In the culinary world, efficiency and precision are paramount. The tools designed for food preparation are indispensable assets that significantly enhance productivity and quality. Understanding how to maintain and troubleshoot these vital machines can greatly extend their lifespan and ensure optimal performance.

Regular upkeep is crucial for preventing issues that could disrupt daily operations. Familiarity with the specific components and functions of your appliances allows for prompt identification of potential problems. By mastering the fundamentals of care and restoration, users can avoid costly downtime and repairs.

This comprehensive guide offers insights into common challenges and solutions for maintaining high-performance kitchen equipment. Whether you are a seasoned professional or just starting out, equipping yourself with the right knowledge will empower you to keep your devices running smoothly and efficiently.

Understanding Robot Coupe Machines

The world of commercial food preparation equipment encompasses a variety of high-performance devices designed to enhance efficiency in kitchens. These appliances are essential for both large-scale operations and small establishments, facilitating the processing of ingredients in various ways. Their innovative design and functionality make them indispensable tools for chefs and culinary professionals alike.

At the core of these machines lies a commitment to quality and versatility. They are engineered to perform multiple tasks, ranging from chopping and slicing to mixing and pureeing. This multifunctionality not only saves time but also streamlines the cooking process, allowing for greater creativity and precision in meal preparation.

Durability is another key aspect of these devices. Built with robust materials and advanced technology, they can withstand the rigors of daily use in busy kitchens. This reliability ensures that culinary professionals can focus on their craft without the constant worry of equipment failure.

In addition to their practical applications, these machines are designed with user-friendliness in mind. Intuitive controls and ergonomic designs make them accessible to users of all skill levels. Whether a novice or a seasoned chef, anyone can operate these appliances with ease, promoting an enjoyable cooking experience.

Finally, maintaining the efficiency of these vital kitchen companions requires an understanding of their components and functionalities. Regular upkeep not only prolongs their lifespan but also ensures consistent performance, making knowledge of proper handling essential for any culinary setting.

Common Issues with Robot Coupe

When using food processing equipment, various challenges can arise that affect performance and efficiency. Understanding these potential problems can help users troubleshoot effectively and maintain optimal functionality.

Here are some frequently encountered concerns:

- Electrical Failures: Devices may stop working due to faulty wiring or power supply issues.

- Motor Malfunctions: Overheating or unusual noises can indicate a need for inspection or replacement.

- Blade Dullness: Blades losing sharpness can lead to inefficient cutting and require sharpening or replacement.

- Jamming: Ingredients can become stuck, affecting processing time and requiring careful disassembly to resolve.

- Leakage: Fluid leaks may occur, often due to worn seals or improper assembly, necessitating immediate attention.

Being aware of these issues can empower users to take proactive steps in maintaining their equipment, ensuring consistent performance and longevity.

Tools Required for Repairs

Having the right instruments is essential for effective maintenance and troubleshooting of your kitchen equipment. Whether you’re addressing minor issues or conducting thorough overhauls, a well-prepared toolkit can significantly ease the process and ensure optimal performance.

| Tool | Purpose |

|---|---|

| Screwdriver Set | To tighten or loosen screws in various components. |

| Wrench Set | For adjusting nuts and bolts securely. |

| Multimeter | To measure electrical properties and diagnose electrical issues. |

| Replacement Parts | Necessary components for any damaged or worn-out parts. |

| Cleansing Tools | For maintaining hygiene and ensuring all parts are clean. |

| Pliers | For gripping and manipulating wires and small components. |

Equipping yourself with these essential tools not only simplifies the process but also enhances the longevity of the equipment, ensuring it remains in peak condition for daily use.

Step-by-Step Repair Procedures

This section outlines a systematic approach to addressing common issues encountered in food processing equipment. Following a structured methodology can significantly enhance the efficiency of troubleshooting and restoring functionality. Each step aims to guide users through the diagnosis and resolution of specific problems while ensuring safety and precision in handling the machinery.

Identifying the Issue

The first step in the process involves recognizing the symptoms of malfunction. Users should observe the equipment’s performance, noting any unusual sounds, irregular operations, or error messages. Gathering detailed information about the issue will aid in determining the root cause and selecting appropriate corrective actions.

Executing the Fix

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your kitchen equipment requires regular upkeep and attention. By following specific maintenance practices, you can extend the lifespan of your appliance and maintain its efficiency. Here are some essential tips to keep your device in top condition.

Regular Cleaning

- Clean the appliance after each use to prevent residue buildup.

- Use mild detergents and warm water; avoid abrasive materials that can scratch surfaces.

- Pay special attention to removable parts; these should be thoroughly washed and dried.

Routine Inspections

- Check all electrical connections for wear and tear.

- Inspect moving parts for signs of damage or excessive wear.

- Ensure that seals and gaskets are intact and replace them if necessary.

By implementing these maintenance strategies, you will not only enhance the performance of your equipment but also significantly prolong its service life. Regular attention can prevent costly repairs and ensure consistent results in your culinary endeavors.

Diagnosing Electrical Problems

Identifying issues related to electrical systems can be a complex task that requires careful analysis and systematic troubleshooting. Understanding the underlying components and their interactions is essential for pinpointing faults effectively. This section outlines key strategies and considerations when faced with electrical malfunctions.

Begin by examining power supply connections to ensure that all cables are securely attached and free of damage. A multimeter can be a valuable tool in this phase, allowing you to check voltage levels and continuity throughout the system. If the power source appears functional, investigate internal components such as switches, fuses, and circuit boards for signs of wear or failure.

Next, focus on any visible indicators of malfunction. Flickering lights, unusual noises, or erratic behavior can provide clues to the source of the problem. Take note of any patterns in these symptoms, as they may help narrow down the issue. Additionally, consult any available documentation for specific diagnostic procedures relevant to the equipment in question.

Lastly, if initial troubleshooting does not yield results, consider isolating individual components to test their functionality. This methodical approach not only helps to identify faulty parts but also aids in understanding the overall system better. Always prioritize safety when dealing with electrical systems, and ensure that all necessary precautions are observed.

Blade Replacement and Care

Maintaining sharp and effective cutting tools is essential for optimal performance in any food preparation setting. Regular inspection and timely substitution of these components can greatly enhance the efficiency and longevity of your appliance. This section provides guidance on how to properly replace and care for cutting instruments, ensuring they remain in peak condition.

Replacement Process

To ensure safety and functionality, follow these steps for replacing the cutting instruments:

| Step | Description |

|---|---|

| 1 | Disconnect the appliance from the power source to prevent accidental activation. |

| 2 | Remove the container or bowl, if applicable, to access the blade assembly. |

| 3 | Carefully detach the old blade by following the manufacturer’s instructions, usually involving unscrewing or releasing clips. |

| 4 | Position the new blade securely in place, ensuring it aligns properly with the assembly. |

| 5 | Reassemble any components you removed and reconnect the power supply. |

Maintenance Tips

To prolong the lifespan of your cutting tools, adhere to the following maintenance practices:

- Regularly inspect the blades for signs of wear or damage.

- Clean the blades thoroughly after each use to prevent food buildup.

- Store blades in a protective cover or designated storage area to avoid accidental damage.

- Sharpen blades as needed, following the recommended guidelines for your specific model.

Cleaning and Sanitizing Your Machine

Maintaining hygiene is crucial for the longevity and efficiency of your culinary appliance. Regular cleaning and proper sanitization not only enhance performance but also ensure that the food prepared remains safe for consumption. This section outlines effective steps for keeping your equipment in optimal condition.

Essential Cleaning Steps

Follow these steps to clean your device thoroughly:

- Unplug the appliance and disassemble all removable parts.

- Rinse the components under warm running water to remove any food residues.

- Use a mild detergent and a soft sponge to scrub the surfaces gently.

- Pay special attention to hard-to-reach areas to eliminate hidden debris.

- Rinse all parts thoroughly to remove any soap residue.

- Allow components to air dry completely before reassembling.

Sanitizing Procedures

To ensure a safe cooking environment, follow these sanitizing tips:

- Prepare a sanitizing solution using a food-safe sanitizer according to the manufacturer’s instructions.

- Apply the solution to the cleaned surfaces using a clean cloth or spray bottle.

- Allow the sanitizer to sit for the recommended contact time to effectively eliminate pathogens.

- Rinse with clean water if required by the sanitizer’s instructions.

- Wipe down all surfaces with a dry cloth before reassembling the machine.

By adhering to these cleaning and sanitizing practices, you can ensure that your kitchen equipment remains in excellent working condition and safe for food preparation.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Proper precautions not only protect the individual conducting the service but also extend the life of the equipment. Adhering to safety guidelines can significantly reduce the risk of mishaps, allowing for a smoother and more efficient workflow.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes gloves to shield hands from sharp components and chemicals, safety goggles to protect eyes from debris, and sturdy footwear to prevent slips and falls. Ensuring that all safety equipment is in good condition is vital before starting any task.

Electrical Safety

Before commencing any work, it is imperative to disconnect the device from its power source. This prevents accidental activation during maintenance. Additionally, be cautious when handling electrical components; use insulated tools and avoid working in wet conditions to minimize the risk of electrical shock.

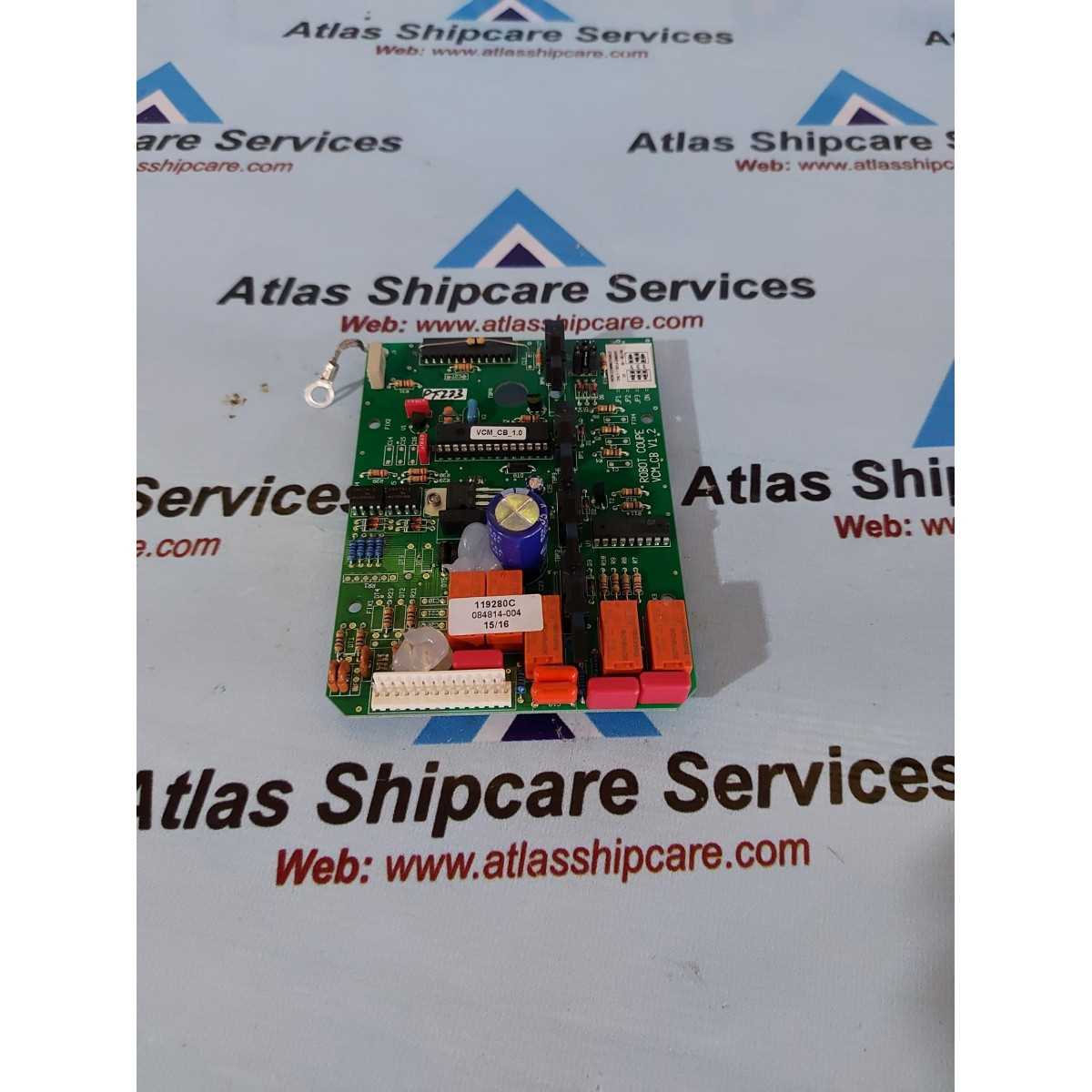

Parts Identification and Ordering

Understanding the components of your kitchen appliance is essential for efficient maintenance and troubleshooting. This section provides guidance on recognizing various parts, ensuring you can accurately identify and order replacements when necessary.

Identifying Components

To effectively manage your equipment, familiarity with its parts is crucial. Here are some common components to know:

- Blades: Essential for chopping and mixing.

- Bowls: The container where food is processed.

- Drive Shafts: Connect the motor to the blades.

- Hoppers: Used for feeding ingredients into the machine.

- Seals: Prevent leaks during operation.

Ordering Replacement Parts

Once you have identified the necessary components, follow these steps to order replacements:

- Refer to the parts list specific to your model.

- Contact authorized suppliers or check online platforms for availability.

- Provide accurate part numbers to ensure compatibility.

- Confirm the shipping and return policies before completing your order.

By following these steps, you can ensure that your appliance remains in optimal working condition, prolonging its lifespan and enhancing its performance.

Troubleshooting Uncommon Malfunctions

Addressing atypical issues in food preparation equipment requires a keen understanding of various components and their interactions. Identifying the root cause of malfunctions can significantly enhance performance and longevity. This section will guide you through some less common problems you may encounter, along with potential solutions.

Inconsistent Performance

If your device exhibits irregular behavior, such as fluctuating speeds or unexpected stops, several factors might be at play. First, inspect the power source to ensure a stable connection. Loose wiring or damaged plugs can lead to power interruptions. Additionally, check for any foreign objects that may hinder the movement of blades or other mechanical parts. Regular cleaning and maintenance can prevent debris accumulation.

Unusual Noises

Sounds outside the normal operational range often indicate internal issues. A persistent grinding or rattling noise may suggest worn bearings or misalignment of parts. To address this, examine the assembly for any loose screws or fittings that may require tightening. If the noise persists, consider consulting a technician for further evaluation to avoid extensive damage.

When to Seek Professional Help

Recognizing the right moment to consult an expert can significantly enhance the longevity and performance of your equipment. Certain issues may arise that, if left unaddressed, could lead to more severe complications or damage. Understanding the signs that indicate a need for professional intervention is crucial for maintaining optimal functionality.

If you encounter persistent operational difficulties, unusual noises, or a lack of responsiveness, these may signal underlying problems requiring specialized knowledge. Additionally, if your attempts at troubleshooting have not yielded positive results, it’s advisable to reach out to a qualified technician. Engaging with an expert not only ensures effective resolution but also safeguards your investment in the long run.

Moreover, if you notice any significant alterations in performance or safety concerns, seeking assistance promptly is vital. Professionals possess the necessary tools and experience to diagnose and resolve issues efficiently, helping you avoid potential hazards or extensive repairs down the line.