The world of marine propulsion systems has evolved significantly over the decades, yet many enthusiasts continue to cherish the vintage models that defined a generation of boating. These engines, with their unique designs and engineering, require a specific understanding to ensure optimal performance and longevity. This guide aims to provide invaluable insights into the upkeep and troubleshooting of these classic marine engines, emphasizing practical techniques and essential knowledge.

Throughout the years, boaters have faced various challenges when it comes to maintaining these powerful machines. From understanding their intricate components to diagnosing common issues, a solid grasp of the fundamental principles is crucial for any owner. This resource serves as a comprehensive toolkit for those looking to navigate the complexities of these vintage engines, empowering them to tackle repairs with confidence.

In this section, readers will find detailed instructions and tips tailored for the distinct characteristics of older models. Whether it’s addressing performance hiccups or conducting routine maintenance, this guide provides the necessary steps to ensure your marine engine remains reliable on the water. Embrace the journey of restoration and care, and enjoy the thrill of mastering your craft.

Understanding Seloc Mercury Outboards

This section aims to provide a comprehensive overview of specific aquatic propulsion systems, focusing on their functionality, maintenance, and the importance of having reliable guidance for repairs. These systems are essential for a variety of marine activities, and understanding their components can enhance performance and longevity.

It is crucial for enthusiasts and professionals alike to have access to detailed resources that outline the intricacies of these engines. A well-structured guide can simplify complex repair tasks, ensuring that users can effectively troubleshoot issues as they arise.

| Component | Function |

|---|---|

| Powerhead | Generates power through combustion |

| Lower Unit | Transmits power to the propeller |

| Fuel System | Delivers fuel to the engine |

| Ignition System | Starts the engine and maintains combustion |

| Cooling System | Regulates engine temperature to prevent overheating |

Having a thorough understanding of these elements not only facilitates effective troubleshooting but also promotes safe and efficient operation on the water. With the right information, users can confidently manage maintenance and repairs, ensuring their aquatic experiences remain enjoyable and trouble-free.

History of Mercury Outboards

The evolution of motorized watercraft engines is a fascinating journey marked by innovation and engineering prowess. From their early days, these machines have transformed the boating experience, providing enthusiasts with power, speed, and reliability. Over the decades, advancements in technology have continually shaped their design and functionality, responding to the needs of both recreational and commercial users.

In the mid-20th century, a significant turning point occurred as manufacturers began to focus on enhancing performance and fuel efficiency. This era saw the introduction of cutting-edge materials and streamlined designs, allowing for improved aerodynamics and reduced weight. These enhancements not only elevated the overall user experience but also established a new standard for excellence within the industry.

The impact of these innovations extended beyond just performance. As boating became more accessible, a diverse range of models emerged, catering to different preferences and uses. From small fishing vessels to powerful leisure crafts, the variety allowed enthusiasts to find the perfect match for their adventures on the water.

Throughout the years, the commitment to quality and reliability has remained paramount. Manufacturers have embraced rigorous testing and quality control processes to ensure that each unit delivers exceptional performance under various conditions. This dedication to craftsmanship has solidified a loyal following among users, who trust these engines for their boating endeavors.

As we look to the future, the journey of these remarkable machines continues, with ongoing research into sustainable technologies and smart features. This promise of innovation guarantees that the legacy of powerful and dependable marine engines will endure, inspiring new generations of boating enthusiasts.

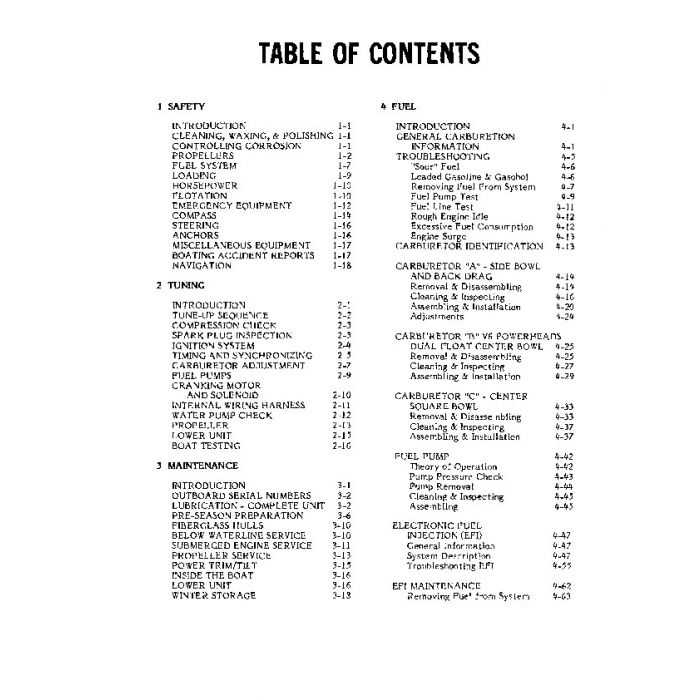

Overview of Repair Manuals

Technical documentation serves as an essential resource for anyone seeking to maintain or restore machinery. These guides provide detailed instructions, troubleshooting advice, and specifications, making them invaluable for both novices and seasoned technicians. By breaking down complex processes into manageable steps, they enable users to tackle a wide range of issues efficiently.

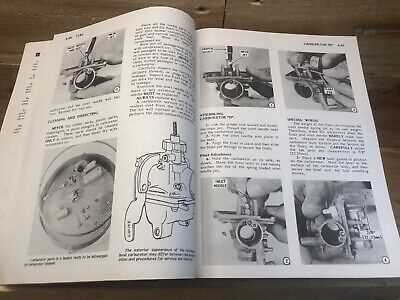

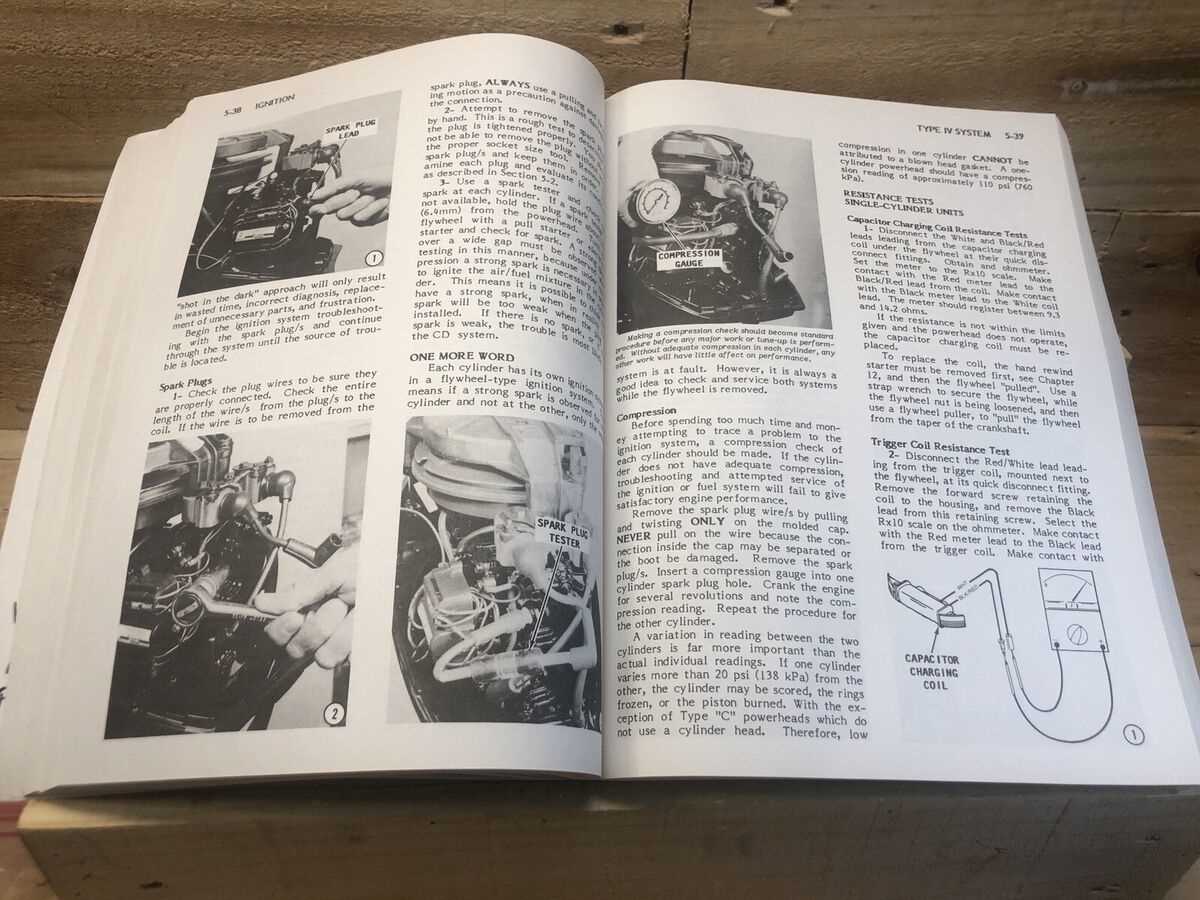

In addition to step-by-step procedures, these resources often include diagrams and illustrations that enhance understanding. This visual aid can significantly ease the learning curve associated with unfamiliar equipment. Furthermore, many documents encompass maintenance schedules and tips, promoting long-term care and reliability.

Ultimately, comprehensive technical literature not only empowers individuals to perform tasks with confidence but also fosters a deeper understanding of how machinery operates. With accurate information at their fingertips, users can approach repairs and maintenance with greater assurance and skill.

Common Issues with Older Models

As time passes, vintage marine engines often encounter a range of challenges that can affect their performance and reliability. Understanding these common problems is essential for enthusiasts and operators aiming to maintain their equipment in optimal condition. From mechanical wear to electrical failures, recognizing these issues can aid in early diagnosis and preventive maintenance.

Mechanical Wear and Tear

One of the primary concerns with aged models is the gradual deterioration of mechanical components. Over the years, parts such as pistons, rings, and bearings can suffer from significant wear. This can lead to decreased efficiency and power loss. Regular inspections and timely replacements are crucial in extending the lifespan of these critical elements.

Electrical System Failures

The electrical systems of older engines are also prone to issues. Corrosion on connectors, degradation of wiring, and failure of ignition components can all lead to performance problems. Addressing these electrical concerns promptly can prevent more serious malfunctions and ensure smooth operation on the water.

Essential Tools for Repairs

Having the right equipment is crucial for maintaining and fixing marine engines effectively. A well-equipped workspace not only enhances efficiency but also ensures safety during the process. Below are key instruments that every technician should consider having on hand to tackle various tasks with confidence.

| Tool | Description |

|---|---|

| Socket Set | Used for tightening or loosening bolts and nuts of various sizes. |

| Screwdriver Set | Includes flathead and Phillips screwdrivers for different fasteners. |

| Wrench Set | Essential for gripping and turning fasteners in tight spaces. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications to avoid damage. |

| Pliers | Useful for gripping, twisting, and cutting wires or small components. |

| Multimeter | Helps diagnose electrical issues by measuring voltage, current, and resistance. |

| Oil Filter Wrench | Specifically designed for removing oil filters easily without damage. |

| Cleaning Supplies | Includes brushes, cloths, and solvents for maintaining cleanliness during work. |

Equipping oneself with these tools can significantly ease the maintenance and troubleshooting processes, leading to more effective outcomes in keeping marine engines in top condition.

Step-by-Step Maintenance Procedures

Regular upkeep of marine engines is essential for ensuring optimal performance and longevity. Following a structured approach to maintenance can help identify potential issues before they escalate, allowing for smoother operations on the water. This section outlines a systematic process for maintaining your engine, covering key aspects from inspections to adjustments.

Routine Inspection

Begin with a thorough visual examination of the engine. Check for any signs of wear, corrosion, or leaks. Ensure that all connections are secure and that the hoses are free of cracks. Pay special attention to the fuel system, as contaminants can lead to significant problems. It’s also advisable to inspect the electrical components for signs of deterioration.

Fluid Checks and Changes

Next, verify the levels of essential fluids. Regularly check the oil, coolant, and fuel levels, ensuring they are within the recommended range. If the oil appears dark or gritty, it should be changed immediately. Similarly, replace the coolant if it shows signs of contamination. Regularly flushing the cooling system can prevent overheating and prolong engine life.

Troubleshooting Engine Performance Problems

When experiencing issues with engine performance, it is essential to identify the root cause to ensure optimal functionality. Various factors can contribute to diminished power, irregular idling, or starting difficulties. By systematically examining each component, one can effectively isolate and address the underlying problems.

Start by checking fuel supply and quality, as contaminated or insufficient fuel can severely impact performance. Next, assess the ignition system, ensuring that spark plugs and wiring are in good condition. Additionally, inspect the air intake and exhaust systems for any obstructions that could hinder airflow.

Regular maintenance plays a crucial role in preventing performance issues. Keep an eye on lubrication levels and ensure all moving parts are well-greased. If problems persist, consulting with a professional may be necessary to delve deeper into mechanical or electronic issues.

Electrical System Diagnostics Explained

Understanding the intricacies of the electrical system is crucial for maintaining optimal performance in marine engines. Effective diagnostics can help identify issues quickly, ensuring reliability and safety during operation. This section delves into the essential steps and methods for evaluating the electrical components, empowering technicians and enthusiasts alike to address potential malfunctions with confidence.

The electrical system in any marine engine comprises various elements, including batteries, wiring, switches, and ignition components. Regular assessment of these parts can prevent unexpected failures. Below is a breakdown of key diagnostic steps and tools utilized in this process:

| Diagnostic Step | Description | Recommended Tools |

|---|---|---|

| Visual Inspection | Check for visible wear, corrosion, or loose connections. | Flashlight, Multimeter |

| Battery Testing | Measure voltage and load capacity to ensure proper function. | Battery Tester, Multimeter |

| Continuity Check | Verify that electrical paths are intact and functional. | Multimeter |

| Voltage Drop Test | Identify voltage loss across circuits to spot weak links. | Multimeter |

| Component Testing | Assess individual components like switches and relays for functionality. | Multimeter, Test Light |

By systematically addressing each component and employing these diagnostic techniques, users can enhance the performance and reliability of their marine engines, ultimately leading to a safer and more enjoyable experience on the water.

Parts Replacement Guidelines

Ensuring optimal performance of your marine engine often requires the timely replacement of specific components. Understanding when and how to replace these parts is crucial for maintaining efficiency and longevity. This section outlines essential practices for identifying, sourcing, and installing replacements.

First, regularly inspect all parts for signs of wear, corrosion, or damage. Components such as fuel lines, spark plugs, and filters should be checked periodically to prevent potential failures. Create a maintenance schedule that includes these inspections to stay proactive.

When it comes to sourcing replacements, always opt for high-quality components. Original equipment manufacturers (OEM) parts are recommended to ensure compatibility and reliability. If OEM parts are not available, select aftermarket alternatives that meet or exceed the original specifications.

During the installation process, follow manufacturer guidelines carefully. Utilize appropriate tools and techniques to avoid further damage to the engine or new components. Additionally, consider documenting the replacement process for future reference, which can aid in troubleshooting any issues that may arise.

Finally, after replacing any parts, conduct thorough tests to ensure everything is functioning as expected. Regularly monitor the performance of the engine post-replacement, making adjustments as needed to maintain peak operational standards.

Safety Precautions During Repairs

Engaging in maintenance tasks requires a thorough understanding of safety protocols to prevent accidents and injuries. Proper preparation and awareness can significantly enhance the experience and effectiveness of the work being performed.

Personal Protective Equipment

Utilizing personal protective equipment (PPE) is essential. This includes gloves, safety goggles, and sturdy footwear to shield against potential hazards. Wearing appropriate attire not only minimizes risk but also fosters a more secure working environment.

Work Area Organization

Maintaining an organized workspace is crucial. Ensure that tools and materials are neatly arranged and easily accessible. This practice reduces the likelihood of accidents and enables quick responses to unexpected situations. Additionally, be mindful of your surroundings, removing any unnecessary clutter that could pose a danger.

Finding Replacement Parts and Accessories

Locating suitable components and enhancements for your marine engine can be a straightforward yet essential task. By understanding the sources available and knowing where to look, you can ensure your vessel operates at its ultimate potential.

Online Retailers: Numerous e-commerce platforms specialize in marine parts, offering a wide variety of options. Utilize search filters to narrow down selections based on your engine’s specifications.

Local Dealers: Visiting nearby dealerships can provide valuable insights and immediate access to necessary items. Engaging with knowledgeable staff can often lead to discovering compatible accessories you might not find online.

Salvage Yards: These can be treasure troves for hard-to-find parts. A visit to a salvage yard may yield components that are no longer in production, often at a fraction of the original cost.

Online Forums and Communities: Connecting with fellow enthusiasts through forums can offer guidance and recommendations for sourcing specific items. Members often share leads on reliable suppliers.

Manufacturer’s Websites: Always check the official websites for any available inventory or recommendations on where to find authentic replacements. They can also provide detailed specifications that ensure compatibility.

By exploring these avenues, you can delve deeper into the world of marine components and keep your engine running smoothly.

Resources for Further Learning

Expanding your knowledge on marine engines can greatly enhance your understanding of their operation and maintenance. Numerous resources are available to help you delve deeper into the intricacies of these powerful machines. From books and online courses to community forums, the options are diverse and accessible to anyone eager to learn.

Books on engine mechanics often provide detailed explanations, diagrams, and troubleshooting techniques. Many authors draw from years of experience, offering insights that can be invaluable for both novices and seasoned enthusiasts. Additionally, video tutorials available on various platforms can visually demonstrate complex procedures, making them easier to grasp.

Online communities and forums are excellent places to connect with fellow hobbyists and experts. Engaging in discussions, asking questions, and sharing experiences can lead to a wealth of knowledge that you might not find in traditional resources. Many sites also offer downloadable guides and FAQs to assist with common issues.

Consider attending workshops or seminars, which can provide hands-on experience and direct interaction with professionals in the field. These events often cover the latest techniques and technologies, ensuring you stay informed about advancements that could benefit your practice.