When it comes to keeping your outdoor equipment in optimal condition, having a comprehensive reference is essential. This resource aims to provide detailed insights and instructions for users seeking to enhance the longevity and performance of their gardening tools. Proper maintenance not only ensures efficiency but also significantly reduces the risk of future malfunctions.

Whether you’re experiencing minor issues or preparing for a seasonal tune-up, understanding the fundamental components and their functions is crucial. This guide covers a variety of topics, including routine checks, common problems, and effective solutions, designed to empower users with the knowledge necessary for self-sufficient upkeep.

With the right approach and a bit of dedication, you can tackle most challenges that arise. By following the outlined procedures, you will gain confidence in handling your equipment, ensuring it remains a reliable companion for all your outdoor tasks. Embrace the opportunity to learn and take control of your maintenance practices.

Understanding Husqvarna 128CD Features

This section delves into the distinctive characteristics of a versatile outdoor power tool designed for efficiency and ease of use. By exploring its various components, users can gain insight into how these features contribute to enhanced performance in various tasks.

Engine Performance: At the heart of this equipment lies a powerful engine that balances fuel efficiency with substantial output. This ensures that users can tackle tough jobs without frequent refueling, making it ideal for extended sessions.

Lightweight Design: The thoughtful engineering results in a lightweight structure that allows for improved maneuverability. This is particularly beneficial when navigating through dense vegetation or performing overhead tasks, reducing operator fatigue.

Versatile Attachments: A range of compatible attachments expands the tool’s functionality, allowing users to switch between trimming, edging, and blowing with ease. This adaptability makes it suitable for various landscaping needs.

Ergonomic Features: Comfort is prioritized through ergonomic handles that reduce strain during prolonged use. The design promotes a natural grip, enhancing control and precision when operating the equipment.

Easy Start System: An intuitive starting mechanism simplifies the ignition process, ensuring that users can get to work quickly without the frustration often associated with starting similar devices.

Durable Construction: Built with robust materials, this tool is designed to withstand the rigors of outdoor use. Its resilience ensures longevity, providing users with a reliable companion for years to come.

Common Issues with the 128CD Model

Every mechanical tool can experience challenges over time, and this particular model is no exception. Users often encounter a variety of problems that can hinder performance and efficiency. Understanding these common issues is essential for maintaining the tool and ensuring optimal functionality.

Starting Difficulties

One prevalent issue reported is difficulty in starting the engine. This can arise from several factors, including a clogged air filter, stale fuel, or a malfunctioning spark plug. Regular maintenance, such as cleaning or replacing the air filter and ensuring fresh fuel is used, can mitigate these problems.

Inconsistent Performance

Another common concern involves inconsistent operation during use. This may be attributed to fuel delivery issues or blockages in the exhaust system. Ensuring that the fuel lines are clear and inspecting the muffler for any obstructions can help maintain steady performance.

By being aware of these typical challenges, users can take proactive steps to address them, leading to a more reliable and efficient experience with their equipment.

Essential Tools for Repairs

When it comes to maintaining outdoor equipment, having the right instruments is crucial for achieving optimal performance and longevity. This section outlines the fundamental items that every enthusiast should have on hand for efficient servicing tasks. Whether you’re addressing minor issues or conducting thorough inspections, these tools will facilitate smooth operations and enhance your repair capabilities.

First and foremost, a quality set of screwdrivers is indispensable. Different sizes and types, including flathead and Phillips, ensure that you can tackle various screws without damage. In addition, pliers, particularly needle-nose and adjustable varieties, offer versatility in gripping and manipulating components. A reliable wrench set is equally important for loosening or tightening bolts, providing the necessary torque for secure fittings.

Moreover, having a pair of scissors and utility knives on standby can assist with cutting through materials such as cords or straps during disassembly. Don’t forget about safety gear; gloves and goggles are essential for protecting yourself while working on machinery. Lastly, a sturdy workbench with good lighting creates an ideal environment for tackling any task, making it easier to see details and organize your tools effectively.

Step-by-Step Repair Process

This section provides a comprehensive guide for troubleshooting and restoring functionality to your outdoor equipment. Following a systematic approach ensures that each component is addressed efficiently, leading to a successful resolution of any issues.

-

Gather Necessary Tools and Materials:

- Screwdrivers (flathead and Phillips)

- Wrenches and pliers

- Replacement parts (if needed)

- Cleaning supplies (brushes, cloths)

- Safety gear (gloves, goggles)

-

Initial Inspection:

- Examine the equipment for visible damage or wear.

- Check fuel levels and quality.

- Inspect air filters and spark plugs for cleanliness.

-

Troubleshooting Symptoms:

- If the engine won’t start, verify the fuel system and ignition components.

- For performance issues, assess the carburetor and exhaust.

- Look for any loose or damaged wiring.

-

Disassembly:

- Carefully remove covers and housing to access internal parts.

- Keep track of screws and components for reassembly.

-

Cleaning and Maintenance:

- Clean all components using appropriate solvents.

- Replace worn or damaged parts as necessary.

- Lubricate moving parts to ensure smooth operation.

-

Reassembly:

- Carefully reattach all components in reverse order of disassembly.

- Ensure all screws and connections are tightened properly.

-

Final Testing:

- Start the equipment to verify successful repairs.

- Monitor for any unusual sounds or behaviors.

- Make adjustments as needed based on performance.

By adhering to these steps, you can effectively restore your outdoor equipment to optimal working condition, ensuring its longevity and reliability for future use.

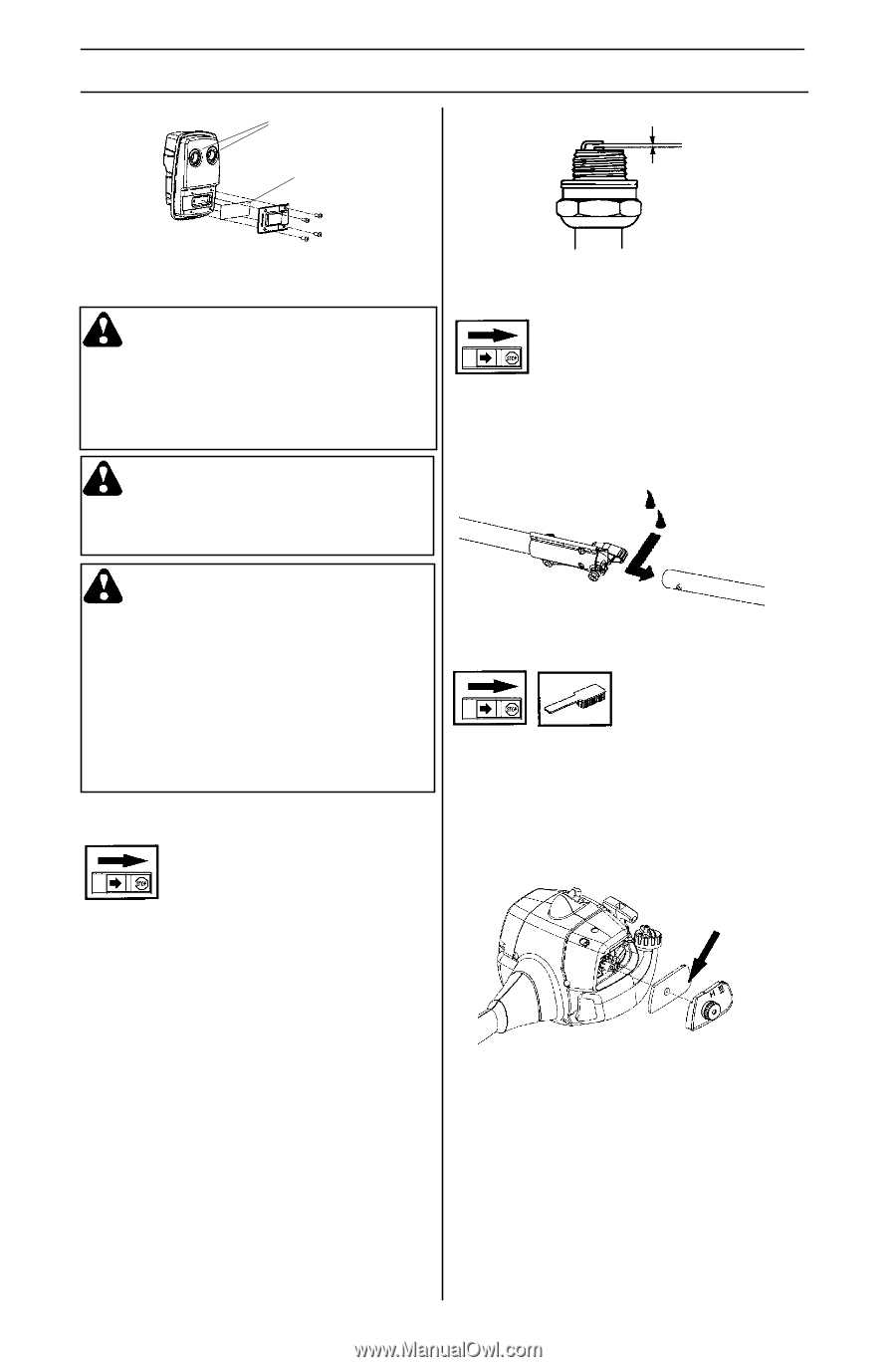

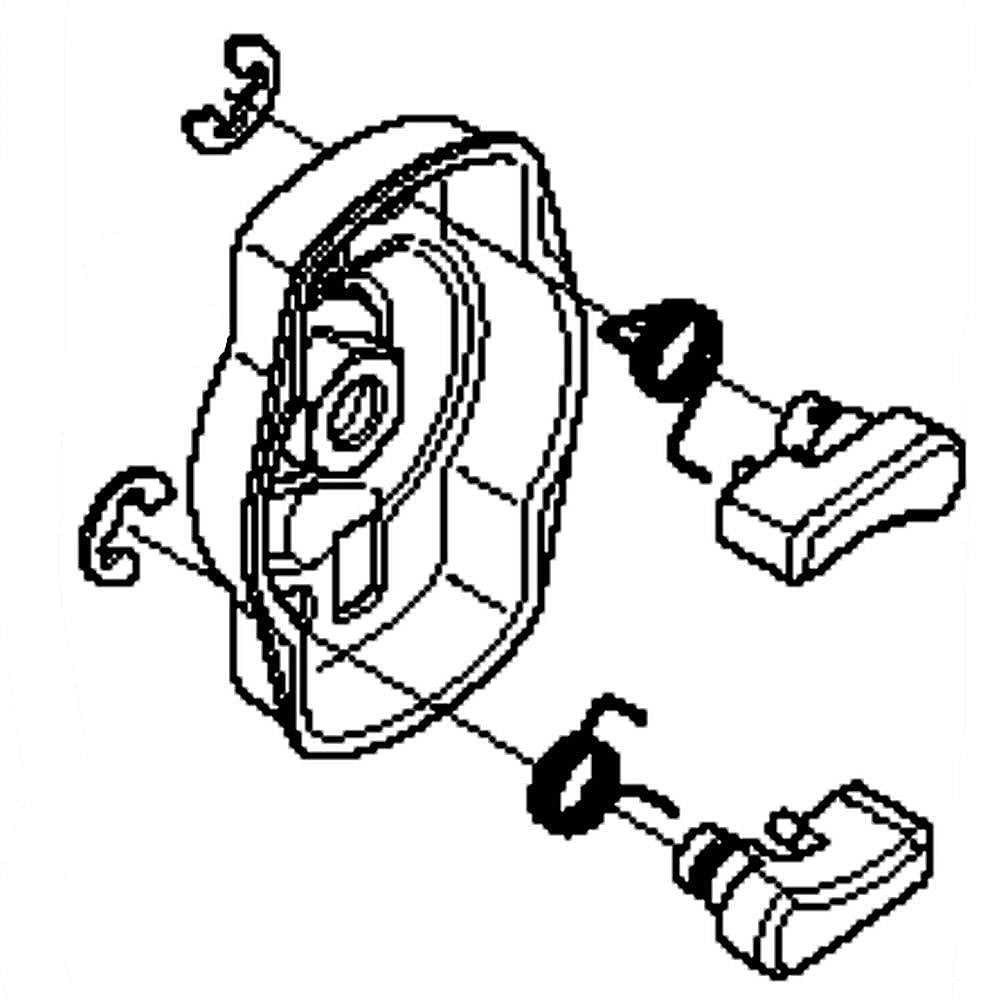

Replacing the Cutting Head

Swapping out the cutting head is a vital maintenance task that ensures optimal performance of your equipment. Over time, wear and tear can affect the efficiency of the trimmer, making it essential to refresh this component. This guide will walk you through the process, helping you achieve a smooth and effective replacement.

Gather Necessary Tools

Before starting, it’s important to collect all required tools. You will typically need a socket wrench, a screwdriver, and protective gloves. Having these items ready will streamline the replacement process and ensure safety while working.

Steps for Replacement

Begin by ensuring that the machine is powered off and disconnected from any power source. Locate the locking mechanism on the cutting head; this often involves pressing a button or releasing a latch. Carefully remove the old head by turning it counterclockwise. Once detached, align the new cutting head with the shaft, ensuring it fits snugly. Secure it in place by turning it clockwise until it locks. Finally, test the new attachment to confirm it is firmly in position and ready for use.

Maintaining the Fuel System

Proper upkeep of the fuel delivery system is essential for ensuring optimal performance and longevity of your outdoor equipment. Regular attention to this area helps prevent common issues such as starting difficulties, engine stalling, and inefficient fuel consumption. Implementing a few straightforward maintenance practices can significantly enhance the reliability and efficiency of your machine.

Key Maintenance Practices

To maintain the fuel system effectively, focus on these critical practices:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fuel Filter Replacement | Every 25 hours | Replace the fuel filter to prevent clogs and ensure a steady fuel flow. |

| Inspect Fuel Lines | Every 10 hours | Check for cracks or leaks in the fuel lines to avoid fuel loss. |

| Clean the Fuel Tank | Annually | Empty and clean the fuel tank to remove any sediment or debris. |

| Use Fresh Fuel | As needed | Always use fresh fuel to prevent varnish build-up and ensure efficient combustion. |

Additional Tips

In addition to the primary tasks, consider using a fuel stabilizer to prolong the shelf life of your gasoline, especially if the equipment is stored for extended periods. Regularly running the engine for short periods can also help keep the fuel system clean and free from obstructions.

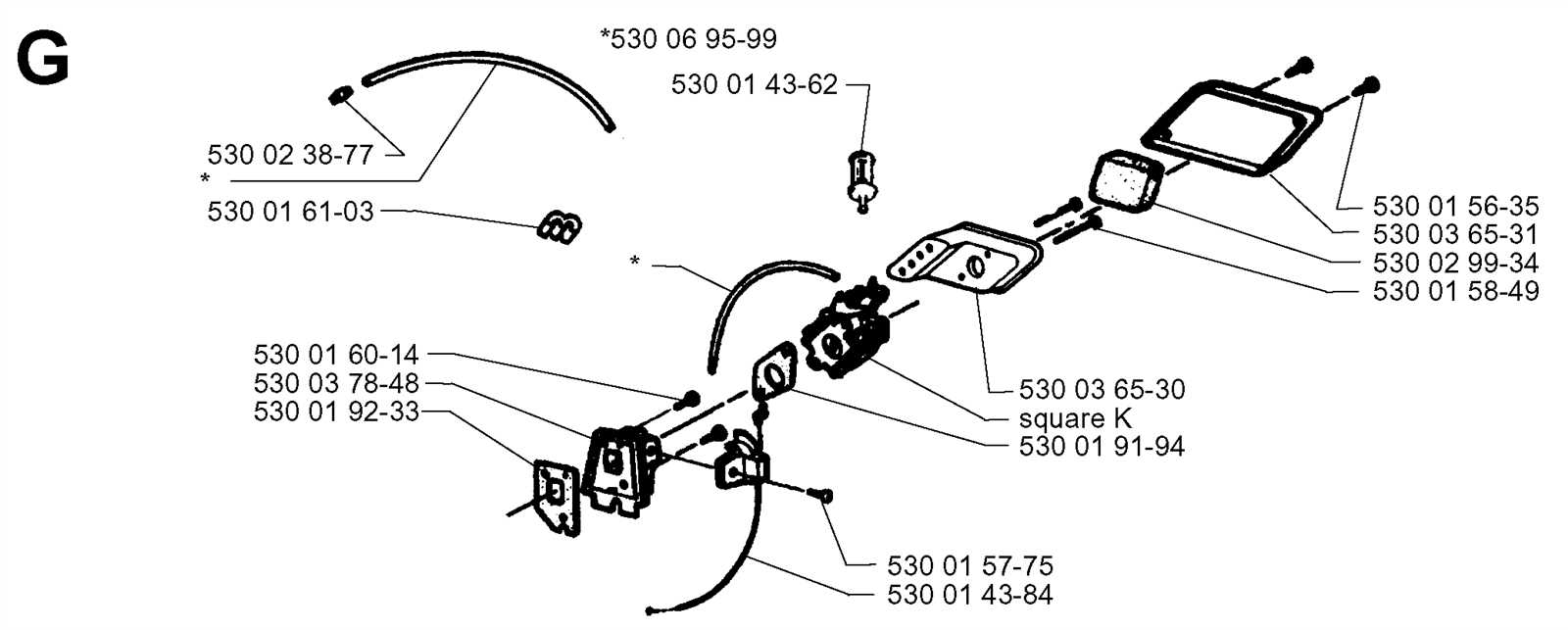

Troubleshooting Engine Performance Problems

When an engine fails to operate efficiently, it can lead to frustration and decreased productivity. Identifying the root causes of performance issues is essential for restoring optimal functionality. Common symptoms include rough idling, stalling, or a noticeable drop in power. Understanding the potential factors at play will aid in diagnosing and resolving these challenges.

Begin by examining the fuel system, as inadequate or contaminated fuel can significantly impact engine performance. Ensure that the fuel is fresh and free from impurities. Additionally, check the fuel filter for clogs that could restrict flow.

Next, assess the ignition components. Worn or damaged spark plugs can lead to misfires and reduced power output. Inspect the ignition coil and associated wiring for any signs of wear or damage that might hinder performance.

Airflow is another critical aspect to evaluate. A clogged air filter can restrict the engine’s ability to breathe, causing inefficiency. Ensure that the air intake system is clear and that the filter is clean or replaced as needed.

Lastly, examine the overall condition of the engine. Regular maintenance, including oil changes and inspections of critical components, can prevent performance issues from arising. If problems persist, it may be beneficial to consult a professional for a thorough examination.

Safety Precautions During Repairs

When engaging in maintenance tasks, ensuring personal safety should be a top priority. Proper precautions not only protect the individual but also contribute to the effective completion of the task at hand. Below are essential guidelines to follow to minimize risks while working on machinery.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and ear protection.

- Work in a well-ventilated area to avoid inhaling harmful fumes or dust.

- Ensure the machine is powered off and disconnected from any power source before beginning any work.

- Keep the work area organized and free from clutter to prevent accidents.

In addition to personal safety gear, it is crucial to understand the machinery’s components and functionalities. This knowledge will aid in identifying potential hazards and enhancing overall safety.

- Review the manufacturer’s guidelines and instructions thoroughly before proceeding.

- Utilize the correct tools and equipment designed for the specific task.

- Be mindful of sharp edges and moving parts to avoid injuries.

By adhering to these safety measures, you can create a secure working environment that allows for efficient and effective maintenance activities.

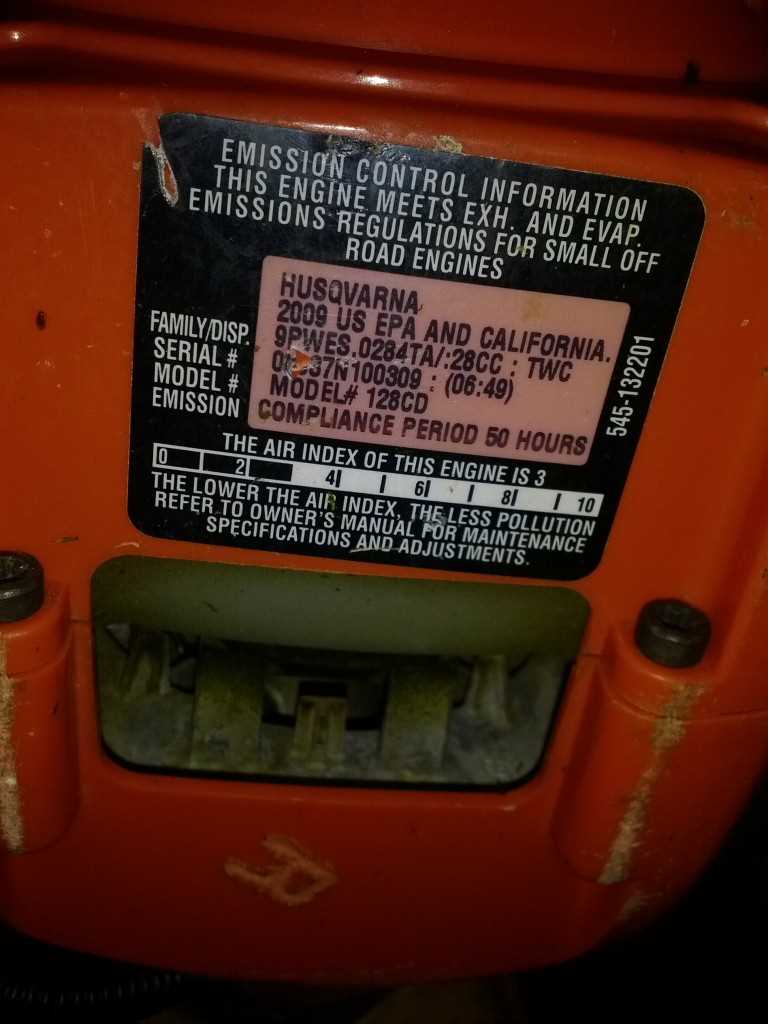

Finding Genuine Replacement Parts

When it comes to maintaining outdoor equipment, ensuring that you use authentic components is crucial for optimal performance and longevity. Using genuine parts not only enhances the reliability of your device but also helps preserve its warranty. This section will guide you in locating and acquiring these essential components.

Why Choose Authentic Components?

Opting for original parts guarantees compatibility and quality. Imitation components may seem cost-effective but often lead to subpar performance and potential damage. Investing in genuine replacements ensures that your equipment operates as intended, allowing you to complete your tasks efficiently.

Where to Find Authentic Parts

To locate original components, consider visiting authorized dealers or reputable online retailers specializing in outdoor machinery. Checking the manufacturer’s official website can also provide you with a list of trusted suppliers. Additionally, local service centers often stock genuine parts, ensuring you have access to what you need when you need it.