Ensuring the optimal performance of your outdoor machinery is essential for maintaining a pristine lawn. This resource provides comprehensive insights into troubleshooting and upkeep, enabling you to maximize the lifespan and efficiency of your equipment. Whether you’re dealing with minor issues or preparing for seasonal challenges, understanding the nuances of your machine is crucial.

With detailed instructions and practical tips, this guide empowers users to tackle common problems independently. From engine diagnostics to maintenance schedules, you’ll find everything needed to keep your machinery in top condition. Emphasizing user-friendly approaches, the content is designed to make the process accessible, even for those with limited technical experience.

Embracing a proactive maintenance strategy not only saves time and money but also enhances the overall performance of your equipment. By familiarizing yourself with the essential components and their functions, you can ensure reliable operation and avoid unnecessary repairs. Dive into this guide to unlock the potential of your outdoor machinery and keep your lawn looking its best.

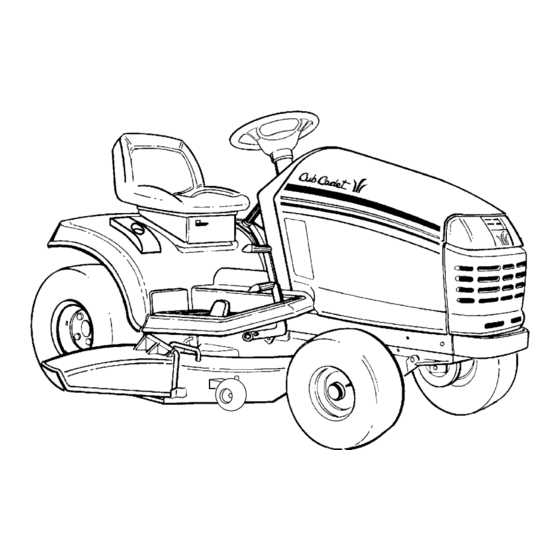

Overview

This section provides a comprehensive look at a specific type of riding mower, highlighting its features, capabilities, and essential functions. Designed for ease of use and efficiency, this equipment is ideal for maintaining residential lawns and larger outdoor spaces.

The model is known for its robust construction and user-friendly design. Key aspects include:

- Powerful engine for enhanced performance

- Efficient cutting system for a clean finish

- Comfortable seating and controls for extended use

- Durable frame to withstand regular use

In terms of specifications, this machine typically offers:

- Engine displacement for optimal power output

- Transmission options for varied terrain handling

- Cutting width to reduce mowing time

- Deck height adjustment for customizable grass length

Overall, this mower is a reliable choice for homeowners seeking to maintain their landscapes with efficiency and precision.

Common Issues with Cub Cadet LT1018

Owning a lawn tractor can bring both convenience and challenges. As with any machinery, certain problems may arise over time, often leading to frustration for users. Identifying these frequent issues is crucial for maintaining optimal performance and ensuring longevity.

One prevalent concern involves the engine failing to start. This can be attributed to various factors, such as a drained battery or a clogged fuel filter. Ensuring that the battery is charged and the fuel system is clean can often resolve this issue.

Another common problem is poor cutting performance. Users may notice uneven grass length or the machine leaving patches uncut. This is typically linked to dull blades or a buildup of debris underneath the deck. Regular maintenance, including sharpening blades and cleaning, can help restore efficiency.

Additionally, transmission difficulties can occur, leading to a lack of power when moving forward or backward. This issue may stem from low fluid levels or worn components. Regularly checking the transmission fluid and addressing any wear can prevent these complications.

Lastly, electrical malfunctions can hinder operation, causing lights to flicker or the starter to malfunction. These issues may result from faulty wiring or blown fuses. Routine inspections of the electrical system can mitigate such problems.

Understanding these common issues allows owners to take proactive measures, ensuring their equipment remains in good working order and reducing the likelihood of extensive repairs.

Essential Tools for Repairs

When it comes to maintaining outdoor machinery, having the right set of instruments is crucial for effective troubleshooting and upkeep. The appropriate tools not only streamline the process but also ensure safety and precision during operations. This section outlines key implements that can facilitate your maintenance tasks, enhancing both efficiency and quality of work.

Basic Tool Kit

A fundamental collection of tools serves as the foundation for any maintenance endeavor. Below is a table detailing essential items to include in your toolkit:

| Tool | Purpose |

|---|---|

| Screwdrivers | Used for tightening or loosening screws of various sizes. |

| Wrenches | Essential for gripping and turning nuts and bolts. |

| Pliers | Great for holding, bending, or cutting wires and other materials. |

| Socket Set | Provides versatility for different bolt sizes and types. |

Specialized Instruments

In addition to basic tools, specialized instruments can significantly enhance your capabilities for specific tasks. Investing in these items can help tackle more complex challenges efficiently:

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures that bolts are tightened to the manufacturer’s specifications. |

| Multimeter | Used for electrical diagnostics and troubleshooting. |

| Pressure Gauge | Measures pressure levels to ensure optimal performance. |

| Fuel Line Wrench | Specialized for working with fuel systems without damage. |

Step-by-Step Maintenance Procedures

Regular upkeep of your equipment is essential for ensuring optimal performance and longevity. Following a systematic approach can help you address common issues and keep your machine running smoothly. This section outlines a series of maintenance tasks that should be performed periodically.

Essential Maintenance Tasks

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Drain old oil and replace it with fresh lubricant to ensure proper engine function. |

| Air Filter Check | Every 25 hours | Inspect and clean or replace the air filter to maintain airflow and engine efficiency. |

| Blade Sharpening | Every season | Sharpen or replace the blades to ensure a clean cut and reduce strain on the engine. |

| Tire Pressure Check | Monthly | Ensure tires are inflated to the recommended pressure for better traction and maneuverability. |

| Battery Maintenance | Every month | Check battery terminals for corrosion and ensure proper charge levels for reliable starts. |

Final Tips

Staying consistent with these maintenance tasks can significantly improve the performance and lifespan of your machine. Always consult the manufacturer’s recommendations for specific guidelines tailored to your equipment. Keeping a maintenance log can also help you track when each task was last performed.

Engine Troubleshooting Tips

Maintaining optimal performance of your machinery often hinges on identifying and resolving engine issues promptly. Understanding common problems and their symptoms can save time and enhance efficiency. Here are some essential strategies to help diagnose engine-related concerns.

- Check Fuel Supply:

- Ensure there is adequate fuel in the tank.

- Inspect fuel lines for leaks or blockages.

- Examine the fuel filter for clogs.

- Examine the Battery:

- Verify that the battery is charged and connections are secure.

- Look for corrosion on terminals.

- Test the battery voltage to ensure proper functionality.

- Inspect the Spark Plug:

- Remove the spark plug and check for wear or damage.

- Clean or replace the spark plug if necessary.

- Ensure the gap is set according to specifications.

- Assess Cooling System:

- Check coolant levels and top off if low.

- Inspect for leaks in hoses or connections.

- Ensure the radiator is free of debris for optimal airflow.

- Monitor Engine Sounds:

- Listen for unusual noises such as knocking or hissing.

- Identify any irregular vibrations during operation.

- Document changes in sound patterns for further investigation.

By following these guidelines, operators can effectively troubleshoot and maintain engine health, ensuring longevity and reliable performance.

Electrical System Diagnostics

Assessing the functionality of the electrical framework is crucial for ensuring the optimal performance of any machinery. Identifying issues within the electrical components can prevent more severe malfunctions and enhance the longevity of the equipment. This section will guide you through essential diagnostic procedures to pinpoint electrical failures effectively.

To conduct a thorough evaluation, follow these key steps:

- Visual Inspection:

- Check for damaged wires and connectors.

- Inspect fuses for signs of burning or corrosion.

- Look for loose connections that may cause intermittent power issues.

- Voltage Testing:

- Utilize a multimeter to measure voltage across battery terminals.

- Test the voltage output from the alternator or charging system.

- Verify voltage at various components to ensure proper operation.

- Continuity Testing:

- Use a multimeter to check continuity in wiring circuits.

- Identify any breaks or shorts in the electrical pathways.

- Confirm that switches and relays are functioning correctly.

- Component Testing:

- Assess the starter motor’s functionality and performance.

- Evaluate the ignition system for any faults.

- Check sensors and electronic modules for proper operation.

By following these procedures, you can systematically diagnose electrical issues, facilitating effective repairs and maintenance. Regular checks will help maintain the efficiency and reliability of the entire system.

Blade Replacement Guide

Maintaining optimal performance of your mowing equipment requires occasional blade changes. This process ensures a clean cut and enhances the overall efficiency of your machine. Understanding the steps involved in replacing the cutting implement is essential for any operator aiming to keep their lawn in pristine condition.

Before starting, ensure you have the necessary tools at hand: a socket wrench, safety gloves, and a new blade suitable for your equipment model. First, secure the machine on a flat surface and disconnect the spark plug to prevent accidental starts. It’s advisable to wear protective gloves to avoid injuries during the replacement process.

Next, locate the blade retention bolt beneath the cutting deck. Use the socket wrench to loosen and remove this bolt, taking care to hold the blade in place to prevent it from spinning. Once removed, carefully detach the old blade and inspect the blade adapter for any signs of wear or damage. If needed, replace the adapter as well.

Position the new blade onto the adapter, ensuring it aligns properly with the mounting holes. Secure it in place by tightening the retention bolt, ensuring it is snug but not overly tight to avoid damaging the threading. After replacing the blade, reconnect the spark plug and check the height adjustment settings to ensure an even cut.

Finally, perform a test run to verify the installation. Observe the cutting performance and listen for any unusual sounds. Regular maintenance, including timely blade replacements, will keep your equipment running smoothly and effectively for many seasons to come.

Transmission Repair Techniques

Understanding the inner workings of a vehicle’s transmission is essential for effective maintenance and troubleshooting. By employing proper methods, one can address various issues that may arise, ensuring optimal performance and longevity of the machinery.

Common Issues and Diagnostics

Identifying symptoms such as slipping gears or unusual noises is the first step in addressing transmission problems. Regular diagnostics can help pinpoint underlying issues, facilitating timely interventions and minimizing potential damage.

Repair Approaches

When tackling transmission concerns, techniques such as fluid replacement, component inspection, and seal replacement are vital. Each method requires careful execution to restore functionality and prevent recurring issues, ultimately enhancing the equipment’s reliability.

Fuel System Cleaning Methods

Maintaining the cleanliness of a fuel system is essential for optimal performance and longevity of any engine. Over time, deposits and contaminants can accumulate, leading to reduced efficiency and potential damage. Implementing effective cleaning techniques can restore functionality and enhance reliability.

Chemical Cleaners are often utilized to dissolve carbon deposits and varnish within the fuel system. These solutions can be added directly to the fuel tank or used in a more concentrated application. It’s important to follow the manufacturer’s instructions to avoid any adverse effects.

Mechanical Cleaning involves the physical removal of debris and buildup. This can be accomplished by disassembling components such as fuel injectors or carburetors. A thorough inspection and manual scrubbing with appropriate tools can help eliminate stubborn contaminants.

Fuel Filters should be replaced regularly to prevent blockages that can affect fuel flow. Installing high-quality filters can significantly reduce the amount of dirt and debris entering the system, thereby extending the intervals between cleaning sessions.

Routine Maintenance is crucial for preventing the accumulation of harmful substances. Regularly checking fuel lines, inspecting for leaks, and ensuring proper fuel quality can help maintain a clean system over time. Consistent attention to these aspects can lead to fewer issues and improved engine performance.

In summary, adopting a combination of chemical and mechanical cleaning methods, along with routine maintenance practices, can effectively keep the fuel system in peak condition, ensuring smooth operation and longevity of the engine.

Seasonal Maintenance Checklist

Regular upkeep of your outdoor equipment is essential for optimal performance throughout the year. This checklist provides key tasks to ensure that your machinery remains in excellent condition, allowing for efficient operation during every season.

Spring Maintenance:

- Inspect and change the oil to promote engine longevity.

- Replace the air filter to enhance airflow and efficiency.

- Sharpen or replace the blades for a clean cut.

- Check tire pressure and tread for safety.

Summer Maintenance:

- Clean the deck and remove grass clippings to prevent rust.

- Inspect fuel lines for leaks or wear.

- Ensure the cooling system is functioning to avoid overheating.

- Lubricate moving parts to minimize friction.

Fall Maintenance:

- Change the oil and replace the oil filter for winter storage.

- Stabilize fuel to prevent degradation over the winter months.

- Clean and store equipment in a dry place to prevent damage.

- Inspect belts and cables for signs of wear.

Winter Preparation:

- Check the battery charge and connections to ensure reliability.

- Cover equipment with a protective tarp to shield from snow and ice.

- Review all safety features to ensure they are in working order.

- Perform a general inspection to catch any issues early.

Following this seasonal checklist will help maintain your machinery’s efficiency and extend its lifespan, making your outdoor tasks easier and more enjoyable.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount. Proper precautions not only protect the individual performing the work but also enhance the longevity and functionality of the equipment. Understanding and implementing these measures can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Wearing the appropriate personal protective equipment (PPE) is essential. This includes gloves to safeguard against sharp edges and hot surfaces, goggles to protect the eyes from debris, and sturdy footwear to prevent slips or falls. Additionally, consider using hearing protection if working with loud machinery.

Work Area Safety

Keeping the workspace organized is critical for safety. Ensure that the area is well-lit and free from clutter. Use tools and equipment only as intended, and always follow the manufacturer’s guidelines. It’s advisable to disconnect any power sources before beginning work to eliminate the risk of accidental activation.

Where to Find Replacement Parts

Finding suitable components for your equipment can be essential for maintaining optimal performance and longevity. Fortunately, there are several reliable sources where you can procure the necessary items, ensuring your machinery operates smoothly without interruption.

Authorized Dealers

One of the most dependable options for sourcing parts is through authorized dealers. These establishments typically stock genuine components, ensuring compatibility and quality. Additionally, the staff can provide valuable advice and support for your specific needs.

Online Retailers

The internet offers a vast array of online retailers that specialize in replacement components. Many of these platforms provide detailed catalogs, allowing you to search for the exact parts you require. Be sure to read customer reviews and verify the retailer’s credibility before making a purchase.