This section provides essential information for the upkeep and troubleshooting of a popular model in the realm of lawn care machinery. Understanding how to effectively maintain your equipment ensures its longevity and optimal performance, allowing you to achieve a pristine lawn with minimal effort.

In the following paragraphs, you will discover detailed insights into the various components and functions of the machine. By familiarizing yourself with its operational characteristics, you will be better equipped to handle common challenges that may arise during use.

Regular inspections and preventive care play a crucial role in sustaining the efficiency of your machinery. This guide emphasizes practical steps and methods that can be employed to identify and rectify issues swiftly, ensuring a smooth mowing experience.

For effective maintenance and troubleshooting of your outdoor equipment, having the right tools is crucial. This section will outline the necessary instruments and devices that facilitate efficient work, ensuring that all tasks can be performed smoothly and safely.

Below is a list of essential tools that you should consider having at your disposal:

| Tool Name | Purpose |

|---|---|

| Wrench Set | To tighten or loosen nuts and bolts. |

| Screwdriver Set | For driving screws into various components. |

| Socket Set | Useful for reaching fasteners in tight spaces. |

| Pliers | To grip, twist, or cut wires and small parts. |

| Utility Knife | For cutting materials or opening packaging. |

| Torque Wrench | Ensures proper tightening of bolts to manufacturer specifications. |

| Multimeter | For testing electrical connections and battery voltage. |

| Oil Can | For lubrication of moving parts. |

| Cleaning Brushes | To remove dirt and debris from components. |

| Protective Gear | To ensure safety while performing maintenance tasks. |

| Work Light | To illuminate work areas in low-light conditions. |

Common Issues with the Model

This section addresses frequently encountered problems that users may face with this specific lawn care equipment. Understanding these issues can aid in effective troubleshooting and maintenance.

- Engine starts but stalls shortly after

- Uneven cutting performance

- Difficulty in starting the engine

- Excessive vibration during operation

- Fuel leakage or odor

Addressing these challenges promptly can enhance the longevity and efficiency of the equipment.

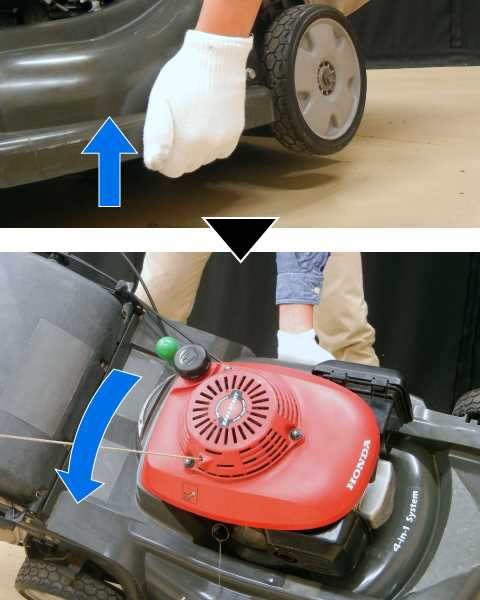

Step-by-Step Maintenance Procedures

This section outlines essential tasks to ensure optimal performance and longevity of your equipment. Regular attention to these procedures not only enhances functionality but also prevents potential issues that may arise from neglect.

Routine Inspection

Begin with a thorough examination of the device to identify any visible signs of wear or damage. Regular checks can help catch minor problems before they escalate.

Cleaning and Lubrication

Maintaining cleanliness is crucial. Remove debris and dirt from the working components, followed by applying suitable lubricants to moving parts. This practice minimizes friction and prolongs the life of the machinery.

| Task | Frequency | Notes |

|---|---|---|

| Inspect for damage | Monthly | Check for any cracks or loose parts. |

| Clean components | After each use | Ensure all dirt and debris are removed. |

| Lubricate moving parts | Every 10 uses | Use recommended lubricant for best results. |

Engine Troubleshooting Techniques

Diagnosing issues in small engine systems requires a systematic approach. By understanding common symptoms and employing effective techniques, one can identify underlying problems that may hinder performance. This section outlines various strategies for troubleshooting engine difficulties.

Common Symptoms and Their Causes

When facing engine troubles, recognizing the signs is crucial. Below are typical symptoms along with potential causes:

| Symptom | Possible Cause |

|---|---|

| Engine Won’t Start | Faulty spark plug, empty fuel tank, or blocked fuel line |

| Overheating | Low oil levels, clogged air filter, or defective cooling system |

| Excessive Smoke | Incorrect oil type, worn piston rings, or damaged gaskets |

| Strange Noises | Loose components, damaged bearings, or insufficient lubrication |

Step-by-Step Diagnostic Approach

To effectively address engine issues, follow these steps:

- Conduct a visual inspection of the engine components.

- Check fluid levels and look for leaks.

- Test the ignition system to ensure proper spark.

- Examine the fuel system for blockages or contamination.

- Perform a compression test to assess engine health.

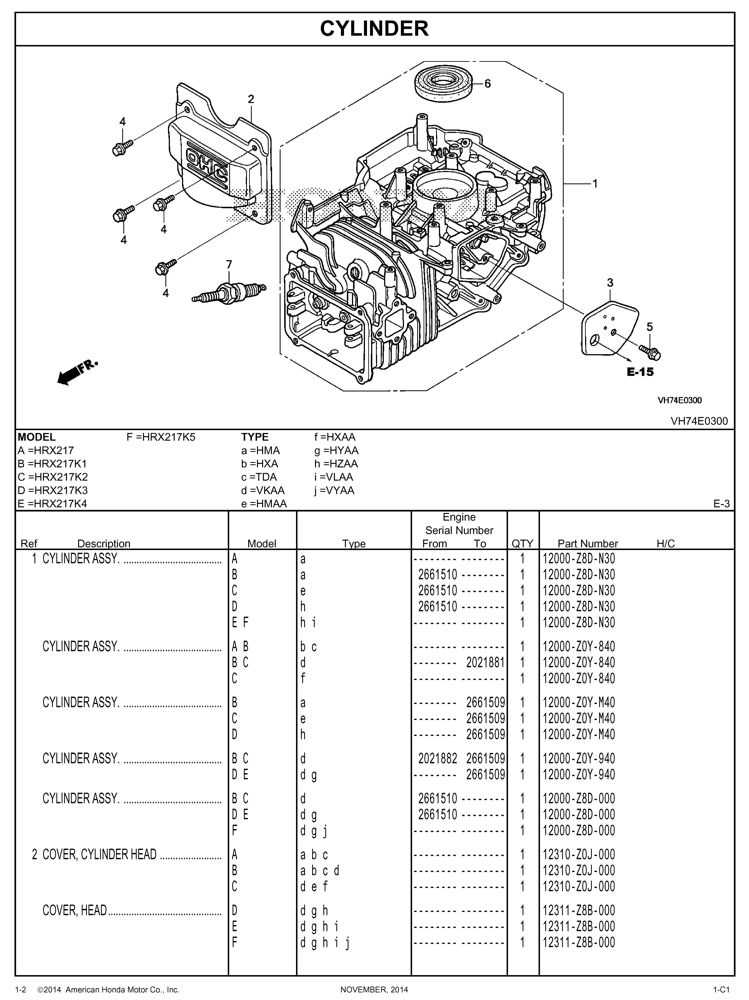

Replacing Worn-Out Parts

Maintaining optimal performance of your equipment often requires the timely replacement of damaged or worn components. Regular inspections help identify parts that no longer function effectively, ensuring longevity and reliability.

When addressing component replacement, consider the following steps:

- Assessment: Regularly inspect all parts for signs of wear, such as cracks, excessive play, or discoloration.

- Documentation: Keep a record of any worn components to track replacement history and schedule future checks.

- Selection: Choose high-quality replacements that meet or exceed original specifications to maintain performance standards.

- Installation: Follow manufacturer guidelines for installation to ensure proper fit and function.

- Testing: After replacing parts, conduct a thorough test to confirm that the equipment operates smoothly and efficiently.

By prioritizing the replacement of worn-out parts, you not only enhance the functionality of your machine but also extend its overall lifespan.

Cleaning and Care Tips

Maintaining the functionality and longevity of your equipment involves regular cleaning and proper care. These practices not only enhance performance but also prevent potential issues that could arise from neglect.

Routine Cleaning: After each use, it is essential to remove grass clippings, dirt, and debris from the surface. This can be accomplished using a soft brush or cloth to avoid damaging sensitive components.

Inspection: Regularly check the blades and other moving parts for wear and tear. Ensuring these components are in good condition will help maintain optimal performance and safety.

Storage: When not in use, store the equipment in a dry, sheltered area to protect it from the elements. Covering it can also prevent dust accumulation.

Lubrication: Periodically apply lubricant to moving parts as per the manufacturer’s recommendations. This will help reduce friction and prolong the life of the machine.

By following these simple guidelines, you can ensure that your equipment remains efficient and ready for use whenever needed.

Electrical System Diagnostics

This section focuses on evaluating and troubleshooting the electrical components of the equipment. Proper diagnostics are essential to ensure functionality and prevent malfunctions that could hinder performance.

Identifying Common Issues

Frequent electrical problems may arise from poor connections, faulty wiring, or defective components. Symptoms such as inconsistent power supply or failure to start can indicate underlying issues. Regular checks can help pinpoint these faults early.

Testing Procedures

Utilizing a multimeter can assist in verifying the voltage and continuity of circuits. Follow systematic testing methods to determine the integrity of each component. Accurate readings will guide you in making informed repairs and replacements.

Understanding Fuel System Problems

Issues related to the fuel system can significantly impact the performance and efficiency of outdoor power equipment. Recognizing the signs of malfunction is crucial for maintaining optimal functionality. This section explores common fuel-related challenges and their implications for equipment operation.

Common Symptoms of Fuel Issues

Several indicators may suggest that the fuel system is experiencing difficulties. These can include hard starting, irregular engine operation, or reduced power output. Observing these symptoms can help in identifying underlying problems that may need attention.

Potential Causes and Solutions

Fuel-related problems can stem from various factors such as contamination, blockages, or improper fuel mixture. Addressing these issues may involve cleaning fuel filters, inspecting lines for leaks, or ensuring the correct type of fuel is used. Regular maintenance can prevent many of these complications.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Adhering to specific guidelines ensures a secure working environment, allowing for effective troubleshooting and servicing of the equipment.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and sturdy footwear. This gear is essential for shielding against potential hazards, including sharp edges and harmful substances. A well-fitted pair of gloves can prevent cuts, while eye protection guards against flying debris.

Work Environment Safety

Maintain a clean and organized workspace to minimize the risk of tripping or dropping tools. Ensure proper ventilation when working with chemicals or during tasks that generate fumes. Additionally, keeping fire extinguishers nearby and ensuring they are accessible can be vital in case of emergencies.

Service Interval Recommendations

Maintaining optimal performance of outdoor power equipment requires regular attention and adherence to specific service timelines. Understanding when to perform essential maintenance tasks ensures longevity and efficiency.

Recommended Maintenance Schedule

- Check oil levels and replace as needed every 25 hours of operation.

- Inspect air filters and clean or replace every 50 hours.

- Sharpen blades at least once per season or after every 25 uses.

- Examine spark plugs and replace annually for consistent ignition.

- Clean fuel system components to prevent clogs and ensure smooth operation every 50 hours.

Seasonal Maintenance Tasks

- Before the start of the mowing season, perform a comprehensive inspection of all components.

- At the end of the season, prepare the equipment for storage by cleaning and checking for any required repairs.

- During extended periods of inactivity, run the engine briefly to keep internal parts lubricated.

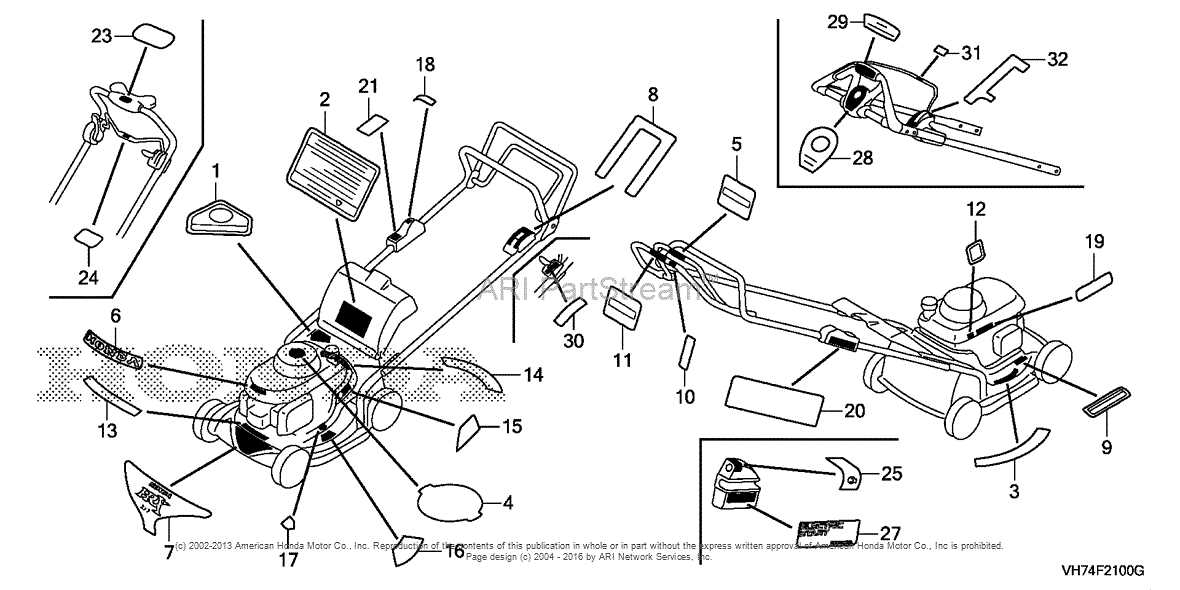

Finding Replacement Components

Identifying suitable substitute parts is crucial for maintaining optimal performance and longevity of your equipment. When components wear out or become damaged, sourcing the right replacements ensures that your device continues to function efficiently and safely.

Start by consulting the manufacturer’s specifications to determine compatible alternatives. Online resources, such as forums and specialized retailers, often provide valuable insights into the most reliable components available. Additionally, consider checking local suppliers who may stock parts tailored for your specific needs.

It is also advisable to verify the quality of replacement items. Prioritize components that meet established standards and are backed by warranties to guarantee their durability. Engaging with knowledgeable technicians can further enhance your ability to select the most effective substitutes.