Understanding how to care for your cleaning appliance is essential for maintaining its effectiveness and longevity. Regular upkeep not only ensures optimal performance but also enhances the user experience, making cleaning tasks more efficient and enjoyable.

In this section, you will discover valuable insights into troubleshooting common issues, performing essential maintenance tasks, and optimizing the functionality of your cleaning device. By following these guidelines, you can keep your equipment in top condition and prolong its lifespan.

Familiarizing yourself with the internal components and typical problems can empower you to tackle minor issues independently. This proactive approach will help you avoid unnecessary expenses and keep your cleaning tasks running smoothly.

Understanding Your Hoover SteamVac

This section aims to provide insights into a popular cleaning device designed for deep sanitation and maintenance of various surfaces. Familiarity with its components and functionality can enhance the overall user experience and ensure optimal performance.

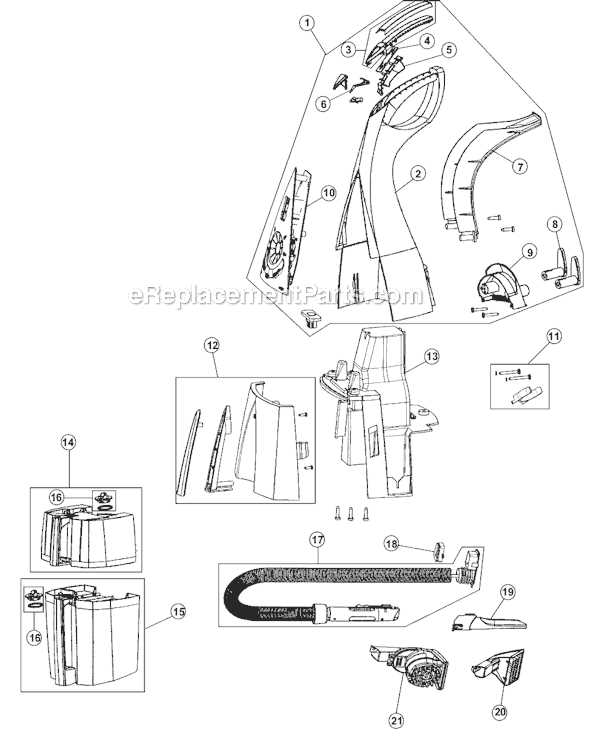

Before delving into specific aspects, it’s essential to recognize the fundamental parts of the machine that contribute to its efficacy. Each element plays a crucial role in delivering a thorough clean, making it imperative to understand their functions.

| Component | Description |

|---|---|

| Water Tank | Holds the cleaning solution and water mixture, crucial for the cleaning process. |

| Brush Roll | Agitates dirt and stains from surfaces, enhancing the cleaning effectiveness. |

| Suction Port | Extracts dirty water and debris from the cleaned area, ensuring a thorough rinse. |

| Control Panel | Allows users to select various settings and monitor the machine’s operation. |

| Hose Attachment | Enables targeted cleaning in hard-to-reach areas, such as upholstery and stairs. |

Understanding these components empowers users to maintain and operate the device more effectively, ultimately leading to a cleaner environment.

Common Issues with SteamVacs

Many users encounter various challenges with their carpet cleaning machines over time. Understanding these common problems can help in troubleshooting and maintaining optimal performance. Regular upkeep and awareness of typical malfunctions are essential for extending the life of the equipment.

Clogged Hoses: One frequent issue arises from blockages in the suction or solution hoses. Debris can accumulate, impeding proper flow and reducing cleaning efficiency. Regular inspection and clearing of these hoses can prevent this problem.

Poor Suction Power: Another common concern is a noticeable drop in suction strength. This can be attributed to a full recovery tank or a dirty filter. Ensuring that the tank is emptied and the filter is cleaned or replaced can often restore lost performance.

Water Leaks: Users may also experience leaks during operation. These can result from damaged seals or connections. Checking for wear and ensuring all fittings are secure can help mitigate this issue.

Faulty Brushes: Worn-out or ineffective brushes can lead to unsatisfactory cleaning results. Inspecting brushes for damage and replacing them as needed is crucial for maintaining the cleaning effectiveness of the device.

By addressing these common issues, users can enhance the longevity and functionality of their cleaning machines, ensuring optimal results for years to come.

Tools Needed for Repairs

When tackling maintenance tasks for your cleaning device, having the right instruments at hand is crucial for efficiency and effectiveness. This section outlines essential tools that will assist you in addressing various issues and ensuring optimal performance.

| Tool | Description |

|---|---|

| Screwdriver Set | A variety of screwdrivers will help you remove and secure different fasteners within the device. |

| Wrench Set | Useful for loosening or tightening nuts and bolts, ensuring that all parts are securely fitted. |

| Pliers | Essential for gripping and manipulating small components, making it easier to replace or adjust them. |

| Multimeter | Helps in diagnosing electrical issues by measuring voltage, current, and resistance. |

| Cleaning Cloths | Used to wipe down components and maintain cleanliness during the maintenance process. |

| Replacement Parts | Having the necessary spare components on hand can expedite the process of restoring functionality. |

Step-by-Step Repair Instructions

This section provides a comprehensive guide for troubleshooting and fixing common issues with your cleaning machine. By following the detailed steps outlined below, you can restore the functionality of your equipment effectively and efficiently.

1. Gather Necessary Tools: Before starting, ensure you have all the required tools at hand. Common items include a screwdriver, a wrench, and a soft cloth for cleaning components.

2. Disconnect the Device: Safety is paramount. Unplug the unit from the power source to prevent any electrical hazards during the process.

3. Inspect the Components: Begin by examining the major parts, such as the water tank and hoses. Look for signs of wear, blockages, or leaks that may be contributing to performance issues.

4. Clean Filters: Remove and clean any filters as dirt accumulation can hinder efficiency. Rinse under warm water and allow them to dry completely before reinstalling.

5. Address Blockages: If suction is weak, check for blockages in the hoses. Use a long object, such as a flexible brush, to clear any debris lodged inside.

6. Reassemble and Test: Once all components are cleaned and inspected, reassemble the unit. Plug it back in and conduct a test to ensure it operates as expected.

7. Document Findings: Take note of any recurring issues or parts that may need replacement in the future. Keeping a record will help in maintaining optimal performance.

Cleaning and Maintenance Tips

Regular upkeep of your cleaning device is essential for optimal performance and longevity. Implementing effective cleaning and maintenance routines will ensure that your equipment continues to operate efficiently, delivering outstanding results every time.

Routine Cleaning

To maintain peak performance, it is crucial to clean the components of your device after each use. Rinse the tanks and brush attachments thoroughly to remove any residue. This will prevent buildup and keep your equipment functioning effectively.

Periodic Checks

Schedule regular inspections to identify any wear or damage. Check the hoses and cords for signs of fraying or leaks. Replacing worn parts promptly will help avoid larger issues and maintain the quality of your cleaning sessions.

Diagnosing Performance Problems

When a cleaning device exhibits subpar performance, it can be frustrating. Understanding the underlying issues is essential for restoring its efficiency. This section outlines key indicators and troubleshooting steps to help identify the root causes of operational challenges.

Reduced Suction Power: One of the most common issues is diminished suction. Check for clogs in the hose or filters, as debris accumulation can significantly impact functionality. Additionally, inspect the brush rolls for tangles or blockages that may hinder their movement.

Inconsistent Cleaning Results: If the device fails to clean evenly, examine the solution tank for proper filling and ensure that the appropriate cleaning solution is being used. Variations in cleaning performance can also stem from worn or damaged brushes.

Excessive Noise: Unusual sounds during operation may indicate mechanical issues. Inspect the motor and belts for wear. A squeaking or grinding noise often points to parts that require lubrication or replacement.

Leaking Solution: If fluid leaks are observed, check the seals and connections for integrity. Cracks in the tank or loose fittings can lead to unwanted spills, affecting both performance and safety.

By systematically addressing these concerns, users can effectively pinpoint performance issues and take the necessary steps to enhance the overall functionality of their cleaning equipment.

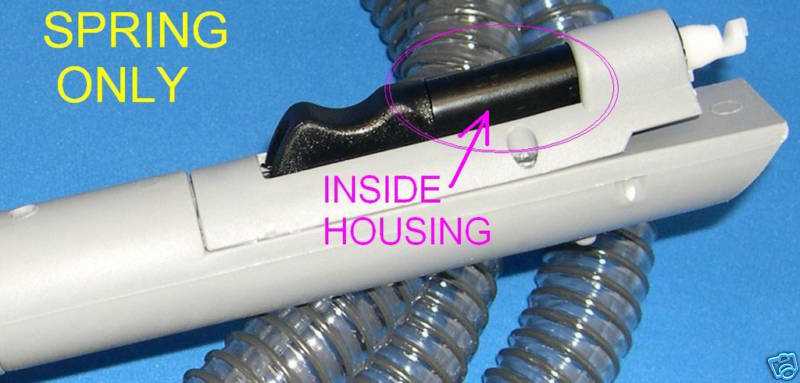

Replacing Worn-Out Parts

Over time, various components of your cleaning appliance may experience wear and tear, affecting its performance. Regular maintenance and timely replacement of these parts are crucial to ensure optimal functionality and prolong the lifespan of the equipment. This section outlines the steps and considerations for identifying and replacing these essential elements.

Identifying Worn Components

Before initiating the replacement process, it is essential to recognize which parts require attention. Common signs of wear include unusual noises, reduced suction power, and visible damage. Below are some typical components that may need to be inspected:

| Component | Signs of Wear |

|---|---|

| Brush Roll | Hair or debris buildup, frayed bristles |

| Hoses | Cracks, leaks, or blockages |

| Filters | Clogged, discolored, or damaged |

| Belts | Frayed edges or slippage during operation |

Steps for Replacement

Once you have identified the worn parts, follow these steps to replace them effectively:

- Gather necessary tools and replacement components.

- Disconnect the device from the power source for safety.

- Carefully remove the damaged parts according to the manufacturer’s guidelines.

- Install the new components, ensuring they are properly aligned and secure.

- Reconnect the device and perform a test to verify functionality.

By following these guidelines, you can maintain the efficiency and performance of your cleaning equipment, ensuring it operates effectively for years to come.

Safety Precautions During Repair

When engaging in the maintenance of cleaning appliances, it is crucial to prioritize safety to prevent accidents and injuries. Understanding the proper procedures and protective measures ensures a secure environment while addressing any issues.

Firstly, always unplug the device before starting any work. This simple step eliminates the risk of electrical shock. Additionally, ensure that the area is dry and free from clutter to avoid slips and falls.

Using appropriate personal protective equipment is essential. Consider wearing gloves to protect your hands from sharp components or chemicals, and safety goggles to shield your eyes from debris or sprays.

Moreover, familiarize yourself with the specific components of the appliance. Knowing where critical parts are located can help in avoiding unnecessary disassembly and potential hazards. If any part appears damaged or worn, handle it with care and consider replacing it promptly.

Finally, always consult guidance from reliable sources if unsure about any aspect of the process. Seeking assistance when needed can significantly reduce the risk of accidents, ensuring a safer experience overall.

How to Test After Repairs

After completing maintenance work on your cleaning apparatus, it’s crucial to ensure that everything functions properly. This section outlines essential steps to verify the effectiveness of your service and confirm that the unit is ready for use.

- Visual Inspection:

- Check for any loose or misaligned components.

- Look for signs of wear or damage on hoses and attachments.

- Ensure that all screws and fasteners are securely tightened.

- Functional Test:

- Plug in the device and power it on.

- Listen for unusual sounds that may indicate issues.

- Test all settings and modes to ensure they operate correctly.

- Performance Check:

- Run the unit on a small area of carpet or flooring.

- Observe the cleaning effectiveness and suction power.

- Check for any leaks or drips during operation.

- Final Assessment:

- Assess the cleanliness of the test area.

- Ensure all attachments are functioning as intended.

- Perform a final inspection for any signs of malfunction.

By following these steps, you can be confident that your device is in optimal condition and ready for effective cleaning tasks.

Frequently Asked Questions

This section aims to address common inquiries regarding maintenance and troubleshooting for cleaning devices. Here, you will find answers to the most pressing questions that users often encounter during operation and care.

1. What should I do if my cleaner is not picking up water?

If your appliance fails to suction properly, check the water tank for clogs and ensure it is correctly seated. Additionally, inspect the filter and hose for blockages that may hinder performance.

2. How often should I clean the filters?

Regular cleaning of the filters is essential for optimal functionality. It is recommended to clean them after every few uses, depending on the frequency of operation and the type of surfaces being cleaned.

3. Can I use any cleaning solution with my device?

It is advisable to use only the recommended cleaning solutions to prevent damage. Using unsuitable products can lead to malfunctions or void warranties.

4. What should I do if there are leaks during use?

Leaks can indicate a problem with the water reservoir or hose. Ensure all components are securely attached and check for cracks or wear that may require replacement.

5. How can I improve the cleaning performance?

To enhance effectiveness, pre-treat heavily soiled areas and ensure the tank is filled with warm water. Regular maintenance, including cleaning brushes and filters, will also contribute to better results.

Where to Find Replacement Parts

When seeking to restore the functionality of your cleaning appliance, locating suitable components is essential. There are several avenues available for sourcing these necessary items, ensuring you can maintain the efficiency of your equipment.

- Manufacturer’s Website: The official site often provides a comprehensive catalog of parts specific to various models. You can typically find diagrams and part numbers for easy reference.

- Authorized Retailers: Many authorized dealers stock a wide range of replacement items. Visiting these stores can also offer the advantage of knowledgeable staff who can assist in identifying the correct components.

- Online Marketplaces: Platforms like Amazon, eBay, and specialized parts websites can be valuable resources. Make sure to verify seller ratings and product descriptions to ensure quality.

- Local Repair Shops: Nearby service centers may have spare parts or can order them on your behalf. Additionally, they may provide insights into the installation process.

- Community Forums: Engaging with online communities dedicated to appliance maintenance can yield recommendations for reputable sources and firsthand experiences from other users.

By exploring these options, you can effectively find the components needed to bring your appliance back to optimal working condition.