Outdoor machinery plays a crucial role in keeping green spaces well-kept and organized. However, with regular usage, various components can experience wear, impacting performance and reliability. Understanding basic upkeep procedures helps restore functionality and extend the lifespan of your machinery.

Essential knowledge in addressing common technical issues can save time and resources. From diagnosing mechanical faults to implementing proper upkeep techniques, mastering these skills empowers owners to independently handle equipment care. This guide covers fundamental maintenance practices and tips to enhance efficiency.

Whether dealing with engine irregularities, blade adjustments, or other mechanical elements, being informed on troubleshooting can make a notable difference. By following practical guidelines, users can confidently address these challenges, ensuring their outdoor tools are always ready for the task.

Essential Guide to Lawn Mower Maintenance

Proper upkeep of outdoor cutting equipment ensures smooth operation, enhances longevity, and maintains performance across seasons. By investing time in regular care, you can avoid costly issues, keep blades sharp, and ensure components are functioning optimally.

Key aspects of upkeep include periodic cleaning, timely oil changes, and inspection of moving parts. Routine attention to these areas prevents unexpected breakdowns and maximizes efficiency, allowing you to achieve a clean, even cut each time.

Additionally, assessing fuel quality, replacing filters, and monitoring tire condition further contributes to a trouble-free experience. Following these steps will help maintain your equipment in peak condition for years to come.

Common Issues and Quick Fixes

For those maintaining outdoor trimming equipment, understanding typical complications can significantly streamline troubleshooting. Here, we outline frequent operational snags along with straightforward methods to get machinery up and running efficiently.

Starting Problems

If the machine hesitates or fails to ignite, several factors might be at play. Often, a clogged fuel line or faulty spark plug is the root cause. Begin by examining the fuel line for any blockages. Additionally, ensure the spark plug is clean and securely connected. If these steps don’t resolve the issue, consider checking the air filter for debris or obstructions.

Uneven Cutting

Another common concern is inconsistent trimming, which can leave patches of uncut grass. This often stems from dull or imbalanced blades. To resolve, inspect the cutting blades and sharpen them if they appear blunt. Additionally, make sure the machine is positioned evenly on the ground, as uneven height can affect the quality of the cut.

Inspecting the Engine for Efficiency

Maintaining optimal performance of the engine involves periodic checks to ensure it operates smoothly and consumes energy efficiently. A well-inspected engine not only extends the machine’s overall service life but also helps in identifying minor issues before they lead to costly repairs.

Key areas of focus include inspecting crucial components, checking for any wear and tear, and testing overall functionality. The table below highlights specific elements to examine during an engine inspection to help maximize operational efficiency.

| Component | Inspection Task | Suggested Action | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Air Filter | Check for blockages and dirt buildup | Clean or replace if clogged | ||||||||||||||

| Spark Plug | Inspect for corrosion or damage | Replace if worn or faulty | ||||||||||||||

| Oil Level | Check for proper oil level and clarity | Refill or replace oil if needed | ||||||||||||||

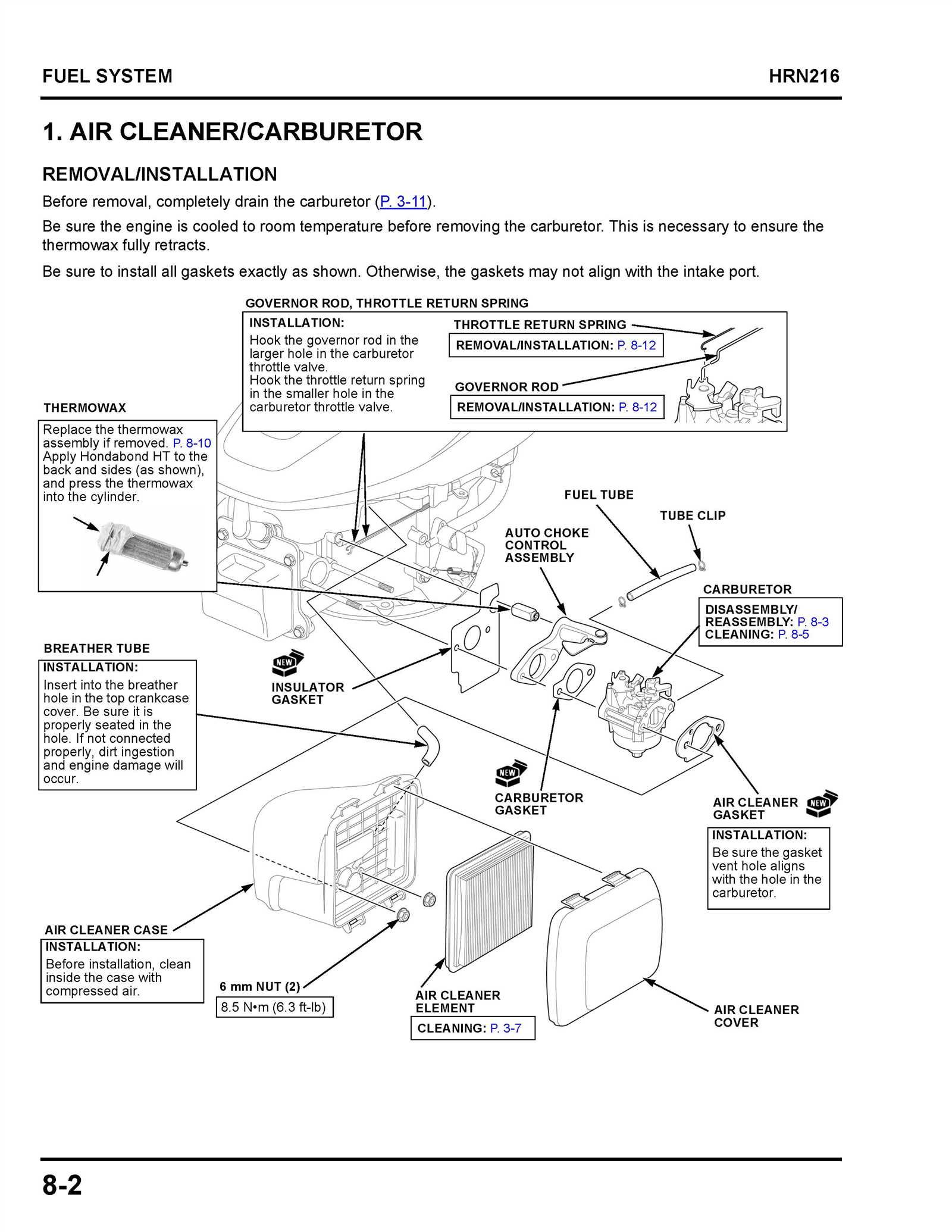

| Fuel System | Examine for le

Sharpening Blades for Optimal Performance

Ensuring that cutting edges remain sharp is crucial for achieving a clean and precise trim with every use. Over time, regular wear can dull the blades, impacting their efficiency and causing uneven cuts. By honing them periodically, you can maintain peak functionality and prolong the lifespan of your equipment. Signs of a Dull BladeA worn blade often leaves behind uneven patches, and the grass tips may appear torn rather than neatly cut. If you notice a decrease in performance or find that extra passes are needed to achieve a smooth finish, it may be time for sharpening. Steps for SharpeningStep 1: Disconnect the power and secure the equipment to prevent movement. Carefully remove the blade using the appropriate tools, noting its orientation. Step 2: Use a metal file or a specialized sharpening tool to restore a clean edge, maintaining the original angle of the blade. Even strokes are essential for uniform sharpening. Tip: Balance the blade after sharpening by ensuring both sides have equal weight. This step prevents potential vibrations during operation. Regularly sharpening and maintaining blade balance not only enhances performance but also reduces strain on the machine, providing better results and smoother operation. Troubleshooting Fuel System ProblemsIssues within the fuel delivery system can disrupt engine performance, causing stalls, poor starting, or inconsistent operation. Understanding potential sources of these problems allows for effective solutions and keeps the engine running smoothly. Common Blockages and ClogsFuel flow can be hindered by blockages, particularly within the filter and fuel lines. Inspecting these areas regularly and clearing out any obstructions can prevent frequent performance disruptions. If fuel appears restricted, replacing filters and ensuring line cleanliness is essential for reliable operation. Addressing Contaminated FuelFuel quality directly affects the system’s performance. Contaminants, such as water or debris, can accumulate over time, leading to inconsistent combustion. Using fresh, clean fuel and periodically draining the tank can mitigate these issues, enhancing the system’s reliability. Replacing Spark Plugs Safely

Maintaining optimal performance in small engine systems often requires attention to various components, one of which is the ignition element. This section focuses on the essential steps for replacing this crucial part with safety in mind, ensuring both efficiency and longevity. Preparation Before ReplacementBefore beginning the process, ensure that the engine is completely cool and disconnected from any power source. Gather the necessary tools, including a socket wrench, a gap gauge, and the correct replacement component. Wearing safety gloves and goggles is advisable to protect against any debris or accidental contact. Steps to Safely Replace

Start by removing the ignition component from its housing, carefully unscrewing it to avoid damaging any surrounding parts. Inspect the old element for wear and ensure the new one is gapped correctly according to the manufacturer’s specifications. Finally, install the new component by securing it firmly, but avoid overtightening to prevent any damage. Cleaning and Adjusting Air FiltersMaintaining optimal performance of your equipment requires regular attention to its components, particularly those involved in airflow. Proper cleaning and adjustment of air filters play a vital role in ensuring that the engine operates efficiently and remains free from debris that can hinder its functionality. To begin, inspect the air filter for dirt and damage. If the filter appears clogged or excessively dirty, it is essential to clean or replace it promptly. For foam or sponge filters, rinse them in soapy water, then allow them to dry completely before reinstallation. Paper filters may simply require a gentle tapping to remove loose debris; however, if they are heavily soiled, replacement is recommended. After cleaning, adjust the air filter to ensure it fits securely within its housing. A snug fit prevents dust and particles from entering the engine, promoting better performance. Regular checks and maintenance of air filters not only enhance the longevity of your equipment but also contribute to smoother operation and improved fuel efficiency. Handling Electrical System Malfunctions

Addressing issues within the power system of outdoor equipment is crucial for maintaining its functionality and performance. Various components may experience failures, leading to disruptions in operation. Recognizing and troubleshooting these electrical faults can enhance the longevity and efficiency of the equipment. Start by examining the primary power source, ensuring that connections are secure and free from corrosion. A faulty battery or power supply can result in inadequate performance. If the power source appears to be functioning properly, inspect the wiring for any signs of wear, such as fraying or disconnections, which can lead to intermittent issues. Another common concern is the ignition system. Verify that the spark plug is clean and properly connected, as a malfunction in this area can prevent the engine from starting. Additionally, checking the ignition coil for continuity can help identify potential problems that may disrupt electrical flow. Safety should always be a priority when dealing with electrical components. Ensure the equipment is powered off and disconnected from any power sources before performing any diagnostic checks. Utilize appropriate tools and follow safety protocols to avoid injury during inspections and repairs. In conclusion, by systematically evaluating the electrical components and addressing any identified issues, you can restore the performance of your outdoor equipment effectively. Regular maintenance and prompt attention to electrical malfunctions can prevent further complications and enhance overall reliability. Preventing Overheating During OperationMaintaining optimal temperature levels during operation is crucial for the longevity and performance of your equipment. Overheating can lead to significant damage, decreased efficiency, and costly repairs. Implementing preventative measures can help ensure that the machinery functions smoothly and reliably. Regular Maintenance: Frequent checks and maintenance are essential to prevent overheating. Clean the air filters and cooling vents to allow for adequate airflow. Regularly inspect the blades for wear and ensure they are sharp, as dull blades can create additional strain on the engine. Proper Fuel and Oil Levels: Ensure that the fuel and oil levels are appropriate for the equipment’s specifications. Using high-quality fuel and oil can improve performance and reduce overheating risks. Monitor these levels regularly to avoid potential issues during operation. Adequate Breaks: Allowing the machinery to rest periodically can help prevent overheating. Continuous operation without breaks can cause excessive heat buildup. Schedule regular pauses to give the engine time to cool down, ensuring efficient performance and longevity. Maintaining the Cutting Deck

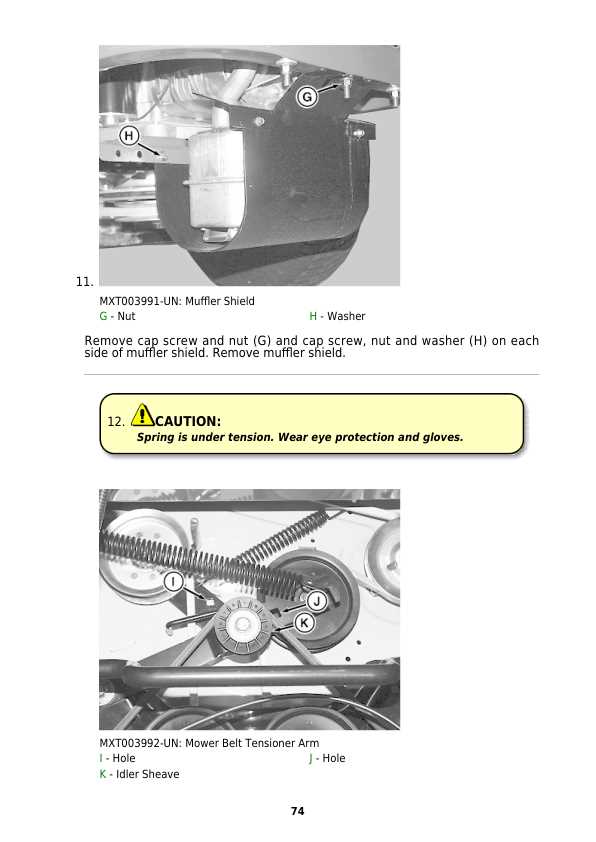

Proper upkeep of the cutting apparatus is crucial for ensuring optimal performance and longevity. Regular attention to this component not only enhances its efficiency but also improves the overall quality of the trimming process. A well-maintained cutting deck facilitates even grass length and reduces the risk of damage to the blades. Routine CleaningTo maintain the effectiveness of the cutting device, it is essential to remove any grass clippings, debris, or buildup after each use. This practice prevents corrosion and ensures the blades operate smoothly. Inspecting for Damage

Regularly check for any signs of wear or damage to the cutting surface. Identifying issues early can prevent costly repairs and ensure a consistently clean cut.

Lubrication Tips for Moving PartsProper maintenance of mechanical devices is essential for ensuring their longevity and optimal performance. One critical aspect of this upkeep involves the appropriate application of lubricants to facilitate smooth operation and reduce wear on components. This section offers valuable insights into effective lubrication practices. Selecting the Right Lubricant

Choosing the appropriate lubricant is paramount. Various options exist, including oils, greases, and sprays, each suited for specific applications. Always consult the manufacturer’s recommendations to identify the best product for your device. Using the wrong type can lead to inadequate protection and potential damage. Application Techniques

When applying lubricant, ensure that all moving parts are clean and free from debris. Avoid over-lubrication, as excessive amounts can attract dirt and create a sticky residue. Instead, apply a small amount to the necessary areas, allowing it to penetrate and coat the surfaces evenly. Regular maintenance will keep your machinery functioning efficiently. Storing the Mower for LongevityProper storage techniques are essential for ensuring the extended life of your grass-cutting equipment. By following a few straightforward guidelines, you can prevent deterioration and maintain optimal performance when the time comes to use it again. Here are key considerations to keep in mind:

By adhering to these storage practices, you can significantly enhance the lifespan and reliability of your cutting equipment, ensuring it remains in prime condition for years to come. |