Understanding the intricacies of small engines is essential for anyone looking to ensure optimal performance and longevity of their machinery. This guide delves into the fundamental aspects of upkeep, troubleshooting, and enhancement of 8 horsepower units, providing a comprehensive resource for enthusiasts and professionals alike.

Regular attention to various components can significantly impact efficiency and reliability. By familiarizing yourself with common issues and solutions, you can maintain your equipment in peak condition, reducing downtime and enhancing productivity.

This document aims to equip you with the necessary knowledge to navigate challenges effectively. Whether you are performing routine checks or addressing more complex concerns, having a clear reference will empower you to take decisive action and extend the lifespan of your engine.

Overview of Briggs and Stratton 8 HP

This section provides an insightful examination of an iconic small engine known for its robust performance and reliability. Frequently utilized in various outdoor power equipment, this engine has earned a reputation for efficiency and durability, making it a favored choice among enthusiasts and professionals alike.

With a power output of 8 horsepower, this model is engineered to deliver optimal performance across a range of applications. Its compact design allows for easy integration into lawn mowers, generators, and other machinery, ensuring versatility in usage. The engine is characterized by its simple maintenance requirements, which contribute to its longevity and user-friendly nature.

Key features of this engine include a reliable ignition system, efficient fuel consumption, and a robust construction designed to withstand rigorous conditions. Users appreciate the smooth operation and the ability to tackle demanding tasks without compromising performance.

Overall, this small engine exemplifies a blend of innovation and practicality, making it a valuable asset for those seeking dependable power solutions in their equipment.

Common Issues in Small Engines

Small power units are essential for various applications, from gardening tools to portable generators. However, they often face specific challenges that can hinder their performance. Understanding these common problems is crucial for maintaining efficiency and prolonging the lifespan of the machinery.

- Fuel Problems:

- Old or stale fuel can cause starting issues.

- Contaminated fuel leads to clogged filters and injectors.

- Ignition Failures:

- Worn spark plugs result in weak or absent sparks.

- Faulty ignition coils can disrupt the engine’s operation.

- Airflow Restrictions:

- Clogged air filters limit air intake, affecting combustion.

- Obstructions in the exhaust system can cause overheating.

- Mechanical Wear:

- Worn piston rings can lead to poor compression.

- Damaged bearings may create unusual noises and vibrations.

Regular maintenance can help address these issues before they escalate, ensuring optimal performance of small engines.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance tasks. Proper tools not only enhance efficiency but also ensure safety during the process. Whether you are tackling minor adjustments or significant overhauls, a well-equipped toolkit is the foundation for successful outcomes.

Basic Hand Tools are indispensable for any maintenance job. A set of wrenches, screwdrivers, and pliers will cover a wide range of tasks. Make sure to have both metric and standard sizes to accommodate various components.

Power Tools can significantly speed up the work. A reliable drill and an impact wrench can help in loosening stubborn fasteners, making disassembly much easier. Always choose quality brands for durability and performance.

Measuring Instruments are essential for ensuring precision. Tools like calipers and torque wrenches help maintain specifications and avoid damage during reassembly.

Cleaning Supplies are often overlooked but are vital for effective maintenance. Keep a good supply of degreasers, brushes, and rags to ensure that all parts are free from grime and buildup.

Lastly, Safety Gear should never be neglected. Always wear gloves, goggles, and appropriate clothing to protect yourself from potential hazards while working.

With these fundamental tools at your disposal, you’ll be well-prepared to handle any maintenance challenge that comes your way.

Step-by-Step Maintenance Procedures

Proper upkeep of small engines is essential for optimal performance and longevity. This section provides a detailed approach to routine tasks that ensure your machinery operates efficiently. Following these steps will help you identify potential issues early and keep your equipment running smoothly.

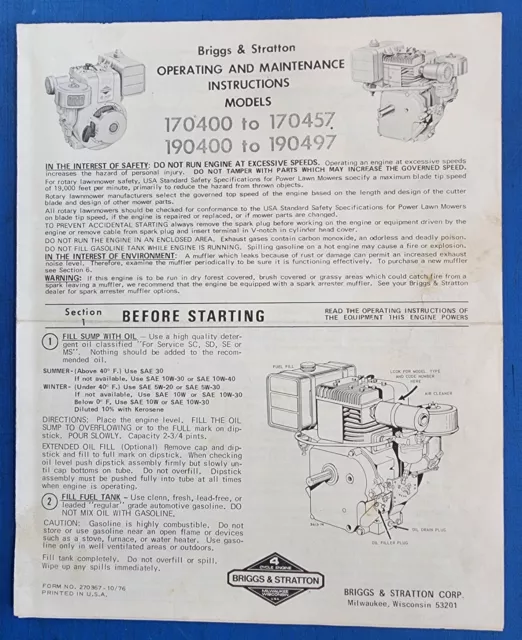

Regular Oil Changes

Changing the oil is a fundamental aspect of maintenance that can significantly extend engine life. Begin by ensuring the engine is cool and level. Drain the old oil by removing the plug and allow it to flow into a suitable container. Once drained, replace the plug securely. Next, refill with the appropriate grade of oil as specified in the specifications, ensuring not to overfill. Regular intervals for this task will vary based on usage but generally should occur every 50 hours of operation.

Air Filter Inspection

The air filter is crucial for maintaining airflow and preventing contaminants from entering the engine. Start by locating the filter housing, which typically requires unscrewing a cover. Remove the filter and inspect it for dirt and damage. If it appears clogged, clean it with compressed air or replace it entirely. Reassemble the housing securely to ensure proper filtration. Regular checks every 25 hours of use will help maintain engine efficiency.

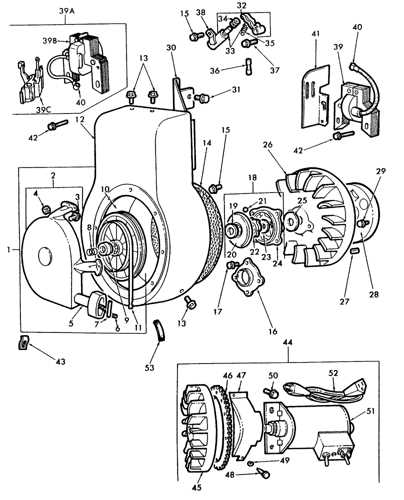

Understanding Engine Components and Functions

Grasping the intricacies of engine parts and their roles is essential for effective maintenance and troubleshooting. Each component contributes to the overall performance and efficiency of the power unit, making familiarity with them invaluable for operators and enthusiasts alike.

Here are some key components commonly found in small engines:

- Cylinder: The main chamber where fuel and air mix and combust.

- Piston: Moves up and down within the cylinder, converting energy from combustion into mechanical motion.

- Crankshaft: Transforms the linear motion of the piston into rotational motion to power the output shaft.

- Valves: Regulate the intake of air and fuel and the expulsion of exhaust gases.

- Ignition System: Creates a spark to ignite the fuel-air mixture for combustion.

- Fuel System: Delivers the necessary fuel to the engine for operation.

- Cooling System: Prevents overheating by dissipating excess heat generated during operation.

Understanding how these components interact allows for better diagnostics and enhances the longevity of the engine. Each part works in harmony to achieve efficient operation, making it crucial to ensure they are all in optimal condition.

Troubleshooting Starting Problems

Encountering difficulties when attempting to start your engine can be frustrating. This section will guide you through various common issues and potential solutions to help restore functionality effectively. Understanding the possible causes is essential for efficient troubleshooting.

Check Fuel Supply: Ensure there is adequate fuel in the tank. Stale or contaminated fuel can hinder ignition. If the fuel appears discolored or has a foul smell, consider replacing it with fresh fuel to improve starting chances.

Inspect the Spark Plug: A faulty spark plug can prevent the engine from igniting. Remove the plug and check for wear or carbon buildup. If necessary, clean or replace it to ensure a strong spark is produced during the starting process.

Examine the Battery: If your engine relies on an electric start, a weak or dead battery may be the culprit. Test the battery’s voltage and connections. Charging or replacing the battery may be required to achieve successful ignition.

Assess the Starter Mechanism: Listen for any unusual sounds when attempting to start. A grinding or clicking noise might indicate an issue with the starter or its components. Inspect and clean connections, and if necessary, consult a professional for repairs.

Check the Air Filter: A clogged air filter can restrict airflow, affecting engine performance. Inspect the filter and clean or replace it as needed to ensure optimal air intake for proper combustion.

By systematically addressing these potential issues, you can increase the likelihood of a smooth and successful starting process. Regular maintenance can also help prevent future complications and ensure your engine operates efficiently.

Replacing Fuel and Air Filters

Maintaining optimal performance in small engines requires regular attention to crucial components. Among these, the fuel and air filters play a vital role in ensuring the engine runs smoothly. Regular replacement of these filters can prevent debris buildup and improve efficiency, ultimately extending the lifespan of your machinery.

Importance of Filter Replacement

Filters serve as the first line of defense against contaminants that can hinder engine function. A clean fuel filter ensures that the engine receives the necessary fuel without impurities, while an unobstructed air filter allows for proper airflow. Neglecting to change these filters can lead to decreased performance and potential damage.

Steps for Replacing Filters

Follow these steps to successfully replace the fuel and air filters:

| Step | Description |

|---|---|

| 1 | Turn off the engine and allow it to cool. |

| 2 | Locate the fuel filter; detach it from the fuel line carefully. |

| 3 | Install the new fuel filter in the correct orientation. |

| 4 | Find the air filter housing and open it. |

| 5 | Remove the old air filter and clean the housing if necessary. |

| 6 | Insert the new air filter and close the housing securely. |

Following these steps will help ensure that your equipment continues to operate efficiently. Regular maintenance of fuel and air filters is essential for optimal performance and reliability.

Oil Change and Lubrication Tips

Maintaining optimal performance in small engines requires regular attention to oil levels and lubrication practices. Ensuring that your equipment is well-lubricated not only extends its lifespan but also enhances efficiency. This section provides essential insights on how to effectively change the oil and keep your engine components properly lubricated.

Steps for Changing Oil

To begin, gather the necessary supplies, including fresh oil, a suitable container for old oil, a funnel, and a wrench. Start by warming up the engine briefly; this helps the oil drain more easily. Once warmed, turn off the engine and let it sit for a few minutes to cool down. Locate the oil drain plug, position your container beneath it, and remove the plug carefully to allow the used oil to flow out completely. After draining, replace the plug securely.

Next, use a funnel to pour new oil into the designated fill port. Be sure to check the manufacturer’s recommendations for the correct type and amount of oil. Once filled, check the dipstick to ensure the level is appropriate. Dispose of the old oil properly, adhering to local regulations.

Lubrication Best Practices

In addition to regular oil changes, proper lubrication of moving parts is crucial. Use high-quality grease for bearings and other friction points. Regularly inspect these components for wear and tear, and reapply lubricant as needed. A well-lubricated engine reduces friction and heat buildup, promoting a longer lifespan.

Always consult the equipment’s specifications for guidance on lubrication intervals and products. Keeping a maintenance log can help track your activities and ensure consistent care. By following these tips, you will help maintain your engine’s performance and reliability for years to come.

Checking and Adjusting Spark Plugs

Ensuring optimal engine performance requires regular attention to critical components, including the ignition elements. Proper maintenance of these parts significantly influences fuel efficiency and overall functionality. This section outlines the essential steps for inspecting and fine-tuning these vital components.

Inspection Procedure

Begin by removing the ignition element from the engine. Examine it for signs of wear, such as carbon buildup or erosion on the electrodes. A clean, properly functioning part should exhibit a light tan color and minimal deposits. If excessive wear is detected, replacement may be necessary to maintain peak performance.

Adjustment Techniques

After inspection, check the gap between the electrodes using a feeler gauge. The specified gap ensures efficient ignition of the fuel-air mixture. If adjustments are needed, gently bend the ground electrode to achieve the correct spacing. Reinstall the part securely, ensuring it is tightened to the manufacturer’s specifications to avoid any issues during operation.

Seasonal Maintenance Checklist

Regular upkeep of your engine equipment is essential for ensuring optimal performance throughout the year. A thorough seasonal inspection can help identify potential issues before they become significant problems, extending the lifespan of your machinery and enhancing its efficiency.

Spring Maintenance Tasks

As the weather warms up, begin by changing the oil to promote smooth operation. Inspect the air filter for dirt and debris, replacing it if necessary. Check the spark plug for wear and replace it to ensure reliable starting. Additionally, examine fuel lines for cracks and leaks, and replace any damaged components. Lastly, clean any accumulated dirt or debris from the cooling fins to prevent overheating.

Fall Maintenance Tasks

Before winter sets in, perform a comprehensive inspection of your equipment. Drain and replace old fuel to prevent varnishing in the carburetor. Change the oil again to keep the engine lubricated during cold months. Inspect the battery, cleaning terminals and ensuring it’s fully charged. Finally, cover your machinery with a protective tarp or stored in a dry location to shield it from harsh weather conditions.

When to Seek Professional Help

Understanding when to call in an expert can save time, money, and frustration. While many maintenance tasks can be handled by enthusiasts, certain situations may require specialized knowledge and tools. Recognizing these instances is crucial for ensuring safety and effective resolution of issues.

Signs of Complex Problems

If you encounter persistent issues that do not improve with basic troubleshooting, it’s wise to consult a professional. Symptoms such as unusual noises, leaks, or inconsistent performance often indicate deeper mechanical failures. These situations can lead to further damage if not addressed promptly and correctly.

Safety Concerns

Safety should always be a priority. If you feel uncertain about handling a particular task or if there are risks involved–such as fuel leaks or electrical components–reaching out to an experienced technician is essential. Their expertise can prevent accidents and ensure that your equipment operates safely and efficiently.