vehicle’s illumination and signaling capabilities.

Common Issues and Quick Solutions

This section addresses frequent challenges encountered by vehicle owners, providing effective and prompt remedies. Understanding these typical problems can significantly enhance the driving experience and extend the life of your automobile.

Frequent Mechanical Problems

- Engine Overheating: A common concern, often stemming from coolant leaks or a malfunctioning thermostat. Regular checks and timely replacements can prevent severe damage.

- Transmission Slipping: This issue can cause a loss of power when accelerating. Regular fluid checks and changes can help maintain proper function.

- Brake Wear: Noisy or unresponsive brakes may indicate worn pads. Immediate replacement is recommended for safety.

Electrical System Glitches

- Battery Drain: Regularly inspect battery terminals for corrosion and ensure connections are secure. If issues persist, consider replacing the battery.

- Dashboard Warning Lights: Various indicators can illuminate due to minor issues. A quick scan with a diagnostic tool can pinpoint the problem.

- Faulty Starter: If the engine fails to turn over, a weak starter may be the culprit. Testing and replacing the starter can restore functionality.