Effective upkeep of engine machinery is essential for ensuring optimal performance and longevity. Understanding the intricacies of engine components and their functions can significantly enhance operational efficiency. This section provides valuable insights into essential practices for maintaining a specific engine model, focusing on common challenges and solutions.

The guidance provided here is designed to assist technicians and enthusiasts alike in navigating through the complexities of engine servicing. By familiarizing oneself with the necessary procedures, users can confidently address various mechanical issues that may arise during operation.

Detailed information on troubleshooting and systematic repairs will be shared, emphasizing the importance of routine checks and timely interventions. With the right approach, users can minimize downtime and maximize productivity, ensuring their machinery operates smoothly for years to come.

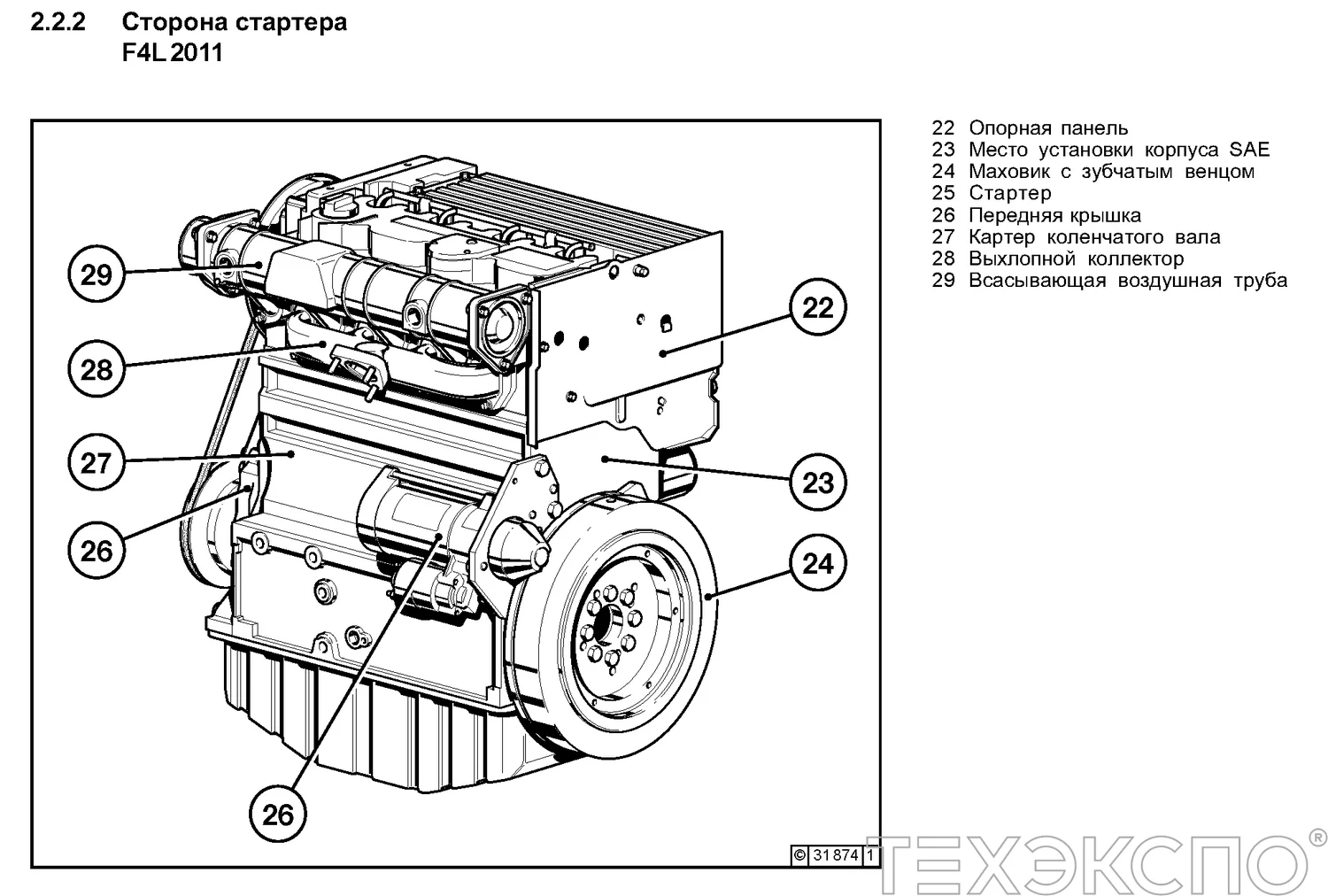

Overview of Deutz F4M2011 Engine

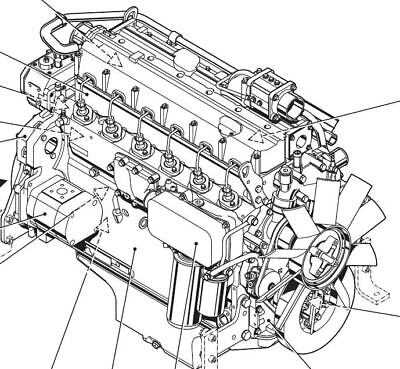

This section provides a comprehensive insight into a specific model of an internal combustion engine, focusing on its key characteristics and functionalities. Renowned for its robust design and efficient performance, this engine serves as a vital component in various industrial applications, delivering reliable power and torque.

The engine is characterized by its four-cylinder configuration, which enhances its operational efficiency while maintaining a compact footprint. This design not only contributes to reduced weight but also supports better fuel economy, making it an ideal choice for numerous machinery and vehicles. Furthermore, the unit operates with advanced technologies that promote lower emissions and noise levels, aligning with modern environmental standards.

Maintenance accessibility is a notable feature, allowing operators to perform routine checks and service tasks with ease. This aspect plays a significant role in minimizing downtime and ensuring optimal performance over the engine’s lifespan. Overall, this power unit exemplifies a blend of innovation, durability, and efficiency, making it a preferred option for various sectors.

Common Issues and Solutions

When working with complex machinery, operators may encounter a variety of common problems that can hinder performance and efficiency. Understanding these frequent issues and their corresponding solutions is essential for maintaining optimal functionality and prolonging the lifespan of the equipment.

Engine Overheating

One of the prevalent concerns is engine overheating, which can result from several factors such as coolant leaks, insufficient coolant levels, or a malfunctioning thermostat. To address this issue, first check the coolant reservoir for any leaks and ensure that the coolant is filled to the recommended level. If the thermostat is suspected to be faulty, it should be tested and replaced if necessary. Regular maintenance of the cooling system can also prevent this issue from occurring.

Starting Difficulties

Another common problem faced by users is difficulty in starting the engine. This may be attributed to battery issues, poor fuel quality, or ignition system failures. Begin troubleshooting by inspecting the battery for charge and corrosion. If the battery is in good condition, examine the fuel system for any blockages or contamination, and ensure that the fuel used meets the required standards. Additionally, checking the spark plugs and ignition components can help resolve starting issues effectively.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of your machinery. By following a structured maintenance routine, you can extend the lifespan of your equipment and avoid costly repairs. Here are some valuable practices to keep in mind:

- Routine Inspections: Conduct frequent assessments to identify potential issues before they escalate.

- Fluid Checks: Regularly examine oil, coolant, and fuel levels. Replace fluids as recommended by the manufacturer.

- Clean Air Filters: Ensure air intake systems are free from debris to promote efficient operation.

- Monitor Belts and Hoses: Inspect for signs of wear or damage, and replace them as necessary to prevent breakdowns.

Implementing these strategies can significantly enhance the reliability of your equipment and minimize downtime.

- Follow Manufacturer Guidelines: Adhere strictly to maintenance schedules outlined in the documentation.

- Keep Records: Maintain detailed logs of all maintenance activities to track performance over time.

- Invest in Quality Parts: Use original or high-quality components for replacements to ensure compatibility and longevity.

By prioritizing these practices, you can ensure your machinery remains in excellent condition, ultimately leading to better productivity and efficiency.

Step-by-Step Repair Procedures

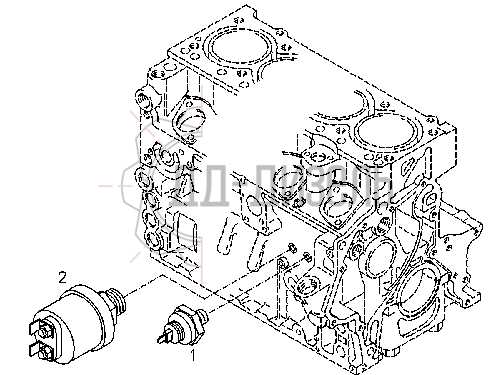

This section outlines a comprehensive approach to addressing mechanical issues, ensuring that users can efficiently resolve problems with their machinery. By following a structured methodology, individuals can systematically identify, troubleshoot, and fix faults, leading to improved performance and longevity of their equipment.

1. Initial Assessment

Begin with a thorough examination of the machinery. Look for visible signs of wear, leaks, or unusual noises. Document any irregularities to aid in diagnosing the issue later.

2. Safety Precautions

Before proceeding, ensure that all safety protocols are in place. Disconnect power sources, wear appropriate protective gear, and familiarize yourself with emergency procedures.

3. Gather Tools and Parts

Compile all necessary tools and replacement components required for the task. Having everything on hand reduces downtime and streamlines the process.

4. Disassembly

Carefully disassemble the affected parts, keeping track of fasteners and components. Use labeled containers to organize these items for easier reassembly.

5. Inspection of Components

Inspect each part for damage or signs of malfunction. Pay close attention to bearings, seals, and other critical elements that may require replacement or servicing.

6. Cleaning

Thoroughly clean all components before reassembly. Remove any dirt, grease, or debris that could hinder performance or lead to further issues.

7. Replacement and Repair

Replace any damaged parts and make necessary repairs. Ensure that all components are installed according to manufacturer specifications to maintain optimal functionality.

8. Reassembly

Reassemble the machinery in the reverse order of disassembly. Verify that all fasteners are securely tightened and that no components are left out.

9. Testing

Once reassembled, conduct a thorough test to ensure everything operates as intended. Monitor for any unusual behavior or sounds that could indicate unresolved issues.

10. Documentation

Finally, document the work completed, noting any changes made and parts replaced. This record will be invaluable for future reference and maintenance.

Essential Tools for Repairs

Effective maintenance and restoration of machinery require a specific set of instruments to ensure precision and efficiency. Having the right tools not only simplifies tasks but also enhances the overall quality of the work performed. This section outlines the crucial implements necessary for tackling various mechanical challenges.

Basic Hand Tools

Basic hand tools are fundamental in any maintenance toolkit. They allow for a wide range of functions, from tightening bolts to adjusting components. Here are some essential hand tools:

| Tool | Purpose |

|---|---|

| Wrenches | To fasten or loosen nuts and bolts. |

| Screwdrivers | To drive screws and make adjustments. |

| Pliers | For gripping, twisting, and cutting wires. |

Power Tools

In addition to hand tools, power tools are invaluable for more intensive tasks. They provide increased efficiency and can handle tougher materials with ease. Key power tools include:

| Tool | Purpose |

|---|---|

| Drills | For creating holes in various materials. |

| Impact Wrenches | To quickly tighten or loosen fasteners. |

| Grinders | For sharpening tools and removing excess material. |

Understanding Engine Specifications

Comprehending the specifications of an engine is crucial for anyone involved in maintenance or performance optimization. These details provide insight into the capabilities and limitations of the power unit, guiding decisions on repairs, enhancements, and compatibility with various applications.

Key Components of Engine Specifications

- Displacement: Refers to the total volume of all cylinders in the engine, influencing power output and efficiency.

- Power Output: Measured in horsepower or kilowatts, this indicates the engine’s ability to perform work.

- Torque: The twisting force produced, vital for understanding the engine’s performance, especially in load-bearing situations.

- Compression Ratio: The ratio of the maximum to minimum volume in the combustion chamber, affecting efficiency and power.

Importance of Specifications

Understanding these parameters helps in several ways:

- Facilitates informed choices when selecting parts for upgrades or replacements.

- Enhances the ability to diagnose issues effectively, leading to quicker resolutions.

- Enables proper matching of the engine with the intended application, ensuring optimal performance.

Grasping these specifications is essential for maintaining engine performance and longevity, ultimately leading to a better overall experience with the machinery.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial for both the technician and the equipment. Adhering to established guidelines helps prevent accidents and promotes an efficient working environment. Below are essential considerations to keep in mind while performing service tasks.

- Personal Protective Equipment (PPE): Always wear appropriate gear, including gloves, goggles, and steel-toed boots, to shield against potential hazards.

- Workspace Organization: Maintain a tidy workspace to minimize risks of tripping or misplacing tools. Ensure that all necessary tools are within reach.

- Power Sources: Before beginning any task, disconnect power sources to avoid accidental activation of equipment.

- Proper Lifting Techniques: When handling heavy components, use proper lifting techniques or mechanical aids to prevent injury.

- Ventilation: Ensure adequate ventilation in enclosed spaces to avoid inhalation of harmful fumes or dust.

By following these precautions, technicians can significantly reduce the likelihood of accidents and create a safer work environment for all involved.

Diagnosing Performance Problems

Identifying issues that affect the efficiency of machinery can significantly enhance operational reliability. Understanding the symptoms and root causes is essential for effective troubleshooting. This section outlines key steps to systematically analyze performance problems.

Begin by observing the equipment during operation. Look for any irregularities that may indicate underlying issues. Common symptoms include:

- Unusual noises or vibrations

- Decreased power output

- Overheating or excessive smoke

- Erratic behavior or stalling

Next, gather performance data to assist in diagnosing the problem. Consider the following:

- Check fuel levels and quality

- Inspect air intake systems for blockages

- Examine exhaust emissions for signs of incomplete combustion

- Review operating temperatures and pressures

Once initial observations and data collection are complete, isolate potential causes. Common factors include:

- Fuel system malfunctions

- Ignition or electrical issues

- Mechanical wear and tear

- Insufficient maintenance practices

Finally, implement diagnostic tests to pinpoint specific faults. These may involve:

- Conducting compression tests

- Performing electrical system checks

- Utilizing diagnostic software tools

- Engaging in visual inspections of critical components

Through careful observation, data analysis, and systematic testing, one can effectively diagnose performance issues and plan for appropriate corrective actions.

Parts Replacement Guide

This section provides essential insights for effectively swapping out components in your machinery. Understanding the necessary steps and precautions will ensure a smooth transition and maintain optimal performance.

Before starting the replacement process, it is crucial to gather all the required tools and parts. Proper preparation helps in minimizing downtime and prevents any unnecessary complications.

| Component | Recommended Tools | Replacement Steps |

|---|---|---|

| Air Filter | Wrench, Screwdriver | 1. Disconnect the intake hose. 2. Remove the old filter. 3. Install the new filter and reconnect the hose. |

| Fuel Injector | Socket Set, Torque Wrench | 1. Depressurize the fuel system. 2. Remove the injector wiring. 3. Unscrew and replace the injector. |

| Oil Pump | Ratcheting Wrench, Gasket Scraper | 1. Drain the oil. 2. Remove the pump assembly. 3. Clean the surface and install the new pump. |

| Water Pump | Socket Set, Pliers | 1. Drain the cooling system. 2. Disconnect the hoses. 3. Replace the pump and reconnect hoses. |

Always consult the specifications for each component to ensure compatibility and follow safety protocols during the replacement process. Regular maintenance and timely part replacements can significantly extend the lifespan of your equipment.

Service Interval Recommendations

Regular maintenance is crucial for ensuring optimal performance and longevity of machinery. Adhering to specified service intervals helps prevent potential issues and promotes efficient operation. This section outlines the key recommendations for maintaining your equipment effectively.

- Oil Changes:

- Every 250 hours of operation or every 6 months, whichever comes first.

- Use high-quality oil suitable for the engine specifications.

- Air Filter Inspection:

- Check the air filter every 100 hours of use.

- Replace if it shows signs of dirt buildup or damage.

- Fuel System Maintenance:

- Inspect fuel filters every 500 hours.

- Replace filters annually or sooner if contaminated.

- Coolant Level Check:

- Verify coolant levels every 100 hours of operation.

- Top off as necessary and flush the system every two years.

- Belt and Hose Examination:

- Inspect belts and hoses every 250 hours for wear and tear.

- Replace any components showing signs of cracking or fraying.

By following these guidelines, you can ensure that your equipment operates smoothly and efficiently, minimizing the risk of unexpected failures and extending its service life.

Resource Links for Further Assistance

For those seeking additional support in maintaining and troubleshooting their equipment, a variety of online resources are available. These platforms provide valuable information ranging from technical specifications to user experiences, ensuring that you can find the help you need to enhance performance and address any issues that may arise.

Official Websites and Forums

Exploring the official sites dedicated to machinery can yield a wealth of data, including downloadable resources and product insights. Additionally, forums often serve as interactive communities where enthusiasts share tips and solutions to common challenges. Engaging in these discussions can provide practical advice and alternative approaches.

Video Tutorials and Online Courses

Numerous platforms offer visual content that can greatly assist in understanding complex tasks. Video tutorials demonstrate step-by-step processes, making it easier to grasp intricate procedures. Furthermore, online courses may provide structured learning experiences, deepening your knowledge and skill set related to machinery maintenance.

By utilizing these resources, you can enhance your proficiency and ensure your equipment operates smoothly.