In the realm of heavy-duty transportation, ensuring optimal performance and longevity of vehicles is crucial for operators and businesses alike. Comprehensive resources that offer guidance on maintenance practices and problem-solving techniques play a vital role in maximizing efficiency. This section delves into essential practices and detailed instructions that empower users to tackle a variety of challenges.

Whether you’re facing minor issues or significant malfunctions, having access to structured information can make all the difference. From routine checks to in-depth diagnostic procedures, the ability to understand and address mechanical needs is key to maintaining operational readiness. With the right knowledge, even the most complex situations can be navigated effectively.

Moreover, familiarizing oneself with the intricacies of vehicle systems enhances not only individual expertise but also contributes to a safer and more reliable transportation environment. By utilizing well-organized references, operators can cultivate a proactive approach to vehicle care, ensuring smooth journeys and minimizing downtime.

Overview of Freightliner Trucks

This section provides a comprehensive insight into a prominent brand known for its durable and efficient vehicles designed for heavy-duty tasks. Renowned for reliability and performance, these vehicles have become a cornerstone in the transportation industry, serving a diverse range of applications.

Key Features

The vehicles from this manufacturer are characterized by their advanced engineering, fuel efficiency, and cutting-edge technology. Designed with the driver in mind, they offer comfort and ease of operation, making long hauls more manageable. Safety features are also a priority, ensuring both operator and cargo are well protected on the road.

Market Position

Common Issues Faced by Owners

Owners of heavy-duty vehicles often encounter a range of challenges that can affect performance and reliability. Understanding these common problems is essential for effective maintenance and ensuring longevity. Below are some typical issues that may arise during operation.

Engine Performance Problems: One of the most frequent concerns involves engine inefficiencies. Symptoms such as rough idling, reduced power, or unexpected stalling can signal the need for thorough diagnostics. Regular checks can prevent more severe complications.

Transmission Difficulties: Transmission issues may manifest as slipping gears or difficulty in shifting. These problems can arise from low fluid levels or worn components, requiring careful attention to maintain optimal function.

Electrical System Failures: A malfunctioning electrical system can lead to various headaches, from dead batteries to faulty wiring. Owners should regularly inspect connections and components to avoid being stranded or experiencing operational failures.

Brake System Concerns: The braking system is crucial for safety. Owners often face issues such as squeaking noises, reduced stopping power, or warning lights. Regular maintenance and inspections are vital to ensure that all parts function correctly.

Suspension and Steering Troubles: Worn suspension components can result in poor handling and a rough ride. Symptoms may include excessive bouncing or difficulty in steering, necessitating prompt attention to enhance driving comfort and safety.

Addressing these issues proactively can lead to a more reliable and efficient vehicle, ensuring peace of mind for the owner.

Importance of a Repair Manual

A comprehensive guide is essential for maintaining the longevity and performance of heavy vehicles. It serves as a valuable resource that provides detailed insights into troubleshooting, maintenance schedules, and technical specifications. Accessing such information empowers operators and technicians to address issues effectively, minimizing downtime and enhancing operational efficiency.

Enhancing Knowledge and Skills

Utilizing a structured guide allows individuals to deepen their understanding of complex systems. Training through these resources equips users with the knowledge necessary to perform diagnostic tasks and execute necessary fixes. Confidence in handling equipment increases as users become familiar with common challenges and solutions outlined within these references.

Cost-Effectiveness

Having an organized reference can lead to significant savings in both time and resources. By following outlined procedures, individuals can often resolve issues without needing to seek external assistance. This self-sufficiency not only reduces repair costs but also minimizes the risk of recurring problems, ensuring that operations run smoothly.

How to Use the Manual Effectively

To maximize the benefits of your guidebook, it’s essential to approach it with a clear strategy. Familiarizing yourself with its structure and organization can lead to a more efficient experience when addressing issues or performing maintenance tasks.

- Familiarize Yourself with the Table of Contents: Start by reviewing the table of contents to identify sections that are most relevant to your needs.

- Utilize the Index: The index at the back can be invaluable for quickly locating specific topics or components.

- Read Safety Precautions: Always begin with safety guidelines to ensure a secure working environment.

Once you understand the layout, you can focus on specific tasks or troubleshooting methods.

- Identify Your Issue: Clearly define the problem you are encountering before consulting the guide.

- Follow Step-by-Step Instructions: Adhere closely to the provided instructions to avoid mistakes and ensure proper execution.

- Take Notes: Jot down any observations or modifications for future reference, enhancing your understanding of the process.

By implementing these strategies, you can navigate the resource more effectively, ensuring you achieve the desired results with confidence.

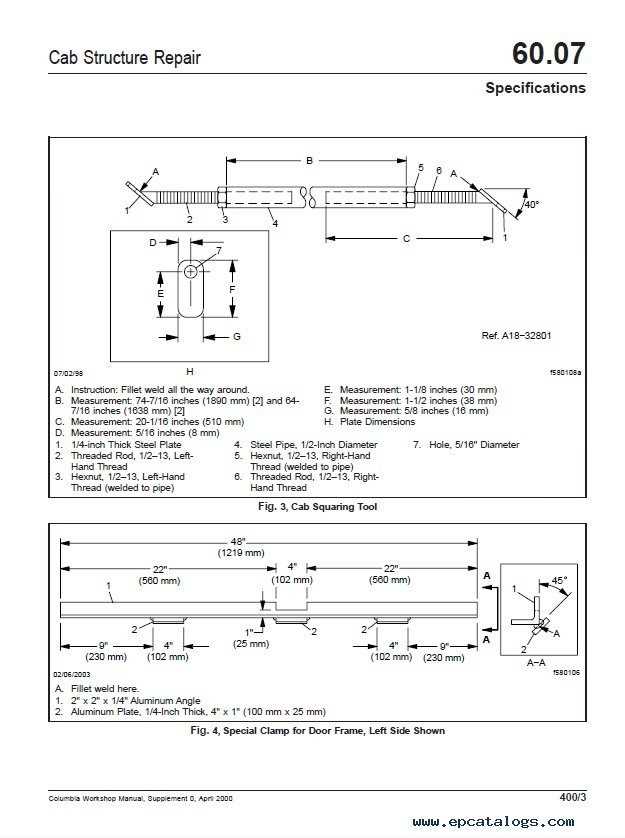

Essential Tools for Repairs

To effectively address maintenance tasks, having the right equipment is crucial. A well-stocked toolkit not only enhances efficiency but also ensures that each job is completed with precision. From basic hand tools to specialized instruments, the right selection can make all the difference in achieving optimal performance.

Basic Hand Tools

Every technician should start with a set of fundamental hand tools. This includes items such as wrenches, screwdrivers, and pliers. These essentials allow for quick adjustments and routine tasks. Quality matters, so investing in durable materials can lead to long-term benefits.

Specialized Equipment

In addition to general tools, certain jobs require specialized equipment. This may involve diagnostic tools that help identify issues, or lifting devices for heavy components. Understanding the specific requirements of each task will guide your selection of these advanced tools, ensuring that every challenge can be met effectively.

Maintenance Tips for Longevity

Ensuring the durability and reliability of your vehicle requires consistent care and attention. By following a systematic maintenance routine, you can extend the lifespan of essential components, minimize costly breakdowns, and enhance overall performance. Below are key strategies to keep your machinery in optimal condition.

Regular Inspections

Conducting frequent assessments is crucial. Look for signs of wear and tear, check fluid levels, and inspect critical systems such as brakes and tires. Early detection of potential issues can save time and resources in the long run. Make it a habit to review your vehicle before and after trips, ensuring everything functions correctly.

Fluid Management

Maintaining proper fluid levels is essential for smooth operation. Regularly change engine oil, coolant, and transmission fluid according to manufacturer guidelines. Using high-quality fluids can enhance performance and reduce the risk of overheating or mechanical failures. Keep a log of fluid changes to stay on track with maintenance schedules.

Understanding Electrical Systems

The electrical systems in heavy vehicles play a crucial role in their overall functionality and performance. These systems are responsible for powering various components, ensuring that everything operates smoothly and efficiently. A solid grasp of how these systems work is essential for effective troubleshooting and maintenance.

Components within electrical systems include batteries, alternators, starters, and wiring harnesses. Each element has a specific function and contributes to the vehicle’s ability to operate effectively. Understanding the interconnections between these components is vital for diagnosing issues that may arise.

One of the key aspects of these systems is diagnostic troubleshooting. This process involves using specialized tools to identify problems, such as short circuits or faulty connections. A systematic approach helps technicians pinpoint the source of an issue, leading to efficient repairs and minimizing downtime.

Moreover, safety is a paramount concern when working with electrical systems. Knowledge of proper procedures and precautions is necessary to prevent accidents and ensure the well-being of both the technician and the vehicle. Always refer to the appropriate guidelines and use protective gear when handling electrical components.

Engine Troubleshooting Techniques

Identifying and resolving engine issues is crucial for maintaining optimal performance and longevity. Understanding the underlying problems can prevent costly repairs and enhance efficiency. This section outlines effective strategies for diagnosing engine malfunctions.

- Visual Inspection:

Begin with a thorough examination of the engine compartment. Look for signs of leaks, wear, or damage. Check hoses, belts, and connections for integrity.

- Listen for Unusual Noises:

Engage the engine and pay attention to sounds. Knocking, hissing, or grinding noises can indicate specific issues requiring further investigation.

- Monitor Engine Performance:

Keep track of any changes in acceleration, power output, or fuel efficiency. Noting these variations can help pinpoint the problem area.

- Check Warning Lights:

Review the dashboard for any illuminated indicators. These lights often provide critical information regarding malfunctions.

- Utilize Diagnostic Tools:

Employ scanning devices to retrieve error codes from the engine’s computer. These codes can direct you to specific systems or components that may be failing.

- Test Fuel Quality:

Ensure that the fuel used is clean and appropriate for the engine type. Contaminated or incorrect fuel can lead to performance issues.

- Examine Electrical Components:

Inspect wiring, fuses, and connections for faults. Electrical issues can often mimic mechanical failures and must be addressed accordingly.

By employing these techniques, one can systematically address engine concerns, ensuring timely interventions and effective solutions.

Transmission Repair Guidelines

Maintaining the functionality of the transmission system is crucial for ensuring optimal performance and longevity of the vehicle. This section outlines essential practices and considerations for addressing issues that may arise within the transmission, helping to facilitate a smoother and more efficient operation.

| Common Issues | Symptoms | Recommended Actions |

|---|---|---|

| Fluid Leaks | Puddles under the vehicle, low fluid levels | Inspect seals and gaskets; replace as necessary |

| Slipping Gears | Unresponsive shifts, high RPM without acceleration | Check fluid levels; assess for worn components |

| No Response | Engine revs but no movement | Examine linkages and electronic controls; troubleshoot as needed |

| Overheating | High temperature readings, burning smell | Check fluid condition; inspect cooling system |

Addressing these issues promptly can prevent further complications and ensure the reliability of the transmission system. Regular inspections and maintenance are key to prolonging the life of this vital component.

Brake System Maintenance Essentials

Maintaining the braking mechanism is crucial for ensuring safety and optimal performance. Regular checks and timely interventions can prevent costly repairs and enhance the longevity of the components. This section outlines key practices and considerations for keeping the braking system in top condition.

Key Maintenance Practices

Routine inspections and proactive maintenance are vital for effective brake function. The following practices should be integrated into a regular maintenance schedule:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Level Check | Monthly | Ensure brake fluid is at the appropriate level to maintain hydraulic pressure. |

| Pad Inspection | Every 6,000 miles | Examine brake pads for wear and replace if thickness is below the recommended level. |

| Line Examination | Annually | Inspect brake lines for leaks, cracks, or corrosion to prevent fluid loss. |

| System Bleeding | As needed | Remove air bubbles from the brake lines to ensure responsive braking. |

Signs of Trouble

Recognizing early warning signs can prevent more serious issues. Be alert for the following indicators:

- Unusual noises during braking

- Increased stopping distance

- Vibrations in the brake pedal

- Warning lights on the dashboard

Resources for Further Learning

Expanding your knowledge and skills in vehicle maintenance can significantly enhance your understanding of mechanics and improve your troubleshooting abilities. There are numerous resources available that cater to various learning styles, whether you prefer reading, watching, or engaging in hands-on practice.

Online Courses and Tutorials

- Websites like Coursera and Udemy offer comprehensive courses on automotive mechanics, covering both basic and advanced topics.

- YouTube channels dedicated to vehicle maintenance provide visual demonstrations that can help reinforce theoretical concepts.

- Interactive platforms such as Khan Academy feature modules on engineering principles relevant to automotive technology.

Books and Publications

- Reference books focusing on automotive systems offer detailed insights into components and their functions.

- Magazines and journals related to the automotive industry often include case studies and the latest advancements.

- Manufacturer-specific guides provide in-depth technical information tailored to specific models and systems.