Proper upkeep of your power tools is crucial for ensuring their longevity and optimal performance. Understanding the intricacies of their design can help you troubleshoot common issues, extend their lifespan, and enhance their functionality. This guide offers a comprehensive look into the steps necessary for maintaining one of the most versatile tools in your workshop.

Every craftsman knows that even the most reliable instruments can encounter problems over time. Whether it’s wear and tear from frequent use or the occasional mishap, knowing how to address these challenges is essential. This article will provide you with insightful techniques and practical tips to restore your device to peak condition, ensuring that it remains a trusted companion in your projects.

From simple adjustments to more complex fixes, being equipped with the right knowledge empowers you to tackle issues with confidence. In the following sections, we will explore various aspects of tool maintenance, including essential components, common failures, and step-by-step procedures to troubleshoot effectively. Equip yourself with the insights needed to keep your equipment running smoothly and efficiently.

Tool Maintenance Guide Overview

This section provides a comprehensive insight into the essential guidelines for maintaining a versatile rotary tool. Understanding these instructions is crucial for ensuring optimal performance and longevity of your equipment.

Key Components

- Motor Assembly

- Power Switch

- Collet System

- Housing

Common Issues and Solutions

- Tool Not Starting

- Check the power source.

- Inspect the switch for damage.

- Excessive Vibration

- Examine the attachment for tightness.

- Replace worn-out components.

- Overheating

- Ensure proper ventilation during use.

- Limit continuous operation time.

Following these recommendations will help you troubleshoot and maintain your rotary tool effectively.

Common Issues with Dremel 3000

When working with versatile rotary tools, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems can help in troubleshooting and maintaining optimal functionality.

Overheating is a frequent concern, especially during prolonged use. If the tool becomes too hot, it may lead to a decrease in performance or even damage internal components. To mitigate this, it’s advisable to take breaks and allow for adequate cooling between tasks.

Another issue is excessive noise. A loud operation can indicate wear and tear on the bearings or motor. Regular maintenance and timely replacement of worn parts can help keep the noise level within acceptable limits.

Inconsistent speed may also occur, causing the tool to struggle with different materials. This inconsistency can often be traced back to electrical issues or a malfunctioning speed control dial. Ensuring that the electrical connections are secure and the dial is functioning correctly is essential for reliable operation.

Lastly, vibration during use can be a sign of imbalance or misalignment within the tool. This not only affects user comfort but can also impact precision. Regular checks and adjustments are necessary to maintain smooth operation.

Tools Required for Repairs

Effective maintenance of power tools necessitates a selection of essential instruments. These tools enable users to perform various tasks efficiently, ensuring optimal functionality and longevity. Understanding the necessary equipment can greatly simplify the process of addressing common issues.

Essential Instruments

- Screwdrivers: A set of both flathead and Phillips screwdrivers is crucial for loosening and tightening screws.

- Wrenches: Adjustable wrenches or socket sets are necessary for removing or securing nuts and bolts.

- Pliers: Needle-nose and standard pliers assist in gripping and manipulating small components.

- Hex keys: Also known as Allen wrenches, these are vital for working with hexagonal screws.

- Cleaning supplies: Brushes and cloths help keep components free from debris and dust.

Optional Accessories

- Multimeter: This tool is useful for diagnosing electrical issues and measuring voltage, current, and resistance.

- Replacement parts: Having a stock of common spare parts can expedite the repair process.

- Lubricants: Proper lubrication can prevent wear and tear on moving parts.

Equipping oneself with the right tools not only facilitates repairs but also enhances the overall experience of tool usage. Investing in quality instruments can lead to better outcomes and prolonged service life.

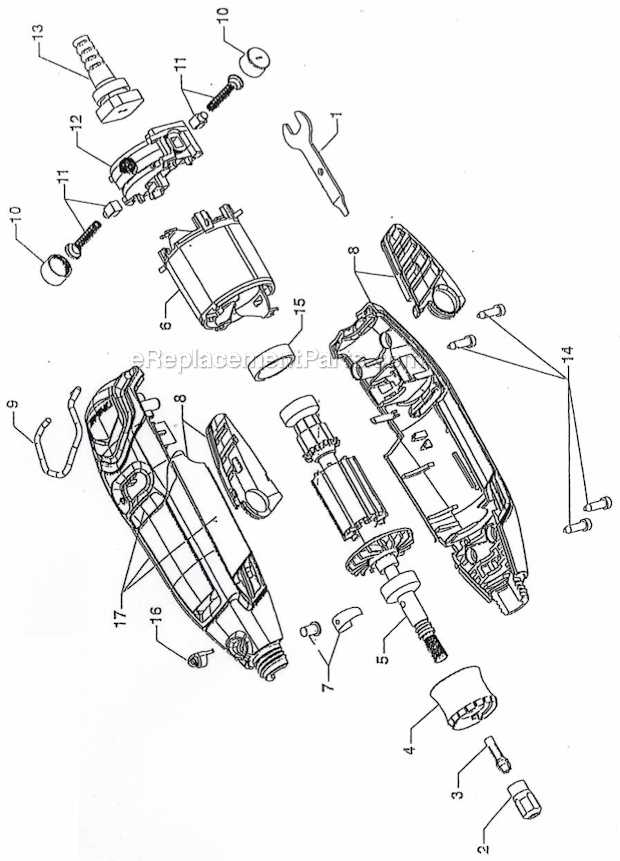

Step-by-Step Disassembly Guide

This section provides a comprehensive guide to carefully dismantling a rotary tool for maintenance or inspection. Following the outlined steps will help ensure that each component is handled properly, minimizing the risk of damage during the process.

Tools Required

- Screwdriver set (Phillips and flathead)

- Plastic prying tool

- Soft cloth or mat

- Tweezers

- Flashlight (for visibility)

Disassembly Steps

- Prepare Your Workspace:

- Choose a clean, well-lit area.

- Gather all necessary tools and materials.

- Place a soft cloth or mat on the surface to protect components.

- Remove the Housing Screws:

- Identify and locate the screws on the outer casing.

- Use the appropriate screwdriver to remove each screw carefully.

- Store screws in a safe place to avoid losing them.

- Open the Housing:

- Gently pry apart the two halves of the casing using a plastic tool.

- Be cautious of any internal components that may be attached.

- Disconnect Internal Wiring:

- Identify any connectors or wires linked to the motor or other parts.

- Carefully detach these connections using tweezers if necessary.

- Remove the Motor Assembly:

- Locate the motor and any retaining screws.

- Unscrew and lift the motor assembly out of the housing.

- Inspect and Clean Components:

- Examine each part for wear or damage.

- Clean components using a soft cloth or appropriate cleaning solution.

Following these steps will help ensure a successful disassembly of the rotary tool, making it easier to address any issues or perform routine maintenance.

Identifying Electrical Problems

Understanding the signs of electrical malfunctions is crucial for maintaining optimal performance and safety in your tools. Recognizing these issues early can prevent further damage and ensure a smoother troubleshooting process. This section provides guidance on how to identify common electrical faults effectively.

Common Symptoms of Electrical Issues

Several indicators can suggest electrical difficulties within your device. If you notice a lack of power, unusual sounds, or erratic behavior, these may be signs of underlying problems. Additionally, burnt odors or visible damage to the cord or connectors can point to serious electrical failures. Regularly inspecting these components is essential for early detection.

Testing for Electrical Failures

To diagnose electrical issues, begin by using a multimeter to check for continuity and voltage. Ensure that the tool is unplugged before performing any checks on the wiring or internal components. Pay close attention to any connections that appear loose or corroded, as these can significantly affect functionality. Properly addressing these concerns will enhance the longevity and reliability of your equipment.

Motor Replacement Instructions

This section outlines the steps necessary for replacing the motor in your rotary tool. By following these guidelines, you can restore optimal functionality and extend the life of your device.

Before beginning the replacement process, ensure that you have the appropriate tools and a compatible motor on hand. Proper preparation will make the procedure smoother and more efficient.

| Step | Action |

|---|---|

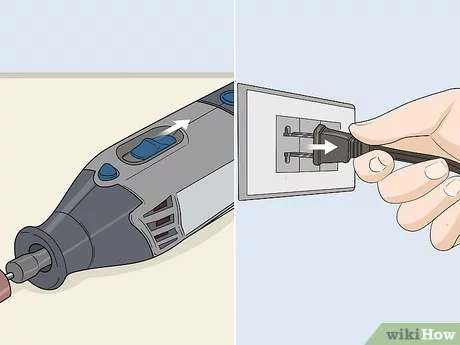

| 1 | Unplug the tool and ensure it is completely powered off. |

| 2 | Remove the outer casing by unscrewing the screws using a screwdriver. |

| 3 | Carefully disconnect the wires connected to the old motor. |

| 4 | Remove the old motor from its housing, ensuring no additional components are damaged. |

| 5 | Install the new motor in the same position as the old one. |

| 6 | Reconnect the wires, making sure to match the original connections. |

| 7 | Replace the outer casing and secure it with screws. |

| 8 | Plug the tool back in and test to ensure it operates correctly. |

After completing these steps, your tool should be ready for use. Always consult the manufacturer’s specifications for any additional instructions or safety warnings related to your specific model.

Maintaining Accessories and Attachments

Proper upkeep of tools and their components is essential for optimal performance and longevity. Regular maintenance not only enhances functionality but also ensures safety during use. Adhering to recommended practices can prevent premature wear and improve overall efficiency.

| Accessory Type | Maintenance Tips |

|---|---|

| Cutting Wheels | Inspect for cracks and replace if damaged. Keep edges sharp and clean from debris. |

| Sanding Drums | Replace sandpaper when worn. Clean the drum to avoid buildup of material. |

| Grinding Bits | Check for chipping and wear. Use a dressing stone to maintain sharpness. |

| Polishing Accessories | Clean regularly to remove residue. Store in a dry place to avoid moisture damage. |

Cleaning and Lubrication Tips

Maintaining your tool’s performance requires regular attention to cleaning and lubrication. Proper care not only extends the life of the equipment but also ensures it operates at peak efficiency. This section provides essential guidance on how to effectively clean and lubricate your device to keep it in excellent condition.

Before starting any maintenance, make sure the tool is unplugged and cool to the touch. Begin by removing any attachments or accessories that may be present. Use a soft brush or cloth to clear away dust and debris from the body and ventilation openings.

| Step | Description |

|---|---|

| 1. Dust Removal | Use a soft brush or cloth to gently remove dust and particles from all surfaces. |

| 2. Inspect Parts | Check for any signs of wear or damage, paying close attention to bearings and motor housing. |

| 3. Lubrication | Apply a small amount of suitable lubricant to moving parts, ensuring not to over-saturate. |

| 4. Reassemble | Once cleaning and lubrication are complete, reattach any accessories and ensure everything is secure. |

Regular maintenance routines can prevent potential issues and keep your tool running smoothly for years to come. Adhering to these cleaning and lubrication practices will contribute significantly to its longevity and performance.

Troubleshooting Speed Control Issues

When working with rotary tools, experiencing fluctuations or inconsistencies in speed can hinder performance and affect the quality of your work. Identifying the root cause of these speed control problems is essential for restoring functionality and ensuring optimal operation.

Check the Power Source: Begin by examining the power supply. Ensure that the outlet is functioning correctly and that the tool is securely plugged in. If using an extension cord, verify its capacity to handle the required load, as inadequate power supply can lead to speed variations.

Inspect the Speed Control Mechanism: The speed adjustment feature is crucial for achieving desired performance levels. Look for any signs of damage or wear in the control dial or switch. If these components are not responding properly, they may need to be cleaned or replaced to restore effective operation.

Examine the Brushes: Carbon brushes play a vital role in transferring electricity to the motor. Inspect these components for signs of wear or carbon buildup. If the brushes are excessively worn down, they may need replacement to ensure smooth operation and consistent speed.

Assess the Motor: If issues persist, the motor itself may be the source of the problem. Listen for unusual noises that could indicate mechanical failure. In some cases, disassembling the tool to clean or lubricate the motor may resolve performance issues, but always refer to proper guidelines to avoid further damage.

Consider Environmental Factors: External conditions can also impact tool performance. High temperatures, humidity, or dust accumulation may affect the internal components. Ensure that the workspace is clean and suitable for operation, as this can prevent speed-related complications.

Reassembling the Dremel 3000

Bringing a tool back to its original state requires careful attention to detail and a systematic approach. This section will guide you through the steps necessary to reassemble your device effectively, ensuring optimal performance and longevity.

Necessary Tools and Components

Before beginning the reassembly process, gather the following items:

- Screwdriver set

- Clean cloth

- Lubricant (if applicable)

- Replacement parts (if any were damaged)

- Work surface

Step-by-Step Reassembly Process

- Start by inspecting all components for any signs of wear or damage.

- Begin with the motor casing, aligning it correctly with the internal mechanisms.

- Secure the casing with screws, ensuring they are tightened adequately.

- Reattach any wiring, following the original layout to avoid confusion.

- Install any additional parts, such as the chuck or attachments, in their designated positions.

- Check all connections and ensure everything is seated properly.

- Conduct a final inspection to confirm that no parts are loose or misaligned.

By following these steps, you can successfully restore your tool to working order, ready for your next project.

Testing Functionality After Repair

After completing maintenance on your tool, it is essential to ensure that it operates effectively and safely. Conducting a thorough functionality check helps identify any lingering issues and confirms that the unit is performing as expected. This process involves a series of systematic evaluations to guarantee optimal performance and user satisfaction.

Initial Power-Up Check

Begin by reconnecting the device to a power source and turning it on. Observe any unusual sounds or vibrations during operation. Pay close attention to the motor’s response; it should start smoothly without hesitation. If the tool features variable speed settings, cycle through these to verify consistent performance at different speeds.

Functional Tests with Accessories

Next, attach various accessories suitable for the tool’s intended applications. Engage in a few brief operational tests, ensuring that the attachments fit securely and function as they should. Monitor the output closely; the tool should demonstrate efficient cutting, grinding, or polishing, depending on the accessory in use. Any signs of irregularity or difficulty may indicate further issues that require attention.

Preventative Maintenance Recommendations

Regular upkeep is essential for extending the lifespan of your tool and ensuring optimal performance. By adhering to specific practices, users can minimize wear and tear, prevent unexpected failures, and maintain efficiency during operations. Below are key recommendations to help you achieve long-lasting functionality.

Routine Cleaning

- After each use, wipe down the exterior to remove dust and debris.

- Periodically inspect and clean air vents to prevent overheating.

- Use a soft brush to eliminate particles from moving parts.

Lubrication and Inspection

- Regularly apply appropriate lubricant to ensure smooth operation of mechanical components.

- Check for any signs of wear, such as cracks or frayed cords, and address them immediately.

- Inspect accessories for damage, replacing any that show signs of deterioration.

By following these recommendations, users can help secure the longevity and effectiveness of their equipment, making future tasks more manageable and efficient.

Resources for Further Assistance

When tackling maintenance or troubleshooting tasks, having access to reliable resources can significantly enhance your experience. Various platforms offer valuable information, from comprehensive guides to community forums where enthusiasts share their insights and solutions. Leveraging these resources can help you resolve issues more effectively and gain a deeper understanding of your equipment.

Online forums and discussion boards serve as excellent venues for exchanging knowledge. Here, users can post questions, share experiences, and receive advice from seasoned individuals who have faced similar challenges. Additionally, video tutorials available on popular streaming platforms can provide step-by-step instructions, making complex procedures more approachable.

For official information, visiting the manufacturer’s website can be beneficial. Often, you’ll find downloadable resources such as detailed guides and specifications that can aid in your tasks. Furthermore, many retailers offer customer support services that can assist with specific queries or concerns, ensuring you have access to expert advice when needed.