For enthusiasts of finely brewed beverages, the art of crafting the perfect cup is paramount. Understanding the inner workings of your favorite appliance can significantly enhance your brewing experience. This section aims to provide essential insights into addressing common issues that may arise, ensuring that your coffee ritual remains uninterrupted.

As with any appliance, wear and tear can lead to various malfunctions, from minor inconveniences to more significant hurdles. Gaining knowledge about potential problems and their solutions empowers users to take action swiftly. With a few straightforward techniques and a bit of guidance, you can restore your beloved apparatus to its optimal condition.

Whether it’s learning how to address temperature inconsistencies or dealing with unusual sounds, having the right information at hand is invaluable. Embrace the opportunity to dive into the troubleshooting process, transforming potential setbacks into seamless solutions that enhance your daily brewing routine.

Common Breville Espresso Machine Issues

Many users encounter a variety of challenges with their coffee brewing devices over time. Understanding these common complications can greatly enhance the overall experience and extend the lifespan of the equipment. Whether it’s problems with functionality, brewing quality, or maintenance, recognizing these issues early can lead to more effective solutions.

Common Functional Challenges

Devices often experience difficulties in achieving the desired temperature or pressure, resulting in subpar coffee. Users may also notice irregularities in the brewing cycle, such as inconsistent extraction times or the inability to create sufficient crema. Regular checks and proper maintenance can help mitigate these concerns.

Maintenance-Related Concerns

Another frequent area of difficulty stems from the build-up of mineral deposits or coffee residue. This can lead to clogs in the system, affecting water flow and overall performance. Implementing a consistent cleaning routine, including descaling and proper cleaning of components, is essential for optimal functionality.

Identifying Extraction Problems

Understanding the nuances of coffee brewing is essential for achieving the desired flavor and quality in your beverages. Various factors can affect the extraction process, leading to undesirable results. This section aims to provide insights into recognizing and diagnosing issues related to the brewing technique, enabling you to enhance the overall experience of your coffee.

Common Symptoms of Extraction Issues

- Inconsistent flavor profile

- Excessive bitterness or sourness

- Poor crema quality

- Unusual brew times

Possible Causes and Solutions

-

Grind Size:

The fineness of the coffee grounds plays a critical role. If the grounds are too coarse, the result may be under-extracted. Conversely, overly fine grounds can lead to over-extraction.

-

Water Temperature:

Temperature fluctuations can significantly impact extraction. Ideally, water should be between 195°F and 205°F for optimal results.

-

Pressure Consistency:

Maintaining consistent pressure during brewing is vital. Fluctuations can lead to uneven extraction and affect taste.

-

Freshness of Coffee:

Stale coffee can drastically alter flavor. Always use freshly roasted and properly stored beans.

Maintaining Your Espresso Machine

Regular upkeep is essential for ensuring optimal performance and longevity of your brewing appliance. By following a consistent maintenance routine, you can enhance the quality of your beverages and minimize the likelihood of malfunctions. This section covers various practices that will help you keep your device in top condition.

Daily Care

Performing simple tasks on a daily basis can significantly impact the functionality of your brewing tool. Consider the following steps:

- Clean the brew basket and portafilter after each use to prevent buildup of coffee residues.

- Rinse the water reservoir and refill it with fresh water to ensure optimal extraction.

- Wipe down the exterior to remove any spills or stains, maintaining a clean appearance.

Periodic Maintenance

In addition to daily tasks, there are periodic checks and actions that should be performed to prolong the life of your device:

- Descale the unit every few months to eliminate mineral deposits from water.

- Inspect and replace any worn or damaged seals and gaskets to prevent leaks.

- Check the power cord and plug for any signs of wear and replace if necessary.

Tools for Effective Repairs

Successful maintenance and troubleshooting rely on having the right tools on hand, enhancing precision, efficiency, and safety. Whether addressing minor adjustments or more intricate fixes, equipping oneself with essential instruments makes each step smoother and more manageable.

Basic Hand Tools

- Screwdrivers: A set of Phillips and flathead screwdrivers, in various sizes, is essential for accessing tight spaces and securing small components.

- Wrenches: Adjustable and socket wrenches are crucial for loosening bolts and nuts of different sizes, especially in areas with limited maneuverability.

- Pliers: Needle-nose and slip-joint pliers provide grip and control, assisting in reaching small or hard-to-access parts.

Specialized Diagnostic Tools

- Multimeter: Ideal for electrical assessments, a multimeter allows for quick voltage, current, and continuity testing, helping to pinpoint faulty circuits.

- Thermometer: Digital thermometers monitor heat levels, which can indicate issues with temperature regulation in key components.

- Pressure Gauge: Useful for evaluating system pressure, helping ensure stability in parts where consistent pressure is critical.

Using the proper tools not only simplifies tasks but also safeguards parts from damage, enabling smoother, long-lasting fixes. These essentials are integral to achieving effective results and extending equipment durability.

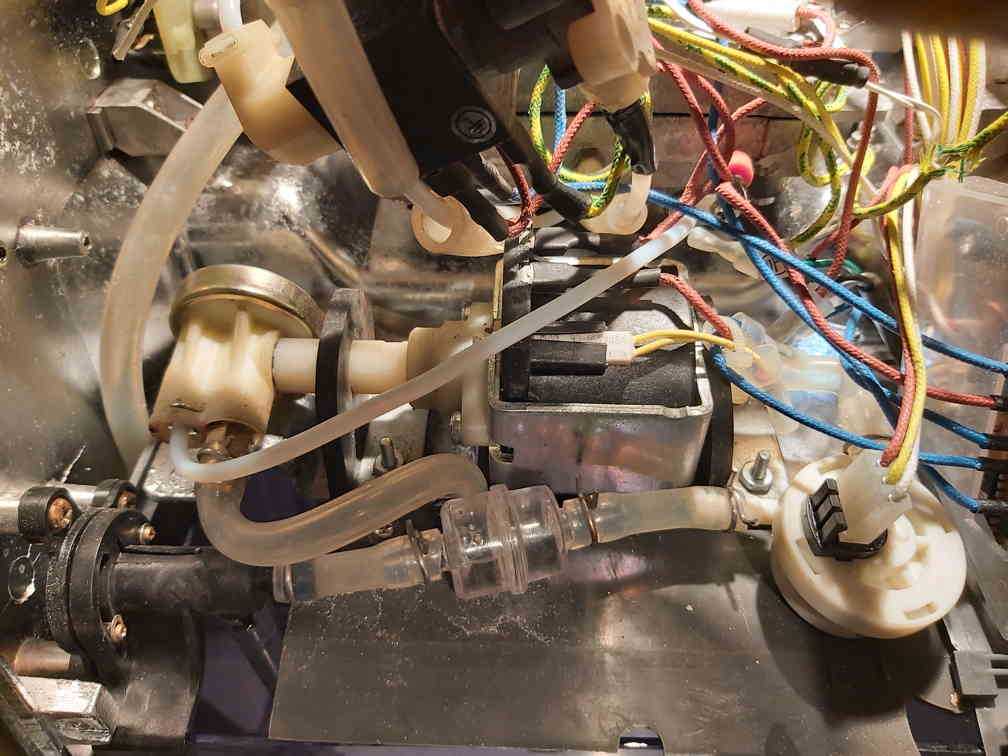

Understanding Espresso Machine Components

To fully appreciate the nuances of making high-quality coffee, it helps to understand the various parts involved in this process. Each component plays a unique role, and knowing their functions can make maintenance and adjustments much easier.

- Boiler: The heart of the brewing process, responsible for heating water to the correct temperature. Consistent heat is essential for achieving rich, balanced flavor.

- Group Head: This is the point where hot water is channeled through the ground beans. A well-maintained group head ensures even distribution for optimal taste.

- Portafilter: The handle and basket assembly that holds the grounds. A snug fit and clean surface here contribute to consistent extraction and pressure.

- Steam Wand: Used to heat and texture milk, this component needs regular cleaning to avoid blockages and maintain efficient steaming.

- Pump: Responsible for delivering water at the required pressure, a steady pump is crucial for achieving a smooth, balanced pour.

Each part works in harmony with the others, making it essential to recognize their individual contributions. Regular maintenance and attention to these components ensure a dependable and high-quality experience over time.

How to Clean the Brew Head

Regular maintenance of the brew head is essential for optimal performance and to ensure flavorful beverages. Keeping this area clean prevents build-up that can impact both functionality and taste quality.

- Begin by turning off and unplugging the unit to ensure safety during cleaning.

- Remove any removable parts around the brew head carefully, if accessible, for a more thorough cleaning.

- Use a small, soft brush to gently clear out any grounds and residue from the head’s openings.

- For deeper cleaning, dampen a cloth with warm water and gently wipe the surfaces around the brew head.

- Once visible debris is removed, consider running a cleaning cycle with water only to flush any remaining particles.

- Allow all parts to dry completely before reassembling and powering the unit back on.

By regularly following these steps, you ensure a consistently smooth brewing experience while extending the equipment’s longevity.

Water Temperature Adjustments

Achieving optimal water temperature is essential for enhancing the depth of flavor and aroma. Adjusting the temperature settings can greatly influence the final outcome, allowing for a more balanced and enjoyable experience.

- Identify Ideal Temperature Range: For balanced results, aim to adjust the water within a moderate temperature range. This helps in balancing both acidity and bitterness.

- Gradual Adjustments: Small, incremental changes to the water temperature often yield the best results. Adjusting in steps allows for better control over taste and consistency.

- Monitor Consistency: Consistent water temperature throughout each brewing session ensures that each cup maintains a stable and desirable flavor profile.

Maintaining and fine-tuning water temperature is an effective way to experiment and personalize each cup’s profile, leading to a satisfying and flavorful result every time.

Troubleshooting Leaks and Drips

Unwanted leaks and persistent drips can disrupt the enjoyment of a well-prepared beverage. When these issues arise, they often point to minor issues within the system, which can usually be corrected through some straightforward checks and adjustments. Regular upkeep and prompt attention to small signs of trouble can help prevent more serious concerns over time.

Identifying the Source of the Leak

To determine where fluid is escaping, carefully examine areas around the water reservoir, the fittings, and the valves. Ensure that seals and gaskets are correctly positioned and intact, as wear or misalignment in these areas is often a common cause. Tightening loose connections and replacing any worn-out parts can often resolve the problem.

Preventing Future Drips

Dripping can sometimes result from accumulated debris or residue. Clean components such as the dispensing system and filtering areas to maintain a smooth flow. Periodic deep cleaning, particularly in areas prone to buildup, helps prevent blockages and maintains consistent performance. Make it a habit to check for small signs of wear and adjust parts as needed to ensure lasting reliability.

Replacing Worn-Out Seals

Over time, seals may become less effective due to regular usage, leading to potential leaks or performance issues. Replacing these components can restore the equipment’s functionality and prevent further wear on internal parts. This section covers the necessary steps and materials required to efficiently replace worn seals, ensuring a reliable and consistent operation.

Tools and Materials Needed

- Replacement seals compatible with your model

- Screwdriver set

- Non-abrasive cleaning cloth

- Lubricant safe for food-related equipment

Step-by-Step Guide to Seal Replacement

- Power Down and Cool Off: Unplug the device and allow any residual heat to dissipate fully.

- Disassemble the Necessary Parts: Use a screwdriver to carefully remove any panels or screws securing the internal components. Keep all screws in a safe place for reassembly.

- Locate and Remove Old Seals: Find the worn seals within the device, noting their position and orientation. Gently pull out the old seals and inspect the surrounding area for any residue or wear.

- Clean and Prepare the Area: Use a non-abrasive cloth to clean any build-up or debris around the seal slots, ensuring a smooth surface for the new parts.

- Install New Seals: Apply a small amount of lubricant if recommended, then carefully insert the new seals into place, ensuring they are aligned and seated correctly.

- Reassemble the Device: Replace any panels or components removed during disassembly, securing all screws firmly.

Once reassembled, test the device to ensure the new seals are functioning properly, and inspect for any minor leaks that may require adjustments. Regular inspection and timely replacement of worn seals can greatly extend the lifespan of the equipment.

Electrical Issues and Solutions

Addressing electrical problems in complex appliances requires a careful approach to identify and resolve underlying power-related disruptions. Recognizing common electrical concerns and understanding their causes can help prevent damage and ensure reliable operation.

Power Connection and Circuit Protection

One of the first areas to examine is the power connection. Faulty or loose connections, often at the plug or socket level, can lead to erratic operation. Inspect the power cord for any visible damage, such as fraying or cracks, and ensure that it is firmly plugged into a working outlet. Additionally, consider the circuit’s capacity; overloaded circuits can trigger protective devices, disrupting the appliance’s performance. Verify that the appliance is on a dedicated circuit to avoid unnecessary tripping of breakers.

Internal Wiring and Component Testing

Internal wiring problems are less obvious but equally impactful. Worn or disconnected wires within the appliance can hinder proper function, often due to prolonged usage or excessive movement. Regularly checking internal connections and ensuring components like fuses and capacitors are in good condition is vital. Use a multimeter to test continuity across wiring and components to pinpoint any breaks or irregularities. Replacing faulty parts or re-securing loose connections can restore optimal function and prevent further electrical issues.

When to Seek Professional Help

Understanding when it’s time to consult a specialist can prevent further complications and ensure a smoother resolution. While some issues can be resolved with simple maintenance, others may require the knowledge of an experienced technician.

Signs That Require Expert Attention

- Unusual noises: Persistent sounds during operation, such as grinding or hissing, may indicate internal problems that need specialized care.

- Inconsistent performance: If you notice fluctuations in output or quality that regular upkeep cannot fix, an expert can diagnose deeper mechanical issues.

- Leakage: Water or steam escaping from unusual areas points to potential damage in seals or connections, which are best handled by a professional.

Technical Indicators of Professional Needs

- Error codes or warning lights: If certain lights or codes appear on the display, they often signify specific malfunctions that require diagnostic tools only professionals have access to.

- Electrical issues: Problems with powering on, frequent shutdowns, or electrical failures should always be addressed by a certified technician to avoid hazards.

Relying on trained experts when these signs emerge can save both time and resources, ensuring optimal performance and longevity.

Benefits of Regular Maintenance Checks

Performing routine upkeep on coffee equipment offers substantial advantages, enhancing both the lifespan and performance quality of the device. Consistent care ensures smooth operation, helping to avoid issues that could disrupt functionality. Users can enjoy reliable operation, greater consistency in brewing, and reduced long-term costs associated with repairs.

- Extended Lifespan: Routine checks help components last longer, minimizing the wear and tear that leads to breakdowns.

- Improved Performance: Well-maintained equipment delivers better flavor, as clean and adjusted parts function optimally.

- Cost Savings: Preventative maintenance helps avoid costly repairs by addressing minor issues before they escalate.

- Enhanced Safety: Regular inspections contribute to safer use, ensuring that all components are functioning as intended.

- Consistent Quality: Regularly cared-for systems provide more reliable brewing quality, giving users a dependable experience each time.

Adopting a maintenance schedule keeps the equipment in peak condition, ultimately making each use more efficient and enjoyable.