In

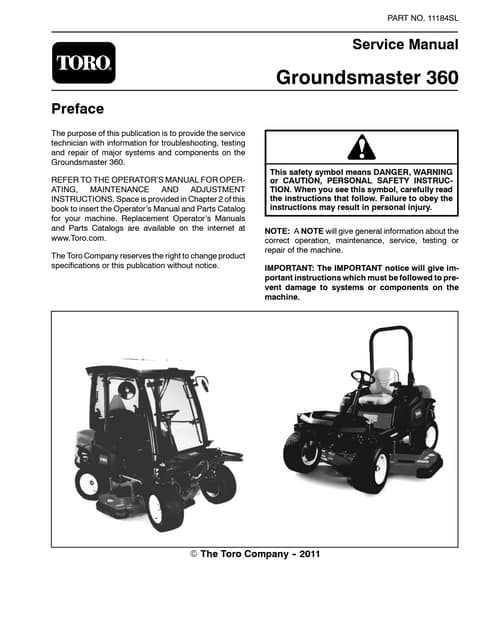

Engine Troubleshooting Tips and Techniques

Identifying engine issues can be challenging, but with a few essential techniques, it’s possible to isolate problems and restore functionality effectively. This guide outlines methods to inspect various components and recognize common signs of wear or malfunction, helping you address underlying issues efficiently.

Key Areas to Inspect

Begin with a comprehensive examination of critical parts such as the fuel system, air filter, and ignition elements. Ensuring each is in optimal condition will reduce common performance issues. Check for any signs of blockages, wear, or damage that may impact engine operation.

Fuel and Air Flow Assessment

Engines require a balanced mix of fuel and air to operate smoothly. Verify that fuel lines are clear and free from leaks. Similarly, inspect the air filter to ensure proper

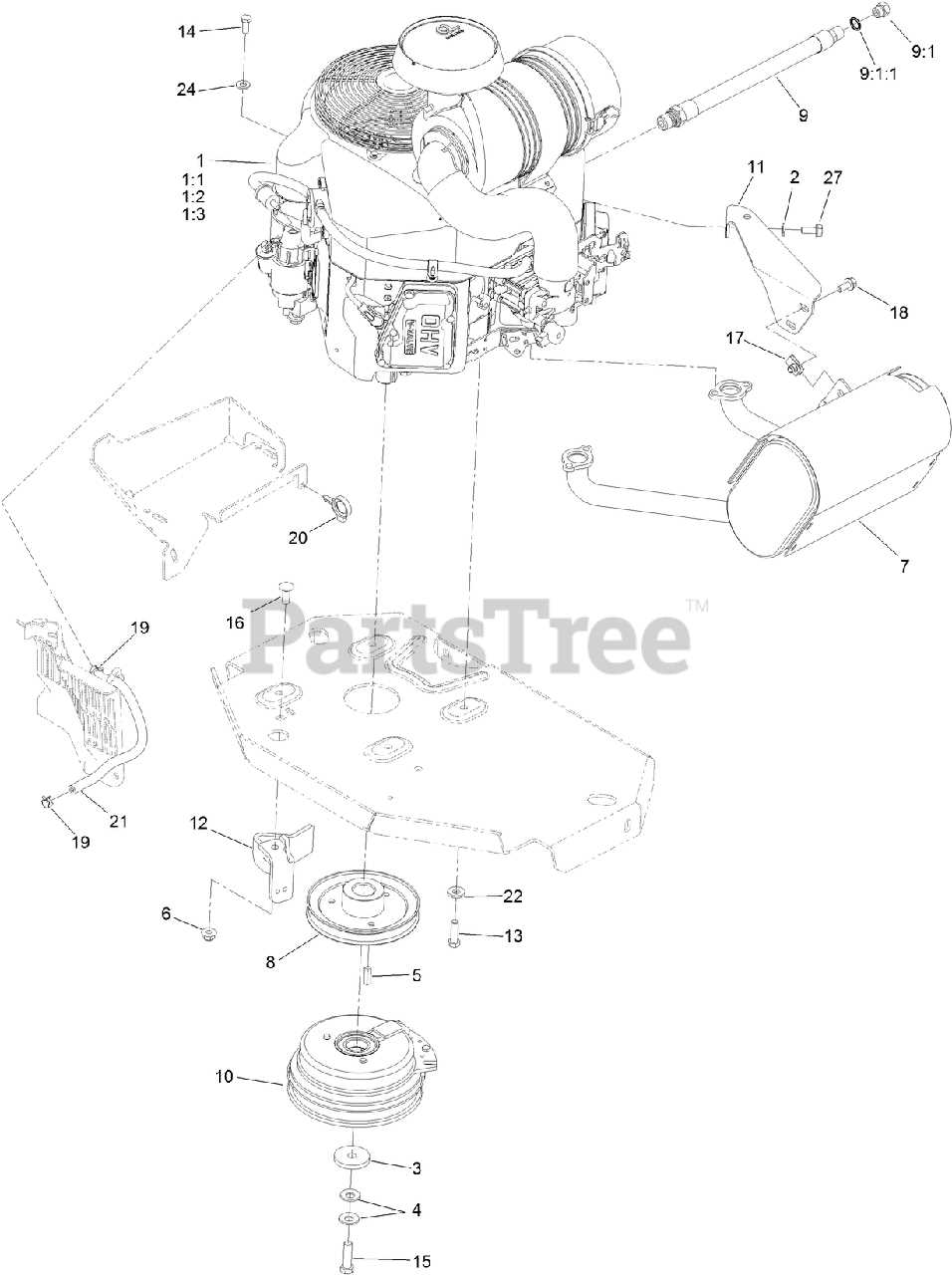

Repairing the Drive System

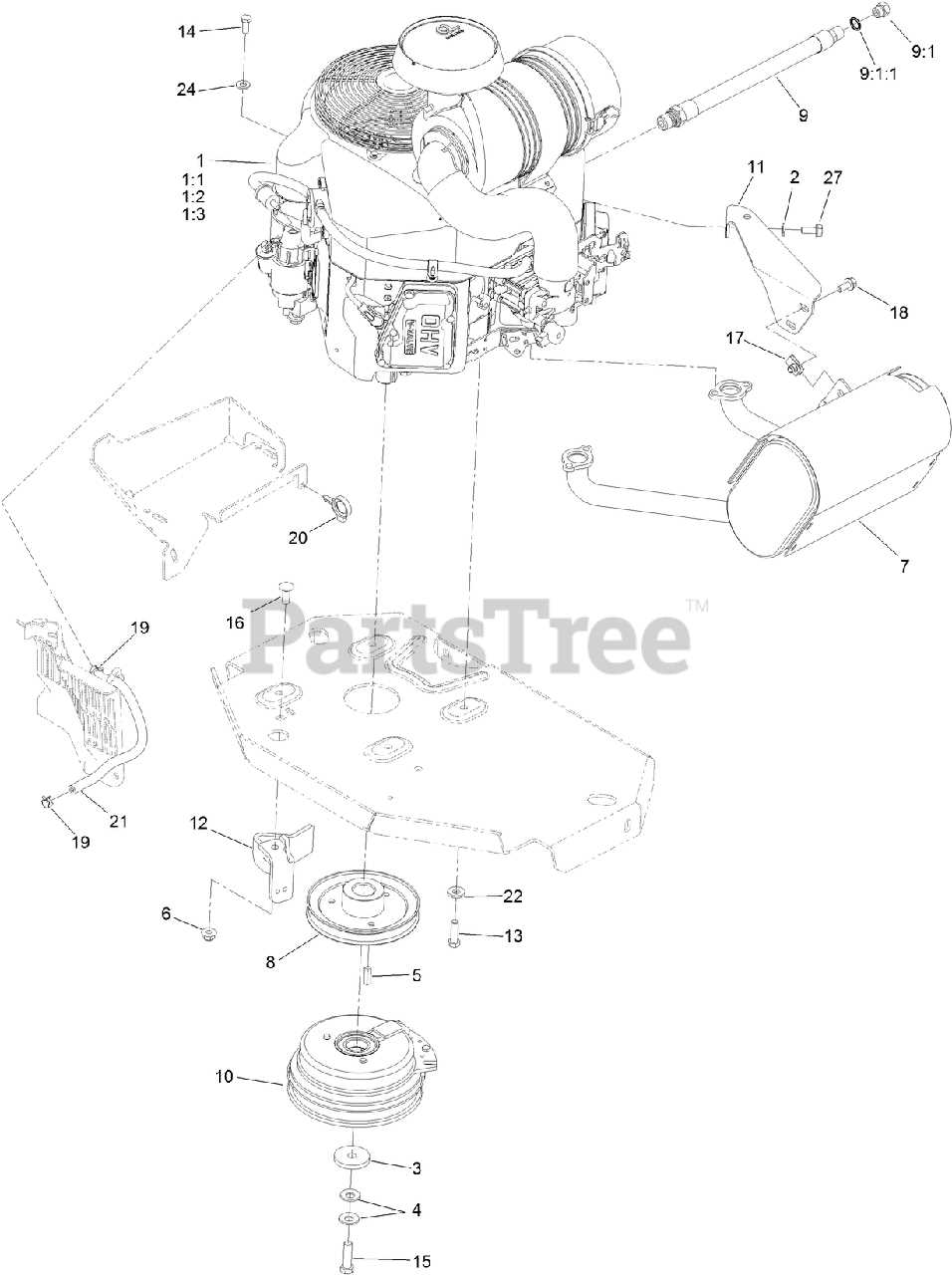

The drive mechanism is crucial for the effective operation of your gardening equipment, enabling smooth movement and maneuverability. Addressing any issues within this system is essential for maintaining optimal performance and ensuring longevity. Common problems may arise from wear and tear, misalignment, or fluid leaks, necessitating a thorough inspection and possible intervention.

Begin by assessing the entire drive assembly, focusing on belts, pulleys, and connections. Look for signs of damage or wear that could affect functionality. Adjust any misaligned components to ensure they are properly seated. If the belts show signs of fraying or cracks, replacement is necessary to prevent further complications.

Next, inspect the hydraulic system if applicable. Check for fluid levels and inspect hoses for leaks or wear. Replace any damaged hoses and top off the fluid as needed. Ensure that all connections are secure, as loose fittings can lead to reduced performance and efficiency.

Finally, once all adjustments and replacements are made, perform a test run to verify that the drive system operates smoothly and responds effectively. Regular maintenance and prompt attention to issues will help extend the life of the equipment and enhance its performance in the long run.

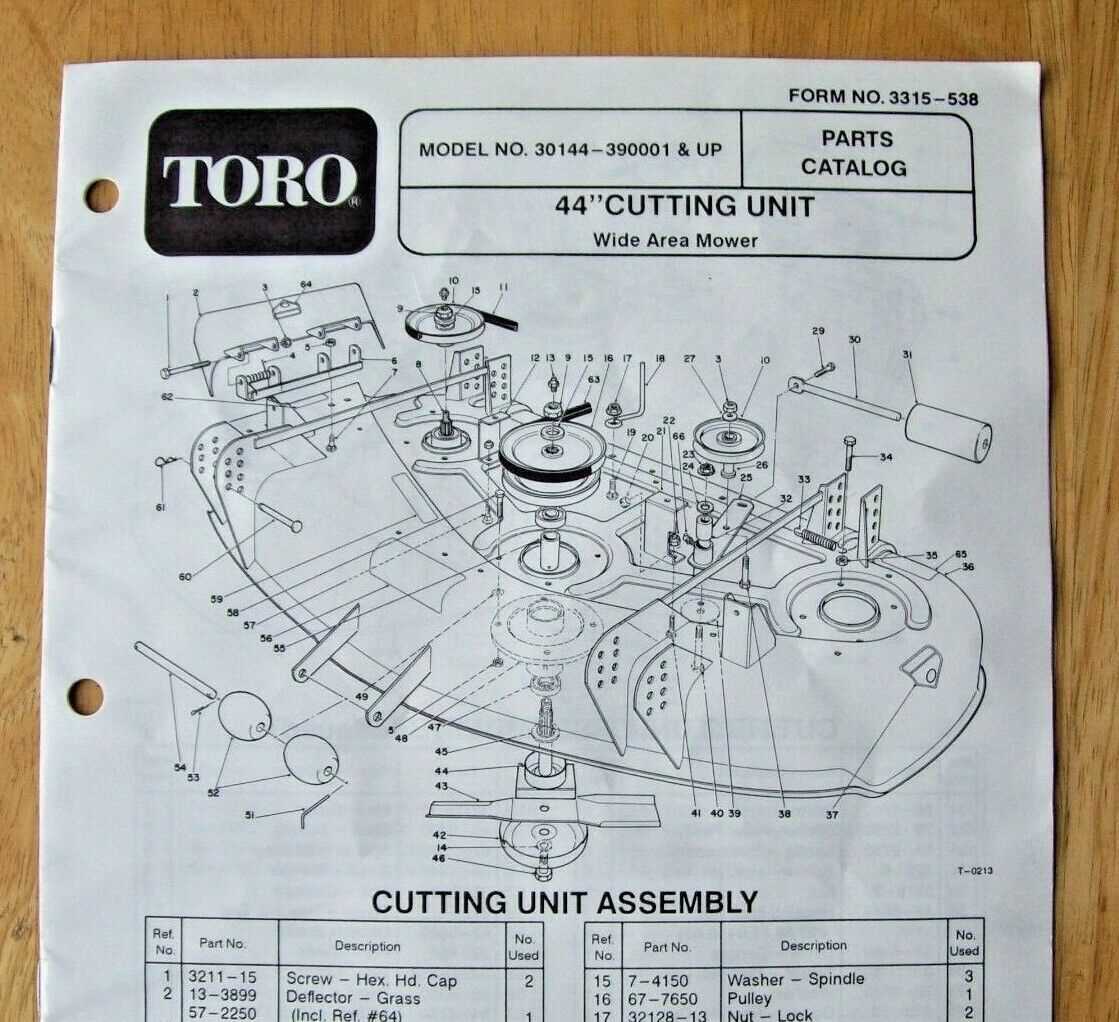

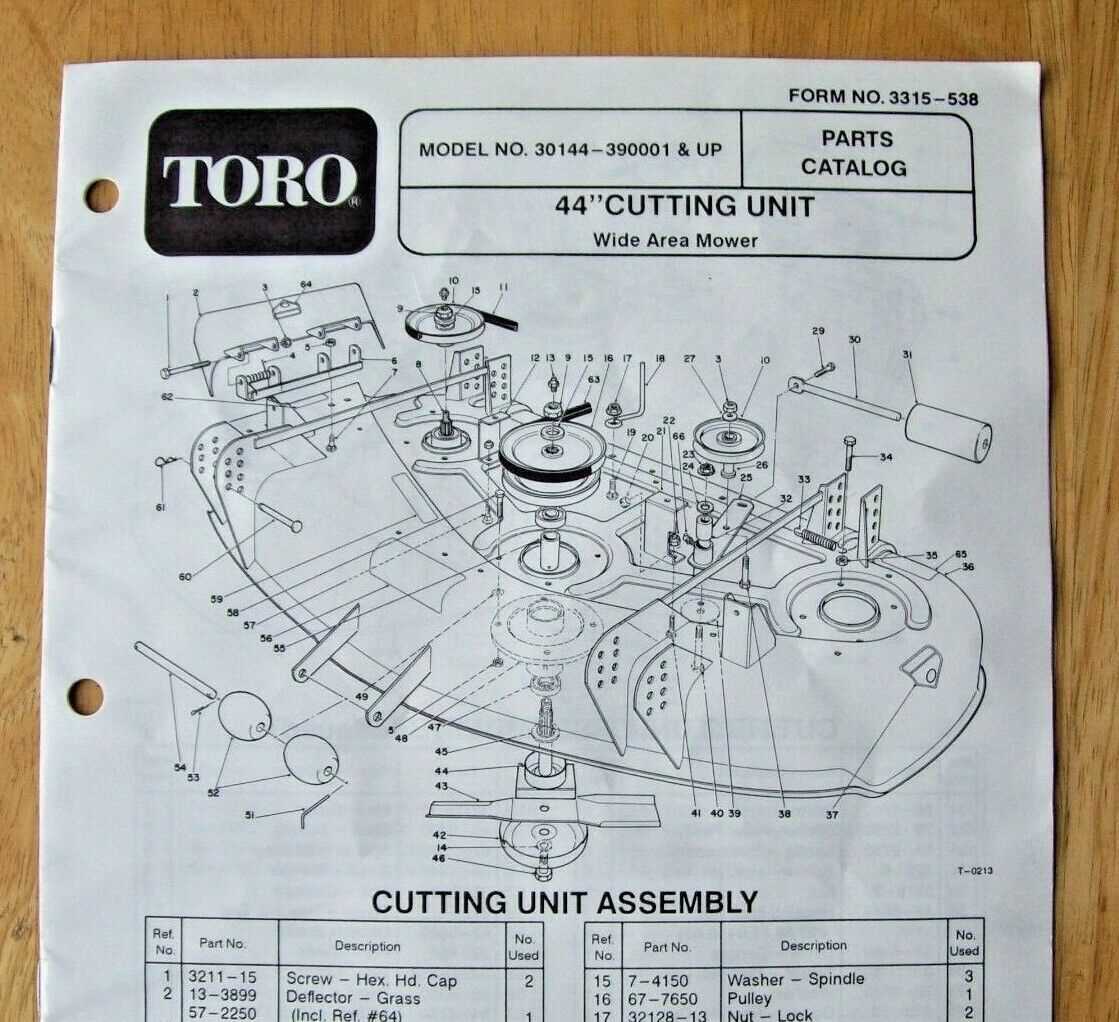

Fixing Cutting Deck Problems

Maintaining the cutting deck is crucial for achieving a clean and even lawn. Various issues can arise, affecting performance and cutting quality. Identifying and addressing these problems promptly ensures your equipment operates efficiently and extends its lifespan.

One common issue is uneven cutting, which may result from dull blades or improper deck leveling. Inspecting and sharpening the blades regularly can significantly improve cutting performance. Additionally, ensure that the deck is adjusted correctly to maintain an even height across the width.

Another frequent problem is debris buildup, which can hinder the deck’s operation. It is essential to clean the underside of the deck regularly to prevent grass clippings and other materials from accumulating. Using a pressure washer can be an effective method for this task.

Lastly, checking for wear and tear on the belts and pulleys can prevent unexpected failures. Regularly inspecting these components and replacing them as necessary will keep the cutting deck functioning optimally.

Electrical System Repair Instructions

The electrical system of your equipment plays a vital role in ensuring optimal performance and functionality. Understanding how to address issues within this system is essential for maintaining the overall efficiency of the machine. This section provides guidance on diagnosing and rectifying common electrical problems, enabling you to restore your device to its full potential.

Identifying Electrical Issues

Start by examining the wiring and connections for signs of wear, damage, or corrosion. A thorough visual inspection can often reveal underlying problems that may affect performance. If any components appear frayed or disconnected, they should be addressed promptly to prevent further complications.

Troubleshooting the Battery

A crucial element of the electrical system is the power source. Ensure the battery is adequately charged and functioning correctly. If the device fails to start, check for loose terminals or corrosion on the battery connections. Cleaning the terminals and ensuring a tight fit can often resolve starting issues.

Testing Fuses and Relays

Inspect the fuses and relays for any signs of damage. A blown fuse can disrupt the electrical flow, while a malfunctioning relay may prevent components from receiving power. Replace any faulty fuses or relays to restore functionality to the affected systems.

Wiring Connections and Components

Pay special attention to the wiring harness and connectors. Loose or damaged connections can lead to intermittent power loss or malfunctioning features. Secure all connections and replace any damaged wiring to ensure consistent operation.

Consulting Technical Resources

If issues persist after basic troubleshooting, consult technical resources for more detailed guidance on electrical system components. Accessing wiring diagrams and specifications can aid in identifying specific issues and understanding how to effectively address them.

Fuel System Maintenance and Repair

Proper upkeep of the fuel system is essential for optimal performance and longevity of the equipment. This section focuses on the key aspects of fuel system care, ensuring that the engine operates smoothly and efficiently. Regular attention to this area can prevent potential issues that may arise from neglect, contributing to better fuel efficiency and overall reliability.

Inspecting Fuel Lines: It is vital to regularly examine fuel lines for any signs of wear, cracks, or leaks. Damaged lines can lead to fuel spills and decreased performance. Ensure all connections are tight and free from corrosion.

Fuel Filter Replacement: The fuel filter plays a crucial role in keeping contaminants from entering the engine. Replacing the filter at recommended intervals helps maintain engine health. Check the manufacturer’s guidelines for specific replacement schedules.

Cleaning the Fuel System: Over time, deposits can accumulate within the fuel system, affecting performance. Using appropriate cleaning agents can help restore the system’s functionality. Follow the instructions carefully to avoid damaging components.

Using Quality Fuel: Always opt for high-quality fuel to minimize the risk of impurities that can clog the system. Storing fuel in clean containers and ensuring it is fresh can significantly enhance the system’s efficiency.

Regular maintenance of the fuel system not only extends the life of the equipment but also enhances its performance, making it crucial for any operator to prioritize these tasks.

Replacing Worn-Out Mower Blades

Keeping the cutting components of your grass-trimming equipment sharp is essential for optimal performance. Dull or damaged blades can lead to uneven cuts and potential damage to the lawn. Regularly checking and replacing these parts ensures a healthy and pristine appearance for your outdoor space.

Identifying Worn-Out Blades

Before proceeding with the replacement, it’s crucial to recognize signs of wear. Look for the following indicators:

- Chipped or cracked edges

- Visible rust or corrosion

- Uneven cutting patterns

- Increased vibrations during operation

Steps for Replacement

Follow these steps to safely and effectively change the blades:

- Ensure the machine is turned off and disconnected from any power source.

- Lift the equipment to access the cutting assembly. Use a jack or blocks for stability.

- Remove the bolts securing the blades using a suitable wrench.

- Carefully detach the worn-out blades from the spindle.

- Position the new blades in place, ensuring they align correctly.

- Secure the blades by tightening the bolts securely.

- Lower the equipment and check that everything is in order before operation.

By maintaining sharp and functional cutting components, you enhance the efficiency of your lawn care tasks and extend the lifespan of your equipment.

Adjusting the Steering for Smooth Operation

Fine-tuning the steering mechanism is essential for achieving optimal performance and ease of control in any lawn care equipment. Proper adjustment ensures a seamless experience, allowing the operator to navigate efficiently while maintaining stability and precision. This section outlines the steps necessary for making those critical adjustments, ensuring a smooth and enjoyable operation.

Identifying Steering Issues

Before making any adjustments, it is crucial to recognize common steering problems. Some indicators include uneven handling, excessive resistance, or unresponsiveness. Identifying these issues early on can prevent more significant complications in the future.

Adjustment Process

To ensure proper steering performance, follow these steps:

| Step |

Action |

| 1 |

Inspect the steering components for wear or damage. |

| 2 |

Loosen the adjustment screws located on the steering linkage. |

| 3 |

Align the steering arms to ensure equal length on both sides. |

| 4 |

Tighten the adjustment screws to secure the alignment. |

| 5 |

Test the steering for responsiveness and make further adjustments if necessary. |

Following these steps will help achieve a well-functioning steering system, enhancing the overall usability and efficiency of your equipment.

Hydraulic System Troubleshooting Guide

The hydraulic system is crucial for the efficient operation of various equipment, enabling smooth movement and functionality. When issues arise, it is essential to identify the symptoms accurately to restore optimal performance. This guide provides a comprehensive overview of common problems and their potential causes, ensuring users can troubleshoot effectively.

Common Symptoms and Causes:

One prevalent issue is insufficient power or slow response from the hydraulic components. This could be attributed to low fluid levels, contamination, or leaks in the system. Another frequent problem is erratic movement, which may indicate issues with the hydraulic pump or malfunctioning valves. Additionally, unusual noises can signal air trapped in the lines or failing hydraulic components.

Troubleshooting Steps:

To diagnose the problem, start by checking the hydraulic fluid level and condition. If the fluid appears dirty or contains debris, it may require replacement. Inspect all hoses and connections for signs of leaks or damage, tightening or replacing components as necessary. Next, examine the hydraulic pump and valves for proper operation, ensuring they are free from blockages and functioning smoothly.

Preventive Measures:

Regular maintenance is vital to avoid hydraulic system failures. Implementing routine checks of fluid levels, filters, and components will help identify potential issues before they escalate. Proper storage and handling of hydraulic fluids also contribute to system longevity, minimizing the risk of contamination and breakdown.

Safety Tips for Mower Repairs

Ensuring safety during maintenance tasks is crucial for both the user and the equipment. Proper precautions can prevent accidents and prolong the lifespan of the machinery. Familiarizing oneself with safety guidelines before beginning any service is essential for a successful outcome.

1. Wear Protective Gear: Always equip yourself with appropriate safety attire, including gloves, goggles, and sturdy footwear. This protective gear helps minimize the risk of injury from sharp objects or moving parts.

2. Disconnect the Power Source: Before initiating any servicing procedures, make sure to disconnect the power supply. This precaution will help avoid unintentional starts while working on the equipment.

3. Work in a Well-Ventilated Area: When conducting maintenance, choose a location with sufficient airflow. Adequate ventilation reduces the accumulation of harmful fumes and improves comfort during lengthy tasks.

4. Keep the Workspace Clean: A tidy environment minimizes hazards. Remove any debris, tools, or materials that could cause tripping or impede movement while working.

5. Follow Manufacturer Guidelines: Always refer to the manufacturer’s instructions for specific safety measures related to your equipment. These guidelines offer valuable insights and help ensure safe practices during maintenance.