When it comes to maintaining heavy machinery, understanding the intricacies of their operation is essential for ensuring longevity and efficiency. This resource aims to equip operators and technicians with the necessary knowledge to troubleshoot and perform routine maintenance on specific models, enhancing their performance and reliability. Whether you’re a seasoned professional or a newcomer to the field, grasping the fundamentals will prove invaluable.

In this guide, readers will find detailed insights into various components and systems, enabling them to address common issues and implement effective solutions. The focus is on practical tips and systematic approaches that empower users to confidently handle their machinery, ensuring optimal functionality under various working conditions. By familiarizing oneself with the underlying mechanics, individuals can prevent minor concerns from escalating into significant setbacks.

With a strong emphasis on safety and efficiency, this document serves as a cornerstone for anyone looking to enhance their technical expertise. The aim is to foster a deeper understanding of equipment maintenance, promoting a proactive mindset that can save time and resources. Let’s delve into the specifics that will help you navigate the complexities of machinery upkeep with ease and proficiency.

Understanding the Case MX 135

This section delves into the intricacies of a well-regarded agricultural machine designed for efficiency and versatility. Its robust build and advanced features make it a favorite among farmers and operators, facilitating a range of tasks from tilling to transportation. By comprehensively exploring its components and functionalities, users can maximize its potential in various farming applications.

Key Features and Specifications

The equipment boasts an impressive power output, enabling it to handle demanding tasks with ease. Its ergonomic design ensures comfort for the operator, while intuitive controls enhance usability. Understanding the specifications is crucial for anyone looking to maintain optimal performance and achieve the best results in the field.

Maintenance and Care

Regular upkeep is essential for sustaining the lifespan and efficiency of this machine. Familiarizing oneself with recommended practices for maintenance not only prevents potential issues but also ensures reliable operation during peak seasons. Investing time in care will yield substantial returns in productivity and performance.

Key Features of Case MX 135

This section highlights the distinctive characteristics that set this agricultural machine apart in the market. It combines advanced engineering with user-friendly functionality, making it a reliable choice for various farming tasks.

| Feature | Description |

|---|---|

| Power Output | Equipped with a robust engine that delivers exceptional horsepower for demanding applications. |

| Hydraulic System | Advanced hydraulics allow for efficient lifting and control of attachments, enhancing productivity. |

| Transmission | Smooth shifting capabilities provide operators with seamless transitions between speeds for optimal performance. |

| Cab Comfort | Designed with ergonomic seating and controls, ensuring operator comfort during long hours of use. |

| Versatility | Compatible with a wide range of implements, making it suitable for various agricultural operations. |

Common Issues with Case MX 135

The machinery in question often encounters a range of challenges that can affect performance and reliability. Understanding these common problems is crucial for effective maintenance and ensuring optimal functionality over time.

Hydraulic System Failures

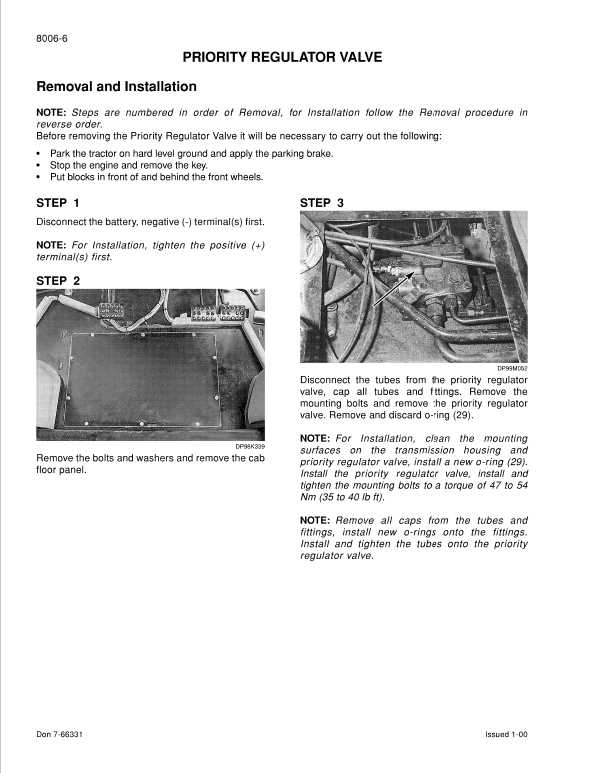

One frequent issue involves the hydraulic system, which may exhibit leaks or pressure drops. These problems can stem from worn seals or damaged hoses, leading to reduced lifting capabilities. Regular inspections and timely replacements of components are essential to maintain hydraulic efficiency.

Engine Performance Problems

Another area of concern is engine performance. Operators may notice issues such as poor starting or uneven power delivery. These symptoms can often be traced back to fuel delivery problems or clogged filters. Ensuring that fuel systems are clean and well-maintained can help prevent these performance hiccups.

Essential Tools for Repairs

When it comes to maintaining and fixing machinery, having the right equipment is crucial for efficiency and effectiveness. A well-equipped toolbox ensures that you can tackle a variety of tasks with confidence and precision. Below, we outline the fundamental instruments you’ll need to perform various maintenance tasks.

Basic Hand Tools

- Sockets and Wrenches: These are essential for loosening and tightening bolts and nuts.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is necessary for assembling and disassembling components.

- Pliers: Useful for gripping, twisting, and cutting wires or other materials.

- Hammer: Ideal for driving nails or fitting parts together.

Diagnostic Equipment

- Multimeter: Essential for measuring voltage, current, and resistance, aiding in electrical troubleshooting.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications.

- Diagnostic Scanner: Helps in identifying issues by reading error codes from electronic systems.

Equipping yourself with these tools will not only make tasks easier but also enhance your ability to maintain machinery effectively.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring machinery operates at peak efficiency and longevity. Establishing a systematic approach to maintenance not only enhances performance but also minimizes the risk of unexpected breakdowns. A well-structured schedule allows operators to address potential issues proactively and maintain optimal functionality.

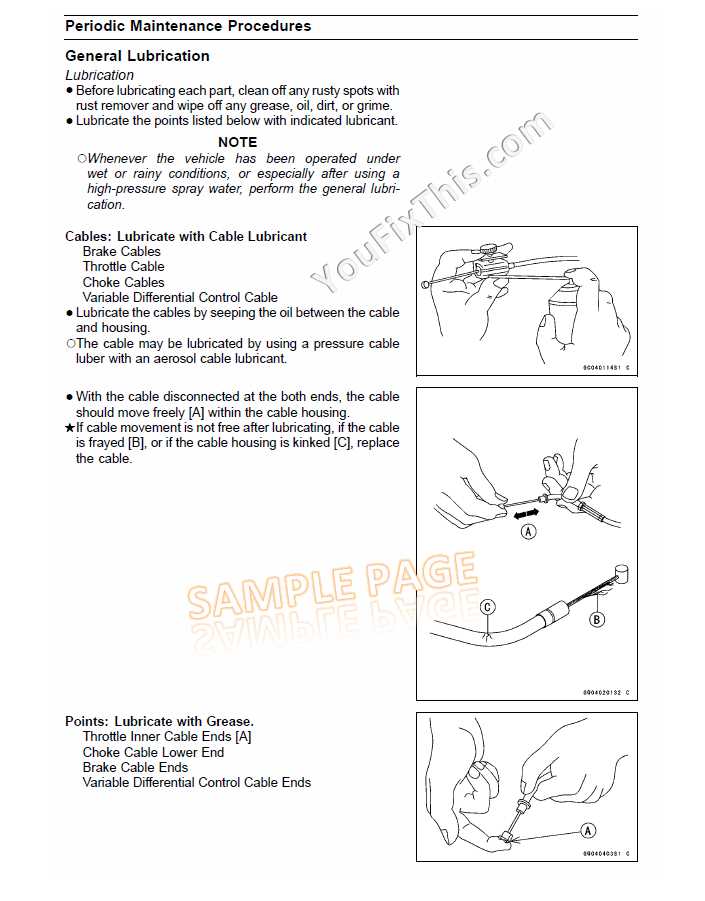

Begin by outlining daily inspections, focusing on key components such as fluid levels, filters, and belts. This routine check ensures that any minor discrepancies are caught early, preventing more significant problems later. Weekly and monthly tasks should include a thorough cleaning of critical parts, lubrication of moving components, and testing of safety features to ensure everything operates smoothly.

Seasonal maintenance is equally important, involving more extensive evaluations and replacements, such as tires, hydraulic fluids, and electrical systems. Keeping detailed records of all maintenance activities helps in tracking the performance history and can aid in identifying patterns that require attention. Adhering to this structured schedule fosters a reliable operational environment and extends the life of the equipment.

Step-by-Step Repair Guide

This section provides a detailed process for addressing common issues in machinery, ensuring optimal performance and longevity. Following these guidelines can help you navigate through various challenges, allowing for effective solutions with minimal hassle.

Begin by gathering all necessary tools and materials. Having everything at hand before starting will streamline the procedure. It’s essential to work in a well-lit and organized space to enhance efficiency and safety.

Next, identify the specific problem you are encountering. Conduct a thorough inspection to pinpoint the source of the malfunction. Document any irregularities or warning signs to reference later.

Once you have diagnosed the issue, consult your resources for specific instructions related to your model. Each step should be approached with caution, ensuring all safety protocols are followed to prevent accidents.

Proceed with disassembly if required. Take care to label and store parts systematically to avoid confusion during reassembly. It’s often helpful to take photos throughout this process for reference.

After addressing the core issue–whether it’s replacing a worn component, cleaning, or adjusting settings–reassemble the machinery carefully. Double-check all connections and ensure that parts are secured properly.

Finally, conduct a test run to confirm that everything operates as intended. Monitor for any unusual sounds or behaviors, and be prepared to make additional adjustments if necessary. Regular maintenance following these guidelines can extend the life of your equipment and prevent future problems.

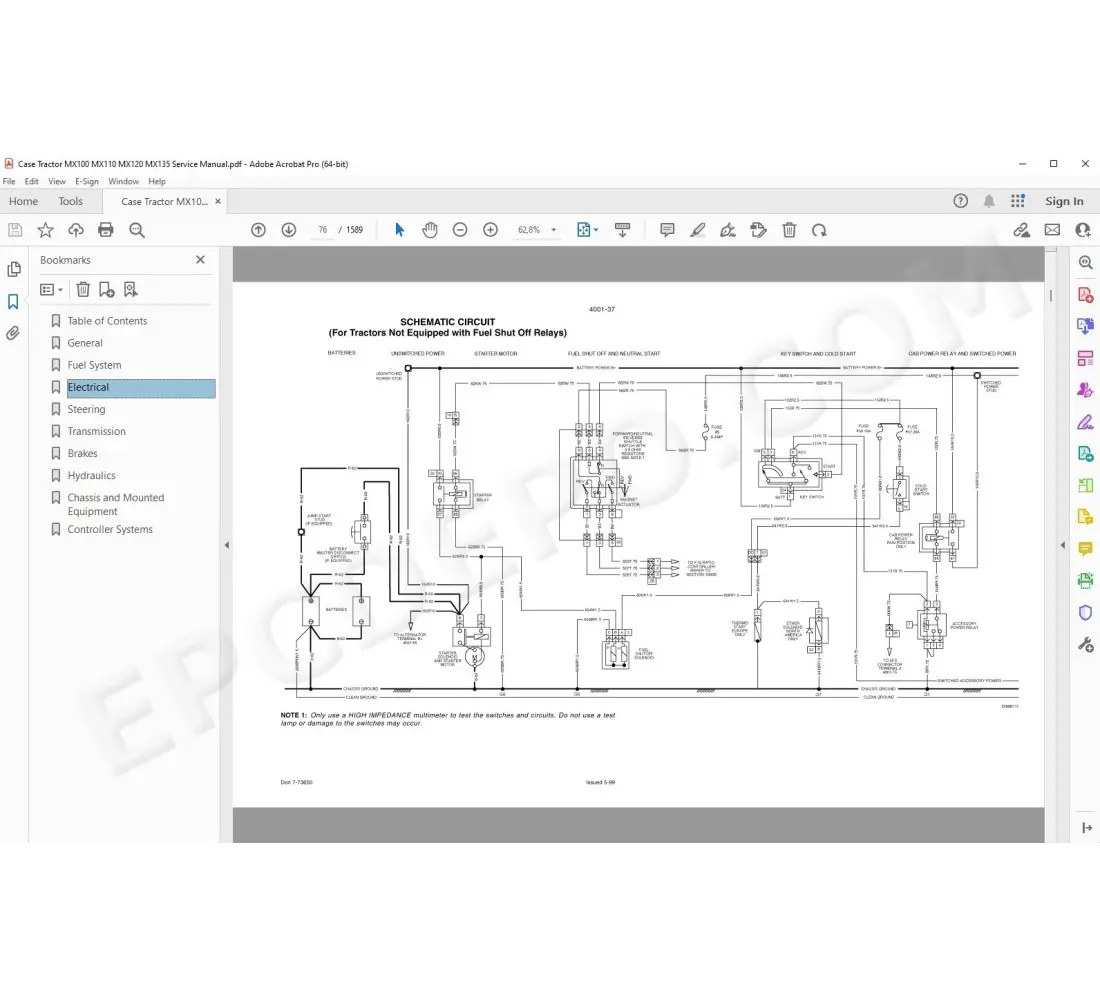

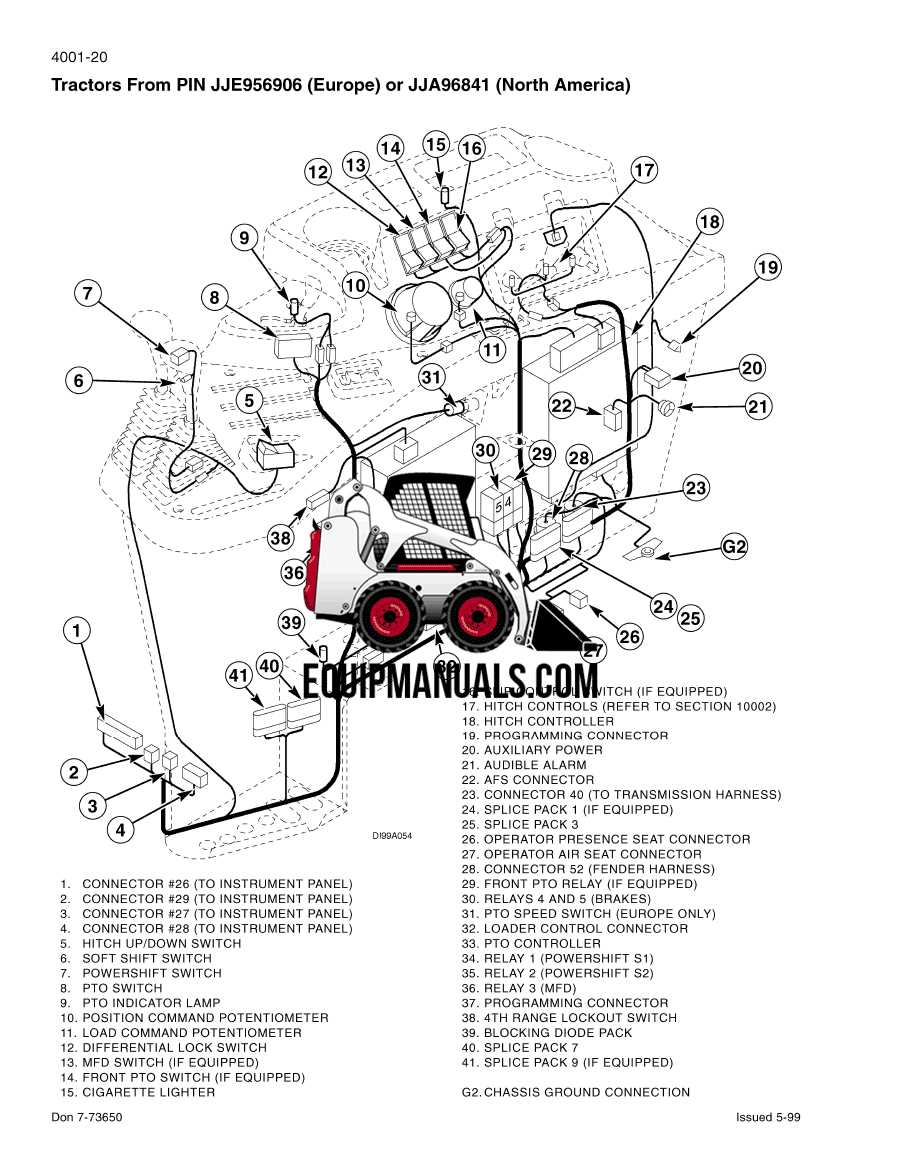

Electrical System Troubleshooting

Troubleshooting electrical systems requires a systematic approach to identify and resolve issues that may hinder performance. This section provides essential steps and tips for diagnosing common problems within the circuitry of your equipment. Understanding the components and their functions will help streamline the troubleshooting process.

Common Symptoms and Their Causes

When facing electrical issues, recognizing symptoms is crucial. Here are some typical indicators and potential underlying causes:

- No Power: Check the battery charge, fuses, and connections.

- Intermittent Operation: Inspect wiring for wear or loose connections.

- Dim Lights: Look for faulty bulbs or voltage drop in the circuit.

- Blown Fuses: Determine if there are short circuits or overloads.

Troubleshooting Steps

Follow these steps to effectively diagnose and fix electrical issues:

- Begin with a visual inspection of all electrical components.

- Use a multimeter to check voltage levels at various points in the system.

- Test the battery and charging system for proper functionality.

- Trace wiring and connections for signs of damage or corrosion.

- Replace any defective parts as needed and retest the system.

By systematically following these guidelines, you can effectively address and resolve electrical challenges, ensuring optimal performance of your machinery.

Engine Overhaul Procedures Explained

Overhauling an engine is a meticulous process that involves a thorough examination and refurbishment of its critical components. This procedure is essential for restoring performance, improving efficiency, and extending the lifespan of the machinery. Understanding the various stages of this undertaking ensures that each aspect is addressed systematically and effectively.

Initial Assessment: The first step is to conduct a comprehensive evaluation of the engine’s condition. This includes checking for leaks, unusual noises, and any signs of wear. Gathering diagnostic information helps in determining the extent of the work required.

Disassembly: After the assessment, the engine is carefully disassembled. Each part must be labeled and organized to ensure proper reassembly later. This stage requires attention to detail, as even small components can significantly impact overall performance.

Cleaning: Once disassembled, all parts undergo a thorough cleaning process. Removing debris, carbon deposits, and old lubricants is crucial to prevent contamination during reassembly. Specialized cleaning agents and techniques are often employed to achieve optimal results.

Inspection: With clean components, the next step is a detailed inspection. Technicians examine for cracks, warping, and other imperfections that could affect functionality. Measuring tolerances with precision tools ensures that parts meet the necessary specifications.

Repairs and Replacements: Damaged components may need to be repaired or replaced. This could involve machining worn surfaces or sourcing new parts. Ensuring high-quality materials and adherence to specifications is vital for the longevity of the overhaul.

Reassembly: Once repairs are completed, the reassembly process begins. Following the original specifications and using the correct torque settings is essential to guarantee that the engine operates smoothly. A systematic approach helps prevent errors during this critical phase.

Testing: After reassembly, rigorous testing is conducted to verify that the engine operates as intended. This includes running the engine under various conditions to check for performance, efficiency, and reliability. Any issues identified during testing are addressed promptly.

In conclusion, understanding the engine overhaul procedures is fundamental for achieving optimal performance and reliability. Each phase, from assessment to testing, plays a pivotal role in the success of the process, ensuring that the engine operates at its best for years to come.

Hydraulic System Insights

The hydraulic system is a crucial component in enhancing the performance and functionality of agricultural machinery. This intricate network of fluid dynamics plays a vital role in powering various attachments and implements, ensuring efficient operation under diverse conditions. Understanding its design and maintenance can lead to improved reliability and longevity of the equipment.

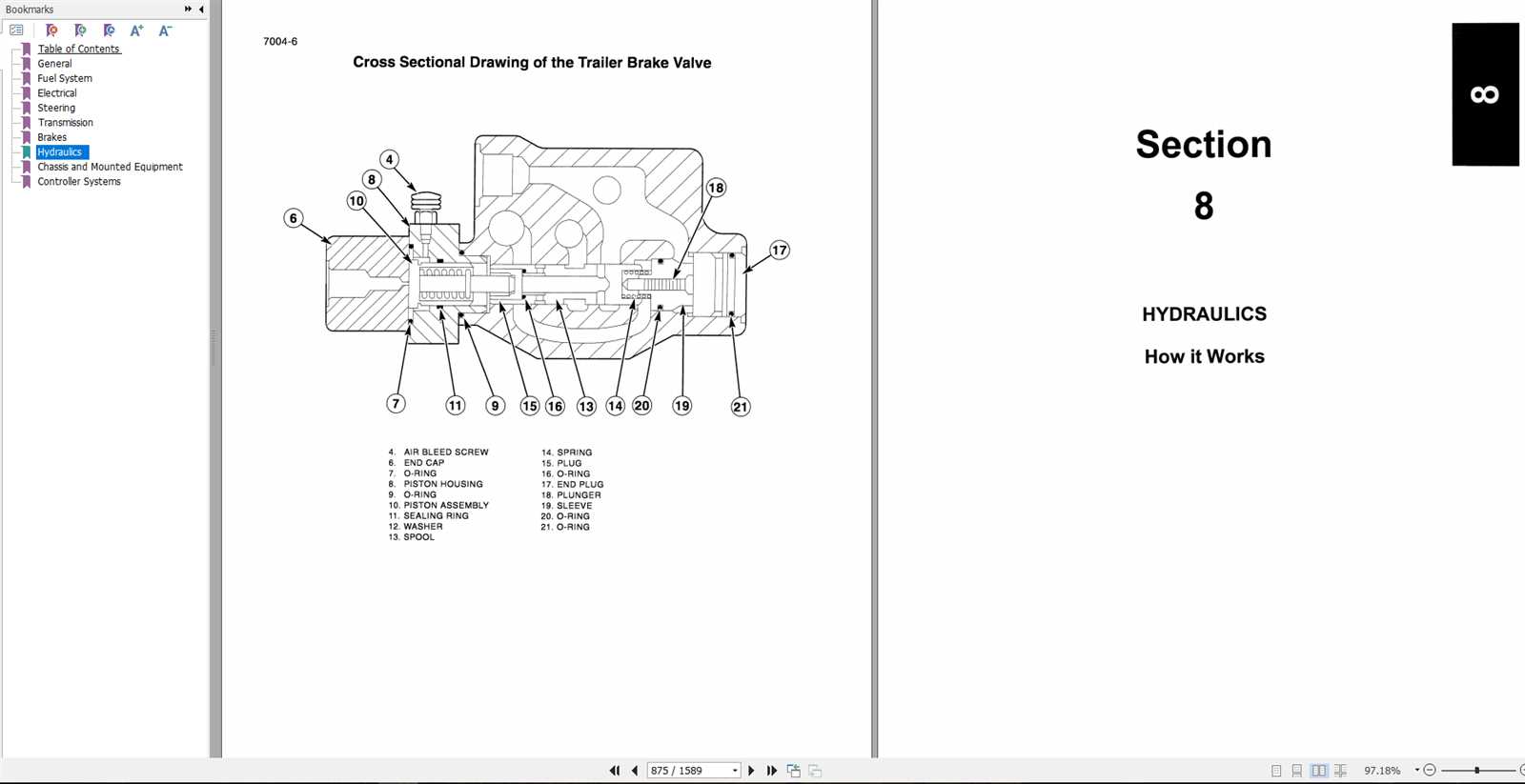

Key elements of a hydraulic system include pumps, cylinders, hoses, and valves. Each of these components must work in harmony to achieve optimal performance. Regular inspection and maintenance are essential to prevent failures and ensure seamless operation.

| Component | Function |

|---|---|

| Pump | Generates hydraulic pressure by circulating fluid |

| Cylinder | Converts hydraulic pressure into linear motion |

| Hoses | Transport hydraulic fluid between components |

| Valves | Control the flow and direction of hydraulic fluid |

Maintaining the integrity of the hydraulic fluid is paramount. Contaminants and moisture can compromise system efficiency, leading to wear and potential failures. Regular fluid checks and timely changes are critical for sustaining performance.

Transmission Repair Techniques

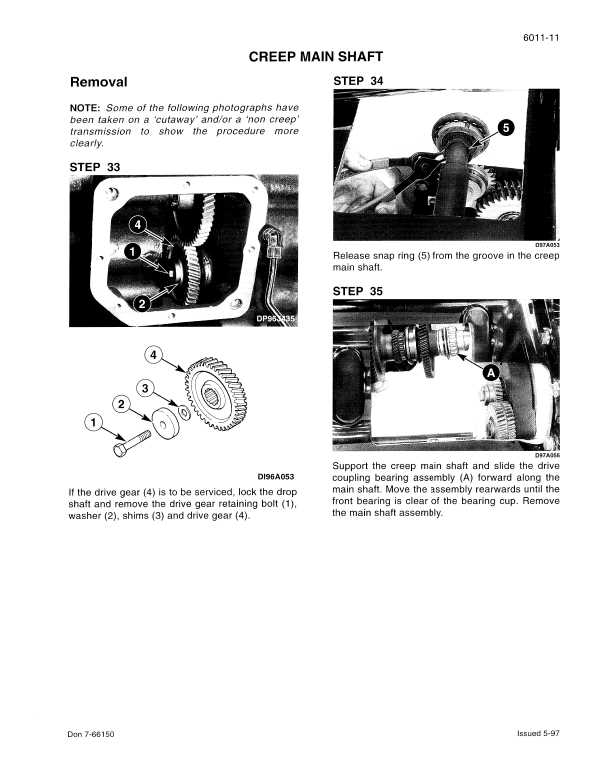

Maintaining the efficiency of a vehicle’s power transfer system is crucial for optimal performance. This section will explore various approaches to addressing issues within these complex mechanisms, ensuring longevity and reliability. Understanding the nuances of these systems allows for effective troubleshooting and resolution of common challenges.

Identifying Common Issues

Before delving into solutions, it is essential to recognize typical problems that may arise within the transmission assembly. Symptoms such as unusual noises, slipping gears, or fluid leaks often indicate underlying concerns that require immediate attention. Conducting a thorough diagnostic assessment can pinpoint the source of these complications, laying the groundwork for targeted interventions.

Effective Techniques for Resolution

Once issues are identified, several techniques can be employed to rectify them. Fluid replacement is a fundamental step, as degraded transmission fluid can lead to inadequate lubrication and overheating. Additionally, sealing leaks with appropriate materials can prevent further fluid loss, enhancing system integrity. In cases of more significant damage, components may need to be disassembled and inspected for wear, allowing for precise replacements or adjustments to restore functionality.

Parts Replacement Best Practices

Ensuring the longevity and efficiency of machinery requires a systematic approach to component substitution. Adhering to best practices not only enhances performance but also minimizes downtime and prevents future issues. This section outlines essential strategies to follow during the replacement process.

Preparation and Planning

Before undertaking any replacement, thorough preparation is crucial. Gather all necessary tools and parts to streamline the process. Developing a clear plan of action helps avoid unnecessary complications. Here are key steps to consider:

| Step | Description |

|---|---|

| 1 | Identify the component needing replacement. |

| 2 | Obtain the correct part specifications. |

| 3 | Gather tools and equipment required for the task. |

| 4 | Review safety protocols and procedures. |

Execution and Follow-up

Once preparation is complete, the actual replacement can commence. It is essential to follow specific guidelines during this phase. After installation, conducting a thorough check ensures everything is functioning correctly. Regular follow-up maintenance can prevent future malfunctions and extend the lifespan of your machinery.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when undertaking maintenance tasks on machinery. Proper precautions not only protect the individual performing the work but also enhance the overall efficiency of the procedure. Awareness of potential hazards and adherence to safety guidelines can significantly reduce the risk of accidents and injuries.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. Always wear gloves, goggles, and sturdy footwear to safeguard against sharp objects and hazardous materials. A hard hat should be used in areas where overhead risks are present. Ensure that all gear fits correctly and is in good condition to provide maximum protection.

Work Environment Safety

Maintain a clean and organized workspace. Clutter can lead to trips and falls, posing a danger during maintenance activities. Ensure that all tools are stored properly and that there is adequate lighting to clearly see your work area. Additionally, it is important to be aware of the machinery’s operation manual, understanding its functions and potential risks before starting any work.