Ensuring the longevity and efficiency of a chainsaw requires a thorough understanding of its components and proper upkeep practices. This section provides insights into maintaining and troubleshooting a specific model, focusing on essential techniques that enhance performance and reliability.

Regular maintenance not only prevents potential issues but also optimizes functionality, allowing users to maximize their equipment’s capabilities. Familiarizing oneself with common challenges and their solutions can significantly improve the user experience and prolong the life of the tool.

By following the guidelines presented here, operators will gain the confidence to handle their device effectively, ensuring safety and productivity during use. The aim is to equip users with the knowledge needed to tackle common problems and maintain their equipment in peak condition.

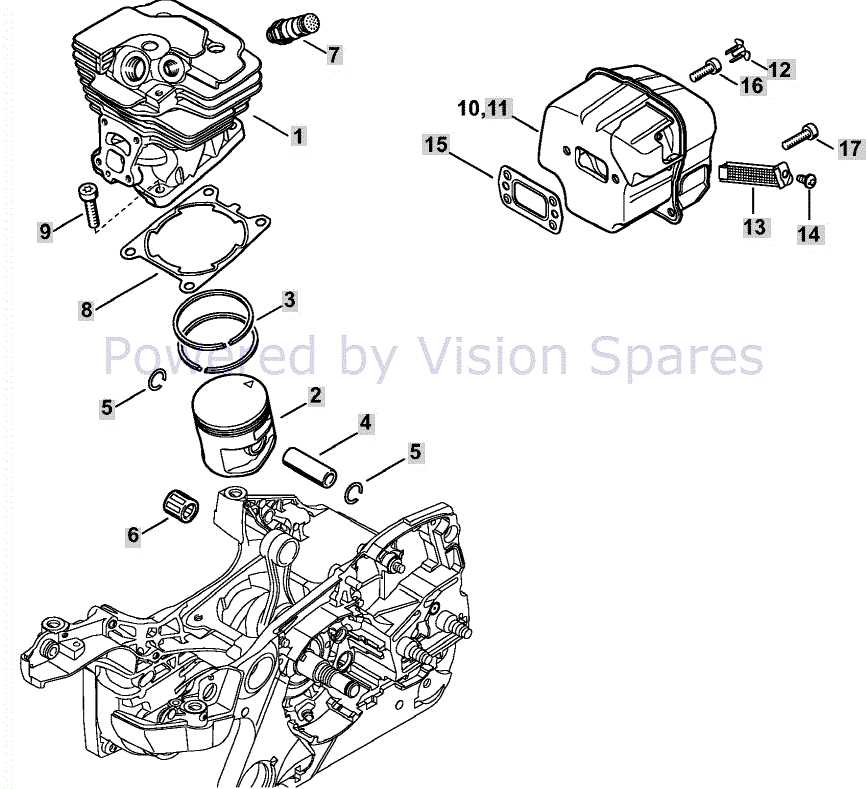

Troubleshooting engine issues can be a daunting task, but with a systematic approach, you can identify and resolve common problems effectively. Understanding the signs of malfunction and knowing where to look is essential for restoring optimal performance.

Here are some key steps to follow when diagnosing engine troubles:

- Listen for Unusual Noises: Pay attention to any strange sounds that may indicate mechanical issues.

- Check for Leaks: Inspect the engine area for any fluid leaks that could affect operation.

- Monitor Engine Performance: Take note of any changes in power output or responsiveness.

- Examine the Fuel System: Ensure the fuel is fresh and the system is free of blockages.

By following these steps and being attentive to the details, you can effectively troubleshoot and resolve engine problems, ensuring smooth operation for your equipment.

Replacing the Bar and Chain

Swapping out the guide bar and cutting chain is an essential maintenance task for ensuring optimal performance and safety. Properly replacing these components can enhance cutting efficiency and prolong the lifespan of your equipment.

Follow these steps to effectively change the guide bar and chain:

- Ensure the engine is off and the spark plug is disconnected to prevent accidental starts.

- Remove any existing protective covers from the guide bar and chain.

- Loosen the tensioning mechanism to relieve tension on the chain.

- Carefully slide the old chain off the guide bar and remove the bar from the machine.

- Inspect the guide bar for any wear or damage and clean it as needed.

- Position the new guide bar in place and thread the new chain around it, ensuring the cutting edges face the correct direction.

- Reattach the guide bar and tighten the tensioning mechanism to ensure the chain is secure.

- Reconnect the protective covers and check that everything is properly aligned.

By regularly replacing the guide bar and chain, you can maintain the efficiency and reliability of your cutting tool.

Cleaning the Air Filter Effectively

Maintaining optimal performance of outdoor equipment requires regular upkeep, including the essential task of cleaning the air filter. A clean filter ensures efficient airflow, preventing dust and debris from entering the engine, which can lead to reduced performance and potential damage.

Steps for Cleaning the Filter

Begin by removing the filter from its housing. Carefully inspect it for any visible dirt or damage. Use compressed air to blow out loose particles, ensuring that you hold the canister upright to avoid moisture accumulation. For stubborn grime, wash the filter with warm soapy water and rinse thoroughly. Allow it to dry completely before reinstallation.

Importance of Regular Maintenance

Regularly cleaning the air filter not only enhances the efficiency of your equipment but also extends its lifespan. A well-maintained filter contributes to better fuel economy and reduces harmful emissions, promoting a healthier environment. Establishing a cleaning routine will ensure your equipment operates smoothly for years to come.

Adjusting Carburetor Settings

Properly calibrating the carburetor is essential for optimal engine performance. This process ensures the right air-fuel mixture, enhancing efficiency and prolonging the lifespan of the equipment. Regular adjustments can help maintain smooth operation and prevent potential issues.

To adjust the carburetor settings, follow these key steps:

| Step | Description |

|---|---|

| 1 | Locate the adjustment screws, typically marked for easier identification. |

| 2 | Start the engine and let it warm up to operating temperature for accurate adjustments. |

| 3 | Use a screwdriver to turn the screws; small adjustments can lead to significant changes in performance. |

| 4 | Monitor engine response after each adjustment, aiming for a steady idle and smooth acceleration. |

| 5 | Once satisfied with the performance, securely fasten any covers to protect the adjustments. |

Preventive Measures for Longevity

Ensuring the durability and efficient performance of outdoor power tools requires regular maintenance and careful handling. By implementing a series of preventive actions, users can extend the lifespan of their equipment and enhance its operational reliability.

Regular Maintenance Practices

- Conduct frequent inspections to identify wear and tear.

- Clean the tool after each use to remove debris and contaminants.

- Sharpen cutting components regularly to maintain efficiency.

- Check and replace filters as needed to ensure optimal airflow.

Proper Storage Techniques

- Store the equipment in a dry, sheltered area to protect it from the elements.

- Avoid placing heavy objects on top to prevent damage.

- Ensure fuel is stored safely and replaced as per manufacturer recommendations.

By adhering to these practices, users can significantly improve the longevity of their tools, ensuring they remain effective and reliable for many years to come.

Safety Tips During Repairs

When undertaking maintenance tasks, ensuring safety should be a top priority. Proper precautions not only protect the individual performing the work but also help to prevent accidents and injuries. Understanding the environment and tools involved is essential for a safe experience.

Here are some important guidelines to follow:

| Tip | Description |

|---|---|

| Wear Protective Gear | Always use appropriate safety equipment, including gloves, goggles, and ear protection, to safeguard against potential hazards. |

| Work in a Well-Lit Area | Ensure that the workspace is adequately illuminated to avoid mistakes and accidents while handling tools and parts. |

| Keep Tools Organized | Maintain a tidy workspace by organizing tools and equipment, which reduces the risk of tripping or misplacing items. |

| Follow Manufacturer Guidelines | Always refer to provided instructions or guidelines specific to the equipment being serviced to ensure proper handling and safety. |

| Stay Focused | Avoid distractions while performing tasks. Maintaining concentration is crucial for safety and precision. |

When to Seek Professional Help

There are instances when attempting to address issues with your equipment may not yield the desired results. Knowing when to involve a skilled technician can save time and prevent further complications. If you encounter problems that seem beyond your understanding, it might be wise to consult an expert.

Signs of Complex Issues

Unusual noises, persistent leaks, or a complete failure to start can indicate deeper underlying problems. If these symptoms persist after basic troubleshooting, it’s advisable to seek assistance from a qualified professional.

Safety Concerns

Safety should always be a priority. If you feel uncertain about handling repairs or if the equipment poses potential risks, engaging a knowledgeable technician is essential. Professionals can ensure that all repairs are performed safely and effectively.

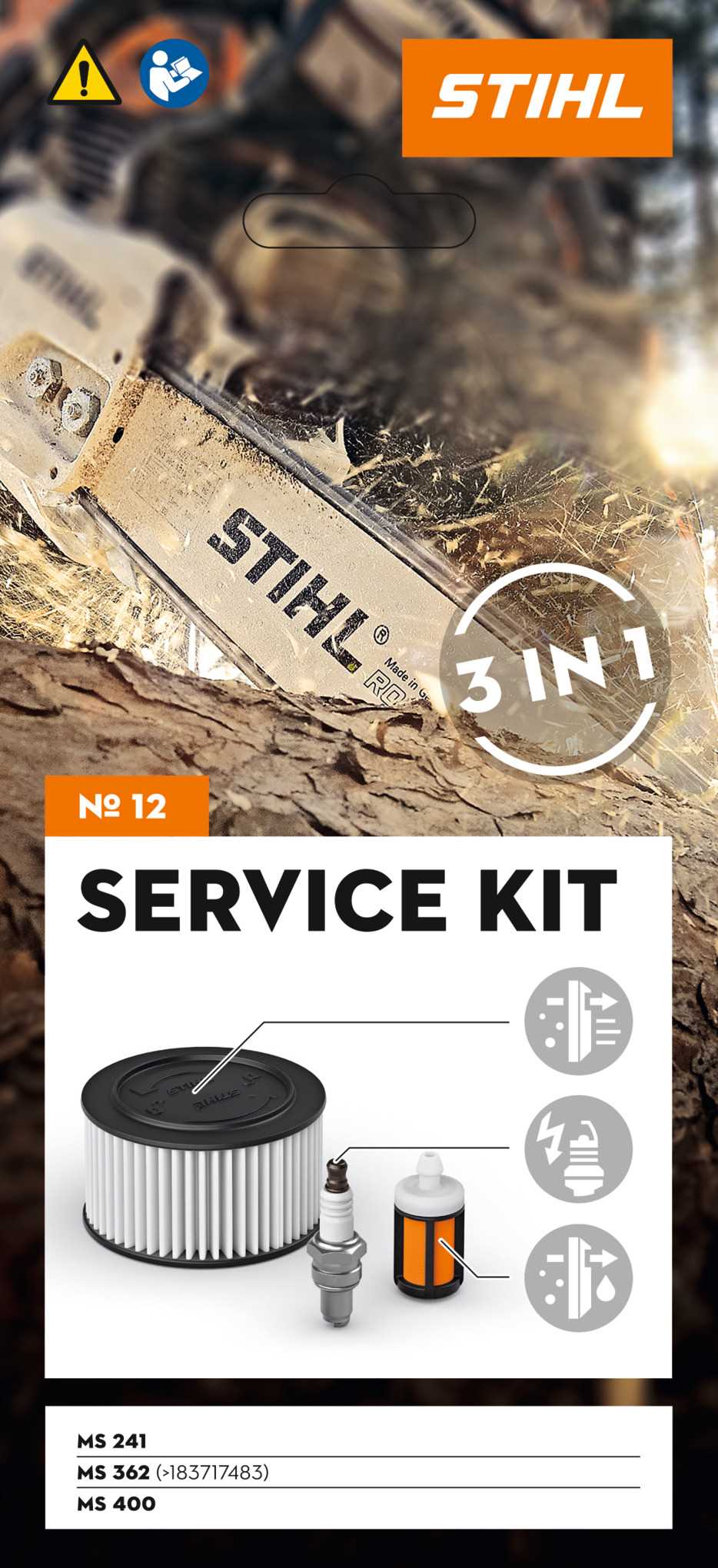

Finding Genuine Replacement Parts

When it comes to maintaining equipment, ensuring the use of authentic components is crucial for optimal performance and longevity. Using original parts guarantees compatibility and reliability, ultimately enhancing the efficiency of your machinery.

Identifying Authorized Dealers

One of the most effective ways to source genuine components is through authorized distributors. These vendors have direct access to original parts and can provide assurance regarding their authenticity. Check for certifications or partnerships with recognized manufacturers to confirm their legitimacy.

Utilizing Online Resources

The internet offers a wealth of information for locating authentic components. Official manufacturer websites often feature parts catalogs, allowing you to search for specific items. Additionally, forums and user groups can provide insights and recommendations for trustworthy suppliers.