In the realm of machinery upkeep, having a thorough understanding of operational devices is essential for optimal performance and longevity. This section delves into essential practices that ensure reliability and efficiency in the field. Whether you’re a seasoned technician or a newcomer, familiarizing yourself with the intricacies of these systems is crucial for success.

Understanding the intricacies of your equipment can make a significant difference in its functionality. This guide aims to provide insights into troubleshooting, routine inspections, and various techniques that can enhance the lifespan of your machinery. With the right knowledge at hand, you can tackle challenges with confidence and keep your operations running smoothly.

Equipped with detailed information and practical tips, this resource serves as a valuable companion for anyone looking to master the art of maintenance. By embracing the fundamentals and addressing potential issues proactively, you will not only improve performance but also ensure safety in your work environment. Dive into the specifics and elevate your expertise in equipment management.

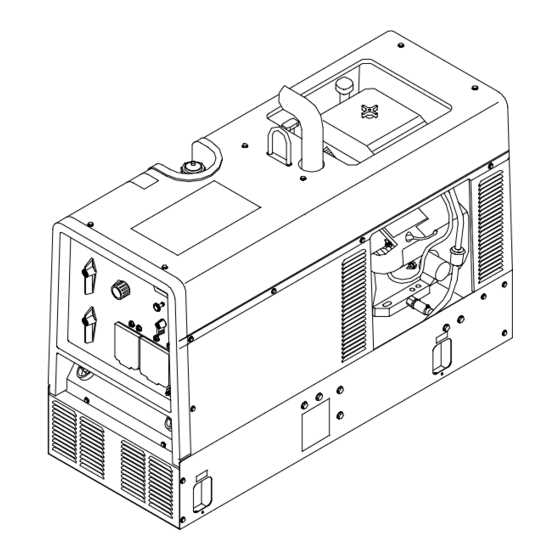

Miller Bobcat 250 Overview

This section provides a comprehensive look at a versatile portable power source designed for various applications. Ideal for both professional and personal use, it combines functionality with ease of transport, making it a popular choice in the industry.

Equipped with advanced features, this unit excels in delivering reliable energy wherever it’s needed. Users benefit from its robust construction, ensuring durability under challenging conditions. Efficiency and performance are key attributes that enhance its usability, allowing it to tackle demanding tasks effectively.

Key Features of the Bobcat 250

This section highlights the essential characteristics that define the performance and efficiency of this powerful machinery. Understanding these attributes can enhance the user experience and optimize operational capabilities.

Performance and Efficiency

The equipment boasts an impressive power-to-weight ratio, allowing it to tackle demanding tasks with ease. Its robust engine delivers reliable performance, ensuring that operators can depend on it for various applications, from construction to landscaping.

User-Friendly Design

Designed with the operator in mind, this model features intuitive controls that simplify operation. The ergonomic layout enhances comfort during prolonged use, while the compact size allows for maneuverability in tight spaces. Maintenance access is also streamlined, facilitating easier upkeep and ensuring longevity.

Common Issues and Troubleshooting

When operating machinery, encountering problems is not uncommon. Identifying and addressing these issues promptly can enhance performance and prolong the equipment’s lifespan. This section outlines frequent complications and offers guidance on resolving them efficiently.

Here are some typical problems you may encounter:

- Starting Difficulties: If the engine fails to start, check the battery connections and ensure there is sufficient fuel.

- Overheating: Regularly inspect the coolant levels and radiator for any blockages or leaks that may cause the engine to run hot.

- Electrical Issues: Flickering lights or malfunctioning controls can indicate wiring problems. Examine all connections for wear and tear.

- Hydraulic System Failures: Low fluid levels or leaks in hoses can lead to decreased performance. Always monitor hydraulic fluid levels and inspect for damage.

To troubleshoot effectively, follow these steps:

- Consult the equipment’s documentation for specific guidance.

- Perform a visual inspection of all major components.

- Test electrical connections with a multimeter to ensure proper voltage.

- Keep a maintenance log to track recurring issues and repairs.

By understanding these common challenges and utilizing effective troubleshooting techniques, operators can maintain optimal functionality and ensure safety while using their equipment.

Maintenance Tips for Longevity

Regular upkeep is essential for extending the lifespan of any machinery. By following a structured maintenance routine, operators can ensure optimal performance and prevent costly breakdowns. Implementing these practices can lead to enhanced efficiency and reliability.

Here are some key maintenance strategies to consider:

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Check Fluid Levels | Weekly | Prevents overheating and wear |

| Inspect Filters | Monthly | Ensures clean operation and airflow |

| Clean the Exterior | After Use | Reduces rust and damage from debris |

| Tighten Loose Components | Monthly | Maintains structural integrity |

| Examine Tires | Weekly | Ensures safety and performance |

Adhering to these guidelines not only fosters a safer working environment but also significantly enhances the durability of the equipment. A proactive approach to maintenance can save time and money in the long run.

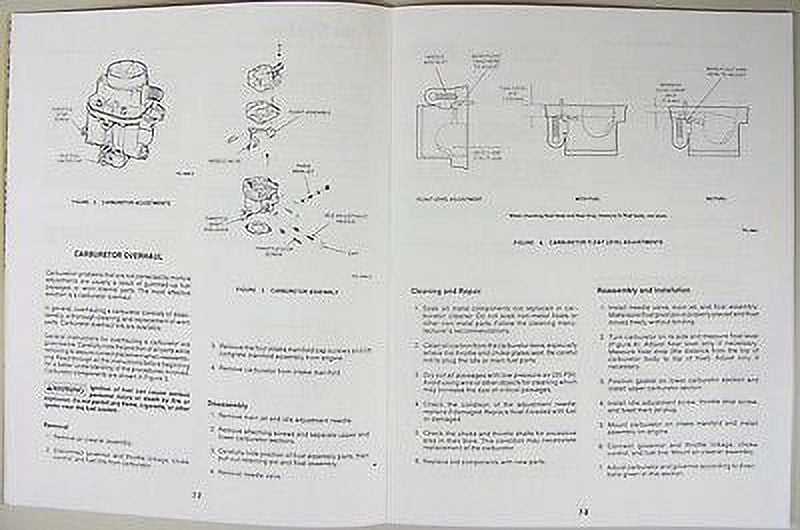

Parts and Components Breakdown

This section offers an in-depth exploration of the various elements that constitute the machinery. Understanding these components is crucial for effective operation and maintenance.

Major Components

- Engine

- Hydraulic System

- Transmission

- Electrical System

Auxiliary Parts

- Fuel Tank

- Cooling System

- Chassis

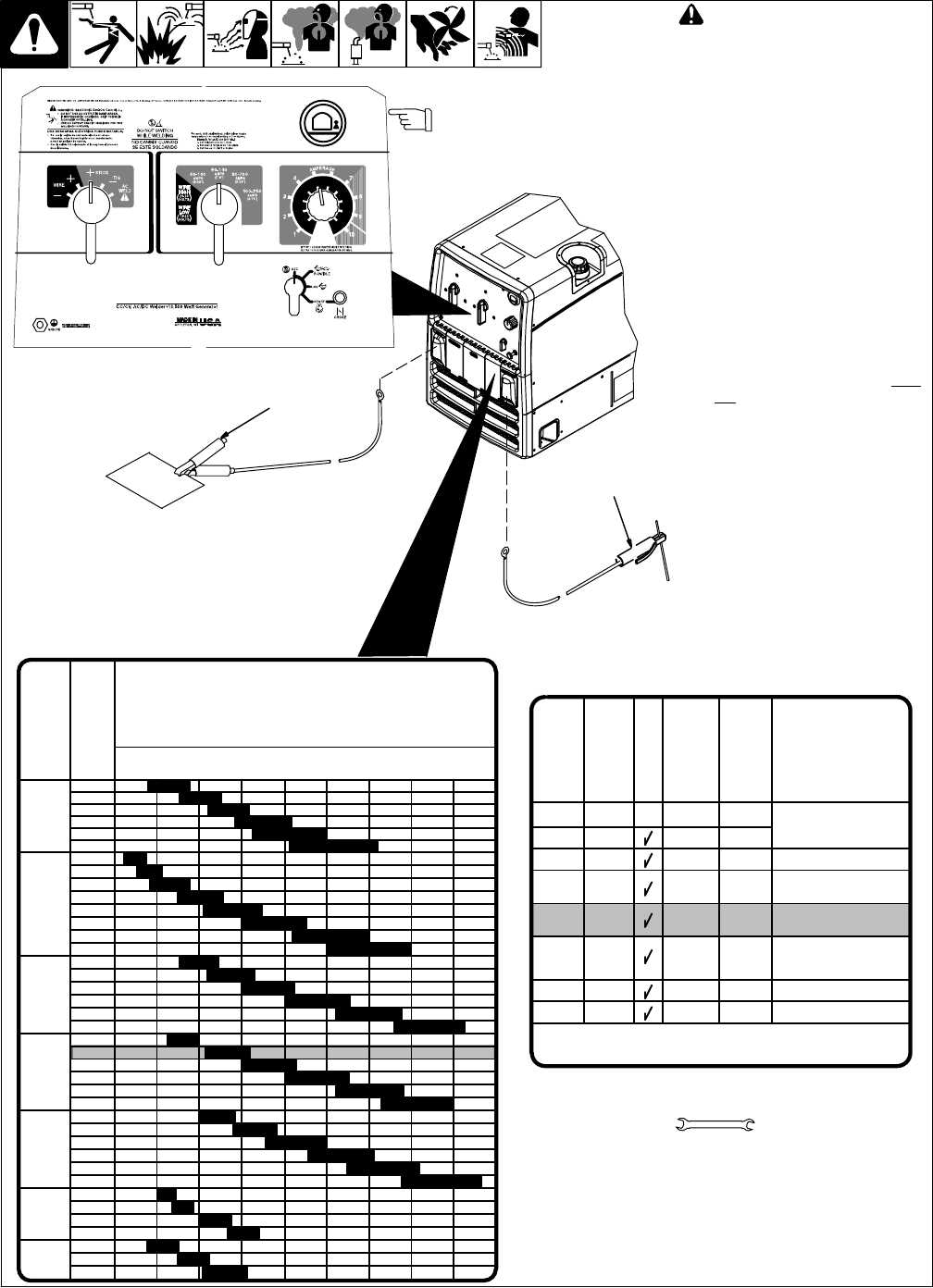

- Control Panel

Each component plays a vital role in the overall functionality, ensuring optimal performance and longevity.

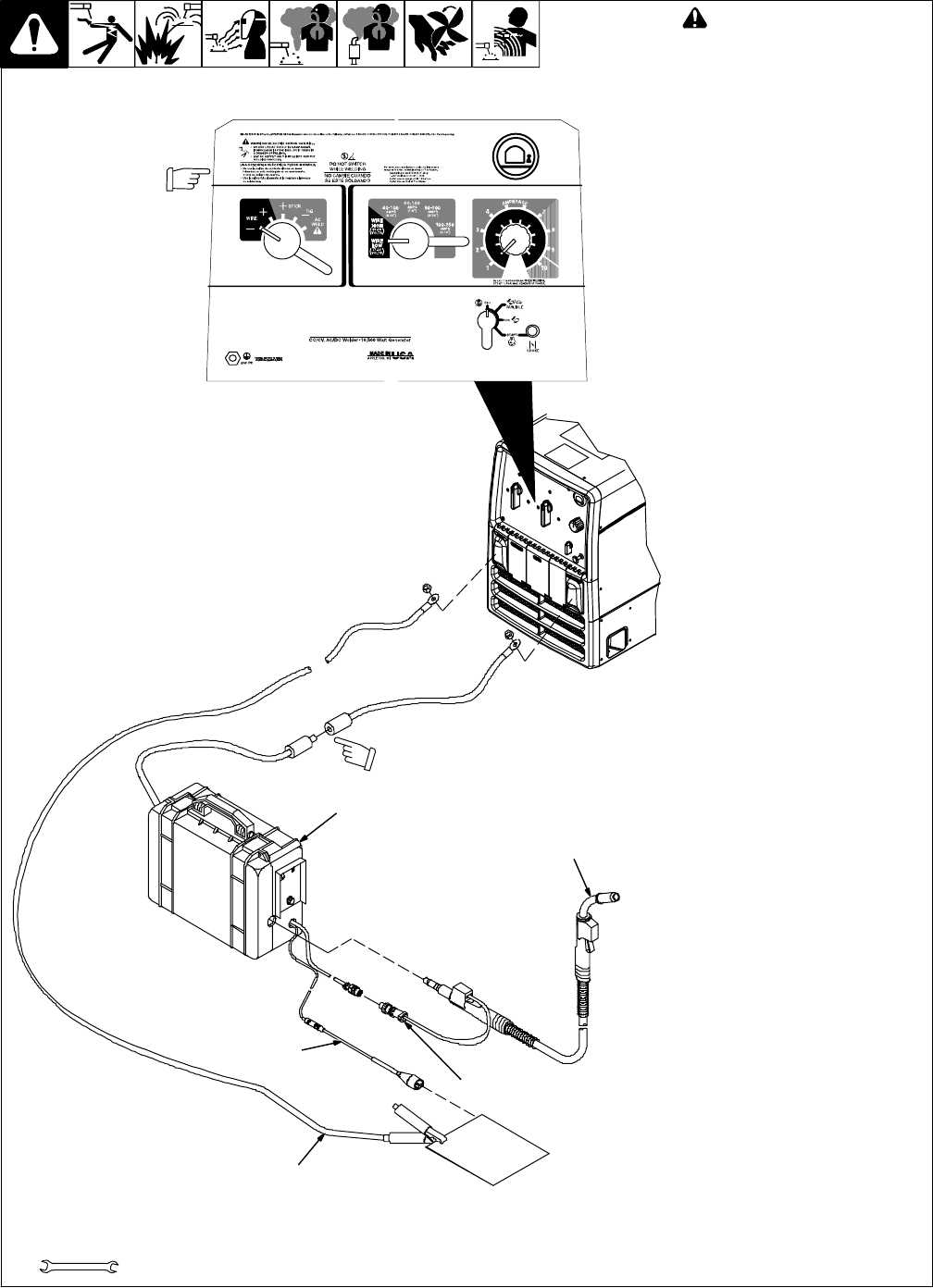

Understanding Electrical Systems

Electrical systems play a crucial role in the functionality and performance of various machinery. A comprehensive understanding of these systems is essential for effective troubleshooting and maintenance. By examining the components and their interactions, one can gain valuable insights into the overall operation and potential issues that may arise.

At the core of any electrical system are several key elements that work together to ensure proper functioning. These components include power sources, wiring, switches, and various types of loads. Each part contributes to the system’s efficiency and reliability, and understanding their roles is vital for anyone involved in equipment management.

| Component | Description |

|---|---|

| Power Source | Provides the necessary energy for the system to operate. |

| Wiring | Conducts electricity between components, facilitating power distribution. |

| Switches | Controls the flow of electricity, allowing for on/off functionality. |

| Load | Devices or systems that consume electrical energy to perform work. |

Familiarity with these components enables individuals to diagnose issues more effectively, ensuring that machinery operates smoothly and efficiently. Regular checks and maintenance of these electrical systems can prevent costly downtime and extend the lifespan of the equipment.

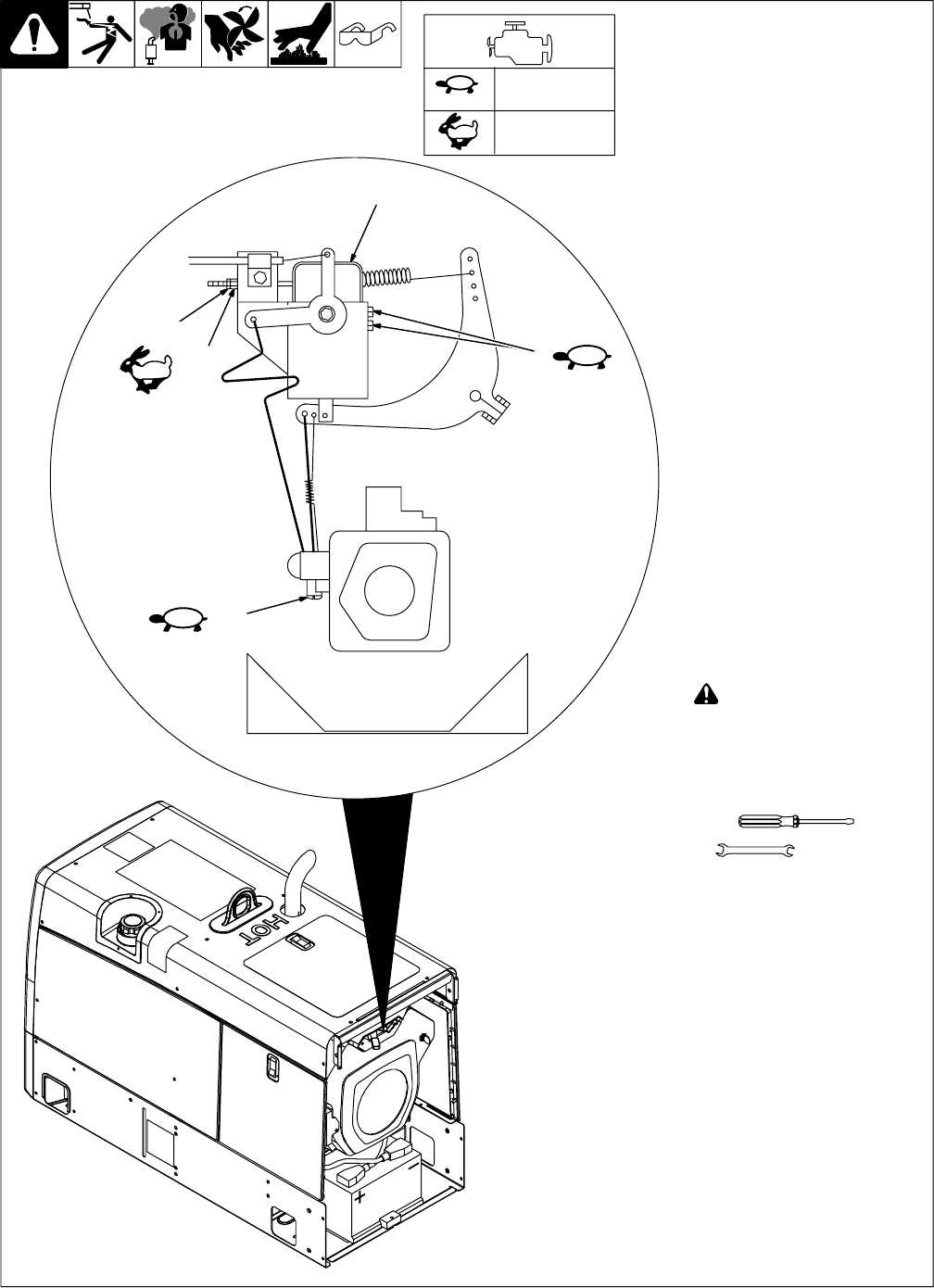

Step-by-Step Repair Procedures

This section outlines the systematic approach to troubleshooting and maintaining your equipment effectively. Following these detailed instructions will ensure that each task is performed thoroughly, enhancing the longevity and functionality of your machinery.

Begin by gathering all necessary tools and components. Familiarize yourself with the specific parts involved in the process, as this knowledge will streamline your work and minimize potential errors.

Next, carefully assess the equipment to identify any visible issues. Document these findings, as they will guide you through the repair sequence. Ensure you have a clear understanding of the operational mechanisms before proceeding.

Once you have established the problems, refer to the appropriate sections that detail disassembly and assembly procedures. Pay close attention to the order of operations, as reversing the steps can lead to complications.

As you progress, take the time to clean and inspect each component. Replace any worn or damaged parts as needed. This proactive approach will prevent future malfunctions and ensure optimal performance.

After reassembling the unit, conduct thorough tests to verify that all systems are functioning correctly. Make any necessary adjustments and document the process for future reference. Adhering to these structured procedures will contribute to successful maintenance and repair outcomes.

Safety Precautions During Repairs

When undertaking maintenance on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Proper precautions ensure not only personal safety but also the longevity of the equipment being serviced. This section outlines essential safety measures that should be followed during any maintenance task.

Essential Safety Gear

Wearing appropriate protective equipment is vital in minimizing risks. Ensure that you are equipped with the following items:

| Safety Gear | Purpose |

|---|---|

| Safety goggles | Protect eyes from debris and chemicals |

| Gloves | Shield hands from sharp objects and harmful substances |

| Steel-toed boots | Prevent foot injuries from heavy equipment |

| Ear protection | Reduce noise exposure during operation |

Work Area Organization

A well-organized workspace can significantly reduce the risk of accidents. Keep the area free of clutter, and ensure tools are stored properly. Additionally, proper lighting is essential to identify potential hazards and ensure safe operation.

Tools Needed for Effective Repairs

Ensuring efficient maintenance requires a selection of essential implements that facilitate the process. These instruments not only enhance the quality of work but also streamline the tasks at hand. Familiarity with the right tools is crucial for achieving optimal results in any service endeavor.

Start with basic hand tools such as wrenches, screwdrivers, and pliers. These are fundamental for assembling and disassembling various components. A set of adjustable wrenches can accommodate different sizes of nuts and bolts, making them versatile for multiple applications.

Power tools also play a significant role in expediting repairs. Drills, impact wrenches, and grinders can save considerable time and effort, especially when dealing with stubborn fasteners or heavy materials. Choosing high-quality power tools ensures durability and reliability during intensive tasks.

In addition to hand and power tools, safety equipment cannot be overlooked. Items such as gloves, goggles, and ear protection are vital for maintaining personal safety while working. Investing in proper protective gear fosters a safer working environment and minimizes the risk of accidents.

Finally, having a well-organized workspace with toolboxes and storage solutions allows for easy access to implements when needed. A tidy setup not only boosts efficiency but also enhances focus, allowing for a smoother workflow during maintenance activities.

When to Seek Professional Help

Understanding the limits of your expertise is crucial when it comes to machinery maintenance and troubleshooting. While many issues can be resolved independently, there are certain scenarios where enlisting the assistance of a qualified technician becomes essential. Recognizing these moments can save time, prevent further damage, and ensure safety during operation.

Signs of Complex Issues

If you encounter persistent problems that do not resolve with basic troubleshooting methods, it may indicate a deeper, more complex issue. Unusual noises, erratic behavior, or warning lights that remain illuminated are all signs that professional evaluation is necessary. These symptoms often suggest underlying mechanical or electrical faults that require specialized knowledge and tools to diagnose accurately.

Safety Concerns

When safety is at stake, it is imperative to seek expert help. If you notice any signs of potential hazards, such as leaks, excessive vibrations, or smoke, it is critical to stop using the equipment immediately. Attempting to fix such issues without proper training can lead to accidents or serious injury. In these situations, contacting a skilled professional ensures that any risks are appropriately managed and that the equipment is restored to safe operating condition.

Comparing Bobcat 250 to Competitors

When evaluating a particular model in the compact machinery segment, it is essential to consider its performance, features, and overall value in relation to other options available on the market. Understanding how this equipment stacks up against its rivals can help potential buyers make informed decisions that best suit their operational needs.

Performance Metrics: One of the key areas of comparison is the performance capabilities of various machines. This model is known for its robust engine and hydraulic systems, which contribute to superior lifting capacity and operational efficiency. In contrast, competitors may offer similar specifications but vary in reliability and long-term durability.

Features and Technology: Advanced technology often differentiates products in this category. While some alternatives may boast enhanced control systems or connectivity features, this particular model typically emphasizes user-friendly interfaces and straightforward maintenance protocols, which can be advantageous for operators who prioritize simplicity.

Cost of Ownership: Another critical factor is the total cost of ownership, which encompasses initial purchase price, maintenance expenses, and fuel efficiency. While some rival models might have lower upfront costs, they may incur higher maintenance fees or require more frequent servicing, leading to increased long-term expenditures.

Customer Support and Parts Availability: Lastly, examining the availability of customer support and spare parts is crucial. This model benefits from an extensive network of service centers and readily accessible replacement components, ensuring that downtime is minimized. Conversely, some competitors might struggle with part availability, impacting their operational reliability.

User Experiences and Testimonials

This section aims to provide insights into the real-life experiences of users who have interacted with this particular equipment. Feedback from operators and technicians can offer valuable perspectives on performance, durability, and maintenance, helping potential users make informed decisions.

Operator Insights

Many operators have shared their satisfaction with the overall efficiency of the machine. One user emphasized, “The reliability of this equipment has greatly improved my productivity on-site.” Such testimonials highlight the importance of dependable machinery in various applications, from construction to landscaping.

Maintenance Experiences

Technicians often comment on the ease of upkeep. One expert noted, “Performing routine checks and minor adjustments is straightforward, making my job easier and more efficient.” This feedback underscores the design’s user-friendliness, allowing for quicker repairs and less downtime.