Maintaining agricultural machinery is crucial for ensuring optimal performance and longevity. Understanding the intricacies of these machines can help operators navigate common issues and enhance productivity in their daily operations. This guide aims to provide a comprehensive overview of maintenance practices tailored for specific models, addressing various aspects from troubleshooting to routine upkeep.

Every piece of equipment requires special attention and a clear understanding of its components. By familiarizing oneself with the operational guidelines and techniques, users can not only extend the lifespan of their machinery but also minimize downtime. The information presented here serves as a valuable resource for those seeking to master the nuances of their agricultural tools.

In this section, we will delve into the various procedures and best practices essential for maintaining your equipment effectively. With the right approach and knowledge, operators can tackle challenges confidently and ensure their machinery continues to perform at its best.

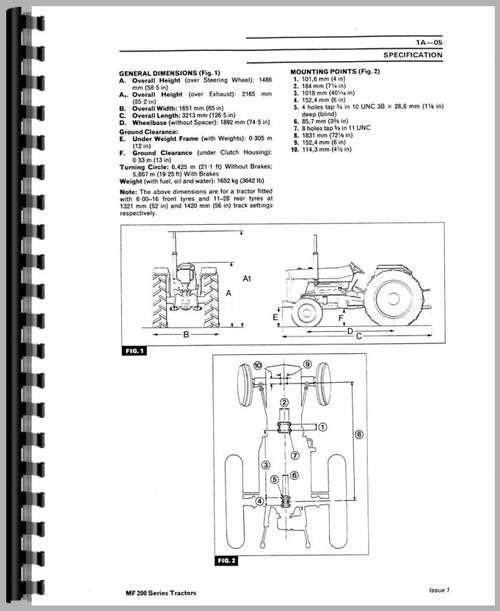

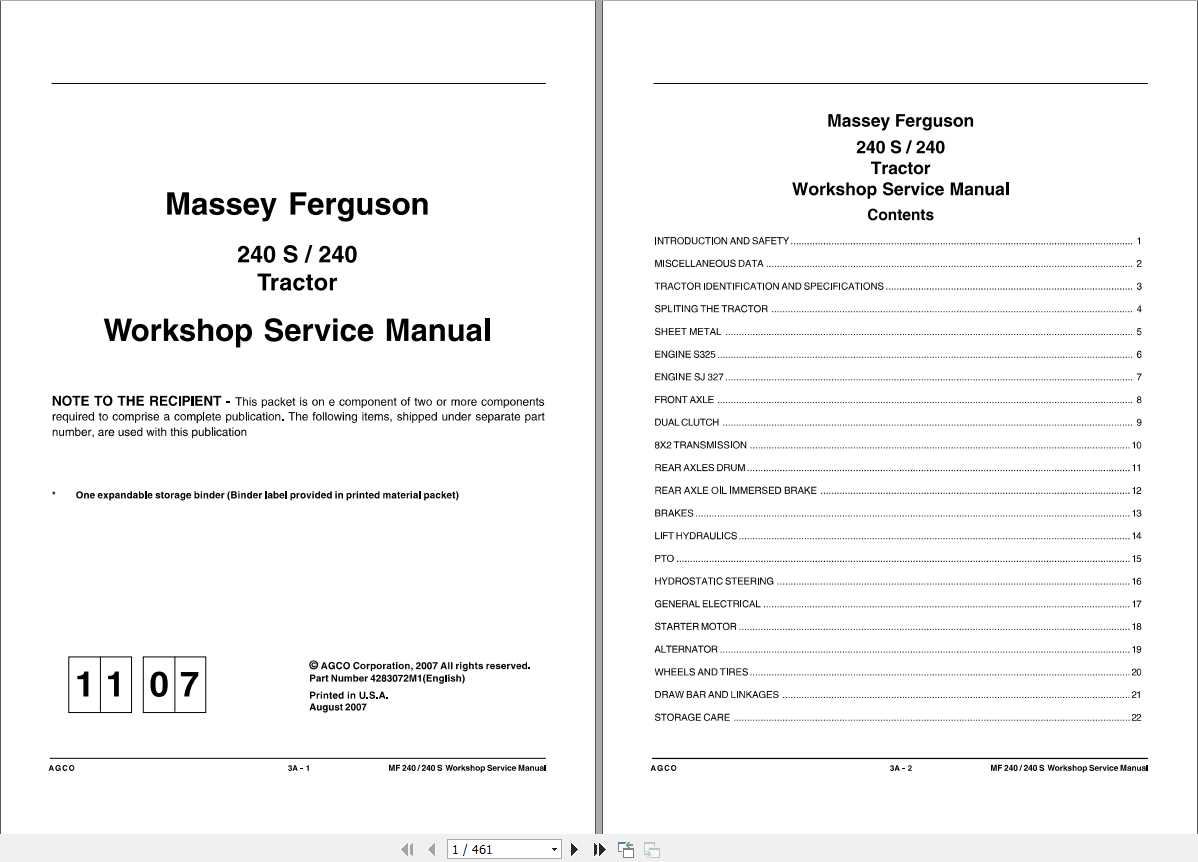

Massey Ferguson 240 Overview

This section provides a comprehensive introduction to a widely recognized agricultural machine, focusing on its features, performance, and applications. Designed for versatility, this equipment has become a staple in various farming operations, contributing significantly to productivity and efficiency.

Key Features

- Powerful engine options for reliable performance

- Robust build quality ensuring durability

- User-friendly controls for ease of operation

- Efficient fuel consumption for cost savings

- Variety of attachments available for diverse tasks

Applications

- Soil preparation and tillage

- Cultivation and planting

- Harvesting of various crops

- Transport of goods and materials

- Landscaping and maintenance tasks

This machine’s combination of power and adaptability makes it an essential asset for both small and large-scale agricultural operations, allowing users to tackle a wide range of tasks with confidence.

Key Features of MF 240

This section highlights the notable attributes of a widely recognized agricultural machine, known for its reliability and performance in various farming tasks. With a blend of power, efficiency, and user-friendly design, this model stands out in its category.

| Feature | Description |

|---|---|

| Engine Performance | Equipped with a robust engine that delivers consistent power for various applications, ensuring effective operation in different conditions. |

| Fuel Efficiency | Designed to maximize fuel usage, allowing for longer operational periods with minimal consumption, thus reducing overall costs. |

| Transmission | Features a smooth and reliable transmission system that enhances maneuverability and control during work. |

| Durability | Constructed with high-quality materials, this machine is built to withstand the rigors of daily agricultural use, ensuring longevity. |

| Ease of Maintenance | Engineered with accessibility in mind, allowing for straightforward maintenance procedures to keep the machine in optimal condition. |

| Versatility | Can be adapted for a variety of tasks, from plowing to hauling, making it a valuable asset for diverse farming operations. |

Common Issues with Massey Ferguson 240

When operating agricultural machinery, it’s not uncommon to encounter various challenges that can hinder performance and efficiency. Understanding these prevalent issues can significantly aid in timely troubleshooting and maintenance, ensuring optimal operation and longevity of the equipment.

Frequent Problems

Operators may notice a range of mechanical and electrical difficulties. Regular inspections can help in identifying these issues early, preventing more severe damage and costly repairs.

| Issue | Description |

|---|---|

| Engine Starting Issues | Difficulties in starting the engine often arise from battery failure or fuel system blockages. |

| Hydraulic Failures | Commonly caused by leaks or low fluid levels, leading to inadequate lifting capabilities. |

| Transmission Problems | Shifting difficulties can stem from worn gears or low transmission fluid, impacting overall performance. |

Preventive Measures

Regular maintenance checks and timely replacements of worn components are essential strategies to mitigate these issues. By adhering to a consistent upkeep schedule, operators can enhance the reliability of their machinery and reduce the likelihood of unexpected breakdowns.

Essential Tools for Repairs

When it comes to maintaining machinery, having the right equipment at your disposal is crucial. A well-equipped toolkit not only enhances efficiency but also ensures that tasks are completed safely and effectively. Below is a guide to the fundamental tools necessary for tackling various maintenance tasks.

Basic Hand Tools

- Wrenches: A set of adjustable and fixed wrenches is essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for working with different screw types.

- Socket Set: A comprehensive socket set allows for quick and easy fastening in tight spaces.

- Pliers: Needle-nose and slip-joint pliers provide versatility for gripping and manipulating objects.

Specialized Equipment

- Torque Wrench: This tool ensures that bolts are tightened to the specified level, preventing over-tightening.

- Multimeter: Ideal for diagnosing electrical issues, a multimeter measures voltage, current, and resistance.

- Hydraulic Jack: Useful for lifting heavy components safely, allowing for easy access to undercarriages.

- Diagnostic Scanner: A modern necessity for reading error codes and troubleshooting complex systems.

Investing in these essential tools will prepare you for a variety of tasks, enabling you to keep your machinery in optimal condition.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues that may arise in agricultural machinery. By following a structured methodology, users can efficiently diagnose problems and implement appropriate solutions.

Initial Assessment

Begin by conducting a thorough examination of the equipment. Look for obvious signs of wear or damage. This initial assessment will help narrow down potential issues.

- Check fluid levels (oil, coolant, fuel).

- Inspect belts and hoses for cracks or fraying.

- Examine electrical connections for corrosion or loose wires.

Systematic Troubleshooting

Once the initial assessment is complete, proceed with a systematic troubleshooting process.

- Start the machine and note any unusual noises or vibrations.

- Test all gauges and indicators for proper functionality.

- Observe the performance under different loads.

- If issues persist, consult the specific component diagrams to identify potential faults.

Document each step taken to facilitate further investigation if necessary. This organized approach ensures that nothing is overlooked, leading to a more effective resolution.

Engine Maintenance Tips and Tricks

Proper upkeep of your machinery’s power source is essential for optimal performance and longevity. By following a few key practices, you can ensure that your engine operates smoothly and efficiently, minimizing the risk of costly repairs and downtime.

Regular Oil Changes: One of the most critical aspects of engine care is maintaining clean oil. Frequent oil changes prevent sludge buildup and reduce wear on internal components. Always use the recommended oil type for your engine to ensure proper lubrication.

Air Filter Maintenance: A clean air filter is vital for optimal engine performance. Clogged filters restrict airflow, leading to reduced efficiency and increased fuel consumption. Check and replace the air filter regularly, especially in dusty environments.

Coolant System Checks: Keeping the cooling system in good condition is crucial to prevent overheating. Regularly inspect coolant levels, and flush the system as recommended. Ensure that hoses and connections are free from leaks or wear.

Battery Care: A well-maintained battery ensures reliable starts and smooth operation. Clean the terminals regularly and check the fluid levels. If you notice any signs of corrosion, address them promptly to avoid starting issues.

Regular Inspections: Conduct routine inspections of belts, hoses, and other components. Look for signs of wear or damage that could lead to bigger problems down the road. Early detection is key to maintaining overall engine health.

Use Quality Fuel: Always opt for high-quality fuel that meets the manufacturer’s specifications. Contaminated or low-grade fuel can lead to poor performance and increased engine wear over time.

Implementing these strategies will not only enhance your engine’s performance but also extend its lifespan. Consistent attention to maintenance can save time, money, and effort in the long run.

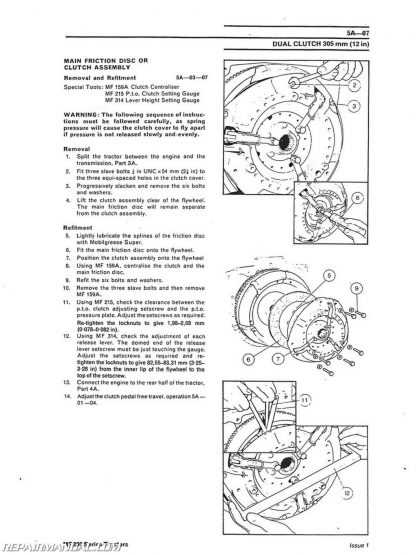

Transmission Repair Procedures Explained

This section delves into the intricate processes involved in addressing issues within the transmission system of agricultural machinery. Understanding these procedures is essential for maintaining optimal performance and extending the lifespan of the equipment. The following guidelines outline the steps necessary to diagnose and resolve common transmission problems effectively.

| Procedure | Description | Tools Required |

|---|---|---|

| Diagnosis | Identify symptoms such as slipping gears or unusual noises to pinpoint issues. | Diagnostic tools, service manual |

| Fluid Check | Inspect transmission fluid levels and quality; replace if contaminated. | Fluid gauge, replacement fluid |

| Disassembly | Carefully disassemble the transmission unit to access internal components. | Socket set, screwdrivers |

| Component Inspection | Examine gears, bearings, and seals for wear and damage. | Inspection mirror, calipers |

| Replacement | Replace any faulty components with new parts to restore functionality. | Replacement parts, assembly tools |

| Reassembly | Carefully reassemble the transmission, ensuring all parts are properly aligned. | Torque wrench, assembly lubricant |

| Fluid Refill | Refill the system with the appropriate transmission fluid. | Funnel, new fluid |

| Testing | Conduct a series of tests to ensure the transmission operates smoothly. | Testing equipment, checklist |

By following these outlined steps, operators can effectively address transmission issues, ensuring reliable performance and longevity of their machinery. Regular maintenance and timely interventions are crucial for preventing major failures and costly repairs in the future.

Hydraulic System Diagnostics

Understanding the functionality of the hydraulic system is crucial for maintaining optimal performance in agricultural machinery. This section delves into the essential diagnostic procedures that help identify issues within the hydraulic circuit. Proper assessment ensures that the equipment operates efficiently, reducing downtime and repair costs.

Common Symptoms of Hydraulic Issues

Operators may encounter various signs indicating a malfunction in the hydraulic system. These can include abnormal noises, reduced lifting capacity, and sluggish or erratic movements. Identifying these symptoms early allows for timely intervention, preventing further damage and ensuring that the equipment remains operational.

Diagnostic Techniques

To accurately assess hydraulic system performance, several diagnostic techniques can be employed. Pressure testing is a fundamental method, allowing users to measure fluid pressure at different points in the system. Additionally, visual inspections for leaks and wear can reveal critical information about the integrity of hoses and seals. Regular fluid analysis can also provide insights into potential contaminants or degradation, helping to maintain the system’s overall health.

Electrical System Troubleshooting

Identifying and resolving issues within the electrical framework of machinery is crucial for optimal performance. This section outlines common problems and provides guidance on how to effectively diagnose and address electrical faults. A systematic approach will help ensure that electrical components function correctly and reliably, enhancing the overall efficiency of the equipment.

Common Issues

Electrical failures often manifest in various ways, such as dimming lights, non-functioning starter motors, or inconsistent battery charging. Start by checking the battery voltage and connections. Corroded terminals or loose connections can lead to poor conductivity and operational failures. Ensure that all wiring is intact and free from damage, as frayed wires can cause shorts or intermittent power loss.

Troubleshooting Steps

Begin troubleshooting by isolating the problem area. Use a multimeter to test voltage at different points in the circuit. Verify that switches, fuses, and relays are functioning correctly. If necessary, consult circuit diagrams to understand the flow of electricity through the system. Document any irregularities you find, as this will assist in making informed repairs or replacements.

Parts Replacement Guide

Ensuring optimal performance of your agricultural machinery often requires timely component substitutions. Understanding the process and knowing which parts to replace can significantly enhance the longevity and efficiency of your equipment.

Common Components to Replace

- Air Filter

- Fuel Filter

- Oil Filter

- Battery

- Belts and Hoses

Replacement Steps

- Identify the component that requires replacement.

- Gather the necessary tools for the task.

- Ensure the machinery is turned off and properly secured.

- Carefully remove the old part, taking note of how it is installed.

- Install the new component, ensuring a snug fit.

- Test the equipment to confirm functionality.

By following these guidelines, you can maintain the effectiveness of your machinery and prevent potential breakdowns.

Regular Maintenance Schedule

Maintaining agricultural machinery is essential for ensuring optimal performance and longevity. A well-structured maintenance schedule helps prevent unexpected breakdowns and keeps equipment operating efficiently. Regular checks and servicing not only enhance productivity but also minimize repair costs over time.

Daily Maintenance: Every day, operators should inspect fluid levels, including engine oil, coolant, and hydraulic fluids. Ensure that all filters are clean and free from debris. Additionally, check for any visible leaks or unusual noises that might indicate underlying issues.

Weekly Checks: Conduct a more thorough inspection once a week. This includes tightening any loose bolts, checking tire pressure, and examining belts and hoses for signs of wear. Clean any accumulated dirt or debris from the machinery to prevent overheating.

Monthly Servicing: On a monthly basis, replace engine oil and filters, as well as lubricate all moving parts. It’s also advisable to inspect the battery connections and clean terminals to ensure optimal electrical performance.

Seasonal Maintenance: At the start of each season, perform a comprehensive evaluation of all systems. This includes checking the cooling system, testing the brakes, and examining safety features. It’s also a good time to assess any necessary repairs or part replacements before peak usage periods.

Annual Overhaul: An annual inspection by a qualified technician is crucial. This includes a detailed examination of all mechanical and electrical systems, along with any necessary adjustments. Documenting maintenance history can provide insights into recurring issues and help plan for future needs.

Adhering to a consistent maintenance routine not only ensures the smooth operation of your equipment but also enhances safety and reliability in the field.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when conducting maintenance or troubleshooting on machinery. By following established guidelines and employing best practices, individuals can minimize risks and enhance their efficiency. This section emphasizes the importance of safety measures that should be adhered to while performing any tasks related to equipment servicing.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective gear is essential. This includes safety glasses to shield eyes from debris, gloves to protect hands from sharp objects and chemicals, and steel-toed boots to safeguard feet from heavy components. Additionally, utilizing ear protection can prevent hearing damage when working near loud machinery.

Work Area Organization

Maintaining a tidy workspace is vital for preventing accidents. Ensure tools and parts are organized and easily accessible, reducing the likelihood of trips and falls. Clear any unnecessary items from the area, and make sure there is adequate lighting to enhance visibility while working. Following these practices not only promotes safety but also improves overall workflow efficiency.

Resources for Further Assistance

When facing challenges with agricultural machinery, having access to reliable resources can significantly enhance the troubleshooting and maintenance process. A variety of options are available for those seeking guidance, whether through printed materials, online platforms, or community support networks.

For detailed instructions and technical information, consider seeking out specialized literature that focuses on the specific equipment in question. Many publications are dedicated to providing comprehensive insights into operation and maintenance. Additionally, online forums and social media groups can be invaluable for connecting with fellow enthusiasts and experts who share their experiences and solutions.

Furthermore, manufacturer websites often feature downloadable resources, including instructional videos and FAQs, which can aid in understanding complex issues. Engaging with local dealers or service centers can also provide professional advice and hands-on assistance, ensuring that your machinery remains in optimal condition.