Maintaining your equipment is essential for optimal performance and longevity. This section aims to provide detailed insights into the processes and techniques necessary to keep your chainsaw in peak condition. Whether you are a seasoned user or new to handling such tools, understanding the intricacies of care can enhance your experience and ensure safety during operation.

Technical knowledge is invaluable when it comes to troubleshooting common issues. Here, you will find step-by-step instructions that simplify complex procedures, making them accessible for anyone eager to learn. Emphasis is placed on practical advice that can help avoid common pitfalls and improve the overall functionality of your device.

Additionally, we will explore essential maintenance tasks that every user should be familiar with. Regular upkeep not only enhances performance but also contributes to a safer working environment. By following the guidance provided, you will be equipped to address various challenges confidently and effectively.

Ensuring the extended lifespan of your equipment requires consistent care and attention. By following a few essential practices, you can keep your device in optimal condition and enhance its performance over time.

Regular Cleaning

One of the most effective ways to maintain your equipment is through regular cleaning. Dirt and debris can accumulate, causing wear and tear. Here are some steps to follow:

- Use a soft brush to remove dirt from hard-to-reach areas.

- Wipe down surfaces with a damp cloth to eliminate dust.

- Inspect filters and replace them if they appear clogged or damaged.

Routine Inspections

Conducting routine inspections helps identify potential issues before they become major problems. Consider the following:

- Check all moving parts for signs of wear.

- Ensure that all bolts and screws are secure.

- Test functionality to catch any irregularities early.

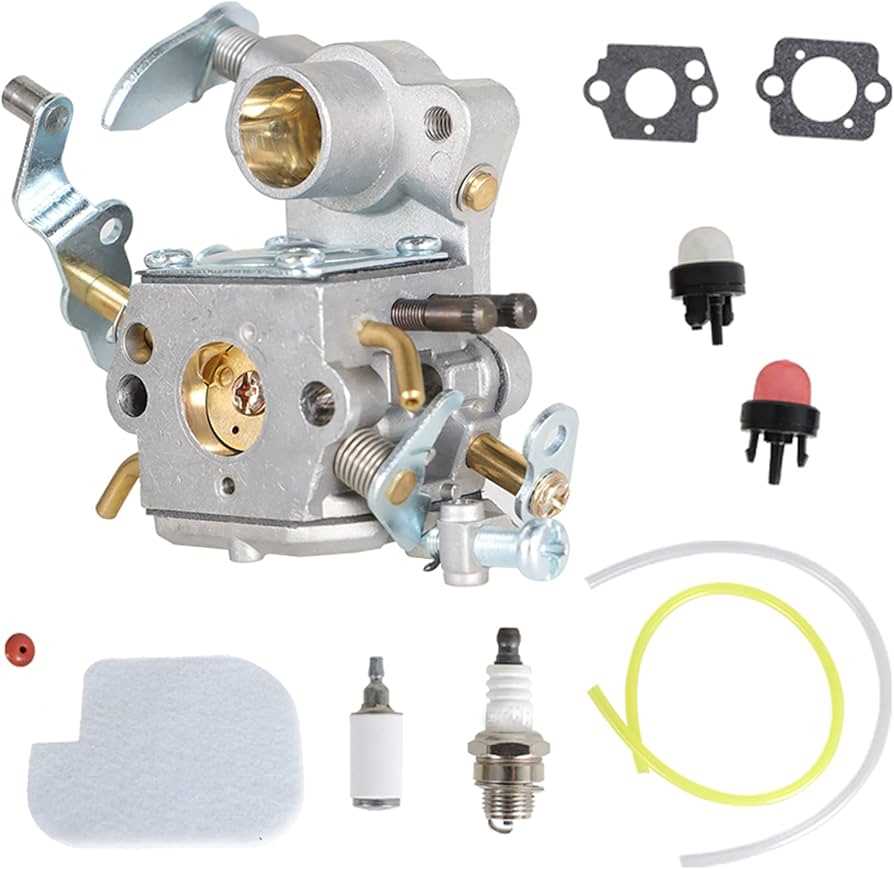

Parts Replacement Guide

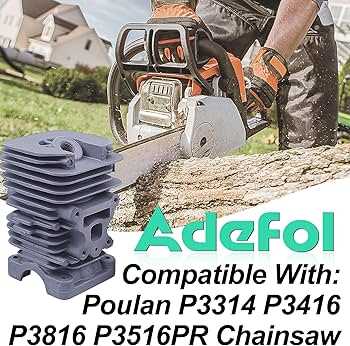

This section provides essential information on how to effectively replace components in your equipment. Proper maintenance and timely replacements can enhance performance and extend the lifespan of your machine.

Follow these steps for a successful parts replacement:

- Identify the component that needs replacement.

- Gather the necessary tools and new parts.

- Refer to the specifications to ensure compatibility.

- Carefully remove the old part following safety protocols.

- Install the new component securely and check for proper functionality.

Common parts that may require replacement include:

- Chains and blades

- Filters and air intakes

- Fuel lines and hoses

- Spark plugs

- Battery and electrical connections

Regular inspections will help you determine when parts need to be changed. Always consult with your supplier for the best replacement options to ensure efficiency and safety.

Tools Needed for Repairs

When tackling maintenance tasks on outdoor equipment, having the right instruments is essential for efficiency and effectiveness. A well-prepared toolkit not only simplifies the process but also enhances safety and precision. Below are some of the crucial implements that can aid in various procedures.

Essential Tools

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for loosening and tightening screws in various components. |

| Wrench Set | Helps in adjusting nuts and bolts, ensuring a secure fit. |

| Pliers | Useful for gripping and bending wires or other small parts. |

| Socket Set | Allows for efficient removal and installation of larger fasteners. |

| Cleaning Brushes | Assists in removing dirt and debris from delicate areas. |

Safety Equipment

In addition to standard tools, ensuring personal safety is paramount during maintenance tasks. Always wear protective gear, including gloves and safety goggles, to safeguard against potential hazards.

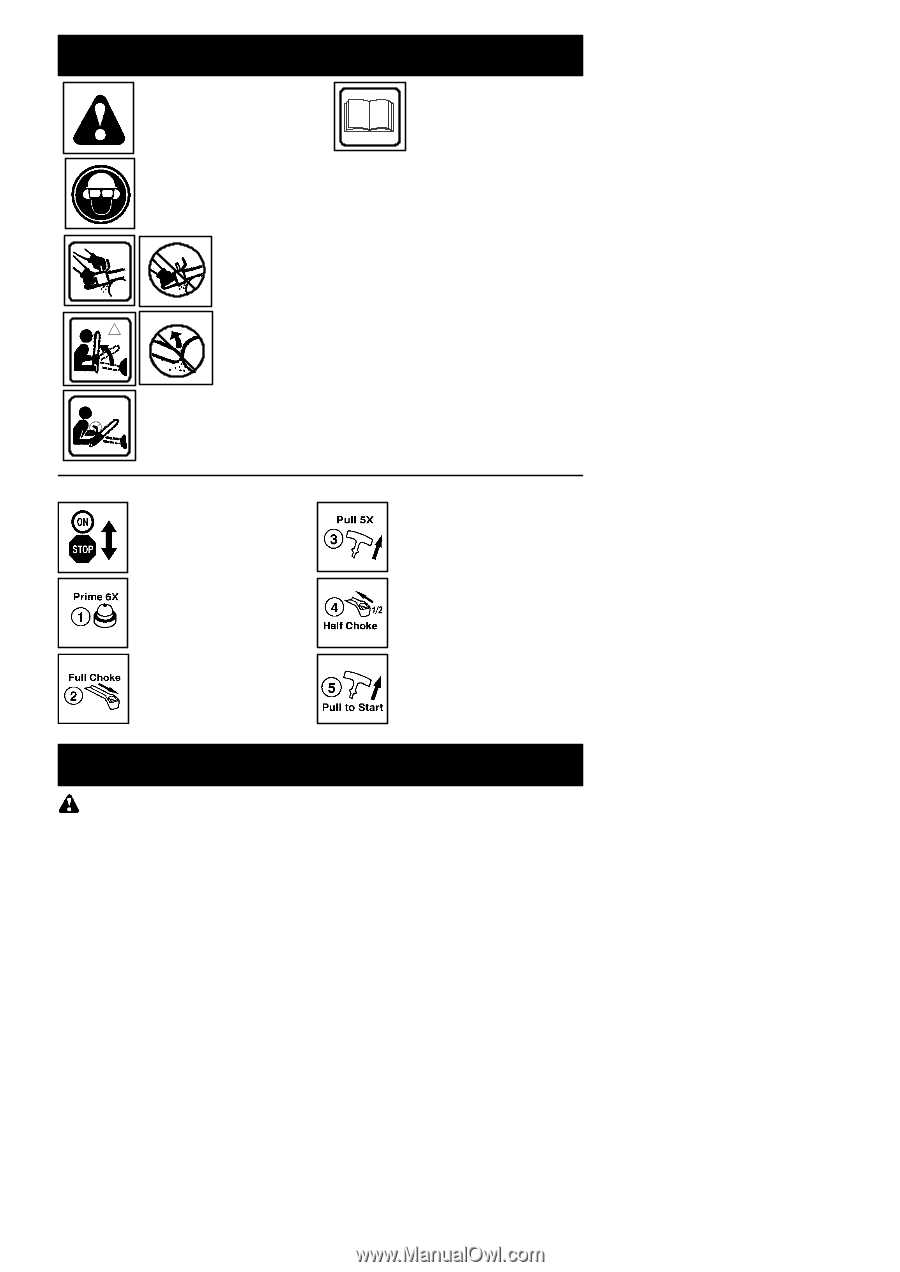

Step-by-Step Repair Process

This section outlines a comprehensive procedure for addressing common issues encountered with outdoor power equipment. Following a structured approach ensures that each component is assessed and restored effectively, enhancing the longevity of the machine.

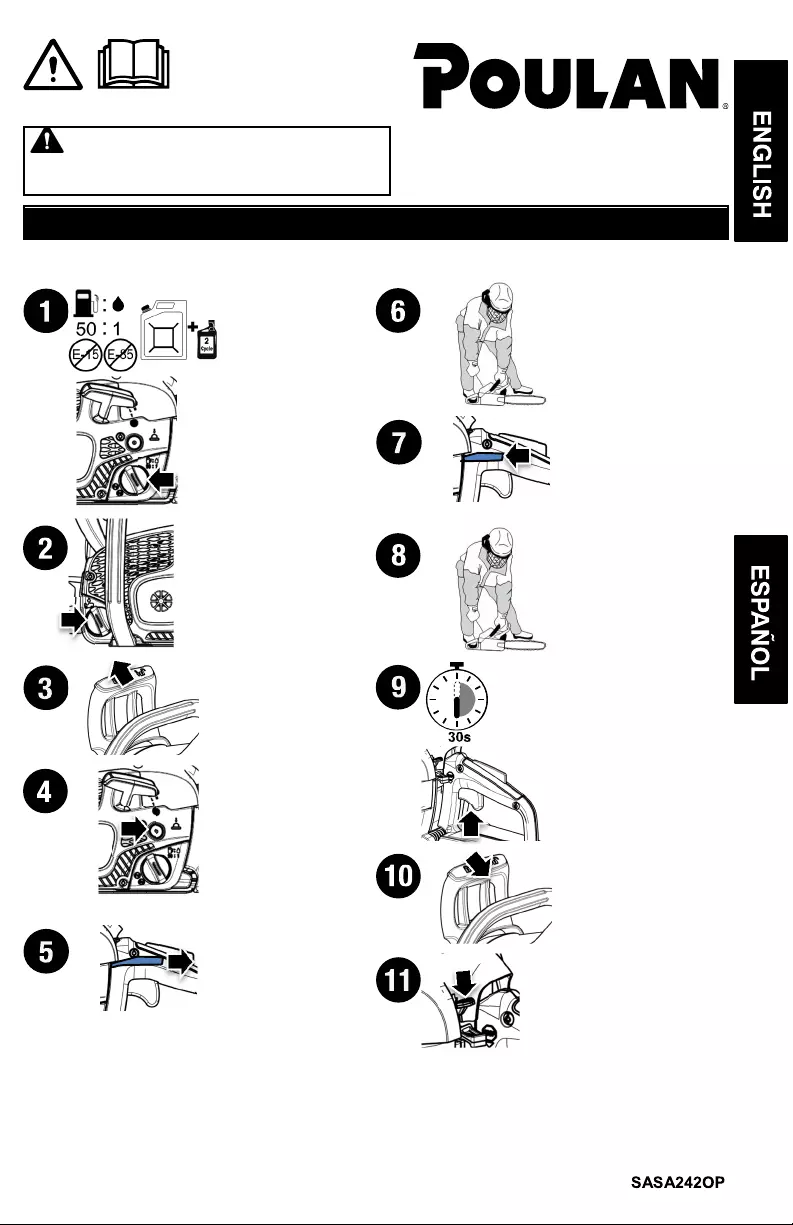

- Preparation

- Gather all necessary tools and materials.

- Ensure the working area is clean and well-lit.

- Review safety precautions to avoid injuries.

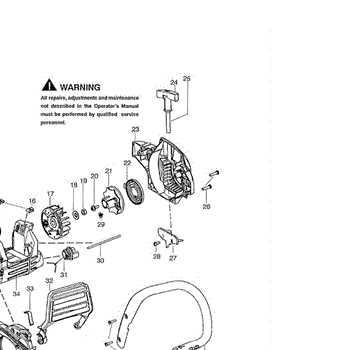

- Disassembly

- Carefully remove the housing to access internal parts.

- Document the position of each component for reassembly.

- Inspect for any visible damage or wear.

- Diagnosis

- Test the electrical components for functionality.

- Check the fuel system for blockages or leaks.

- Examine the cutting mechanism for sharpness and integrity.

- Replacement

- Order suitable parts based on the diagnosis.

- Install new components according to the specifications.

- Ensure all connections are secure and properly aligned.

- Reassembly

- Reattach the housing, following your initial documentation.

- Double-check all screws and fasteners are tightened.

- Perform a final inspection before starting the equipment.

- Testing

- Start the machine and observe for any unusual sounds or movements.

- Test its operation under normal conditions.

- Make adjustments as necessary to ensure optimal performance.

By adhering to these steps, users can effectively restore functionality to their outdoor machinery, ensuring reliable operation for future tasks.

Safety Precautions During Repairs

When undertaking maintenance tasks on equipment, it is essential to prioritize safety to prevent accidents and ensure a smooth workflow. Proper precautions not only protect the individual performing the service but also help maintain the integrity of the machinery.

Personal Protective Equipment

Wearing appropriate personal protective gear is crucial. This includes safety goggles to shield your eyes from debris, gloves to protect your hands from sharp edges, and sturdy footwear to guard against falling objects. Additionally, ear protection may be necessary when operating loud tools.

Workspace Organization

Maintaining a clean and organized workspace reduces the risk of injuries. Ensure that all tools are easily accessible and that the area is free from clutter. Clearly marking hazardous zones and keeping flammable materials away from the workspace can also enhance safety during maintenance activities.

Understanding Engine Components

Engines are intricate systems composed of various parts that work together to convert fuel into motion. Each component plays a vital role in ensuring the engine operates efficiently and reliably. By familiarizing oneself with these elements, users can gain insights into how to maintain and troubleshoot their equipment effectively.

The primary parts include the cylinder, where combustion occurs, and the piston, which moves up and down to generate power. The crankshaft converts this linear motion into rotational energy, driving the machinery forward. Additionally, the carburetor mixes air and fuel in the correct proportions, while the ignition system ignites the fuel, initiating the combustion process.

Understanding the function of these components enables operators to identify potential issues early, ensuring longevity and optimal performance. Regular inspections and maintenance can help in recognizing wear and tear, allowing for timely interventions before more serious problems arise.

Troubleshooting Electrical Problems

When facing issues with electrical components, it’s essential to approach the situation methodically. Understanding the basic principles of electrical systems can help identify and resolve common malfunctions effectively.

| Symptoms | Possible Causes | Solutions |

|---|---|---|

| Device won’t start | Dead battery or faulty switch | Check battery charge and replace if necessary; inspect and repair the switch. |

| Intermittent power | Loose connections | Examine all connections and tighten any that are loose. |

| Flickering lights | Overloaded circuit | Redistribute the load to different circuits. |

| Unusual noises | Worn-out components | Inspect and replace any damaged parts. |

Resources for Additional Help

When seeking assistance with your equipment, a variety of resources can provide valuable information and support. Whether you’re looking for troubleshooting tips, maintenance advice, or technical specifications, these options can enhance your understanding and effectiveness.

- Online Forums: Communities dedicated to similar devices often share experiences and solutions. Engaging with fellow users can offer insights and practical advice.

- Manufacturer’s Website: Official sites usually feature product documentation, FAQs, and customer service contacts, ensuring you have access to accurate information.

- YouTube Tutorials: Video guides can visually demonstrate techniques and repairs, making it easier to follow along with the processes involved.

- Local Repair Shops: Professionals in your area can provide hands-on assistance and may offer workshops to enhance your skills.

- User Groups: Joining local or online clubs related to your equipment can connect you with others who share your interests and challenges.

Frequently Asked Questions

This section addresses common inquiries regarding maintenance and troubleshooting for outdoor equipment. Here, you will find concise answers to frequently posed questions, designed to assist users in resolving typical issues and enhancing their understanding of the product.

- What should I do if my device won’t start?

Check the fuel level and ensure that the spark plug is clean and properly connected.

- How often should I perform maintenance?

Regular checks should be done before each use, while comprehensive servicing is recommended at least once a season.

- What type of fuel is recommended?

Always refer to the specifications for the appropriate fuel type to ensure optimal performance.

- How can I sharpen the blade effectively?

Use a sharpening tool specifically designed for blades, following the manufacturer’s instructions for best results.

- Where can I find replacement parts?

Authorized dealers and reputable online retailers usually stock a range of spare parts for your device.