Ensuring optimal performance and longevity of your outdoor tools is crucial for maintaining their efficiency. This section aims to provide comprehensive insights into the upkeep and troubleshooting processes that can enhance the functionality of your machinery. With proper attention, you can extend the lifespan of your devices and reduce the risk of unexpected failures.

In this guide, you will find detailed instructions and helpful tips designed to assist both novice and experienced users. By familiarizing yourself with common issues and their solutions, you can tackle problems proactively, ensuring that your tools remain in peak condition. Understanding the mechanics and care requirements of your equipment empowers you to make informed decisions and perform necessary adjustments.

Whether you are dealing with minor adjustments or more complex challenges, this resource serves as a valuable companion. Equip yourself with the knowledge to diagnose issues, perform routine checks, and conduct maintenance tasks efficiently. Embrace the journey of becoming more adept at caring for your essential tools, ensuring they serve you well for years to come.

Understanding the Stihl HT 75

The HT 75 is a versatile tool designed for effective tree maintenance and pruning. Its robust engineering and innovative features make it a preferred choice among professionals and enthusiasts alike. This section aims to explore the key components and functionalities that define this equipment.

Key features include:

- Powerful Engine: Equipped with a reliable power source that ensures efficiency in cutting.

- Lightweight Design: Facilitates ease of use and reduces operator fatigue during extended tasks.

- Adjustable Pole Length: Allows for reaching higher branches without the need for ladders.

- Durable Build: Constructed with high-quality materials to withstand challenging working conditions.

When considering this tool, it’s essential to understand its operational aspects:

- Safety Precautions: Always wear appropriate protective gear and follow safety guidelines to prevent accidents.

- Maintenance Routines: Regular checks and upkeep are vital to ensure longevity and optimal performance.

- Usage Techniques: Familiarizing oneself with effective cutting techniques can enhance efficiency and results.

In summary, the HT 75 stands out in the realm of outdoor maintenance equipment, offering users a blend of power, functionality, and ease of use. Understanding its features and operational best practices will greatly enhance the user experience.

Common Issues with HT 75

The HT 75, like any piece of outdoor equipment, can encounter a range of problems that may affect its performance. Understanding these common issues can help users identify and address them efficiently, ensuring optimal functionality and longevity of the tool.

Engine Problems

One frequent challenge with this model involves engine performance. Users may notice difficulty in starting, which can stem from various factors such as fuel quality, spark plug issues, or carburetor clogs. Regular maintenance and proper fuel storage are essential in preventing these complications.

Cutting Efficiency

Another common concern relates to cutting efficiency. If the device struggles to make clean cuts, it may be due to dull blades or improper tension settings. Keeping blades sharp and correctly adjusted is vital for achieving the best results in any task.

Essential Tools for Repairs

When undertaking maintenance tasks, having the right equipment at your disposal is crucial. The appropriate tools not only facilitate efficient work but also ensure safety and precision. Below are some indispensable items you should consider having in your toolkit.

- Wrenches: Various sizes are needed to tackle different nuts and bolts.

- Screwdrivers: A set that includes both flathead and Phillips types is essential.

- Socket Set: This allows for greater torque and easier access to hard-to-reach fasteners.

- Pliers: Useful for gripping, twisting, and cutting wires or small components.

- Cutting Tools: A reliable pair of scissors or a utility knife can be beneficial for various tasks.

Investing in high-quality tools can significantly improve the outcome of your maintenance efforts. Make sure to keep your tools organized and in good condition for the best results.

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment efficiently. Following a structured method can help ensure that you tackle each issue systematically, leading to successful results. Whether you are addressing a malfunction or performing routine maintenance, a clear plan will aid in navigating the process with confidence.

- Gather Necessary Tools and Parts

- Screwdrivers (flat and Phillips)

- Wrenches

- Replacement parts as needed

- Protective gear (gloves, goggles)

- Review the Equipment

Inspect for visible signs of wear or damage. This includes checking the condition of the cutting head, power unit, and fuel lines.

- Disconnect Power Source

Always ensure the power source is removed before beginning any maintenance work to prevent accidents.

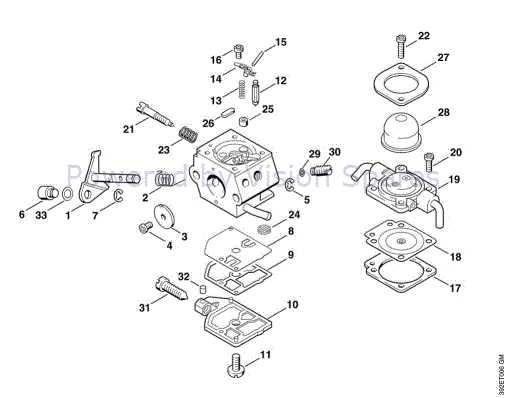

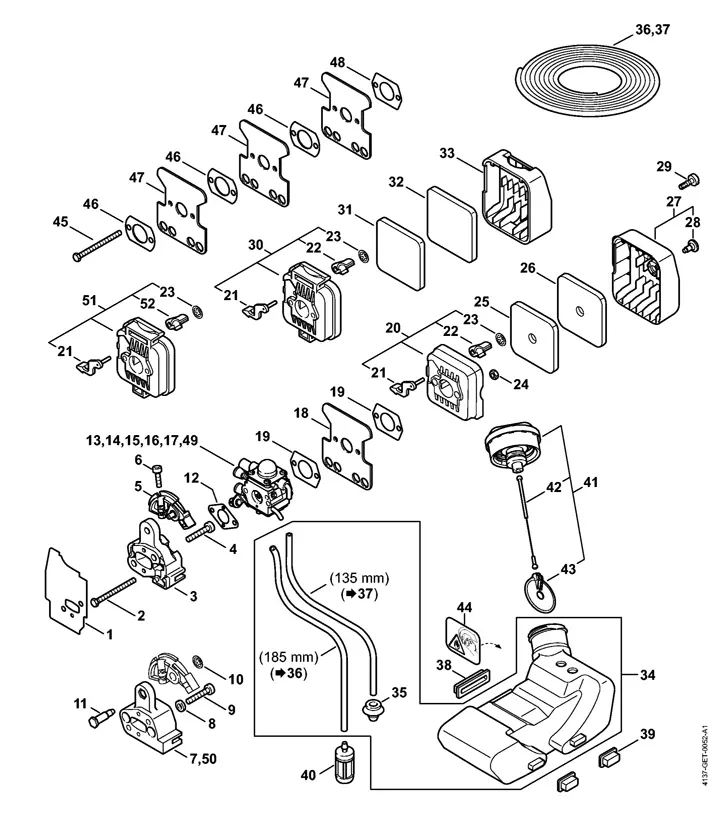

- Disassemble Components

Carefully remove screws and fasteners to access internal parts. Keep track of each component for reassembly.

- Diagnose Issues

Identify any faulty parts or areas needing adjustment. Look for clogs, breaks, or other common problems.

- Replace or Repair Parts

Install new components where necessary, ensuring they are fitted correctly. Lubricate moving parts to enhance performance.

- Reassemble the Equipment

Follow your initial disassembly steps in reverse order, making sure all screws and fasteners are securely tightened.

- Test Functionality

Reconnect the power source and perform a test run to confirm that everything operates smoothly.

- Final Inspection

After testing, conduct a thorough check to ensure all components are functioning as expected.

By adhering to this structured approach, you can effectively manage the maintenance tasks and ensure your equipment remains in optimal working condition.

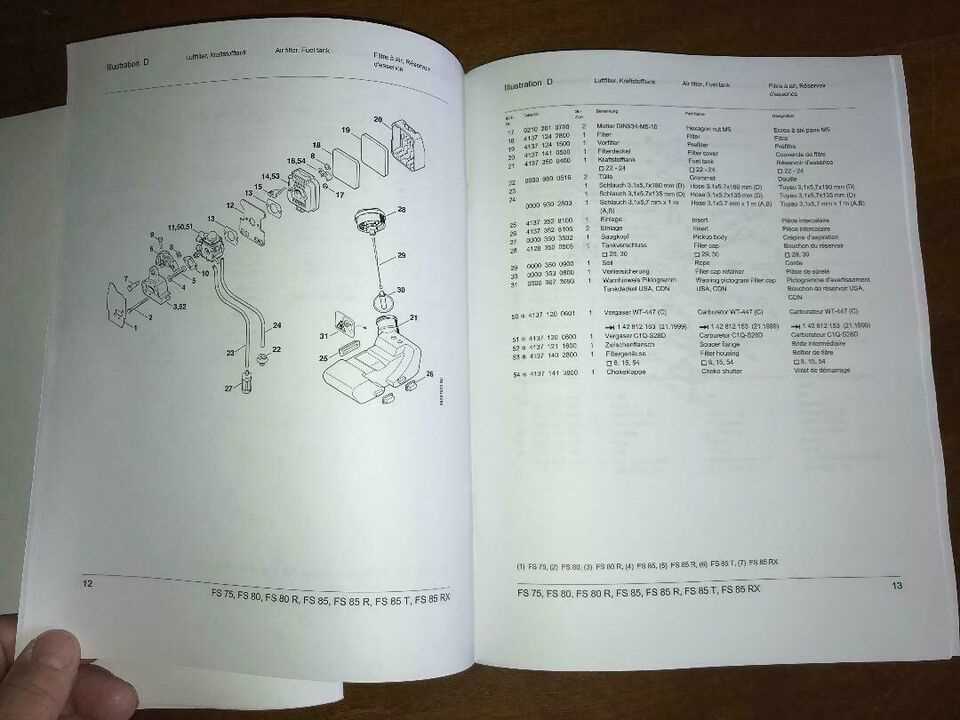

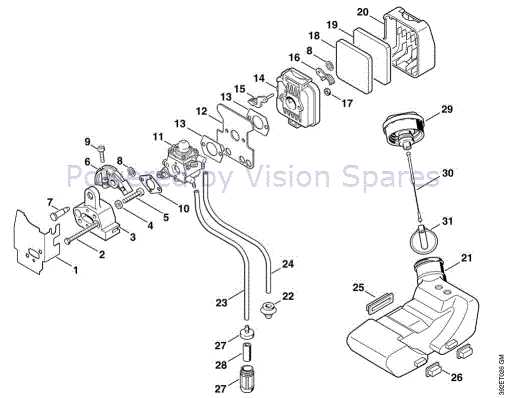

Replacing the Fuel System

Maintaining optimal performance in your outdoor equipment often requires attention to the fuel delivery components. This section outlines the essential steps to efficiently replace these elements, ensuring smooth operation and longevity.

Necessary Tools and Materials

- New fuel lines

- Fuel filter

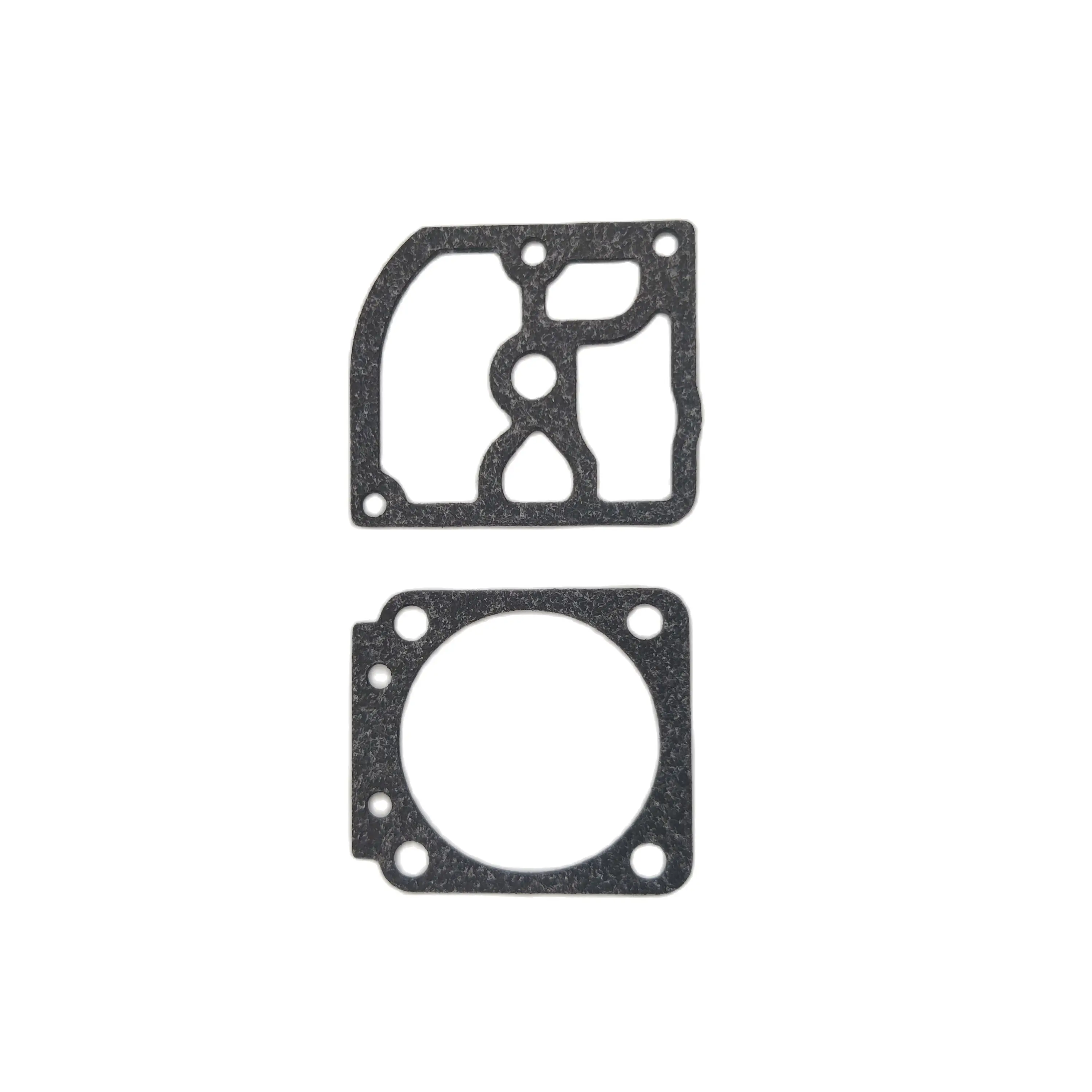

- Fuel tank gasket

- Basic hand tools (screwdriver, pliers, etc.)

- Safety gloves and goggles

Steps for Replacement

- Start by disconnecting the spark plug for safety.

- Drain any remaining fuel from the tank.

- Remove the fuel tank and inspect all components.

- Replace the old fuel lines and filter with new ones.

- Reattach the fuel tank, ensuring a secure fit with the new gasket.

- Reconnect the spark plug and refill the tank with fresh fuel.

Following these steps will help maintain the efficiency of your machinery, allowing it to perform at its best.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your equipment. Adopting a routine maintenance schedule can prevent potential issues and extend the lifespan of your tools. Here are some essential practices to keep in mind.

Regular Cleaning

- After each use, remove debris and dirt from the equipment.

- Check air filters and clean or replace them as needed.

- Inspect and clean cutting components to maintain optimal performance.

Scheduled Inspections

- Conduct regular checks on all mechanical parts for wear and tear.

- Ensure that bolts and screws are tightened to prevent loosening during operation.

- Monitor fuel and oil levels, refilling as necessary to avoid engine damage.

Implementing these strategies will not only enhance the performance of your tools but also contribute to their long-term reliability and efficiency.

Diagnosing Electrical Problems

Identifying issues related to electrical components is crucial for ensuring the proper functioning of your equipment. Electrical failures can manifest in various forms, from complete power loss to intermittent operation, making it essential to follow a systematic approach when troubleshooting.

Common Symptoms of Electrical Issues

- Device not turning on

- Inconsistent performance or flickering

- Unexpected shutdowns during operation

- Visible damage to wires or connectors

Troubleshooting Steps

- Inspect all connections for corrosion or looseness.

- Check the condition of the power source; ensure it is functioning properly.

- Examine fuses or circuit breakers for any signs of damage.

- Use a multimeter to test voltage levels at various points in the circuit.

- Look for any signs of wear in components like switches or relays.

By methodically analyzing each aspect of the electrical system, you can effectively pinpoint the source of the malfunction and implement appropriate corrective measures.

Chain Tensioning Procedures

Proper adjustment of the chain tension is essential for optimal performance and safety when using cutting equipment. Maintaining the correct tension helps prevent accidents and prolongs the life of the chain and bar. This section outlines the necessary steps to ensure your chain is appropriately tensioned.

Importance of Correct Chain Tension

Having the right tension on the chain is crucial for various reasons:

- Enhances cutting efficiency.

- Reduces wear on the chain and bar.

- Minimizes the risk of chain derailment.

- Ensures safer operation for the user.

Steps for Adjusting Chain Tension

- Ensure the equipment is turned off and cool to the touch.

- Locate the tensioning mechanism, typically found near the guide bar.

- Loosen the bar retaining nuts slightly to allow movement.

- Use the tensioning tool or knob to adjust the tension:

- Turn clockwise to tighten.

- Turn counterclockwise to loosen.

- The chain should lift slightly, but not come off.

- A gap of approximately 1/8 inch is ideal.

Regularly checking and adjusting chain tension not only promotes efficiency but also enhances safety during operation. Always refer to specific guidelines provided by the manufacturer for best practices tailored to your equipment.

Lubrication and Care Practices

Maintaining optimal performance of your equipment requires diligent attention to lubrication and care. Proper upkeep not only enhances functionality but also extends the lifespan of the machine. Regular checks and applications of suitable oils are essential for smooth operation.

Adhering to recommended practices ensures that all moving parts are well-protected and functioning efficiently. Below is a summary of key practices for effective lubrication and care:

| Practice | Description |

|---|---|

| Regular Lubrication | Apply appropriate lubricant to all pivot points and bearings at specified intervals. |

| Cleaning Components | Remove dirt and debris from the machine regularly to prevent wear and tear. |

| Inspect Seals and Gaskets | Check for signs of wear or damage, replacing them as necessary to maintain efficiency. |

| Storage Practices | Store the equipment in a dry, cool environment to avoid rust and degradation. |

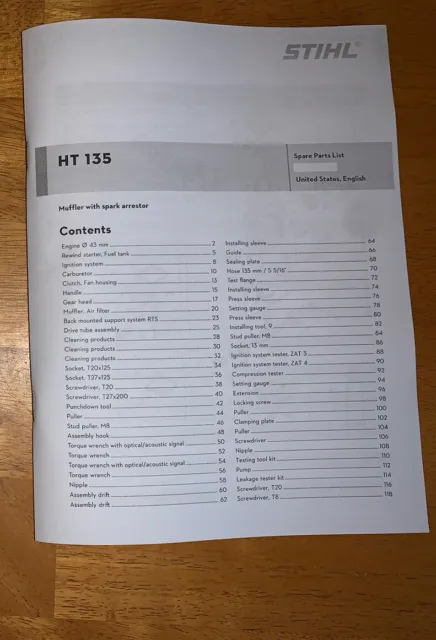

Parts Identification and Ordering

Understanding the components of your equipment is essential for effective maintenance and optimal performance. This section focuses on how to identify the necessary parts and navigate the ordering process efficiently.

Accurate identification of parts can save time and ensure that you procure the correct items needed for upkeep. Here are some steps to help you with parts identification:

- Consult the original documentation to familiarize yourself with the equipment layout.

- Utilize online resources or parts catalogs specific to your model for visual references.

- Take note of part numbers when available; these are crucial for accurate ordering.

Once you have identified the parts you need, the next step is to proceed with the ordering process. Consider the following options:

- Authorized Dealers: Visit or contact local dealers for authentic parts.

- Online Retailers: Explore reputable websites that specialize in equipment components.

- Second-hand Market: Check platforms for pre-owned parts, ensuring they are in good condition.

Before finalizing your purchase, always verify compatibility with your specific equipment model to avoid any mismatches. Keeping a record of your orders can also be beneficial for future maintenance needs.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when engaging in maintenance tasks on machinery. Proper precautions help to minimize the risk of accidents and injuries, creating a secure space for both the technician and the equipment. Awareness of potential hazards and adherence to safety guidelines can significantly enhance the overall experience and outcome of the procedure.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves to protect your hands from sharp edges and hot surfaces, as well as safety goggles to shield your eyes from debris. Additionally, ear protection may be necessary when operating power tools, and sturdy footwear can prevent slips and falls.

Work Area Safety

Maintaining a clean and organized workspace is vital for safety. Ensure that all tools are in good condition and stored properly when not in use. Clear away any clutter that might pose a tripping hazard, and make sure to have adequate lighting to see clearly. Being mindful of your surroundings and keeping the area free from distractions can greatly reduce the likelihood of accidents during maintenance tasks.

Upgrading Components for Performance

Enhancing the efficiency and functionality of outdoor equipment often involves careful consideration of component upgrades. By selecting superior parts, users can significantly improve performance, durability, and overall satisfaction with the machine. This process can transform an ordinary tool into a high-performing asset for various tasks.

One of the primary areas for enhancement is the engine. Upgrading to a high-performance air filter or exhaust system can increase airflow, leading to better combustion and power output. Additionally, fine-tuning the carburetor settings can optimize fuel delivery, resulting in more efficient operation.

Another vital component to consider is the cutting head. Replacing it with a more advanced design can enhance cutting efficiency and reduce wear over time. For instance, a head designed for specific types of vegetation can provide smoother operation and superior results, ultimately making the job easier and faster.

Moreover, examining the transmission system can yield significant benefits. Upgrading to higher-quality gears or belts can improve torque delivery and reduce maintenance needs. This ensures that the equipment operates smoothly under various load conditions, enhancing reliability during use.

Finally, investing in high-grade materials for the frame and housing can lead to a more robust machine. Durable materials resist wear and tear better, extending the lifespan of the equipment and maintaining its performance over time. By focusing on these critical upgrades, users can maximize their tool’s potential and achieve superior results in their outdoor tasks.

FAQs About HT 75 Maintenance

This section addresses common inquiries regarding the upkeep and care of the HT 75 model. Understanding these aspects can help ensure optimal performance and longevity of the equipment.

-

What type of fuel should I use?

It is recommended to use a mixture of high-quality gasoline and two-stroke oil in the correct ratio for optimal engine performance.

-

How often should I clean the air filter?

The air filter should be inspected and cleaned regularly, ideally after every few uses or when you notice a drop in performance.

-

When should I replace the spark plug?

Replacing the spark plug is typically advised after every 100 operating hours or when you observe difficulty in starting the unit.

-

How do I maintain the cutting attachment?

Regularly check the sharpness of the blades and ensure they are free from debris. Sharpen or replace them as necessary to maintain cutting efficiency.

-

What is the best way to store the equipment?

Store the unit in a cool, dry place, and consider using a protective cover. Make sure to empty the fuel tank if storing for an extended period.

-

Are there any seasonal maintenance tips?

Before winter, it’s advisable to check all components and consider performing a thorough cleaning. In spring, inspect the fuel system and replace any aged components.