Maintaining large vehicles is crucial for ensuring their longevity and optimal performance. This comprehensive guide delves into the intricacies of keeping these robust machines in prime condition, covering essential techniques and insights that every operator should know. Whether you’re a seasoned professional or a newcomer to the field, understanding the intricacies of maintenance can significantly enhance your operational efficiency.

Throughout this section, you will discover practical tips and strategies that address various aspects of upkeep, from routine inspections to troubleshooting common issues. Emphasizing preventative measures and detailed procedures, this guide aims to equip you with the knowledge needed to tackle challenges effectively and avoid costly downtimes.

By focusing on best practices and innovative solutions, this resource not only aids in immediate concerns but also fosters a deeper appreciation for the machinery’s mechanics. With the right approach, you can ensure that your vehicles remain reliable assets in your fleet for years to come.

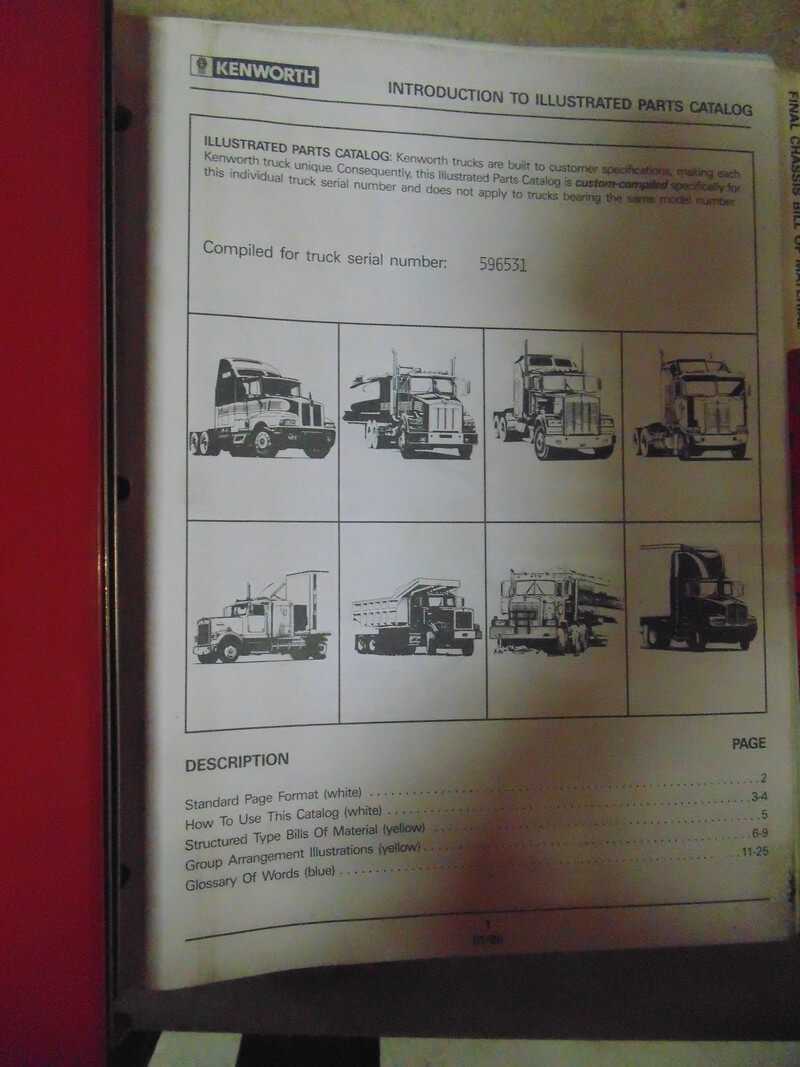

Understanding Kenworth Truck Models

In the realm of heavy-duty vehicles, a diverse array of models serves distinct purposes and functionalities. Each design reflects unique characteristics that cater to various industries and requirements. Grasping the nuances of these models is essential for optimal performance and maintenance.

Each model features specific attributes, from engine types to cab configurations, influencing their efficiency and suitability for different tasks. Recognizing these variations can aid operators and technicians in making informed decisions regarding utilization and upkeep.

Furthermore, the evolution of these vehicles has led to advancements in technology, enhancing safety and fuel efficiency. Understanding the lineage and development of each model provides valuable insights into their operational capabilities and potential challenges.

By familiarizing oneself with the range of models available, stakeholders can better appreciate the significance of proper handling and servicing. This knowledge ultimately contributes to the longevity and reliability of these powerful machines in the field.

Common Issues in Kenworth Trucks

When it comes to heavy-duty vehicles, various challenges can arise during their operation. Understanding these common problems is crucial for maintaining optimal performance and longevity. Identifying issues early can prevent extensive damage and costly repairs down the line.

Frequent Mechanical Problems

- Engine Overheating

- Transmission Failure

- Brake System Malfunctions

- Electrical System Failures

Each of these mechanical concerns can significantly impact functionality, so regular inspections are essential to ensure everything is in working order.

Maintenance Challenges

- Oil Leaks

- Worn Belts and Hoses

- Suspension Wear

- Fuel System Issues

Addressing these maintenance challenges promptly can enhance performance and prevent more serious complications in the future.

Importance of Regular Maintenance

Consistent upkeep of machinery is essential for ensuring optimal performance and longevity. By adhering to a scheduled maintenance plan, operators can prevent unexpected breakdowns, enhance safety, and ultimately save on repair costs. The significance of regular checks cannot be overstated, as they play a crucial role in identifying potential issues before they escalate into major problems.

Benefits of Scheduled Upkeep

Implementing a routine maintenance schedule brings numerous advantages. Regular inspections help in maintaining efficiency, prolonging the lifespan of equipment, and ensuring compliance with safety regulations. Additionally, well-maintained machinery typically yields better fuel economy, resulting in lower operational costs.

Key Maintenance Practices

There are several essential practices that should be part of any maintenance routine. These include checking fluid levels, inspecting belts and hoses, and ensuring that all components are functioning correctly. Below is a table summarizing these practices:

| Maintenance Practice | Frequency | Purpose |

|---|---|---|

| Fluid Level Check | Every 1,000 miles | Prevent overheating and ensure lubrication |

| Inspection of Belts and Hoses | Monthly | Identify wear and prevent failures |

| Brake System Check | Every 5,000 miles | Ensure safety and reliable stopping power |

DIY Repairs for Truck Owners

For those who take pride in their heavy-duty vehicles, understanding basic maintenance and fixing issues independently can be incredibly rewarding. Not only does this knowledge save money, but it also fosters a deeper connection with the machinery. With a little guidance, anyone can tackle common problems and keep their vehicle in peak condition.

Here are some essential tips and tricks to help you get started on your journey of self-sufficiency:

| Task | Tools Needed | Steps |

|---|---|---|

| Change Oil | Oil filter wrench, wrench set, oil pan | 1. Warm up engine. 2. Drain old oil. 3. Replace filter. 4. Add new oil. |

| Replace Air Filter | Screwdriver, new air filter | 1. Locate filter housing. 2. Remove old filter. 3. Insert new filter. |

| Check Tire Pressure | Tire pressure gauge | 1. Remove valve cap. 2. Press gauge onto valve. 3. Adjust pressure as needed. |

| Replace Wiper Blades | New wiper blades | 1. Lift arm. 2. Remove old blade. 3. Attach new blade. |

Equipping yourself with the right tools and knowledge can transform routine maintenance into a straightforward process. By addressing these simple tasks, you can extend the life of your vehicle and enhance its performance, ensuring that it remains a reliable partner on the road.

Essential Tools for Kenworth Repair

Having the right set of equipment is crucial for maintaining heavy vehicles. The efficiency and effectiveness of any maintenance task depend significantly on the tools at hand. A well-equipped workspace not only ensures precision but also enhances safety during the servicing process.

Basic Hand Tools: A variety of hand tools such as wrenches, screwdrivers, and pliers are fundamental for any maintenance job. These tools allow for quick adjustments and replacements, making them indispensable for everyday tasks.

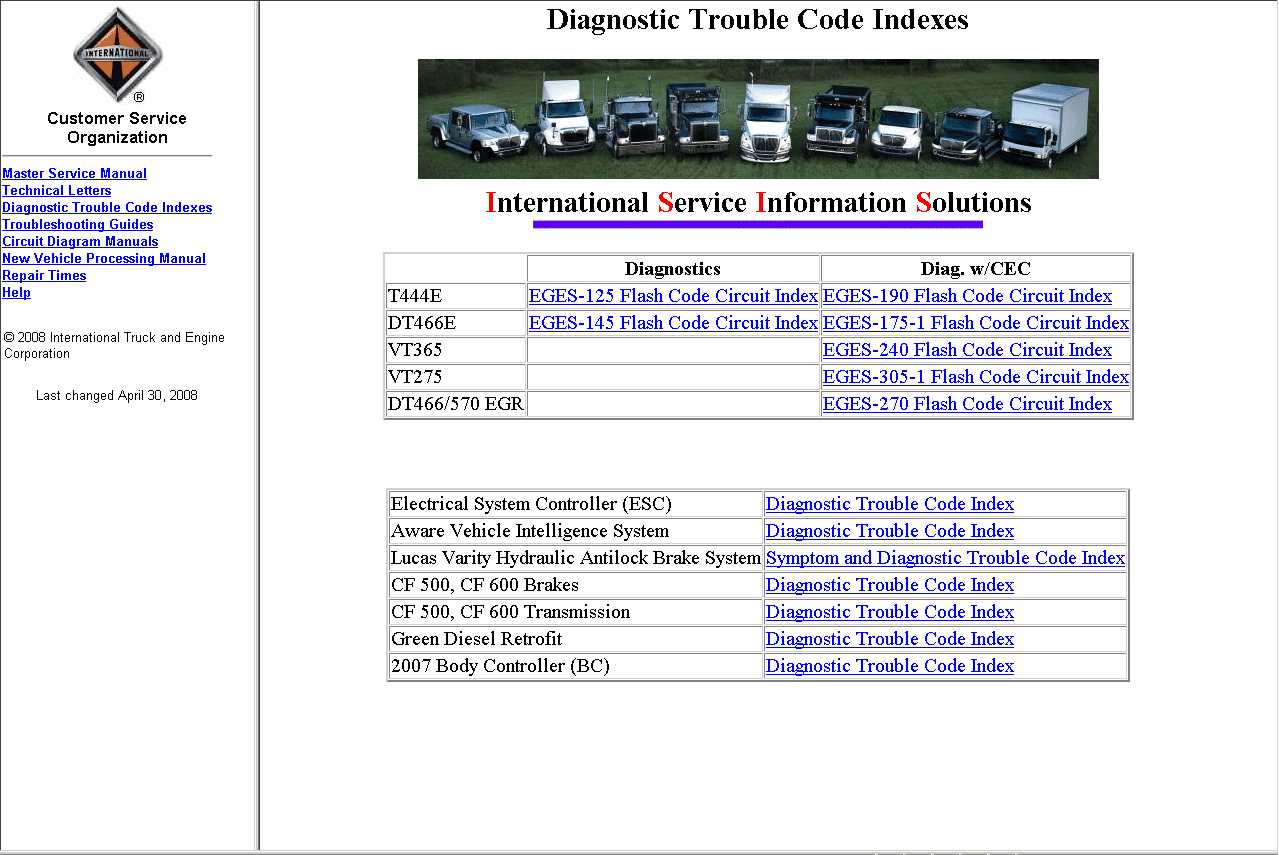

Diagnostic Equipment: Utilizing advanced diagnostic tools can greatly streamline the troubleshooting process. These devices help identify issues quickly, ensuring that problems are addressed before they escalate.

Power Tools: Electric or pneumatic tools can significantly reduce the time required for more strenuous tasks. Impact wrenches and grinders, for example, enhance efficiency and precision when working on larger components.

Safety Gear: Personal protective equipment such as gloves, goggles, and ear protection is essential. Prioritizing safety ensures that the working environment is secure for all involved, minimizing the risk of injury.

Specialized Tools: Depending on the vehicle’s design, some tasks may require unique instruments tailored for specific functions. These tools are essential for handling complex repairs that standard equipment may not adequately address.

Finding Official Repair Manuals

Locating authentic guides for maintenance and troubleshooting is essential for ensuring the longevity and performance of heavy-duty vehicles. These documents provide critical insights and step-by-step instructions that aid in addressing various mechanical issues effectively.

Where to Look for Official Guides

There are several reliable sources to consider when searching for these essential documents:

- Manufacturer Websites: Most producers offer downloadable versions or online access to their technical documentation.

- Authorized Dealers: Visiting or contacting authorized service centers can yield physical copies or insights into where to obtain them.

- Automotive Forums: Engaging with communities dedicated to heavy machinery can lead to recommendations on where to find these resources.

- Online Retailers: Certain websites specialize in selling technical literature and may have the specific guides you need.

Tips for Ensuring Authenticity

When acquiring these documents, it is crucial to ensure their legitimacy:

- Verify the Source: Always check that the source is reputable and recognized in the industry.

- Look for Updates: Ensure the document is current and reflects the latest standards and procedures.

- Check for Reviews: Read feedback from other users to confirm the reliability of the guide.

By following these guidelines, you can effectively find and utilize official literature for optimal vehicle upkeep.

Safety Practices During Repairs

Ensuring a secure environment while conducting maintenance tasks is paramount. Adopting effective safety measures not only protects individuals involved but also enhances the overall efficiency of the service process. Implementing a set of well-defined practices can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. This includes wearing gloves, safety goggles, and sturdy footwear to safeguard against potential hazards. Each piece of equipment serves a specific purpose, providing necessary protection against various risks encountered in maintenance activities.

Workspace Organization

Maintaining an organized workspace can greatly contribute to safety. Keeping tools and materials properly stored reduces clutter and minimizes the likelihood of accidents. Regularly inspecting the area for potential hazards, such as spills or loose cables, is crucial in creating a secure environment for all involved.

When to Seek Professional Help

Understanding the right moments to call in experts can save time and prevent further complications. While some issues may seem manageable, there are scenarios where professional intervention is essential to ensure safety and optimal functionality. Recognizing these signs can lead to more efficient resolutions and enhance the longevity of your equipment.

Signs You Should Consider Expert Assistance

Identifying the right indicators can help you decide when to seek help. Here are some key situations:

| Situation | Reason for Professional Help |

|---|---|

| Persistent Issues | Recurring problems may indicate underlying complications that require expert diagnosis. |

| Complex Repairs | Some repairs involve intricate systems that necessitate specialized knowledge and tools. |

| Safety Concerns | Any situation that poses a risk to safety should be handled by professionals to prevent accidents. |

Benefits of Seeking Expertise

Engaging qualified personnel not only ensures the correct resolution of issues but also brings peace of mind. Their experience and access to advanced technology can lead to better outcomes and improved performance of your machinery.

Upgrading Kenworth Truck Components

Enhancing vehicle elements can significantly improve performance, safety, and efficiency. By focusing on the right upgrades, owners can achieve superior driving experiences while extending the lifespan of their assets.

Engine Enhancements: Upgrading the powertrain can lead to increased horsepower and torque. Consider investing in a performance exhaust system or advanced fuel injectors for optimal efficiency.

Suspension Modifications: A robust suspension system is crucial for stability and comfort. Installing upgraded shock absorbers or air ride systems can provide better handling and ride quality.

Brake System Improvements: Enhancing braking components ensures safety and reliability. Opt for high-performance brake pads and rotors to improve stopping power.

Electrical System Upgrades: Modernizing the electrical system can improve functionality and reliability. Installing upgraded lighting and auxiliary power systems can enhance visibility and convenience.

Ultimately, thoughtful upgrades can lead to a more efficient and enjoyable driving experience, ensuring your vehicle meets your performance needs.

Understanding Warranty Coverage

Warranty coverage is a critical aspect of owning any heavy-duty vehicle, providing peace of mind and financial protection against unforeseen issues. It outlines the terms under which repairs or replacements are covered, ensuring that owners are aware of their rights and responsibilities.

Typically, warranty policies include several key components:

- Duration: The length of time or mileage during which coverage is effective.

- Scope of Coverage: Specific components and systems that are included or excluded from the warranty.

- Claim Process: Steps to take when filing a claim, including required documentation and approval procedures.

Understanding these elements is vital for maximizing the benefits of your warranty. Here are some common types of warranties you might encounter:

- Basic Warranty: Covers essential components and systems for a specified duration.

- Powertrain Warranty: Focuses on the engine, transmission, and drivetrain components.

- Extended Warranty: Optional coverage that can be purchased for additional protection beyond the basic terms.

In addition to knowing the types of coverage, it is crucial to follow maintenance schedules and adhere to service recommendations to maintain warranty validity. Failing to do so may lead to denied claims and increased out-of-pocket expenses.

Ultimately, a thorough understanding of warranty coverage empowers owners to make informed decisions and ensures that they are adequately protected against potential repair costs.

Cost Estimates for Common Repairs

When it comes to maintaining heavy-duty vehicles, understanding the financial implications of typical maintenance tasks is essential. This section provides an overview of anticipated expenses for frequent service procedures, ensuring that operators can budget accordingly and make informed decisions.

Engine Overhaul: A complete engine overhaul can be one of the most significant investments, with costs ranging from $4,000 to $15,000 depending on the complexity and components involved.

Transmission Replacement: Replacing the transmission is another major expense, generally costing between $3,000 and $7,000. This figure may vary based on the type of transmission and labor rates in the area.

Brake System Repair: Addressing issues with the braking system typically falls between $300 and $2,500, depending on whether pads, rotors, or the entire system require replacement.

Suspension Work: Repairs or replacements within the suspension can average around $500 to $2,000. This range depends on the extent of the damage and the parts that need attention.

Electrical System Diagnostics: Diagnosing and fixing electrical problems often costs between $100 and $1,500. This expense is influenced by the complexity of the issue and the parts involved.

Planning for these typical expenditures can help ensure that operators maintain the performance and safety of their vehicles while managing their financial commitments effectively.

Resources for Kenworth Enthusiasts

For those passionate about heavy-duty vehicles, finding reliable information and support can greatly enhance the ownership experience. A variety of resources are available, catering to both novices and seasoned aficionados. These materials can provide insights into maintenance, performance enhancements, and community engagement.

Online Forums and Communities

Engaging with fellow enthusiasts through online platforms allows for the sharing of experiences and knowledge. Dedicated forums offer a space to discuss modifications, troubleshoot issues, and exchange tips. Members often share valuable resources, including guides and personal insights.

Specialized Literature

Books and magazines focused on heavy machinery can provide in-depth information about models and maintenance practices. Many publications feature articles written by experts that cover various aspects of ownership, from operational techniques to historical perspectives.

Workshops and Events

Participating in workshops and meetups can foster a sense of community. These gatherings often include hands-on sessions and presentations, allowing participants to learn directly from professionals and fellow owners. Networking at these events can lead to lasting connections and shared resources.

Videos and Tutorials

Visual learners can benefit from numerous online tutorials and video series dedicated to the subject. Platforms like YouTube host a plethora of content, ranging from basic maintenance tips to complex troubleshooting procedures, making it easier to follow along and apply what you learn.

Local Clubs and Associations

Joining local clubs provides opportunities for camaraderie and shared passion. These organizations often organize events, provide newsletters, and connect members with local resources, making it easier to stay informed and engaged.

By leveraging these diverse resources, enthusiasts can deepen their understanding, enhance their skills, and enjoy a more fulfilling journey with their heavy-duty vehicles.