Maintaining a powerful cutting tool is essential for optimal performance and longevity. In this section, we will explore the intricacies of upkeep, focusing on the various components that contribute to the efficient operation of your machine. Understanding these elements can help you avoid common pitfalls and ensure smooth functionality throughout its lifespan.

Regular upkeep is not just a routine task; it is a crucial practice that directly impacts the effectiveness and safety of your equipment. From engine tuning to chain adjustment, each step plays a significant role in enhancing performance. This guide aims to provide you with clear and detailed insights into each aspect of maintenance, empowering you to take control of your tool’s condition.

Whether you’re a seasoned professional or a casual user, knowledge of proper care techniques can save time and money in the long run. By familiarizing yourself with the essentials, you can confidently tackle any issues that may arise and maintain your tool in peak condition for years to come. Join us as we delve into the essential aspects of chainsaw maintenance and troubleshooting.

Understanding the Stihl MS361 Model

This section delves into a popular tool designed for both professionals and enthusiasts. Its robust features and efficient performance make it an essential piece of equipment for various tasks, from landscaping to heavy-duty cutting. Understanding its components and capabilities can enhance user experience and ensure optimal operation.

Key Features

This model boasts several standout characteristics that contribute to its effectiveness. Among these are a powerful engine, lightweight design, and user-friendly controls, all of which facilitate ease of use during demanding projects.

| Feature | Description |

|---|---|

| Engine Type | Two-stroke engine for efficient power delivery |

| Weight | Lightweight construction for improved maneuverability |

| Bar Length | Available in various lengths for different cutting needs |

| Safety Features | Equipped with a chain brake and low-vibration technology |

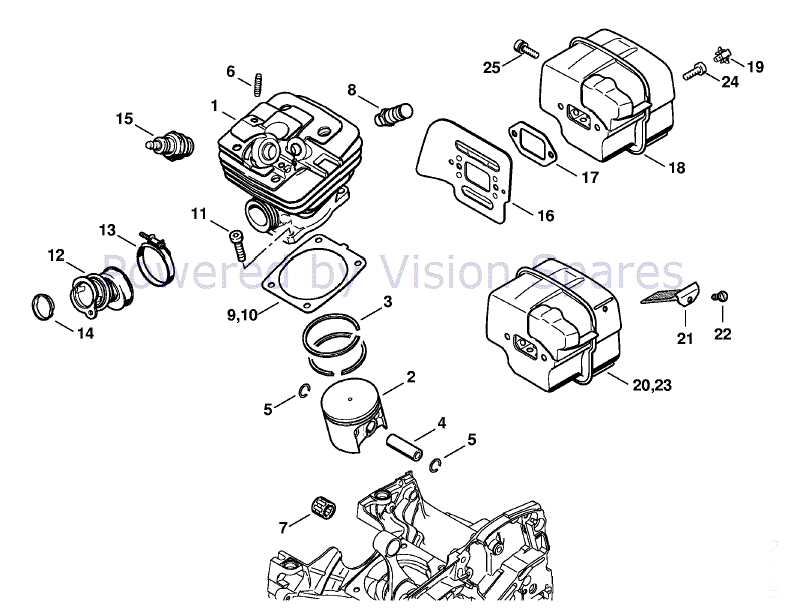

Maintenance Considerations

Regular upkeep is essential to prolong the life of this tool. Basic maintenance tasks include checking the chain tension, cleaning air filters, and ensuring proper lubrication. Following a consistent maintenance routine can prevent potential issues and maintain high performance.

Common Issues with Stihl MS361

When operating a high-performance chainsaw, several common challenges may arise, affecting its efficiency and reliability. Understanding these frequent problems can help users identify and address issues promptly, ensuring optimal performance and longevity of the equipment.

One prevalent concern involves difficulty starting the engine. This can stem from various factors, such as a faulty spark plug, clogged fuel lines, or issues with the carburetor. Regular maintenance of these components is essential to prevent starting difficulties.

Another issue often encountered is inadequate power during operation. This can be attributed to dull chains, improper tensioning, or fuel quality. Ensuring that the cutting chain is sharp and well-maintained, as well as using high-quality fuel, can mitigate this problem.

Users may also experience excessive vibrations, which can be uncomfortable and indicate underlying mechanical issues. This might be related to worn-out mounts or imbalances in the cutting assembly. Inspecting these parts regularly can help reduce vibrations and enhance user comfort.

Lastly, fuel leakage is a significant concern that not only affects performance but also poses safety hazards. This can result from damaged fuel lines or improper sealing. Regular inspections and prompt repairs of fuel components are crucial to maintaining a safe operating environment.

Essential Tools for Repair

When it comes to maintaining and restoring equipment, having the right instruments at hand is crucial. Proper tools not only facilitate the process but also enhance the quality of the work performed. Understanding which items are necessary can greatly improve efficiency and effectiveness during the task at hand.

Basic Toolkit

A foundational set of tools is essential for tackling a variety of maintenance jobs. This basic toolkit should include items that cater to the most common needs encountered during the process.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening and tightening screws. |

| Wrenches | To adjust and secure bolts and nuts. |

| Pliers | For gripping and twisting wires or components. |

| Utility Knife | For cutting through materials as needed. |

Advanced Instruments

In addition to the basic tools, certain advanced instruments can significantly aid in more complex tasks. These specialized tools help achieve precision and ensure that all parts are functioning optimally.

| Tool | Purpose |

|---|---|

| Torque Wrench | To apply specific torque to fasteners. |

| Multimeter | For measuring electrical parameters. |

| Chain Breaker | To remove and install chains effectively. |

| File Set | For sharpening and smoothing edges of components. |

Step-by-Step Maintenance Guide

Proper upkeep of your cutting tool is essential for ensuring optimal performance and longevity. This section outlines a systematic approach to routine care and preventive measures that can enhance efficiency and reduce the likelihood of malfunctions.

Tools Needed

- Protective gloves

- Screwdriver set

- Wrench

- Cleaning brush

- Chain oil

- Fuel mix

Maintenance Steps

-

Clean the Air Filter:

- Remove the air filter cover.

- Take out the air filter and brush off any debris.

- Rinse with warm, soapy water if necessary and allow to dry completely.

-

Inspect the Cutting Chain:

- Check for wear and damage.

- Sharpen the chain if it appears dull.

- Ensure proper tension is maintained.

-

Check the Fuel System:

- Inspect the fuel lines for cracks or leaks.

- Replace old fuel with a fresh mixture.

- Ensure the fuel filter is clean and functioning.

-

Examine the Spark Plug:

- Remove the spark plug and inspect for wear.

- Clean or replace as necessary.

- Check the gap and adjust if needed.

-

Lubricate Moving Parts:

- Apply appropriate oil to all moving components.

- Ensure that the chain and bar are adequately lubricated.

By following this guide, you can maintain your equipment effectively, ensuring it operates smoothly and efficiently for years to come.

How to Replace the Chain

Replacing the cutting chain is an essential maintenance task that ensures optimal performance and safety when operating your equipment. A sharp and properly fitted chain enhances cutting efficiency and prolongs the life of your tool. Follow these steps to complete the replacement process smoothly.

Tools and Materials Needed

- Replacement chain

- Wrench or socket set

- Screwdriver

- Protective gloves

- Safety glasses

Step-by-Step Instructions

- Prepare the Equipment: Ensure the tool is turned off and unplugged. Allow the engine to cool completely before starting the replacement.

- Remove the Cover: Use the wrench to loosen and remove the nuts securing the cover over the chain. Set the cover aside carefully.

- Take Off the Old Chain: Slide the old chain off the guide bar. Inspect the bar for any wear or damage and clean it if necessary.

- Install the New Chain: Place the new chain around the guide bar, ensuring that it fits properly into the grooves. The cutting edges should face in the direction of the chain’s movement.

- Reattach the Cover: Position the cover back over the guide bar and chain. Tighten the nuts securely with the wrench.

- Check Tension: Before use, check the chain tension. It should be tight enough to stay on the bar but loose enough to be pulled slightly by hand.

- Test the Equipment: Power on the tool and run it at a low speed to ensure that everything operates smoothly without unusual noise or vibration.

By following these steps, you can successfully replace the chain, ensuring your equipment remains effective and safe for all cutting tasks.

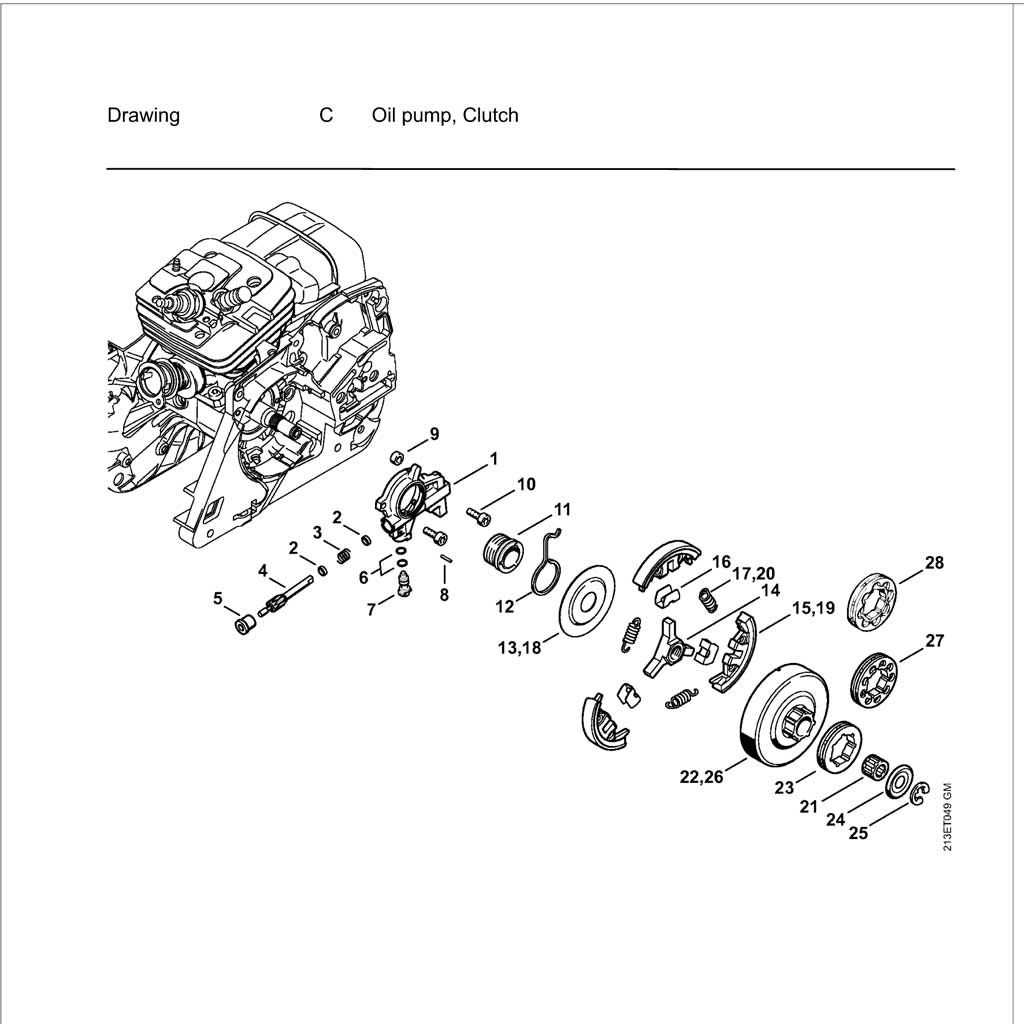

Fixing Fuel System Problems

Ensuring optimal performance of outdoor power equipment often hinges on the efficiency of the fuel delivery system. When issues arise, the engine may exhibit signs of distress, such as poor starting, irregular idling, or a complete lack of power. Addressing these concerns promptly can restore functionality and enhance the longevity of the machine.

Common issues within the fuel system may include clogged filters, faulty lines, or improper fuel mixtures. Here’s a systematic approach to diagnosing and resolving these challenges:

- Check Fuel Quality:

- Inspect for old or contaminated fuel.

- Replace with fresh, clean fuel as needed.

- Examine Fuel Filters:

- Locate and remove the fuel filter.

- Clean or replace it if it appears dirty or damaged.

- Inspect Fuel Lines:

- Look for cracks, leaks, or blockages.

- Replace any damaged sections to ensure a tight seal.

- Check the Carburetor:

- Disassemble and clean the carburetor, focusing on jets and passages.

- Ensure proper adjustment of the mixture screws.

- Evaluate Fuel Pump Function:

- Test the pump for proper operation.

- Replace if it is not delivering fuel as expected.

By systematically following these steps, many fuel system problems can be effectively identified and resolved, leading to a well-functioning machine ready for any task.

Troubleshooting Electrical Components

When faced with issues related to electrical systems in power equipment, a systematic approach can help identify and resolve problems efficiently. Understanding how to diagnose and fix these components is crucial for maintaining optimal performance and safety.

1. Visual Inspection: Begin by examining the equipment for any visible signs of damage, such as frayed wires, burnt connections, or loose terminals. Ensure that all components are securely attached and that there are no obstructions in the electrical pathways.

2. Testing Connections: Utilize a multimeter to check the integrity of connections. Measure voltage levels and continuity to confirm that power is flowing as expected. If readings are inconsistent, consider replacing or repairing the affected wires or connectors.

3. Component Evaluation: Assess individual electrical components, such as switches and relays. A malfunctioning part can disrupt the entire system. Look for any signs of wear or damage, and replace any defective components promptly.

4. Grounding Issues: Ensure that all grounding connections are secure and free from corrosion. Poor grounding can lead to erratic behavior and may compromise the safety of the equipment. Re-establish proper grounding if necessary.

5. Consult Documentation: Refer to technical documentation for specific guidance on electrical systems. These resources often provide schematics and troubleshooting tips tailored to the equipment in question, which can significantly aid in diagnostics.

By following these steps, you can effectively address electrical issues, ensuring the reliable operation of your equipment.

Cleaning and Caring for the Filter

Maintaining the filter in your equipment is crucial for optimal performance. Regular attention to this component ensures that your machine runs smoothly and efficiently, prolonging its lifespan and enhancing its capabilities. A clean filter allows for proper airflow, which is essential for the engine’s operation.

Importance of a Clean Filter

A clean filter not only improves engine performance but also prevents dust and debris from entering vital components. When the filter is clogged, it can lead to overheating and reduced efficiency. Regular inspection and cleaning are therefore essential to avoid costly repairs and ensure that your equipment operates at its best.

Cleaning Steps

To clean the filter, first, remove it from the equipment according to the manufacturer’s guidelines. Use compressed air to blow out any dirt and debris, taking care not to damage the filter material. For a deeper clean, wash it in warm, soapy water, rinse thoroughly, and allow it to dry completely before reinstallation. Regularly check for wear and tear, and replace the filter if necessary.

Remember: Proper care of the filter is a simple yet effective way to maintain your equipment’s efficiency and longevity.

Recognizing Engine Performance Symptoms

Understanding the signs of engine inefficiency is crucial for maintaining optimal functionality and longevity of outdoor power equipment. By identifying these symptoms early, operators can take timely action to prevent further issues and ensure peak performance.

Common Indicators of Engine Issues

- Reduced Power Output: Noticeable decrease in performance during operation.

- Unusual Noises: Grinding, knocking, or excessive vibration can signal underlying problems.

- Difficulty Starting: Struggles to ignite or requires multiple attempts to start.

- Excessive Smoke: Presence of dark or blue smoke during operation may indicate fuel or oil issues.

- Inconsistent Idling: Engine fluctuates or stalls when at rest.

Impact of Ignoring Symptoms

Neglecting these warning signs can lead to more severe complications, including:

- Increased repair costs due to extensive damage.

- Shortened lifespan of the engine.

- Potential safety hazards during operation.

Staying vigilant and addressing performance symptoms promptly can significantly enhance the reliability and efficiency of your equipment.

Safety Tips During Repairs

When working on machinery, prioritizing safety is essential. Adopting the right precautions can prevent accidents and ensure a smooth process. Here are key considerations to keep in mind while servicing equipment.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and ear protection.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes.

- Keep the area clean and free from clutter to minimize the risk of trips and falls.

Before starting any task, it is crucial to:

- Disconnect power sources to prevent accidental activation.

- Familiarize yourself with the equipment and its components.

- Use the correct tools for each job to avoid damaging parts or injuring yourself.

While performing maintenance, maintain focus and avoid distractions. If you feel fatigued or unwell, take a break. It’s better to pause than to rush through tasks, which could lead to mistakes.

Finally, ensure that you have a clear understanding of the assembly and disassembly processes to avoid unnecessary errors. Following these guidelines will help create a safer environment and promote effective servicing.

When to Seek Professional Help

Understanding when to consult an expert is crucial for maintaining equipment in optimal condition. Certain issues may appear manageable at first glance, but they can escalate into more significant problems if not addressed properly. Recognizing the limits of your skills and knowledge can save time and prevent further damage.

Signs of Serious Malfunction

If you notice unusual noises, vibrations, or performance drops, it may indicate a deeper issue. Ignoring these signs can lead to extensive repairs or even replacement of components. In such cases, seeking assistance from a qualified technician is advisable.

Complex Repairs Beyond Basic Maintenance

Some tasks require specialized tools and expertise. If you encounter problems that involve complex assemblies or electrical systems, it’s best to leave these tasks to professionals. Attempting to fix intricate issues without the right knowledge can compromise safety and lead to costly mistakes.