Efficient and smooth-running engines are vital for numerous tasks, and understanding how to care for and troubleshoot them can extend their lifespan and enhance performance. This section provides insights and methods to address common issues, as well as practical upkeep advice to help ensure long-lasting functionality.

Basic checks and routine care are essential steps to keeping your equipment reliable and ready for use. With proper techniques and maintenance, many operational issues can be minimized. Here, we cover essential practices and give practical guidance on inspecting and handling key components.

For any mechanical system, knowing the inner workings and common concerns helps prevent unexpected breakdowns. By following the steps outlined, you can keep your machinery in optimal condition, manage minor complications independently, and achieve cons

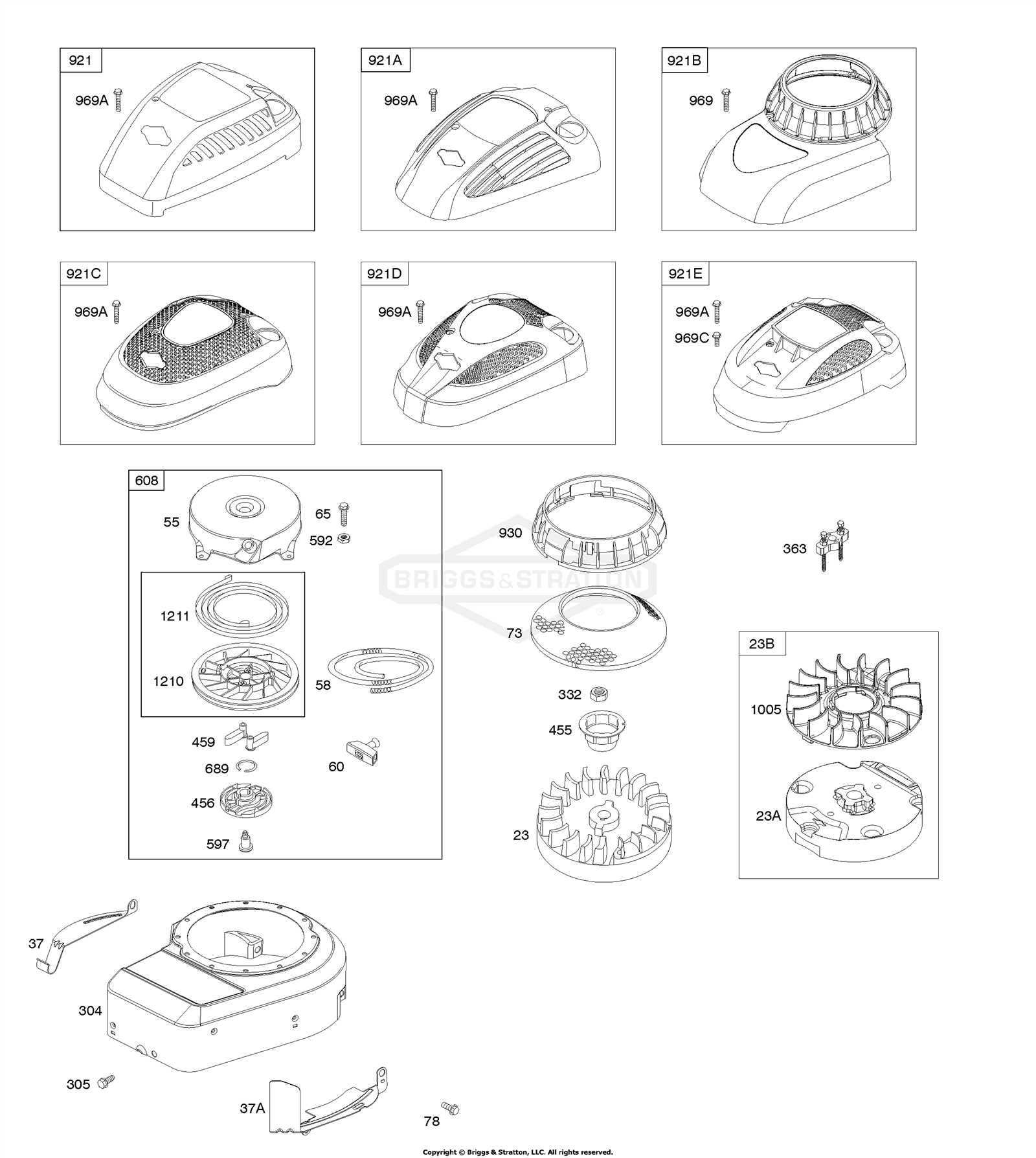

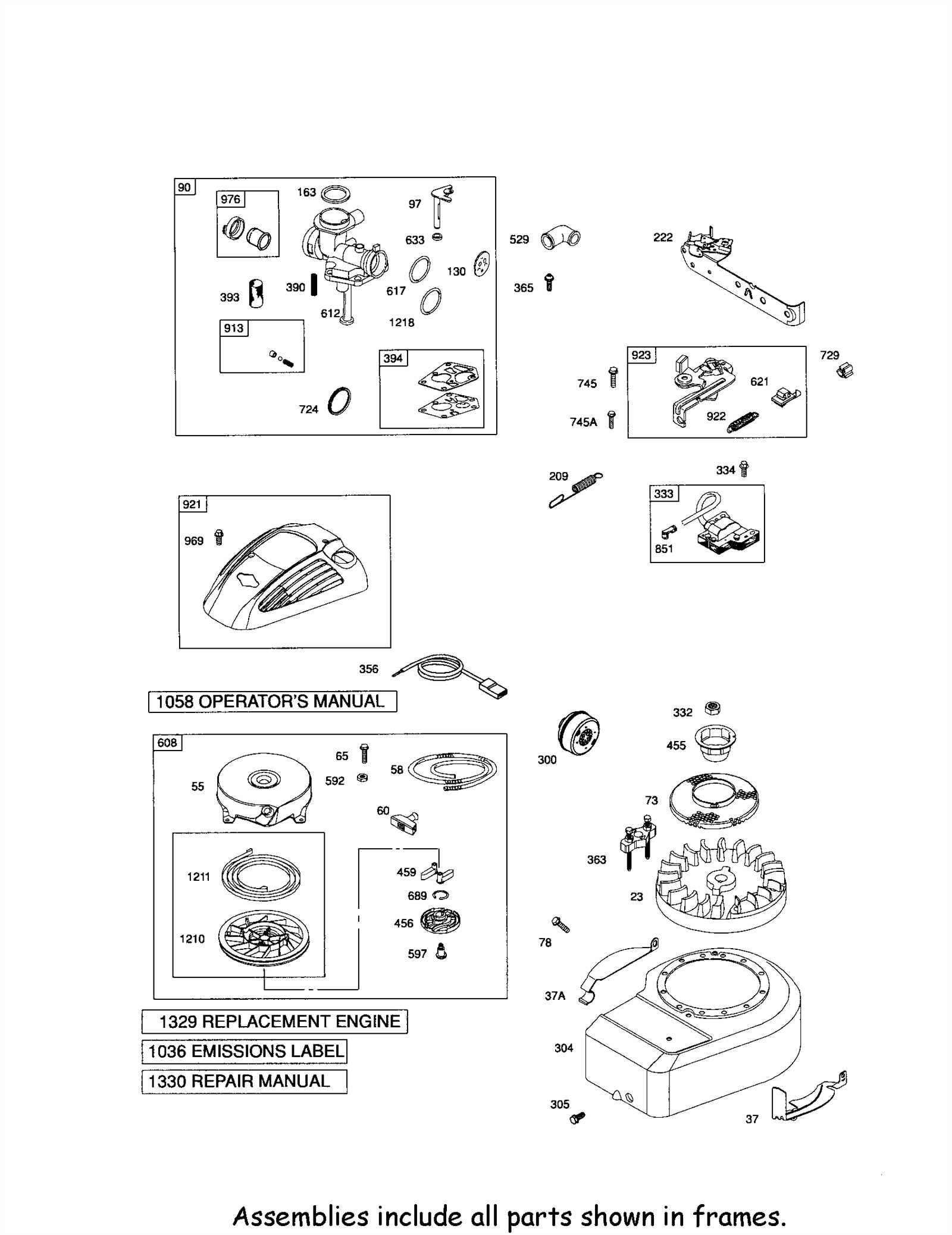

Briggs and Stratton 10T502 Repair Manual

Understanding the maintenance essentials and common issues for a small engine is crucial to ensure its longevity and reliable performance. This guide provides structured insights into preventive care, troubleshooting techniques, and essential maintenance practices, helping you keep your equipment in excellent condition.

Regular Maintenance Steps

- Inspect and clean air filters periodically to prevent dust buildup.

- Change oil at regular intervals to ensure smooth engine operation.

- Check fuel levels and refill using recommended fuel types to avoid unwanted residues.

- Socket and Wrench Set: A quality set of sockets and wrenches is vital for loosening and tightening different-sized bolts and nuts, providing versatility across various tasks.

- Screwdrivers: Both flathead and Phillips screwdrivers in multiple sizes allow for

Identifying Common Issues in Engines

Engines can experience a variety of issues over time, especially as components wear and operational demands increase. Recognizing these problems early on can prevent extensive damage and ensure better performance. Below are some frequent symptoms and their possible causes, which can help pinpoint where attention is needed.

Poor Starting Performance: If an engine struggles to start or requires multiple attempts, the issue may stem from the fuel system or ignition components. Check for clogs in fuel lines, stale fuel, or worn spark plugs that might be hindering ignition.

Uneven Running or Stalling: Engines that run inconsistently or stall unexpectedly often indicate a problem with the carburetor or air intake. A blocked air filter or carb

Step-by-Step Engine Disassembly Guide

Disassembling an engine carefully and systematically allows for a thorough inspection of all components, making it easier to address any wear or damage. This guide provides a structured approach to dismantling, with detailed steps to ensure parts are handled safely and stored properly.

Preparation and Initial Steps

Before starting, ensure the engine is completely cool and the work area is clean and organized. Begin by draining the fuel and oil to prevent spills. Disconnect any wiring or attached components that may obstruct access to the main parts.

Removing Key Components

Replacing Worn Out Engine Parts

Over time, various components within an engine can experience wear, leading to reduced efficiency or even malfunction. Replacing these parts ensures that the machine operates smoothly and maintains peak performance.

Start by identifying which parts need attention. Components such as the air filter, spark plug, and carburetor are often subject to frequent wear. Check these elements thoroughly, as they play a key role in fuel combustion and airflow, impacting the engine’s overall function.

Once you identify worn parts, carefully remove them following safe practices, avoiding damage to surrounding components. Installing new parts in place of old ones can revitalize the system, offering a significant improvement in efficiency. Make sure each replacement is securely fitted and compatible with the engine model.

Regular inspection and timely replacement of worn parts can prevent larger mechanical issues and extend the life of the engine. Keeping up with these simple yet effective practices contributes to reliable and smooth operation.

Tips for Improving Engine Efficiency

Enhancing the performance of an engine involves several key practices that can lead to increased efficiency and longevity. By focusing on regular maintenance and mindful usage, one can ensure optimal functionality and minimize unnecessary wear and tear.

Regularly checking and replacing the air filter can significantly improve airflow, allowing the engine to breathe better and perform more effectively. Ensuring that the fuel system is clean and free of contaminants will also contribute to smoother operation.

Using high-quality fuel can enhance combustion, leading to better power output and reduced emissions. Additionally, maintaining proper tire pressure and ensuring all components are well-lubricated can further optimize performance.

Finally, adopting efficient driving habits, such as smooth acceleration and avoiding excessive idling, can greatly influence overall engine efficiency. By implementing these strategies, users can experience a notable improvement in engine performance.

Engine Reassembly Techniques for Beginners

Reassembling an engine can be a daunting task for newcomers, but with the right approach and techniques, it can also be a rewarding experience. Understanding the essential steps and proper methods is crucial to ensure that the engine functions correctly after reassembly. This section outlines fundamental practices to simplify the process and enhance your confidence.

Essential Tools and Materials

Before beginning the reassembly, gather the necessary tools and materials to make the process smoother. Here is a list of items you’ll likely need:

- Torque wrench

- Socket set

- Screwdrivers (flat and Phillips)

- Pliers

- Cleaning supplies (degreaser, rags)

- Gaskets and seals

Step-by-Step Reassembly Process

Following a systematic approach during reassembly helps prevent mistakes. Consider these steps:

- Start by cleaning all components to remove any dirt or debris.

- Carefully inspect each part for wear and damage, replacing as necessary.

- Begin with the lower block assembly, ensuring that all gaskets are properly placed.

- Attach the crankshaft, making sure to use the correct torque specifications.

- Proceed to install the piston and connecting rod, taking care to align them accurately.

- Reassemble the cylinder head, ensuring all bolts are tightened evenly.

- Complete the assembly by reattaching any additional components, such as the intake and exhaust systems.

By following these techniques and tips, beginners can successfully navigate the engine reassembly process, paving the way for a smoother operation and longer lifespan of the engine.

Proper Maintenance for Longevity

Ensuring the durability of your equipment involves regular upkeep and attention to detail. By adhering to a structured maintenance routine, you can significantly enhance performance and extend the lifespan of your machinery. This section will outline essential practices that contribute to optimal functioning and reliability.

Regular Cleaning and Inspection

One of the most critical aspects of maintenance is keeping the machinery clean. Debris and dirt can lead to overheating and inefficiency. Regularly inspect the components for wear and tear, replacing any parts that show signs of damage. This proactive approach prevents minor issues from escalating into major repairs.

Lubrication and Fluid Checks

Proper lubrication is vital for the smooth operation of moving parts. Regularly check and replenish fluids to ensure everything runs efficiently. Using the recommended lubricants can reduce friction and wear, thus enhancing performance. Make it a habit to review these elements routinely to avoid unexpected breakdowns.

Understanding the Fuel System

The fuel system is a crucial component in any small engine, responsible for delivering the right mixture of air and fuel to ensure optimal performance. This system plays a vital role in the engine’s operation, impacting efficiency, power output, and overall reliability.

Within this system, several elements work together to facilitate fuel flow. The fuel tank stores the fuel, while the fuel pump transports it to the carburetor or injector. Proper filtration is essential to keep contaminants from entering the system, which could hinder performance or cause damage.

Understanding how each part functions will enable you to diagnose issues effectively. Regular maintenance, including checking fuel quality and ensuring all components are clean and functioning properly, can prevent common problems associated with fuel delivery.

Troubleshooting Electrical Components

This section aims to guide users through diagnosing issues related to electrical systems in small engines. Understanding common electrical problems can significantly aid in restoring optimal performance and functionality.

When facing electrical malfunctions, consider the following steps to identify and resolve the issues:

- Inspect the Battery: Ensure the battery is fully charged and connections are clean and secure.

- Check Fuses: Examine all fuses for continuity. Replace any that are blown.

- Examine Wiring: Look for any frayed, damaged, or corroded wires that could interrupt the circuit.

- Test the Ignition System: Verify that the ignition coil is functioning properly by testing for spark at the spark plug.

If issues persist after these checks, consider seeking assistance from a qualified technician for further diagnosis.

Cleaning and Care for Engine Components

Maintaining engine components is crucial for optimal performance and longevity. Regular cleaning helps prevent the buildup of dirt, grime, and other debris that can impair functionality. Proper care ensures that all parts work efficiently, reducing wear and extending the lifespan of the equipment.

Essential Cleaning Techniques

To begin, detach any removable parts from the engine. Use a soft brush to gently remove loose dirt, followed by a cloth dampened with a suitable cleaning solution. For stubborn stains, a mild abrasive can be applied with care. Always ensure that no moisture enters electrical components, as this can cause damage.

Regular Maintenance Tips

In addition to cleaning, regularly inspect engine components for signs of wear or damage. Lubricate moving parts according to manufacturer recommendations, and replace any worn or broken components promptly. Keeping the engine clean and well-maintained will contribute significantly to its overall efficiency and reliability.

Choosing the Right Replacement Parts

Selecting the appropriate components for your equipment is crucial for ensuring optimal performance and longevity. Identifying high-quality replacements that meet the specifications of your machinery will help maintain its functionality and efficiency.

Factors to Consider

When searching for suitable components, it is important to take several factors into account:

Factor Description Compatibility Ensure that the parts match the specifications of your equipment. Quality Opt for components made from durable materials to enhance longevity. Brand Reputation Choose manufacturers known for their reliability and quality standards. Price Evaluate the cost in relation to the value and performance of the part. Where to Source Parts

Components can be acquired from various sources, including local dealers, online retailers, and specialty shops. Researching reviews and feedback will assist in identifying reputable vendors that provide genuine parts.

Essential Tools for Effective Repairs

To ensure maintenance tasks are efficient and successful, having the right set of tools is crucial. Equipped with essential items, you can address various mechanical issues confidently and achieve reliable results.