The performance of small engines often hinges on the efficiency of their fuel delivery systems. Understanding how to maintain and troubleshoot these components can significantly enhance the longevity and functionality of your machinery. This section aims to provide insights into the intricacies of these vital parts, ensuring optimal operation through effective upkeep.

In this guide, you will discover essential techniques for enhancing the fuel management systems. Whether addressing common issues or performing routine maintenance, knowing the right steps to take can prevent future complications and costly repairs. With the right approach, you can ensure your equipment runs smoothly, providing reliable performance whenever needed.

Equipped with detailed knowledge, users can confidently navigate the challenges associated with these engine systems. By adopting proper maintenance practices, you can ensure a seamless operation, prolonging the life of your equipment and enhancing its efficiency. Empower yourself with the skills necessary to tackle fuel system issues and keep your engine performing at its best.

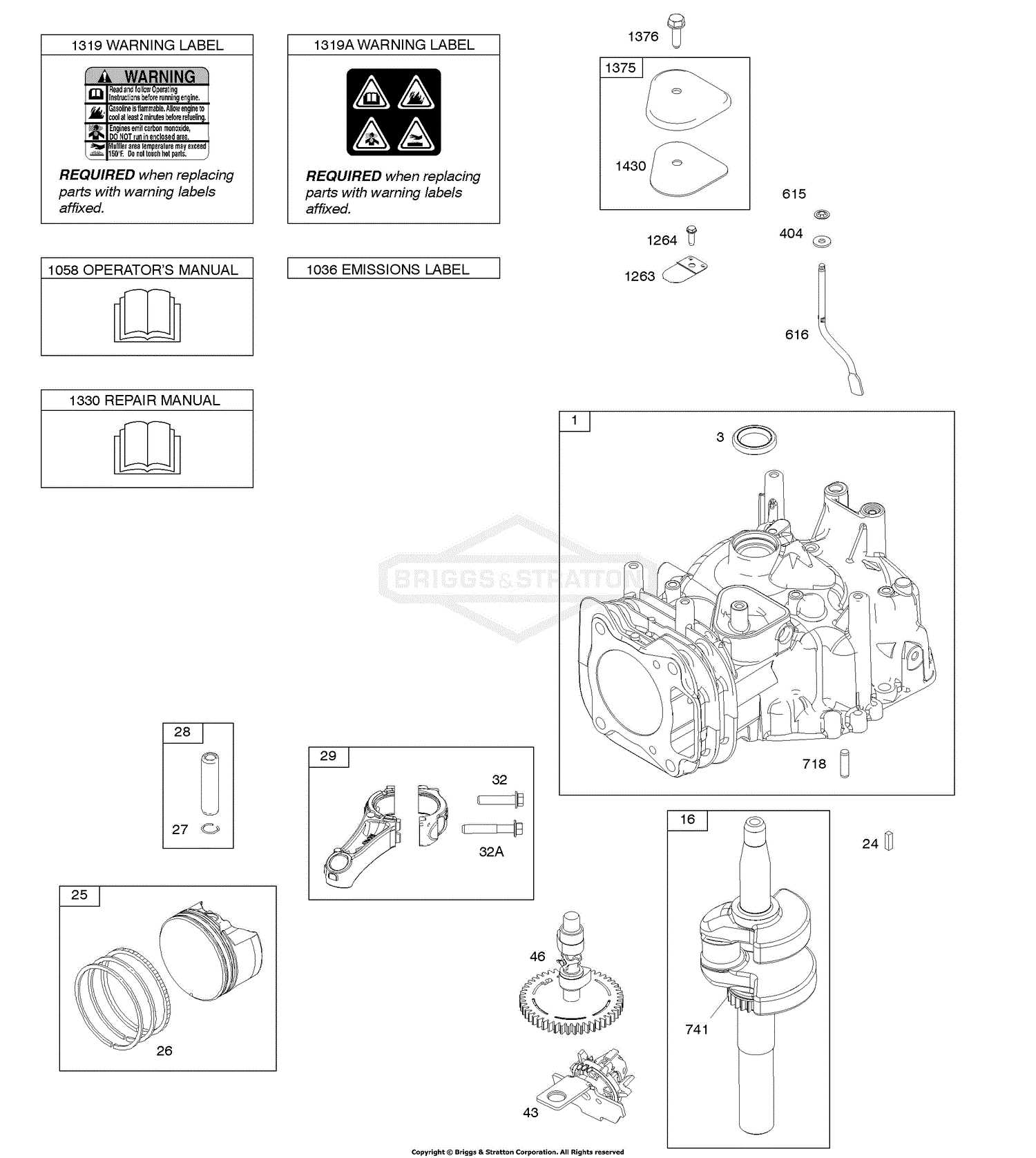

This section provides a comprehensive introduction to the mechanisms and functions associated with a specific type of fuel mixing device used in various engines. Understanding the design and operation of these components is crucial for maintenance and troubleshooting.

In this overview, we will explore several key aspects:

- Purpose: The main role of these devices in engine performance.

- Components: A breakdown of essential parts that contribute to the functionality.

- Types: Various models available and their unique features.

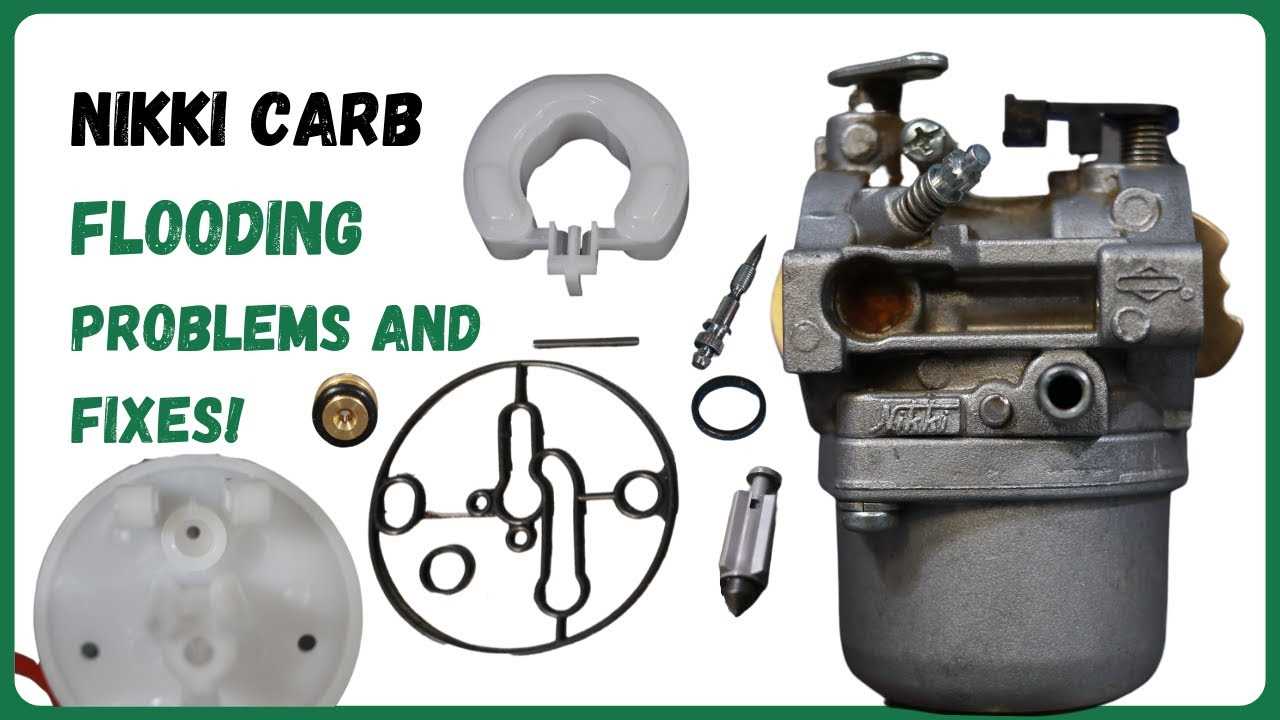

- Common Issues: Frequent problems encountered and their symptoms.

- Maintenance: Importance of regular care and common practices to ensure longevity.

- Adjustments: Necessary modifications for optimal performance.

By delving into these topics, readers will gain a solid foundation for understanding how to properly care for and address issues related to these devices.

Common Issues with Carburetors

Carburetors are vital components that play a significant role in the performance of small engines. However, they can often encounter various challenges that may affect their efficiency. Understanding these common problems is essential for maintaining optimal engine functionality.

Fuel Delivery Problems

One frequent issue is related to fuel delivery. Insufficient fuel flow can lead to poor engine performance, causing it to stall or run unevenly. This can result from clogged fuel lines, dirty filters, or malfunctioning fuel pumps. Ensuring that all components in the fuel system are clean and functioning properly is crucial for consistent performance.

Air Mixture Imbalances

Another common concern involves air and fuel mixture imbalances. An overly rich or lean mixture can lead to starting difficulties and reduced power output. Adjusting the mixture settings can help rectify these imbalances. Regular inspections of the adjustment screws and gaskets are recommended to maintain the correct ratios and prevent engine damage.

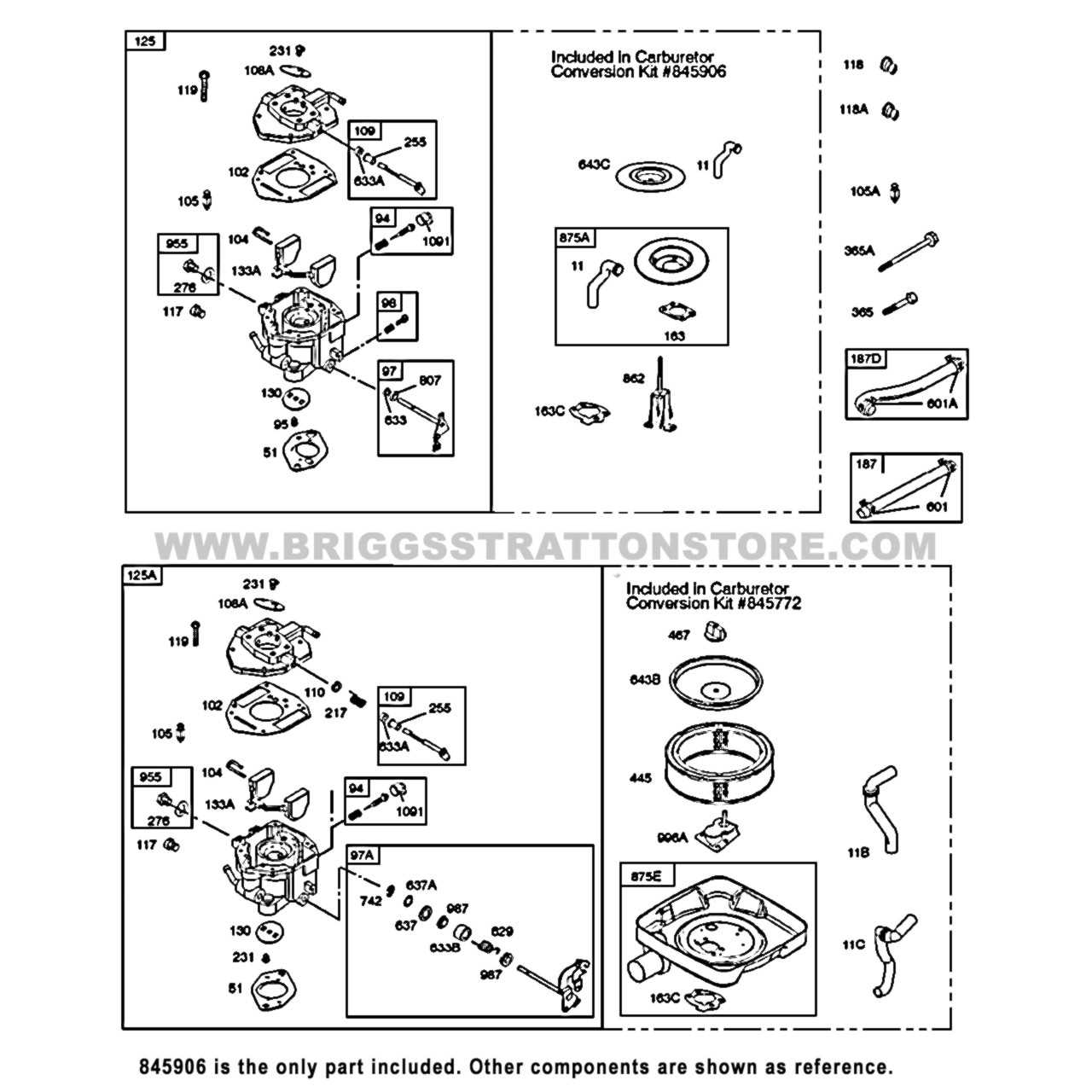

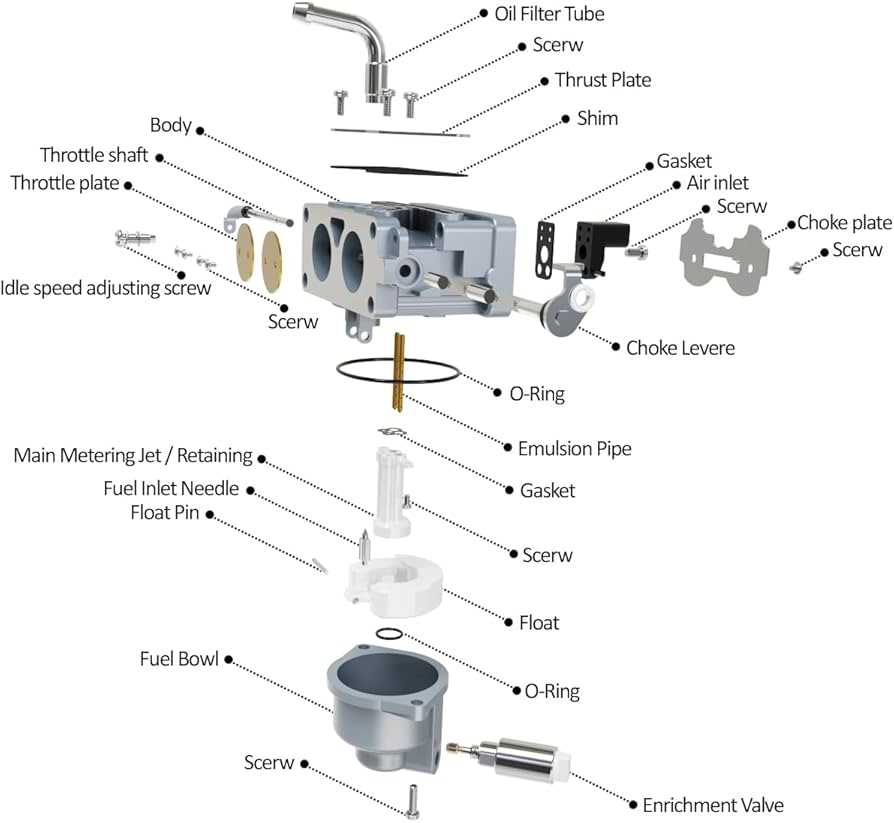

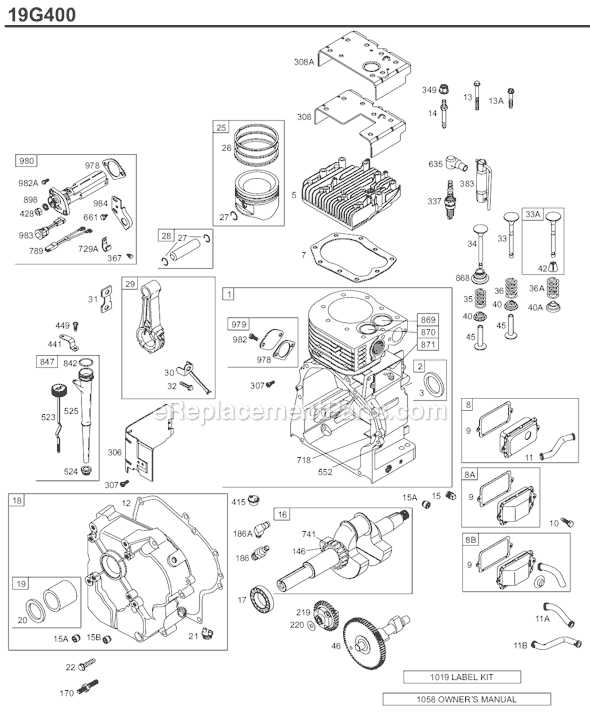

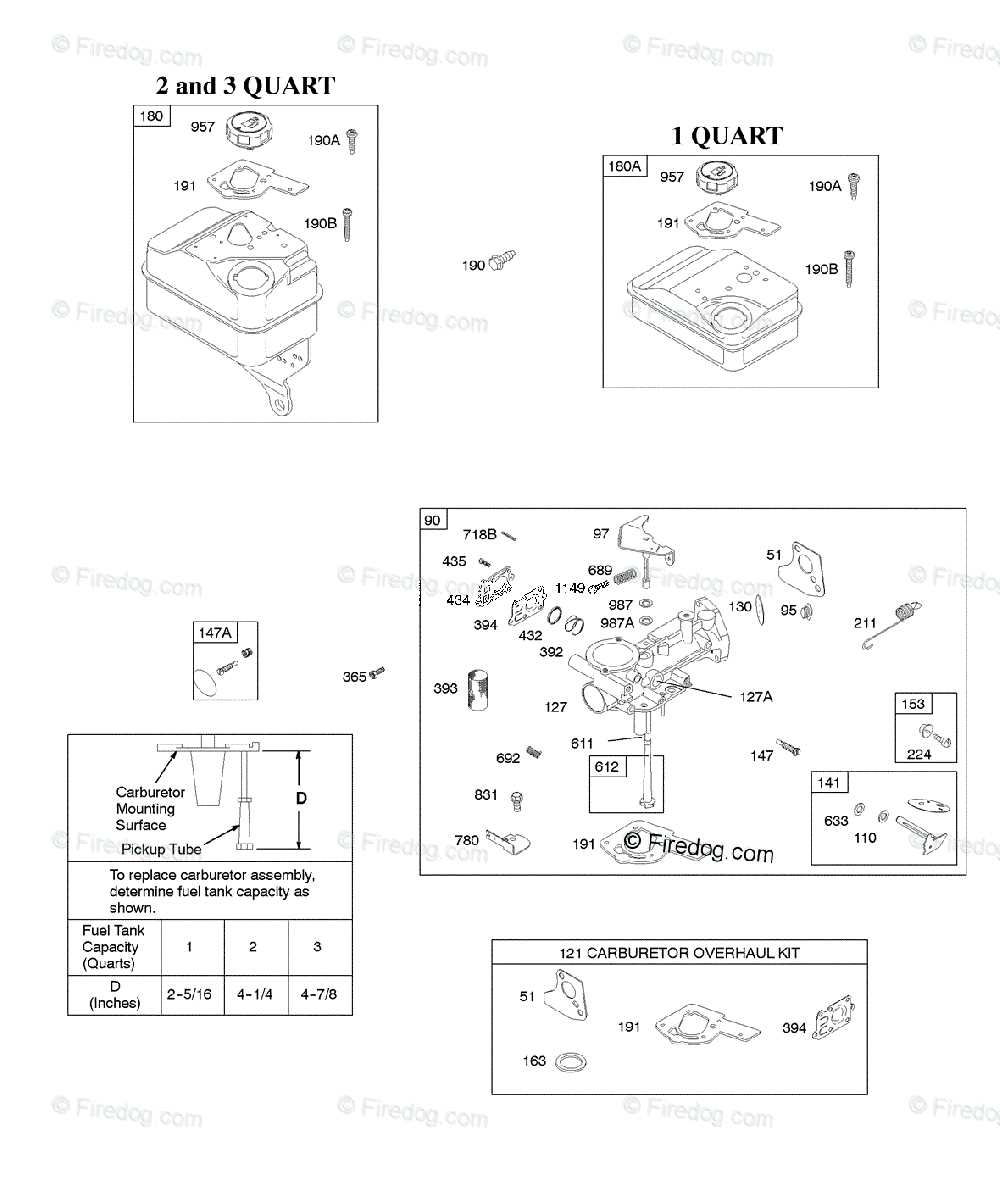

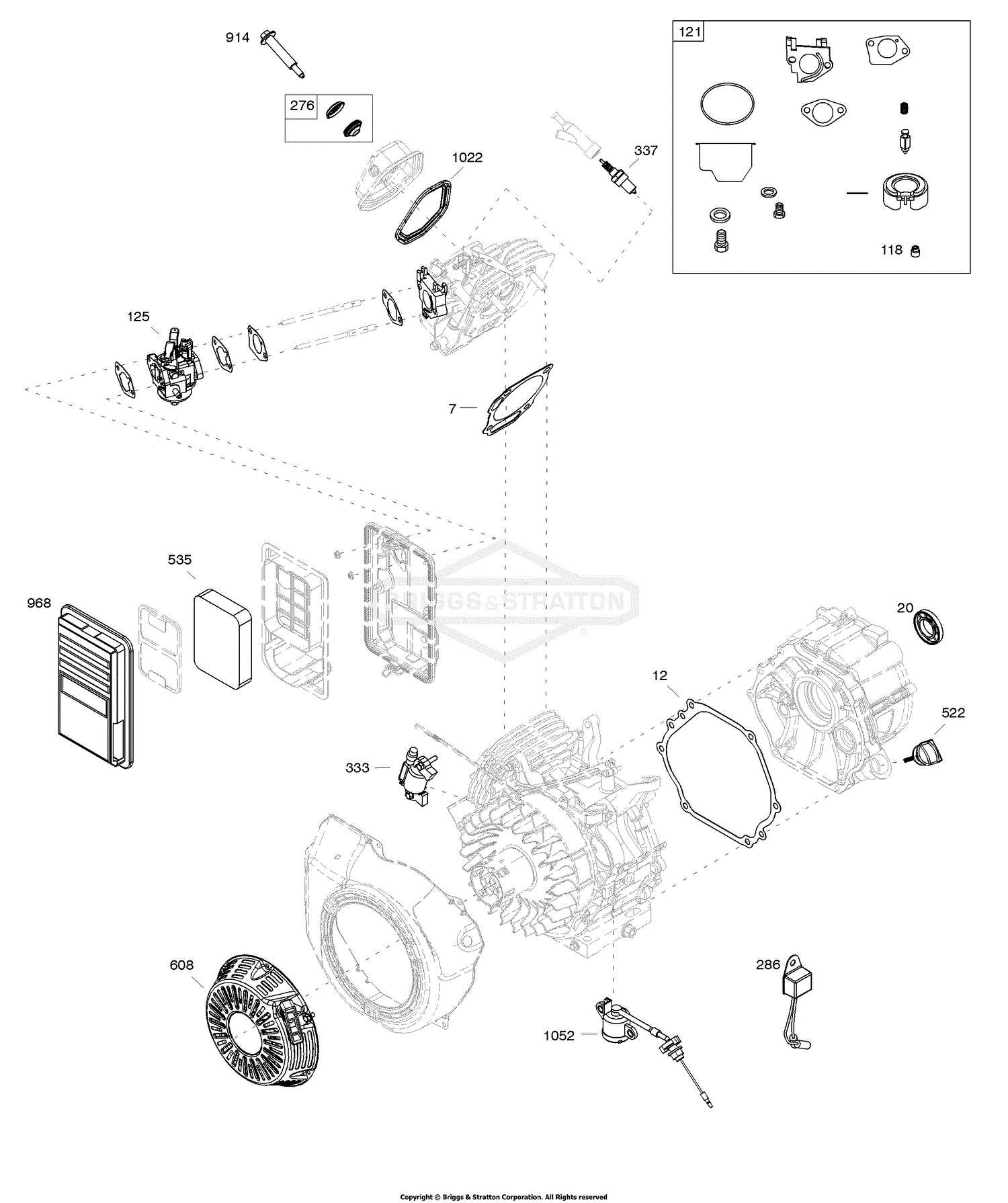

Understanding Carburetor Components

The heart of any internal combustion engine is its fuel delivery system, which plays a crucial role in optimizing performance and efficiency. Within this system, certain elements work together to ensure a proper mix of air and fuel enters the combustion chamber. By examining these key components, one can appreciate their function and importance in maintaining engine operation.

One primary part is the float chamber, which regulates the fuel level and ensures a consistent supply. It operates in conjunction with a float, a small device that rises and falls with the fuel level, signaling when to open or close the inlet valve. This mechanism prevents overflow and maintains stability in fuel delivery.

Another essential element is the throttle valve, responsible for controlling the airflow into the engine. By adjusting the amount of air, it influences engine power and speed. This component can be manually operated or controlled automatically based on engine requirements.

The main jet also plays a significant role by metering the fuel that mixes with the incoming air. Proper calibration of this part is vital for optimal engine performance, as it directly affects the air-fuel mixture ratio.

In addition, the choke valve is crucial during cold starts, enriching the fuel mix to help the engine ignite more easily. Understanding how these components interact provides valuable insight into the intricate workings of the engine’s fuel delivery system.

Tools Needed for Repair

When tackling maintenance tasks on small engines, having the right equipment is essential for achieving optimal results. A well-prepared workspace with the appropriate instruments can significantly enhance the efficiency and effectiveness of your work. Below is a list of essential tools that will assist you in your endeavors.

| Tool | Description |

|---|---|

| Screwdrivers | Essential for loosening and tightening various screws, available in different sizes and types. |

| Wrenches | Used to secure nuts and bolts, ensuring all connections are tight and secure. |

| Pliers | Helpful for gripping, twisting, and cutting wires or small components. |

| Socket Set | Provides versatility for different sizes of nuts and bolts, allowing for quicker adjustments. |

| Cleaning Brushes | Useful for removing dirt and debris from intricate parts, ensuring optimal performance. |

| Fuel Line Clamp | Helps in securing fuel lines during disassembly, preventing spills and leaks. |

Step-by-Step Disassembly Guide

This section provides a comprehensive approach to carefully taking apart a specific engine component. By following these detailed steps, you can ensure that all parts are removed correctly, allowing for thorough cleaning or inspection without damaging any critical elements.

Required Tools

Before starting the disassembly process, gather the necessary tools to facilitate a smooth operation. Below is a list of essential items:

| Tool | Purpose |

|---|---|

| Socket Wrench Set | To loosen and remove bolts |

| Screwdriver Set | For various screw types |

| Cleaning Brush | To clean residue from components |

| Container | For holding small parts |

Disassembly Steps

Follow these sequential steps to safely disassemble the component:

- Ensure the engine is off and cool before starting.

- Disconnect any fuel lines connected to the assembly.

- Remove the mounting screws using a socket wrench.

- Gently detach the assembly from its housing.

- Take out the inner parts carefully, noting their arrangement for reassembly.

- Place all removed components in a designated container to avoid loss.

Cleaning Techniques for Carburetors

Proper maintenance of fuel delivery components is essential for optimal engine performance. Regularly cleaning these parts helps prevent issues such as poor fuel atomization and inefficient combustion. Employing the right techniques not only extends the lifespan of these components but also enhances overall functionality.

Essential Tools and Materials

Before starting the cleaning process, gather the necessary tools and materials. Having the right items at hand can simplify the procedure and improve results. Below is a list of common tools and supplies needed:

| Tool/Material | Purpose |

|---|---|

| Cleaning solution | Removes deposits and residues |

| Brushes | Facilitates scrubbing hard-to-reach areas |

| Compressed air | Clears out passages and jets |

| Soft cloths | Wipes surfaces and removes contaminants |

| Safety goggles | Protects eyes from cleaning agents |

Step-by-Step Cleaning Process

Follow these steps to effectively clean fuel delivery components:

- Remove the assembly from the engine, ensuring all connections are disconnected.

- Disassemble the unit, taking care to keep track of small parts.

- Apply the cleaning solution to all surfaces, letting it sit for a few minutes.

- Use brushes to scrub any stubborn deposits, paying attention to jets and passageways.

- Utilize compressed air to blow out any remaining debris and ensure all pathways are clear.

- Wipe down surfaces with soft cloths to remove any residual cleaning agent.

- Reassemble the component and reinstall it on the engine, ensuring all connections are secure.

Reassembling the Carburetor Properly

Reassembling an engine’s fuel delivery component requires careful attention to detail and a methodical approach. This crucial process ensures optimal performance and longevity. Following a structured sequence can prevent common issues and enhance the efficiency of the engine.

Step-by-Step Assembly Process

Begin by gathering all necessary components and tools to avoid interruptions. Carefully position each part as per the manufacturer’s specifications. Pay special attention to the gaskets and seals, ensuring they are correctly aligned to prevent leaks. Gradually tighten screws in a cross pattern to maintain even pressure, which is essential for proper sealing.

Final Checks and Adjustments

After assembly, inspect all connections and components to confirm they are secure. Adjust settings as needed for optimal operation. It’s also advisable to conduct a functional test to verify that everything operates smoothly. Properly reassembling this vital component is key to maintaining the engine’s overall efficiency and reliability.

Tuning the Carburetor for Performance

Optimizing the fuel delivery system is essential for enhancing the overall efficiency and responsiveness of an engine. Fine-tuning this component can significantly improve acceleration, power output, and fuel economy. This section explores key adjustments that can be made to achieve optimal performance.

Adjusting Air-Fuel Mixture

One of the most crucial aspects of tuning involves the air-fuel ratio. An optimal mixture ensures the engine runs smoothly and efficiently. To achieve this, it is important to monitor the engine’s performance at various settings. A richer mixture may provide better acceleration, while a leaner mix can improve fuel efficiency. Regular adjustments based on engine conditions can lead to enhanced performance.

Idle Speed Configuration

The idle speed setting is another important factor that influences overall functionality. Ensuring that the engine idles at the correct RPM can prevent stalling and improve responsiveness. Fine-tuning the idle speed can help maintain a stable operation, especially during low-load conditions. Make gradual adjustments while observing engine behavior to find the perfect balance.

Testing After Repairs

Once the necessary adjustments and enhancements have been completed, it is essential to evaluate the functionality of the system to ensure optimal performance. This phase is crucial for verifying that all components are operating effectively and that the adjustments made have yielded the desired results. Proper testing will help identify any lingering issues that may need further attention.

Steps to Conduct the Evaluation

Follow these steps to thoroughly assess the system:

| Step | Description |

|---|---|

| 1 | Check fuel supply to ensure it is reaching the system without obstruction. |

| 2 | Examine airflow and make sure it is unobstructed and flowing correctly. |

| 3 | Start the engine and observe its operation for any irregularities. |

| 4 | Monitor performance under load conditions to assess power output and efficiency. |

Final Assessment

After conducting the tests, compile the observations to determine if the adjustments have successfully resolved any previous issues. If problems persist, further investigation may be necessary to diagnose and rectify the situation. Regular evaluations post-enhancements ensure continued efficiency and reliability in the system’s operation.

Preventive Maintenance Tips

Regular upkeep is essential for ensuring optimal performance and longevity of your engine components. Implementing a routine maintenance schedule can help identify potential issues before they escalate, saving time and resources in the long run. By following these guidelines, you can maintain efficiency and enhance the overall functionality of your equipment.

Routine Inspections

Conduct frequent checks on your machinery to identify any signs of wear or malfunction. Look for leaks, corrosion, or loose connections. Addressing these issues promptly can prevent more significant problems from developing.

Cleaning and Adjustments

Regular cleaning of vital parts is crucial. Use appropriate cleaning solutions to remove dirt and debris, ensuring that all components function smoothly. Additionally, make necessary adjustments to settings as specified by the manufacturer to maintain peak performance.

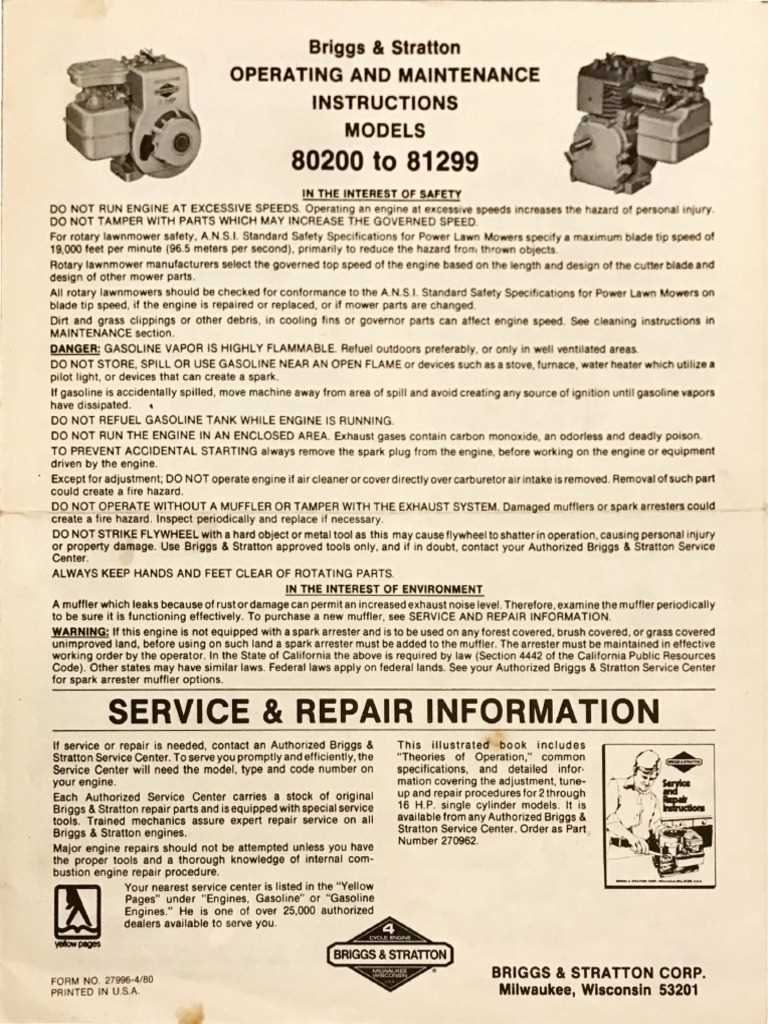

When to Seek Professional Help

Understanding the limits of your skills is crucial when dealing with engine components. While many tasks can be handled independently, there are specific situations where seeking assistance from a qualified technician is advisable. Knowing when to step back can save time and prevent further complications.

Complicated Issues: If you encounter persistent problems that resist your efforts, it’s time to consult an expert. Complex malfunctions may require specialized tools or knowledge that go beyond basic troubleshooting.

Safety Concerns: If you’re unsure about handling potentially hazardous situations, it is wise to involve a professional. Safety should always be a priority, especially when dealing with machinery that can pose risks.

Time Constraints: When faced with limited time or resources, outsourcing the task may be the best option. A skilled mechanic can often diagnose and resolve issues more efficiently, allowing you to focus on other priorities.

Warranty Issues: If your equipment is still under warranty, attempting repairs yourself may void it. Consulting a professional ensures that the integrity of the warranty remains intact.

Resources for Further Assistance

When tackling issues with engine components, it’s essential to have access to reliable resources that can provide guidance and support. Whether you’re looking for troubleshooting tips, instructional videos, or expert advice, numerous platforms can enhance your understanding and skills. Utilizing these resources can significantly improve your ability to address various challenges effectively.

Online Forums and Communities

Engaging with online forums and communities dedicated to engine maintenance can be invaluable. Members often share their experiences, insights, and solutions to common problems. Participating in discussions can help you gain different perspectives and learn new techniques from fellow enthusiasts and professionals.

Video Tutorials and Workshops

Video tutorials are an excellent way to visualize processes and techniques. Many channels focus on engine components, offering step-by-step guides that cater to various skill levels. Additionally, attending local workshops or classes can provide hands-on experience and the chance to learn directly from experienced instructors.

Frequently Asked Questions

This section aims to address common inquiries related to the maintenance and troubleshooting of small engine fuel delivery systems. Understanding these elements can help ensure optimal performance and longevity of your equipment.

What are the common signs of a malfunctioning fuel delivery system?

Typical indicators include engine stalling, difficulty starting, and irregular idling. Additionally, if there is a noticeable decrease in power or acceleration, these could be signs that something is wrong within the fuel system.

How can I improve the efficiency of my engine?

Regular maintenance is key to enhancing efficiency. This includes ensuring clean fuel, inspecting filters, and checking for any blockages. Using high-quality fuel can also contribute to better performance.