Keeping your cleaning device in optimal condition is essential for ensuring its longevity and efficiency. Regular upkeep not only enhances performance but also helps in avoiding costly replacements. This section provides insights into common issues and effective solutions tailored for your model, ensuring you can tackle any challenge that arises.

Understanding your device’s components is crucial for effective troubleshooting. Familiarity with the various parts enables you to quickly identify potential problems and take appropriate measures. Whether it’s a blockage or a mechanical issue, knowing the inner workings allows for more efficient resolutions.

By following the guidelines outlined here, you can empower yourself to address maintenance tasks confidently. Embrace the opportunity to learn about the functionalities and intricacies of your cleaning apparatus, leading to a smoother cleaning experience and optimal results every time you use it.

Understanding the Dyson DC17 Design

The innovative design of this vacuum cleaner model emphasizes functionality and user-friendliness. It incorporates advanced engineering principles aimed at enhancing cleaning efficiency while minimizing user fatigue. The overall structure not only contributes to its performance but also reflects a commitment to modern aesthetics.

Key Features of the Design

This model showcases several distinct characteristics that set it apart in the market. The ergonomic handle ensures comfortable maneuverability, while the lightweight materials facilitate ease of use. Additionally, the unique filtration system is designed to trap dust and allergens effectively.

Technical Specifications

| Feature | Description |

|---|---|

| Weight | Approximately 15 lbs |

| Dimensions | 12 x 15 x 43 inches |

| Filtration System | HEPA filtration |

| Dust Capacity | 0.55 gallons |

| Power Rating | 1200 watts |

Common Issues with the Dyson DC17

Vacuum cleaners, while essential for maintaining cleanliness, can sometimes develop problems that hinder their performance. Understanding the common challenges associated with these devices can help users troubleshoot effectively and ensure optimal functionality.

Frequent Problems

- Loss of Suction: This is a common complaint, often resulting from clogged filters or blockages in the hose.

- Overheating: Units may shut off unexpectedly due to overheating, usually caused by obstructions or dirty filters.

- Strange Noises: Unusual sounds can indicate issues such as foreign objects caught in the mechanism or worn-out parts.

Maintenance Tips

- Regularly check and clean filters to maintain airflow.

- Inspect hoses for blockages or damage to ensure proper operation.

- Listen for abnormal sounds and address any mechanical issues promptly.

Tools Needed for Repairs

When addressing maintenance tasks for your device, having the right equipment is essential for a successful outcome. A selection of basic and specialized instruments will streamline the process, ensuring efficiency and safety while working on various components.

First, you’ll require a set of screwdrivers, including both flathead and Phillips types, to remove and secure fasteners. Pliers and wire cutters will assist in manipulating and cutting wires or small parts. Additionally, a torque wrench can be valuable for tightening screws to the manufacturer’s specifications.

For cleaning and thorough inspections, brushes and compressed air can effectively remove dust and debris from intricate areas. It’s also advisable to have a multimeter on hand to check electrical connections and diagnose issues with the circuitry.

Finally, protective gear such as gloves and safety goggles should not be overlooked to ensure personal safety while handling tools and components. With this assortment of equipment, you will be well-prepared to tackle maintenance tasks effectively.

Step-by-Step Repair Guide

This section provides a comprehensive approach to addressing common issues with your vacuum device. By following the outlined procedures, you can effectively troubleshoot and resolve various malfunctions, ensuring optimal performance.

-

Gather Necessary Tools:

- Screwdrivers (Phillips and flathead)

- Multimeter for electrical testing

- Replacement parts as needed

- Cleaning cloths and brushes

-

Initial Assessment:

Begin by examining the unit for any visible signs of damage. Check for blockages in the hose and filters, as these are common issues that can affect functionality.

-

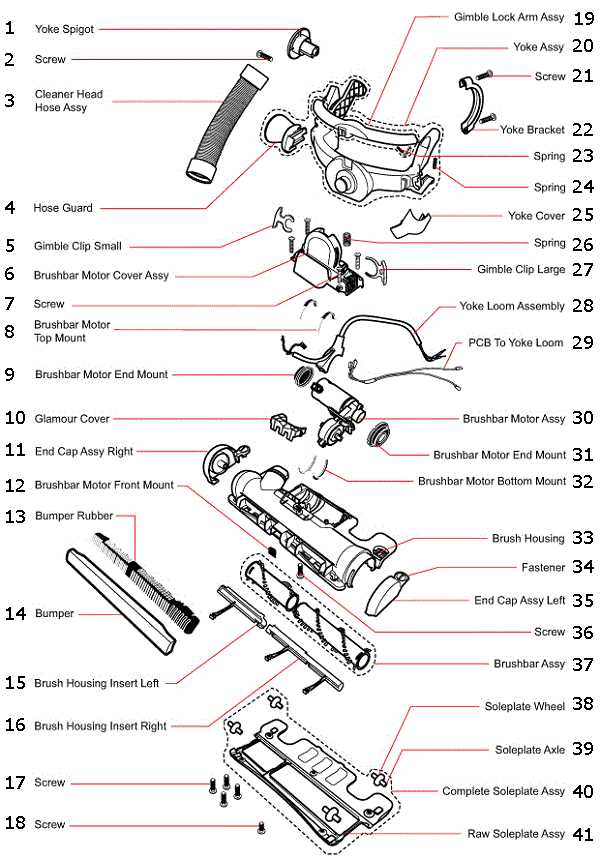

Disassemble the Unit:

Carefully remove the casing and components according to the specific model’s guidelines. Take notes or photographs during this process to aid reassembly.

-

Inspect Internal Parts:

Look for worn or damaged components, such as belts or brushes. Use the multimeter to test electrical connections and motors for continuity.

-

Replace Faulty Parts:

If any components are defective, replace them with high-quality substitutes. Ensure compatibility with your specific model.

-

Reassemble the Unit:

Carefully put all parts back together, following your notes or photographs to ensure everything is in the correct place.

-

Final Testing:

Once reassembled, plug in the device and conduct a thorough test to verify that all functions are operating correctly.

Following these steps will help restore your device to peak condition, allowing for continued efficient use.

Replacing the Filters Effectively

Maintaining optimal performance in your cleaning device requires regular attention to its filtration system. Properly replacing the filters ensures that dust, allergens, and other particles are effectively captured, enhancing the overall efficiency of the machine. Understanding the process and timing for filter changes can greatly impact the longevity and effectiveness of your equipment.

Identifying the Right Filters

Before proceeding with the replacement, it is essential to identify the appropriate filters specific to your model. Refer to the user guidelines or product specifications to ensure compatibility. Using incorrect filters can lead to reduced performance and may even damage the unit.

Steps for Effective Replacement

Begin by turning off the machine and unplugging it from the power source. Carefully remove the existing filters, following the manufacturer’s instructions for best practices. Clean any accessible areas to prevent debris buildup. Insert the new filters securely, ensuring they are seated correctly. Regularly check and replace the filters as needed to maintain peak performance and extend the lifespan of your appliance.

Motor Maintenance and Troubleshooting

Proper upkeep of the motor is essential for ensuring optimal performance and longevity of your appliance. Regular checks and basic troubleshooting can prevent more significant issues and enhance efficiency. This section outlines key practices for maintaining the motor and identifying common problems.

Regular Maintenance Steps

To keep the motor in good condition, consider the following maintenance steps:

| Task | Frequency | Description |

|---|---|---|

| Inspect Air Filters | Monthly | Check and clean or replace filters to prevent dust buildup. |

| Check for Blockages | Every Use | Ensure that all airflow paths are clear to avoid overheating. |

| Clean the Motor Housing | Quarterly | Dust and debris can accumulate, so regular cleaning is necessary. |

Troubleshooting Common Issues

If you encounter problems with the motor, refer to these common issues and solutions:

| Problem | Possible Cause | Solution |

|---|---|---|

| Motor Won’t Start | Power Supply Issue | Check the power cord and outlet for any faults. |

| Unusual Noises | Foreign Objects | Inspect the motor area for any objects causing noise. |

| Overheating | Blocked Vents | Clear any obstructions around the vents to allow proper airflow. |

Cleaning the Brush Bar

Maintaining the cleanliness of the brush bar is essential for optimal performance of your vacuum cleaner. Regular upkeep not only enhances suction power but also prolongs the life of the device. This section outlines the necessary steps for effectively cleaning the brush mechanism.

Before starting, ensure the appliance is unplugged to avoid any accidental activation. Gather the necessary tools, which typically include a soft cloth, scissors, and possibly a small screwdriver, depending on the design of the unit.

| Step | Action |

|---|---|

| 1 | Remove the brush bar from the cleaner head by following the manufacturer’s instructions. |

| 2 | Use scissors to carefully cut away any tangled hair or fibers wrapped around the brush. |

| 3 | Wipe the brush bar with a damp cloth to remove dust and debris. |

| 4 | Inspect the bearings and connections for any signs of wear or damage. |

| 5 | Reassemble the brush bar back into the unit securely. |

By following these simple steps, you can ensure that the brush mechanism operates efficiently, contributing to the overall performance of your vacuum cleaner.

Checking and Replacing Hoses

Ensuring the proper function of your vacuum’s hoses is crucial for maintaining optimal performance. Over time, these components can become clogged or damaged, leading to decreased suction and efficiency. Regular inspection and timely replacement can prevent further issues and extend the lifespan of your cleaning device.

Start by inspecting the hoses for any visible signs of wear, such as cracks, tears, or blockages. A thorough examination will help you identify any problems that may hinder performance. If you notice any damage, it is advisable to replace the affected hose to restore proper functionality.

To replace a damaged hose, first, disconnect it from the main unit and any attachments. Follow the manufacturer’s guidelines to ensure a secure fit for the new component. It’s important to select a hose that matches the specifications of your device to maintain compatibility and efficiency.

Regular maintenance of your hoses will help to prevent buildup of debris and improve overall performance. Consider cleaning the hoses periodically to remove any dirt or dust that may accumulate. By following these steps, you can ensure your vacuum operates at its best.

Electrical Components Inspection

Conducting a thorough examination of electrical components is crucial for ensuring optimal functionality and safety in any device. This process involves assessing various elements, such as wiring, connectors, and circuits, to identify potential issues that may hinder performance or lead to failures.

Visual Assessment

Begin with a visual inspection of all accessible parts. Look for signs of wear, corrosion, or damage, which can indicate underlying problems. Check for loose connections and ensure that all components are securely attached. Any irregularities should be addressed promptly to prevent further complications.

Testing Electrical Connections

Utilize a multimeter to measure voltage and continuity across different components. This step helps verify that the electrical flow is uninterrupted and that connections are functioning correctly. If discrepancies are found, it may be necessary to replace faulty parts to restore proper operation.

Reassembling the Vacuum Properly

When putting the cleaning device back together, it is crucial to follow a systematic approach to ensure all components fit correctly and function efficiently. This process enhances performance and extends the lifespan of the equipment.

Begin by laying out all parts in the order they were removed. This method allows for easier identification and reduces the likelihood of missing components during reassembly.

| Step | Description |

|---|---|

| 1 | Align the main body with the base, ensuring all locking mechanisms are properly positioned. |

| 2 | Secure the motor cover, taking care to engage all clips and fasteners firmly. |

| 3 | Reattach the filter compartment, ensuring a tight seal to prevent debris leakage. |

| 4 | Reinsert any hoses and attachments, verifying that each connection is snug and properly oriented. |

| 5 | Finally, conduct a brief inspection of the assembled unit to confirm that all components are securely in place. |

By adhering to these steps, you will restore the device to its optimal state, ready for effective cleaning tasks ahead.

Safety Tips During Repairs

When undertaking maintenance tasks on household devices, prioritizing safety is essential to prevent accidents and ensure a smooth process. Adhering to basic safety guidelines can help minimize risks and protect both the equipment and the user.

Preparation and Environment

Before starting any servicing, ensure that your workspace is clean and well-lit. Clear any clutter that may obstruct movement or create hazards. Additionally, gather all necessary tools and materials in advance to avoid distractions during the process.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is crucial. This includes gloves to protect hands from sharp edges and dust, goggles to shield eyes from debris, and masks to filter out harmful particles. Always choose PPE that fits properly for maximum effectiveness.

| Equipment | Purpose |

|---|---|

| Gloves | Protect hands from sharp parts and dirt |

| Goggles | Shield eyes from debris and dust |

| Mask | Filter harmful particles from the air |

When to Seek Professional Help

Recognizing when to call in experts can save time and prevent further issues. Certain situations may arise during maintenance or troubleshooting that require specialized knowledge or tools. Understanding these scenarios is crucial for effective device management.

Indicators of Professional Assistance

There are specific signs that indicate it may be time to consult a technician. These include persistent issues despite following troubleshooting steps, unfamiliar sounds or smells, and noticeable loss of performance.

Potential Risks of DIY Approaches

Attempting complex repairs without adequate experience can lead to further damage or safety hazards. It is essential to weigh the potential risks against the benefits of attempting a fix independently.

| Signs to Seek Help | Description |

|---|---|

| Persistent Problems | Issues remain unresolved after multiple attempts to fix them. |

| Unusual Noises | Unexpected sounds may indicate internal damage or malfunction. |

| Decreased Efficiency | Notable reduction in performance or effectiveness during use. |

| Visible Damage | Physical harm to components that may worsen if not addressed. |