The complexity of modern engines necessitates a comprehensive understanding of their components and functions. Proper care and attention are vital to ensure longevity and optimal performance. This section delves into critical aspects of engine upkeep, focusing on best practices and troubleshooting techniques.

With a wealth of knowledge and experience, vehicle owners can navigate common challenges that arise in engine operation. Understanding the inner workings not only enhances efficiency but also empowers individuals to tackle issues proactively. In this guide, we explore the essential processes that contribute to reliable performance and increased durability.

From routine checks to advanced diagnostic procedures, every detail matters in maintaining engine health. By familiarizing oneself with key elements, readers can take informed steps toward ensuring their machinery runs smoothly for years to come. This section serves as a valuable resource for anyone looking to deepen their expertise in engine maintenance.

Overview of Cummins 6.7 Engine

This section provides a comprehensive look at a popular diesel powertrain widely recognized for its reliability and performance. It is often utilized in heavy-duty applications, ensuring exceptional torque and efficiency. Understanding its key features and specifications can help users make informed decisions regarding maintenance and upgrades.

Key Features

The engine is renowned for its robust construction and advanced technology. Incorporating high-strength materials, it is designed to withstand demanding conditions. Its turbocharged system significantly enhances power delivery, while innovations in fuel injection improve overall efficiency and reduce emissions.

Applications

This powerplant finds use in a variety of vehicles, from trucks to agricultural machinery. Its versatility allows it to excel in different environments, providing dependable performance for both commercial and recreational purposes. Owners appreciate its balance of power and fuel economy, making it a preferred choice in the industry.

Common Issues with 6.7 Cummins

Engines of this type are known for their reliability and performance, yet they can encounter specific challenges over time. Understanding these common problems can help owners take preventative measures and ensure optimal operation.

Frequent Challenges

- Fuel System Failures: Issues such as clogged filters or faulty injectors can lead to reduced performance.

- Turbocharger Malfunctions: Signs of wear or failure may affect power output and efficiency.

- EGR System Problems: A malfunctioning exhaust gas recirculation system can result in increased emissions and overheating.

Signs to Watch For

- Unusual noises from the engine.

- Check engine light activation.

- Poor acceleration or sluggish performance.

- Excessive exhaust smoke.

Awareness of these typical issues can aid in early detection and maintenance, prolonging the life of the engine and enhancing performance.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your engine requires a commitment to regular upkeep and attention to detail. By following a few essential practices, you can enhance performance and minimize the risk of unexpected issues. Consistency in maintenance routines is key to achieving optimal results.

Regular Inspections

Conducting frequent inspections is crucial for early detection of potential problems. Look for signs of wear and tear, such as leaks or unusual noises. Pay close attention to fluid levels, including oil and coolant, and replace them as needed. Timely intervention can save you from costly repairs down the road.

Proper Lubrication

Maintaining adequate lubrication is vital for smooth operation. Ensure that all moving parts are regularly greased and that oil changes occur at recommended intervals. Using high-quality lubricants can significantly enhance performance and reduce friction. Remember that the right products contribute greatly to longevity.

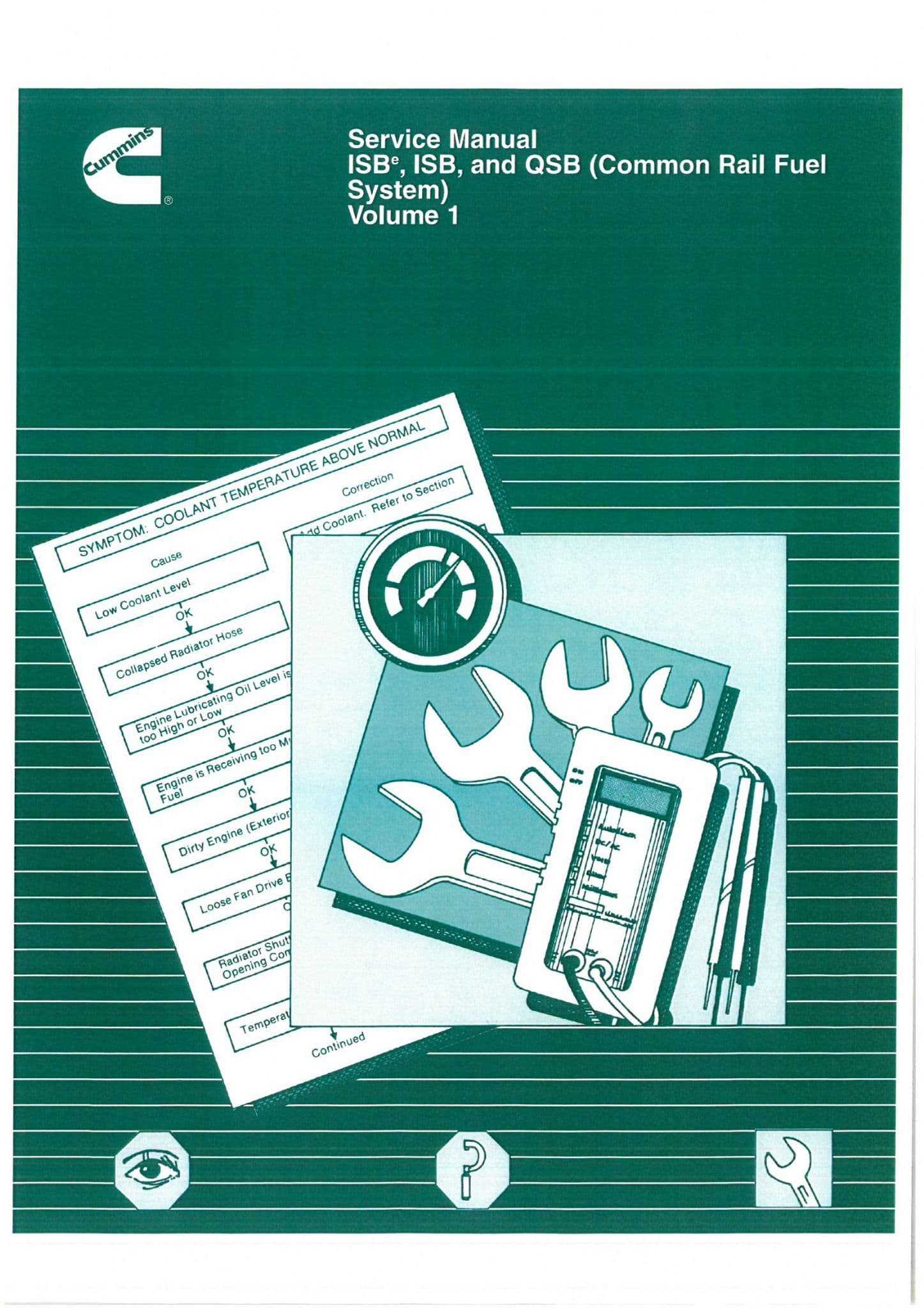

Essential Tools for Repairing Cummins

When it comes to maintaining and servicing high-performance engines, having the right instruments is crucial. This section will explore various essential devices that aid in ensuring optimal functionality and longevity. From diagnostic equipment to hand tools, a well-equipped workshop can significantly enhance the efficiency of maintenance tasks.

Key Diagnostic Instruments

Effective troubleshooting starts with reliable diagnostic tools. These instruments not only help in identifying issues but also streamline the repair process.

| Tool | Description |

|---|---|

| OBD-II Scanner | Used to read error codes and monitor engine performance in real-time. |

| Multimeter | Essential for measuring voltage, current, and resistance, ensuring electrical systems function properly. |

| Compression Tester | Helps assess the condition of cylinders by measuring compression levels. |

Hand Tools and Equipment

In addition to diagnostic instruments, having a set of quality hand tools is vital for carrying out various tasks effectively. These tools provide the precision and leverage needed for intricate repairs.

| Tool | Description |

|---|---|

| Socket Set | A comprehensive collection allows for tackling different fastener sizes with ease. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications, preventing damage. |

| Screwdriver Set | A variety of types and sizes caters to different screws and fasteners. |

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving issues that may arise in your engine system. By following a structured methodology, you can efficiently pinpoint the root cause of malfunctions and implement the necessary corrective actions.

1. Gather Information: Start by collecting detailed information about the problem. Note any unusual sounds, warning lights, or performance issues that have occurred. This initial data is crucial for effective diagnosis.

2. Perform Visual Inspection: Conduct a thorough visual examination of the engine and its components. Look for any signs of leaks, loose connections, or physical damage that may indicate a malfunction.

3. Check Fluid Levels: Ensure that all essential fluids, such as oil, coolant, and fuel, are at appropriate levels. Low fluid levels can lead to various performance issues and should be addressed immediately.

4. Inspect Electrical Systems: Examine the electrical connections and wiring for any signs of corrosion or damage. Use a multimeter to check the voltage and continuity of critical components.

5. Conduct Diagnostic Tests: Utilize diagnostic tools to run tests on the engine. This may include scanning for error codes and evaluating system performance to gather additional insights.

6. Analyze Results: Review the data collected from your inspections and tests. Identify patterns or specific areas of concern that may require further investigation.

7. Implement Solutions: Based on your analysis, take the necessary corrective measures. This could involve replacing faulty parts, tightening connections, or adjusting settings to restore optimal function.

8. Test the Engine: After making repairs, run the engine to verify that the issue has been resolved. Monitor its performance closely to ensure that everything operates smoothly.

9. Document Findings: Record your observations, tests performed, and any repairs made. Keeping detailed records will aid in future troubleshooting efforts and help maintain a history of the engine’s performance.

Understanding Engine Specifications

Comprehending engine specifications is crucial for optimal performance and maintenance. These details provide essential insights into the power unit’s design, capabilities, and operational parameters, enabling enthusiasts and professionals alike to make informed decisions.

Engine specifications encompass various attributes that define its functionality, including:

- Displacement: The total volume of all the cylinders, which directly influences power output and efficiency.

- Horsepower: A measure of the engine’s ability to perform work over time, critical for understanding potential performance.

- Torque: The rotational force produced, essential for determining towing capacity and acceleration.

- Compression Ratio: The ratio of the cylinder’s volume at its largest to its smallest capacity, affecting fuel efficiency and power.

- Fuel System: Details on fuel delivery methods, whether carbureted or fuel-injected, impacting overall performance and emissions.

Recognizing these specifications allows users to assess compatibility with their needs, whether for heavy-duty applications or daily driving. Additionally, awareness of these parameters aids in troubleshooting and upgrading, ensuring the engine operates at its peak.

In conclusion, mastering engine specifications is vital for anyone involved with vehicle maintenance or performance tuning, serving as the foundation for enhancing and preserving the machine’s capabilities.

Fuel System Repair Techniques

The integrity of the fuel system is crucial for optimal engine performance. Ensuring that each component functions correctly can prevent a range of issues, from inefficiency to complete breakdowns. This section outlines effective strategies for addressing common fuel system challenges.

| Component | Common Issues | Repair Techniques |

|---|---|---|

| Fuel Pump | Weak pressure, noise | Inspect for debris, replace if necessary |

| Fuel Filter | Clogging, reduced flow | Replace regularly, check for leaks |

| Injectors | Leakage, poor atomization | Clean with ultrasonic methods, test flow rates |

| Lines and Hoses | Cracks, leaks | Inspect thoroughly, replace damaged sections |

| Fuel Tank | Contamination, rust | Clean thoroughly, consider coatings to prevent corrosion |

By systematically addressing these elements, one can enhance the overall functionality of the fuel system. Regular maintenance and timely interventions will lead to improved performance and longevity of the engine.

Electrical System Diagnostics Explained

The effective functioning of any machinery relies heavily on its electrical components. Understanding how to assess and troubleshoot these systems is crucial for maintaining optimal performance and preventing potential failures. This section delves into the key principles and methodologies involved in diagnosing electrical issues.

Identifying Symptoms: The first step in the diagnostic process is recognizing the signs of electrical problems. Common indicators include unusual noises, erratic behavior, and warning lights. These symptoms can point to various underlying issues that require careful examination.

Utilizing Diagnostic Tools: A variety of instruments are available for pinpointing electrical faults. Multimeters, for example, measure voltage, current, and resistance, providing essential data for analysis. Additionally, specialized scan tools can read fault codes from the system’s computer, offering valuable insights into potential malfunctions.

Testing Procedures: Once symptoms are identified and tools are gathered, a systematic approach to testing is vital. Begin by checking the power supply and ground connections, as these are fundamental to the system’s operation. Following this, inspect wiring and connectors for damage, corrosion, or loose connections that could disrupt functionality.

Interpreting Results: After conducting tests, it’s important to analyze the collected data accurately. Understanding the significance of readings and correlating them with expected values will help in diagnosing issues more effectively. Each component must be evaluated in the context of the entire electrical system to ensure a comprehensive assessment.

Implementing Solutions: Once a fault is identified, the next step is to implement appropriate corrective measures. This may involve replacing damaged components, repairing connections, or updating software in electronic control units. Properly addressing these issues not only restores functionality but also enhances the longevity of the machinery.

In summary, a thorough understanding of electrical diagnostics is essential for effective maintenance and troubleshooting. By systematically identifying symptoms, utilizing the right tools, conducting tests, and interpreting results, operators can ensure the reliability and efficiency of their equipment.

Upgrades and Performance Enhancements

Enhancing the performance of your diesel engine can significantly improve its efficiency and power output. By implementing various modifications and upgrades, you can achieve a more responsive driving experience, increased towing capacity, and better fuel economy. This section will explore effective ways to optimize engine performance, ensuring you get the most out of your vehicle.

Common Modifications

One of the most popular upgrades involves improving air intake and exhaust systems. By replacing factory components with high-performance alternatives, you can enhance airflow, which leads to better combustion and increased horsepower. Additionally, upgrading the turbocharger can provide a substantial boost in torque, enabling your vehicle to handle heavier loads with ease.

Tuning and Calibration

Reprogramming the engine’s control unit is another effective method to enhance performance. Custom tuning allows you to adjust fuel maps and timing, optimizing the engine for your specific needs. Many enthusiasts find that a well-calibrated engine not only delivers better power but also improves overall drivability and responsiveness.

Resources for Finding Replacement Parts

Locating high-quality components for your vehicle can often feel like a daunting task. However, with the right resources and strategies, you can ensure that you find the necessary items efficiently and effectively. This section explores various avenues for sourcing essential parts that meet your specific requirements.

Online Marketplaces: One of the most accessible options for acquiring components is through online platforms. Websites like eBay and Amazon offer a vast array of choices, often at competitive prices. Always check seller ratings and reviews to ensure reliability.

Specialty Retailers: Engaging with retailers that specialize in automotive parts can provide you with expert guidance. These businesses typically have knowledgeable staff who can assist you in finding the exact items you need, and they often carry brands renowned for their quality.

Forums and Online Communities: Participating in online forums dedicated to automotive enthusiasts can be invaluable. Members often share experiences, recommendations, and sources for obtaining parts, making it easier to navigate your options.

Local Junkyards: Visiting salvage yards can be a cost-effective way to find used components. While this approach requires some effort, it can lead to significant savings and the discovery of hard-to-find parts.

Manufacturer Websites: For original equipment manufacturer (OEM) components, visiting the official websites can provide direct access to reliable parts. This ensures that you receive high-quality items that are specifically designed for your vehicle.

Utilizing these resources will enhance your chances of finding the right components while ensuring that you maintain the performance and reliability of your vehicle.